Automatic oil immersion device for fittings for machining

A technology for mechanical processing and accessories, which is applied in the field of automatic oil immersion devices for mechanical processing accessories, and can solve problems such as inability to achieve effective oil immersion, excessive film transition, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

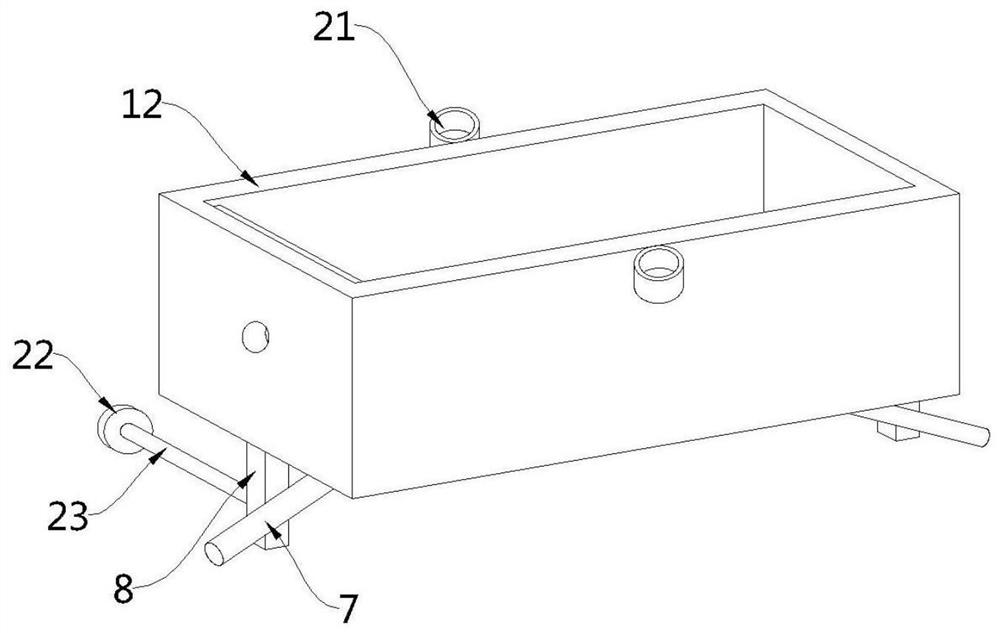

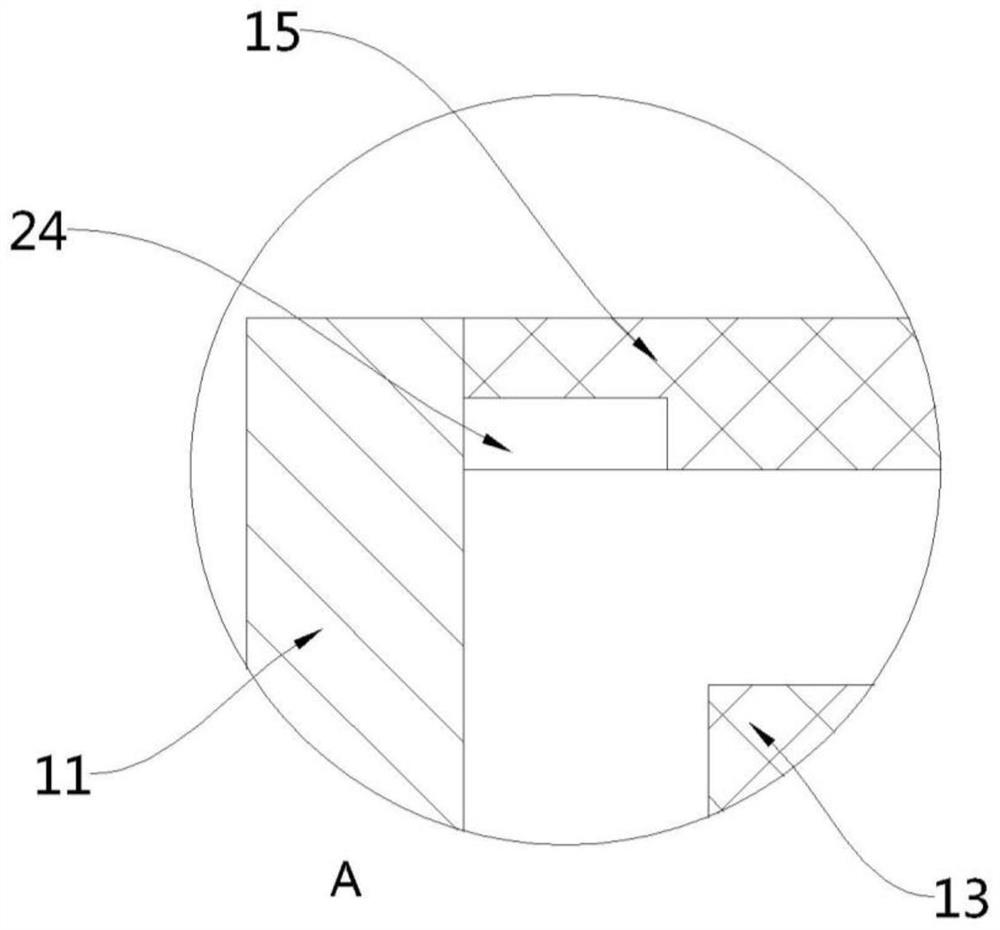

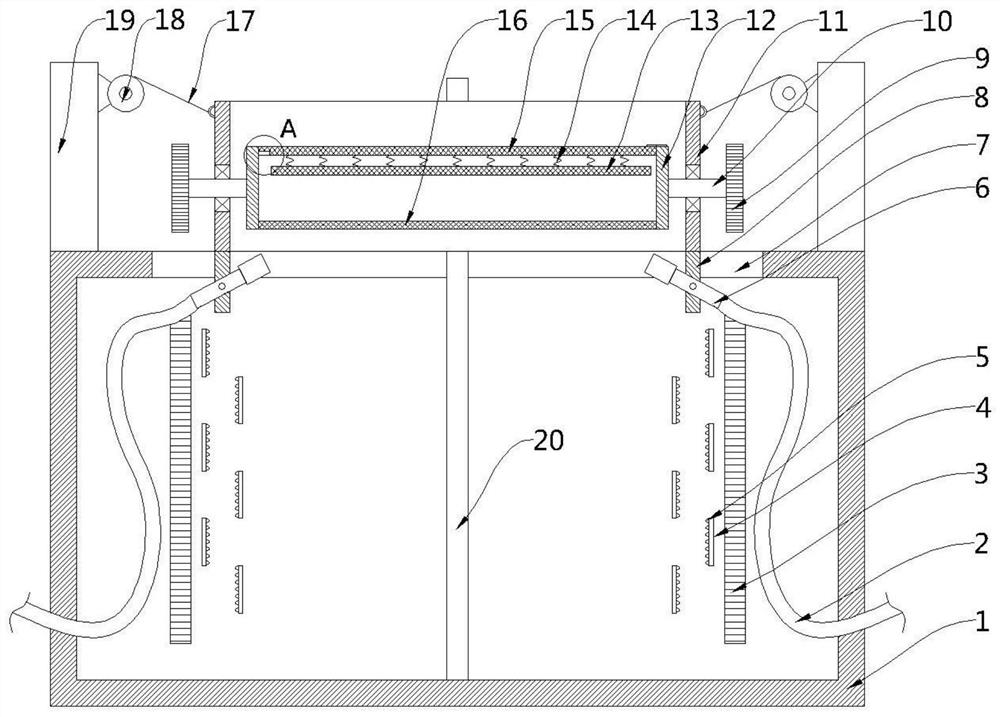

[0024] see Figure 1-3 , this embodiment provides an automatic oil immersion device for mechanical processing accessories, including an oil storage tank 1 and an accessory holding assembly arranged above the oil storage tank 1, and an opening 7 is opened on the upper wall of the oil storage tank 1, and the storage The upper part of the oil tank 1 is provided with a drive assembly for driving the accessory storage assembly to move from the port 7 to the inside of the oil storage tank 1. Specifically, the accessory storage assembly includes an outer box 11 for holding and a storage box 11 arranged in the storage tank 1. Put the inner box 12 on the inside of the outer box 11, the outer box 11 and the inner box 12 are open up and down, and the bottom of the inner box 12 is fixed with a bottom plate 16, the inner box 12 The upper part is hinged with a cover plate 15, and the side wall of the inner box 12 is fixed with a first rotating rod 10, which passes through the outer box 11 a...

Embodiment 2

[0036] see Figure 1-2 , an automatic oil immersion device for mechanical processing accessories. Compared with Embodiment 1, the bottom of the storage outer box 11 is fixedly provided with a fixed plate 8, and the side wall of the air intake hard pipe 6 is fixedly provided with a second Two rotary rods 23, the end of the second rotary rod 23 away from the intake hard pipe 6 passes through the fixed plate 8 and is fixedly connected with the second gear 22, and the inside of the oil storage tank 1 is located on the left and right sides of the fixed plate 8. A plurality of support plates 4, the side of the support plate 4 facing the fixed plate 8 is provided with a plurality of tooth pieces 5, and the support plates 4 located on the left and right sides of the fixed plate 8 are dislocated up and down.

[0037] When the outer box 11 is moved down inside the oil storage tank 1, the second gear 22 alternately meshes with the tooth pieces 5 of the side walls of the support plate 4 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com