Spherical metal product surface anti-rust oil soaking device

A technology for metal products and anti-rust oil immersion, which is applied to devices and coatings that apply liquid to the surface, and can solve problems such as affecting the effect of immersing metal spheres in oil, affecting the quality of oil body, and increasing the content of impurities and dust. To improve the quality of immersion oil, improve the effect of immersion oil, and improve the effect of contact range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

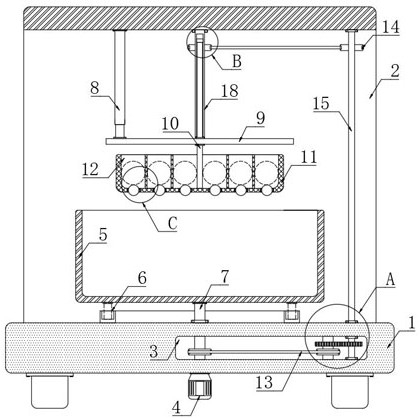

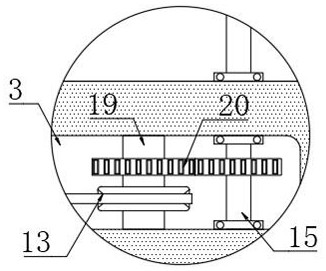

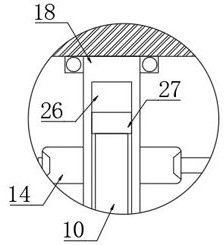

[0028] refer to Figure 1-5 , a device for soaking the surface of a spherical metal product with antirust oil, comprising a base plate 1, a mounting frame 2 is installed on the upper end of the base plate 1, a hydraulic telescopic rod 8 is mounted on the lower end of the mounting frame 2, and the telescopic end of the hydraulic telescopic rod 8 is fixedly connected with a connection plate 9, the lower end of the mounting frame 2 is rotatably connected with a first rotating rod 18, and the lower end of the connecting plate 9 is rotatably connected with a second rotating rod 10, where the rotating connection is realized by a bearing, and the lower end of the second rotating rod 10 is fixed Connected with a placement frame 11, the placement frame 11 is a mesh-like frame, the upper end of the placement frame 11 is provided with a plurality of placement slots 12, the inner bottom of each placement slot is provided with a mounting port, and the lower end of the first rotating rod 18 ...

Embodiment 2

[0037] refer to Figure 6-7 The difference between this embodiment and Embodiment 1 is that in order to avoid dust and impurities from affecting the quality of the oil, a mesh plate 21 is horizontally arranged in the liquid storage box 5, and the side wall of the mesh plate 21 is in contact with the liquid storage The inner wall of the box 5 is slidably connected, and two handles 23 are symmetrically installed on the upper end of the mesh plate 21, and the mesh plate 21 can be easily taken out through the handles 23, and two rectangular installation slots are symmetrically arranged on the lower end of the mesh plate 21 25. Each rectangular mounting groove 25 is provided with a rectangular magnetic block 24, the lower end of each rectangular magnetic block 24 is elastically connected to the inner bottom of the liquid storage box 5 through a spring 22, and the material of the mesh plate 21 is iron.

[0038] In this embodiment, the height of the mesh plate 21 is higher than the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com