Efficient oil immersion method for spinning frame

A spinning frame and oil immersion technology, applied in textiles and papermaking, can solve the problems of poor oil immersion effect and low oil immersion efficiency of rovings, and achieve the effects of avoiding waste, improving oil immersion effect and ensuring uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

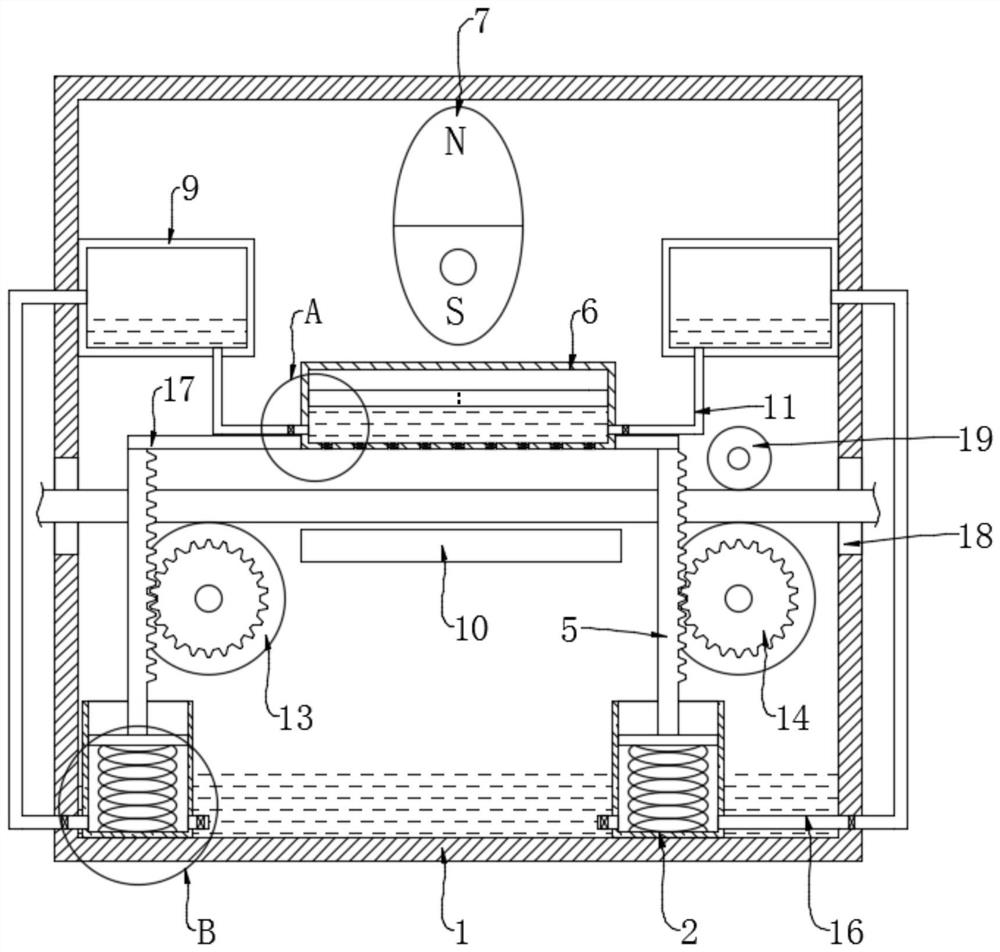

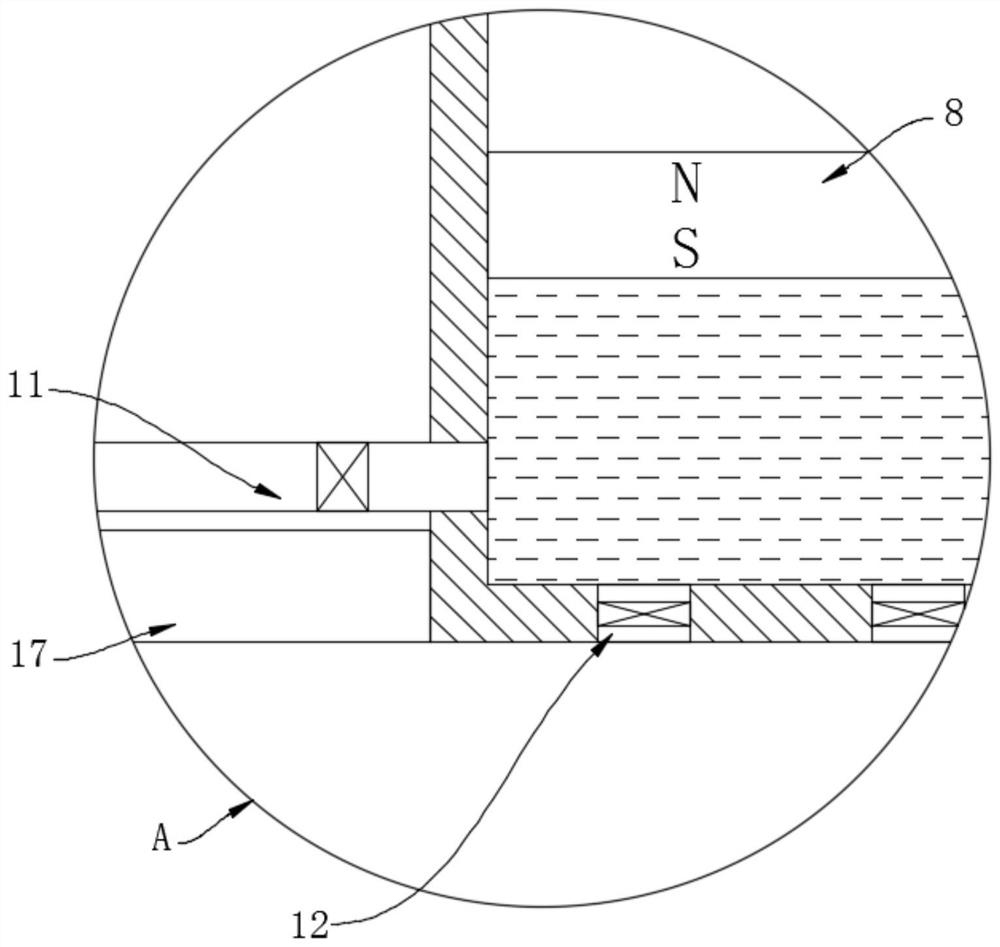

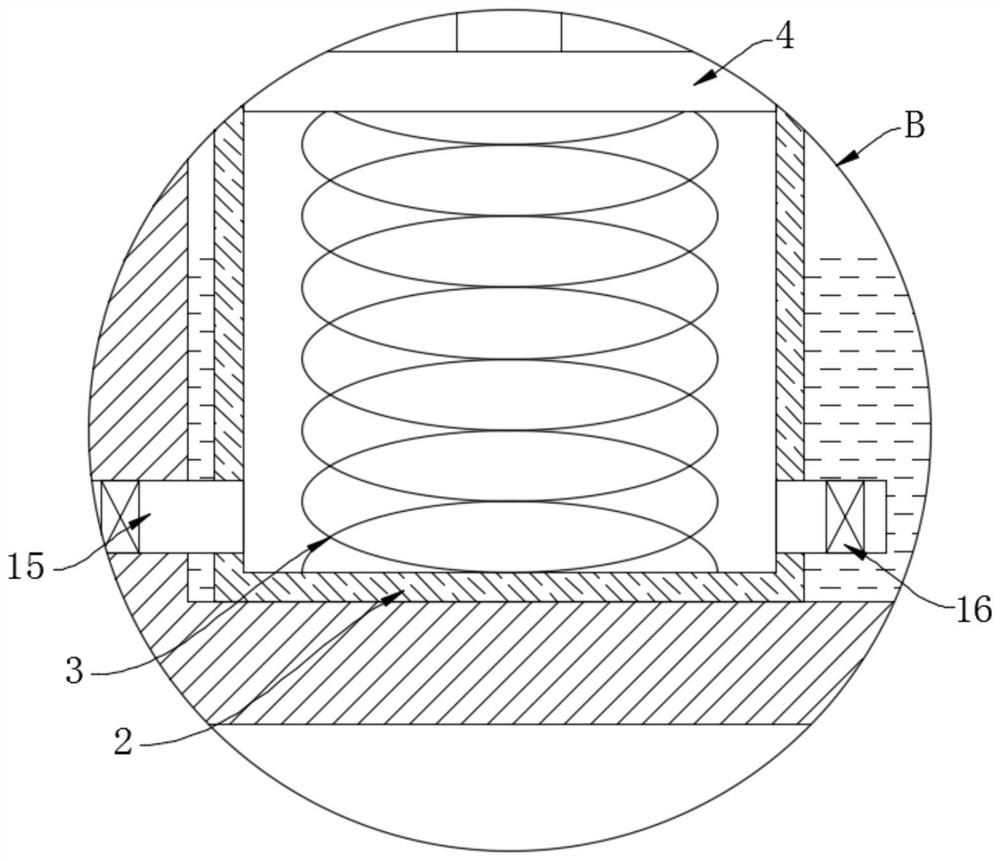

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0026] refer to Figure 1-3 , a high-efficiency oil immersion method for spinning frames, mainly comprising the following steps:

[0027] S1, refueling: fill an appropriate amount of mineral oil in the oil storage tank 9;

[0028] S2, feeding: pass the semi-finished spun yarn through the through hole 18 and the transmission roller 13 in sequence so that the spun yarn is located between the pressure bearing plate 10 and the movable box 6;

[0029] S3. Oil immersion: the spun yarn is conveyed section by section in the box 1 by driving the motor, and the spun yarn is squeezed and oiled at the same time;

[0030] S4. Oil recovery: through the reciprocating motion of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com