Device for soaking parts in anti-rust oil

A technology of anti-rust oil and parts, applied in the field of parts processing, can solve the problems of time-consuming, difficult to clean, cumbersome operation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

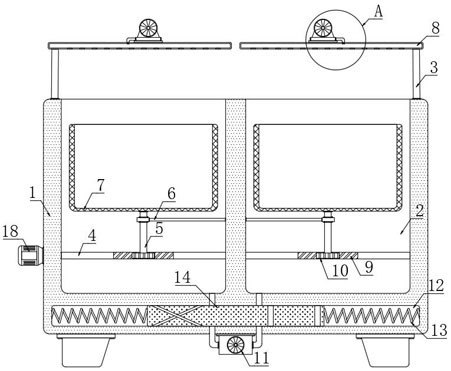

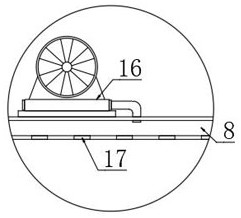

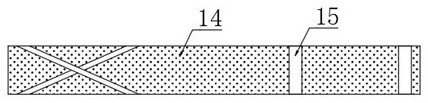

[0031] refer to Figure 1-5 , a device for immersing parts in antirust oil, comprising a housing 1, two treatment tanks 2 are symmetrically arranged on the upper end of the housing 1, and a screen frame 7 is arranged in each treatment tank 2, and the upper end surface of each screen frame 7 Openings are all provided, and mounting frame 6 is installed on the inwall of each treatment tank 2, and the lower end of each screen frame 7 is fixedly connected with vertical rod 5, and the lower end of each vertical rod 5 is connected with the corresponding mounting frame 6. Rotationally connected, the lower end of each vertical rod 5 runs through the corresponding mounting frame 6 and is fixedly connected to the worm wheel 10, and the inner walls on both sides of each treatment tank 2 are connected with a rotating rod 4 in rotation, and each rotating rod 4 is provided with Match the thread layer 9 with the corresponding worm wheel 10, the thread layer 9 is similar to the thread on the w...

Embodiment 2

[0041] refer to Figure 6-8 , the difference between this embodiment and Embodiment 1 is that each rotating rod 4 is sleeved with two sleeves 19, and the inner wall of each sleeve 19 is provided with a slider 21, and each rotating rod 4 There are chute 23 that cooperates with the slider 21, and one side of each slider 21 is elastically connected with the inner wall of one side of the corresponding chute 23 through the vibration spring 22, and the outer wall of each sleeve 19 is fixed A plurality of stirring rods 20 are connected, and magnetic plates 24 are embedded on the inner walls of both sides of each treatment tank 2 , and one of the stirring rods 20 on each sleeve 19 is made of iron.

[0042] In this embodiment, the rotation of the two rotating rods 4 will drive a plurality of sleeves 19 to rotate, thereby causing a plurality of stirring rods 20 to rotate. During the oil immersion process, the stirring of the stirring rods 20 can further disturb the water body and increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com