Forming and processing equipment for exhaust fume collecting hood of kitchen range hood

A technology for forming processing and fume collecting hoods, which is applied in the direction of metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., and can solve the problem of shifting of fume collecting hoods, increasing the processing steps of opening holes, and pushing the holes where holes cannot be opened. Problems such as squeezing limit to achieve the effect of avoiding high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

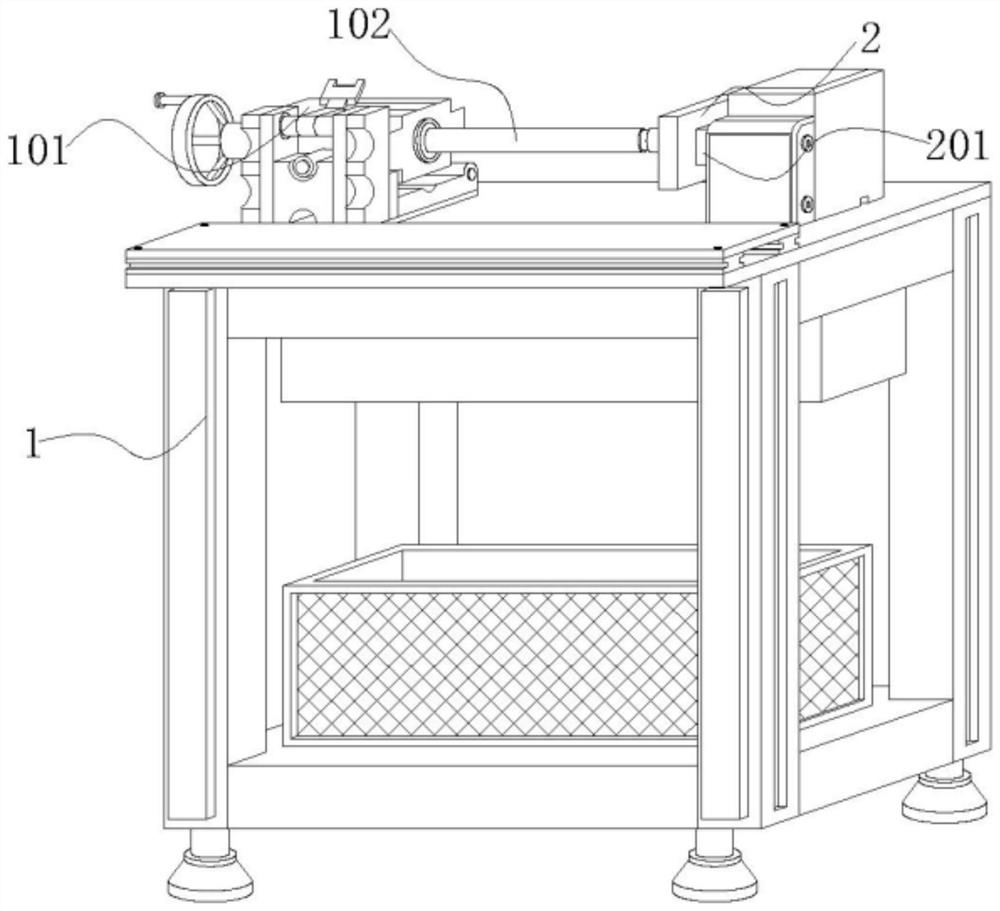

[0042] Embodiment 1: a kitchen range hood fume collecting hood forming processing equipment, including a hole punch 1, the hole end of the hole punch 1 is provided with a clamping mechanism and a hole assembly, wherein the hole assembly includes a motor 101 and a drill bit 102, the drill bit 102 rotates on the side of the clamping mechanism, and the clamping mechanism includes a bracket 2 and a sliding frame 201;

[0043] Wherein: the motor 101 and the drill bit 102, the motor 101 is electrically connected to the power supply through the power cord, the motor 101 drives the drill bit 102 to rotate at a high speed horizontally, and the drill bit 102 opens a hole inside the fume hood;

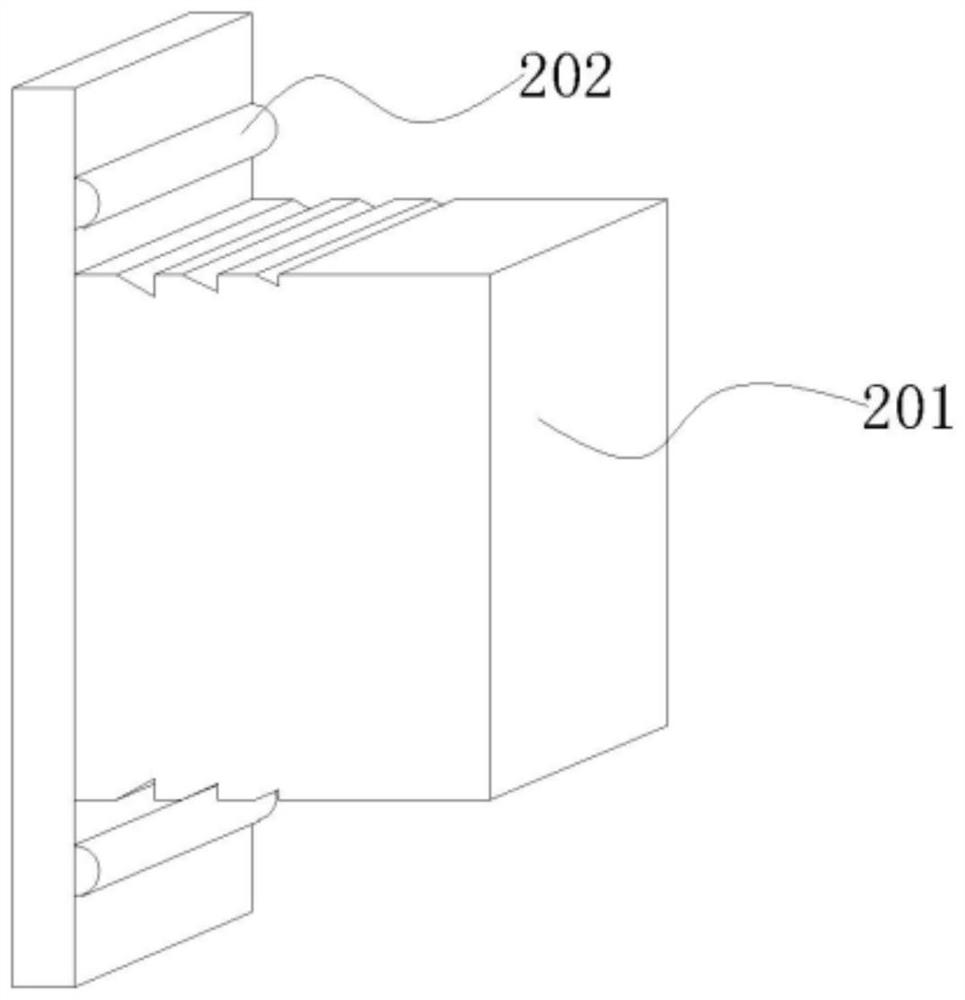

[0044] The bracket 2, the inside of the bracket 2 is arranged in a hollow shape, the bracket 2 and the drill bit 102 are arranged in a horizontal correspondence, the bracket 2 is arranged in a semi-circular arc shape near the inner wall of the sliding frame 201, and the semi-circular arc angle is ...

Embodiment 2

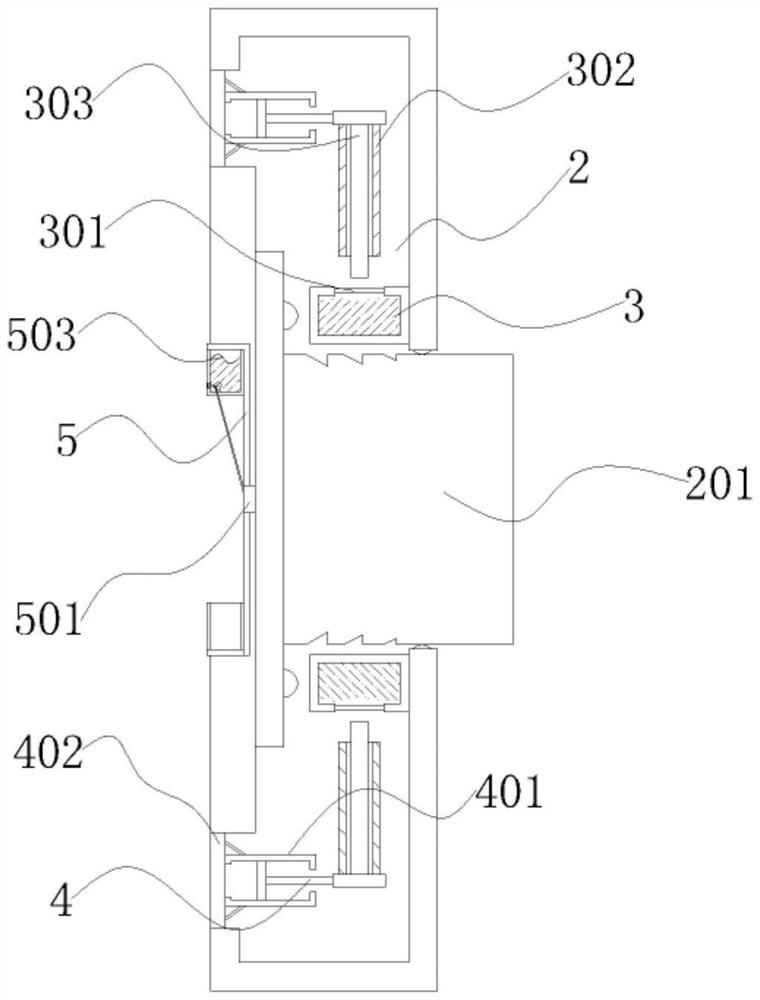

[0048] Embodiment 2: Referring to the drawings 2-5 in the description, it can be known that the difference between Embodiment 2 and Embodiment 1 is that the clamping mechanism includes a bump 202, a water bag 3, a deformation layer 301, a slide rail 302, a slide bar 303, The piston rod 4, the sleeve 401 and the adsorption layer 402, the bumps 202 are inlaid on both ends of the side of the sliding frame 201, the water bag 3 is inlaid on the inner wall of the bracket 2, the deformation layer 301 is inlaid on the inner wall of the water bag 3, and the slide rail 302 is inlaid Inside the bracket 2 , the sliding rod 303 slides and extends to both ends of the sliding rail 302 , the piston rod 4 slides on one end of the sliding rod 303 , the sleeve 401 is installed inside the bracket 2 , and the adsorption layer 402 slides and fits on the sleeve. side of 401;

[0049] Among them: the bump 202, the bump 202 and the side surface of the water bag 3 are horizontally slid and squeezed, an...

Embodiment 3

[0061] Embodiment 3: Referring to the accompanying drawings 6-8, it can be known that the difference between Embodiment 3 and Embodiments 1 and 2 is that the clamping mechanism includes a snap ring 5, a slider 501, a shaft arm 502, a water tank 503, and a rotating disk 6 , the sealing rod 601 and the disc 602, the snap ring 5 is embedded in the side of the bracket 2, the slider 501 slides through the inside of the snap ring 5, the shaft arm 502 is embedded in one side of the slider 501, the water tank 503 is installed on the snap ring 5 At one end of the interior, the rotary disk 6 swings inside the water tank 503, the sealing rod 601 swings on one side of the rotary disk 6, and the disk 603 runs through the side of the water tank 503;

[0062] Among them: the snap ring 5 and the slider 501, the snap ring 5 is arranged in a transverse concave shape, the slider 501 slides and extends to one side of the sliding frame 201, when the sliding frame 201 slides horizontally, the slider...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com