Gear oil immersing device of improved structure

A technology of oil immersion and gear, which is applied to the device and coating of the surface coating liquid, which can solve the problems of high labor intensity, scratches on the gear surface, and affecting the quality of the gear, so as to achieve low labor intensity and avoid collision friction , Improve the effect of immersion oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

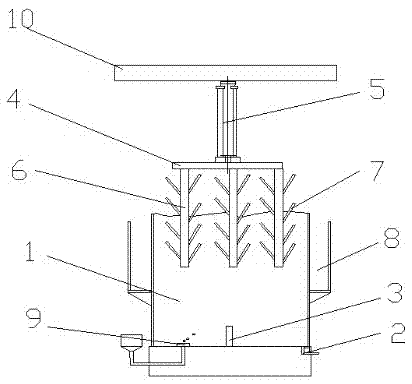

[0016] like figure 1 As shown, a gear oil immersion device with an improved structure of the present invention includes an oil immersion tank 1 for containing liquid immersion oil, the bottom of the oil immersion tank 1 is provided with a drain pipe 2, and the inner center of the oil immersion tank 1 An electric heating tube 3 is provided, and a track plate 4 is arranged directly above the oil immersion tank 1, and a pressing cylinder 5 that can drive the track plate 4 into the oil immersion tank 1 is installed on the track plate 4, and the pressing cylinder The other end of 5 is fixed by a fixed frame 10, and a plurality of vertical brackets 6 are arranged below the track plate 4, and a plurality of slanting hangers 7 are arranged at intervals on the vertical brackets 6.

[0017] Preferably, as another possible embodiment, an overflow tank 8 is provided on the outside of the oil immersion tank 1 .

[0018] Preferably, as another possible embodiment, an agitator 9 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com