A preparation process of high-strength double-permeable curing concrete

A preparation process and concrete technology, which is applied in the field of high-strength double-permeable curing concrete preparation technology, can solve the problems of increasing the coagulation force of finished concrete products, which are lower than those of the outside, so as to improve the uniformity of curing, increase the coagulation force, and improve the quality of finished concrete products. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

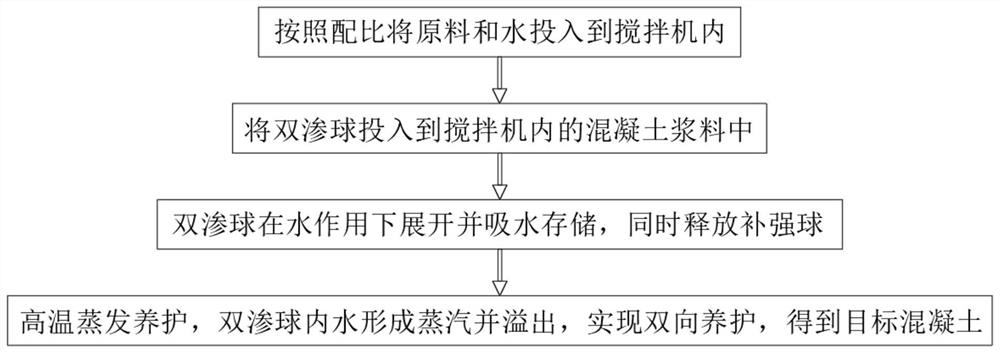

[0044] see figure 1 , a high-strength double-osmotic curing type concrete preparation process, comprising the following steps:

[0045] S1. First, prepare the raw materials according to the type of concrete required, and then put the raw materials and water into the mixer according to the ratio;

[0046] S2. After stirring for 5-10 minutes, the concrete slurry is formed, and the double seepage ball is put into the concrete slurry in the mixer, and stirred again for 5-10 minutes;

[0047] S3. When stirring, during the continuous stirring process of the double seepage ball, the double seepage ball is unfolded under the action of the water in the slurry, and continuously absorbs the water in the concrete slurry, and is transported to the double seepage ball for storage. At the same time, the double seepage ball The outer surface gradually disintegrates with the prolongation of the stirring time, releasing the reinforcing balls 6 and uniformly mixing with the concrete slurry;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com