Biaxially oriented polypropylene film for capacitor

A polypropylene film, biaxial stretching technology, applied in electronic equipment, applications, household appliances, etc., can solve the problems of reduced voltage resistance characteristics, reduced stretchability, roughness difficult to meet the requirements, etc., to achieve good oil immersion, meet High voltage resistance and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

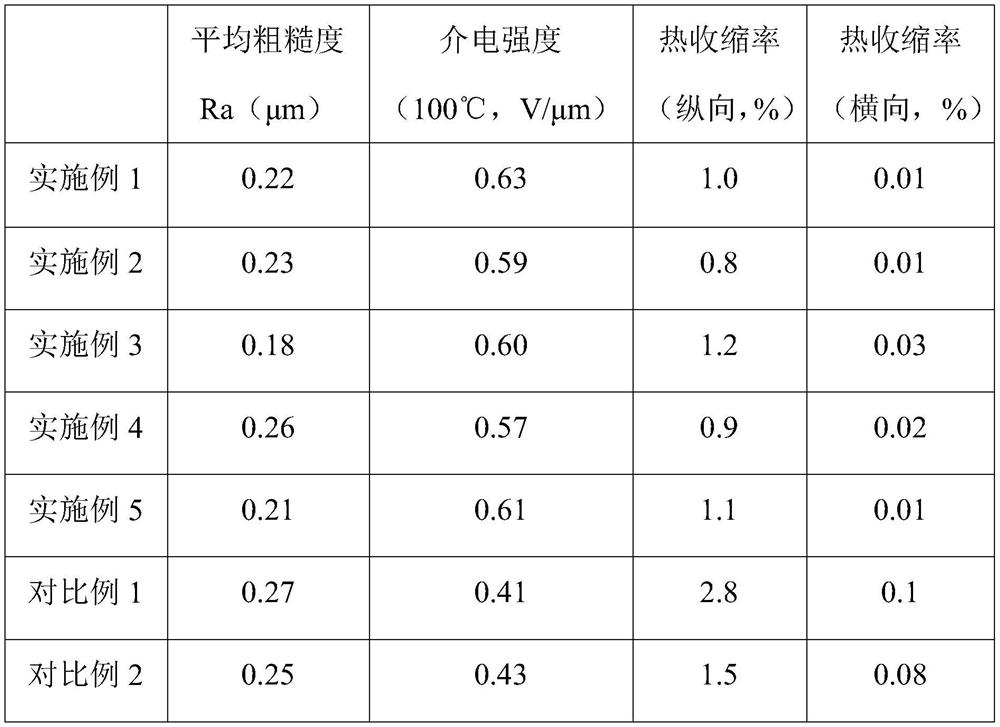

Examples

Embodiment 1

[0032] This embodiment proposes a biaxially oriented polypropylene film for capacitors, including a three-layer structure of an upper surface layer, an intermediate layer, and a lower surface layer. The method for preparing the biaxially oriented polypropylene film for capacitors described in this embodiment includes:

[0033] (1), the isotacticity of 70wt% is 98.8%, the molecular weight distribution Mw / Mn coefficient is 5.0, and the melt flow rate is the polypropylene of 2.1g / 10min and 30wt% isotacticity is 96.4%, the molecular weight distribution Mw The / Mn coefficient is 7.9, and the melt flow rate is 6.3g / 10min after mixing the polypropylene as the middle layer raw material (accounting for 90% of the total mass of the raw material), and the isotacticity is 96.4%, and the molecular weight distribution Mw / Mn coefficient is 7.9 , the melt flow rate is the polypropylene of 6.3g / 10min as surface layer raw material (accounting for 10% of raw material gross mass), after sending in...

Embodiment 2

[0036] This embodiment proposes a biaxially oriented polypropylene film for capacitors, including a three-layer structure of an upper surface layer, an intermediate layer, and a lower surface layer. The method for preparing the biaxially oriented polypropylene film for capacitors described in this embodiment includes:

[0037] (1), the isotacticity of 65wt% is 98.8%, the molecular weight distribution Mw / Mn coefficient is 5.0, and the melt flow rate is the polypropylene of 2.1g / 10min and 35wt% isotacticity is 96.4%, the molecular weight distribution Mw The / Mn coefficient is 7.9, the melt flow rate is the polypropylene of 6.3g / 10min after being mixed as the intermediate layer raw material (accounting for 90% of the total mass of raw material), the isotacticity is 96.4%, the molecular weight distribution Mw / Mn coefficient is 7.9 , melt flow rate is the polypropylene of 6.3g / 10min as surface layer raw material (accounting for 10% of raw material gross mass), after sending into mai...

Embodiment 3

[0040] This embodiment proposes a biaxially oriented polypropylene film for capacitors, including a three-layer structure of an upper surface layer, an intermediate layer, and a lower surface layer. The method for preparing the biaxially oriented polypropylene film for capacitors described in this embodiment includes:

[0041] (1), 75wt% of polypropylene with an isotacticity greater than or equal to 98.8%, a molecular weight distribution Mw / Mn coefficient of 5.0, and a melt flow rate of 2.1g / 10min and 25wt% of a polypropylene with an isotacticity of 96.4% and a molecular weight distribution Mw / Mn coefficient is 7.9, melt flow rate is the polypropylene of 6.3g / 10min after being mixed as intermediate layer raw material (accounting for 90% of raw material total mass), isotacticity is 96.4%, molecular weight distribution Mw / Mn coefficient is 7.9. Polypropylene with a melt flow rate of 6.3 is used as the surface layer raw material (accounting for 10% of the total mass of the raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com