Automatic oil immersion device for rope head of rope winding frame

A technology of oil immersion and rope winding, which is applied to the device and coating of the surface coating liquid, can solve the problems of easy to produce a large number of defective products, difficult to meet the production of large-scale goods, unstable oil immersion quality, etc., to reduce the number of people Eye and experience dependence, high production efficiency, good effect of oil immersion treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

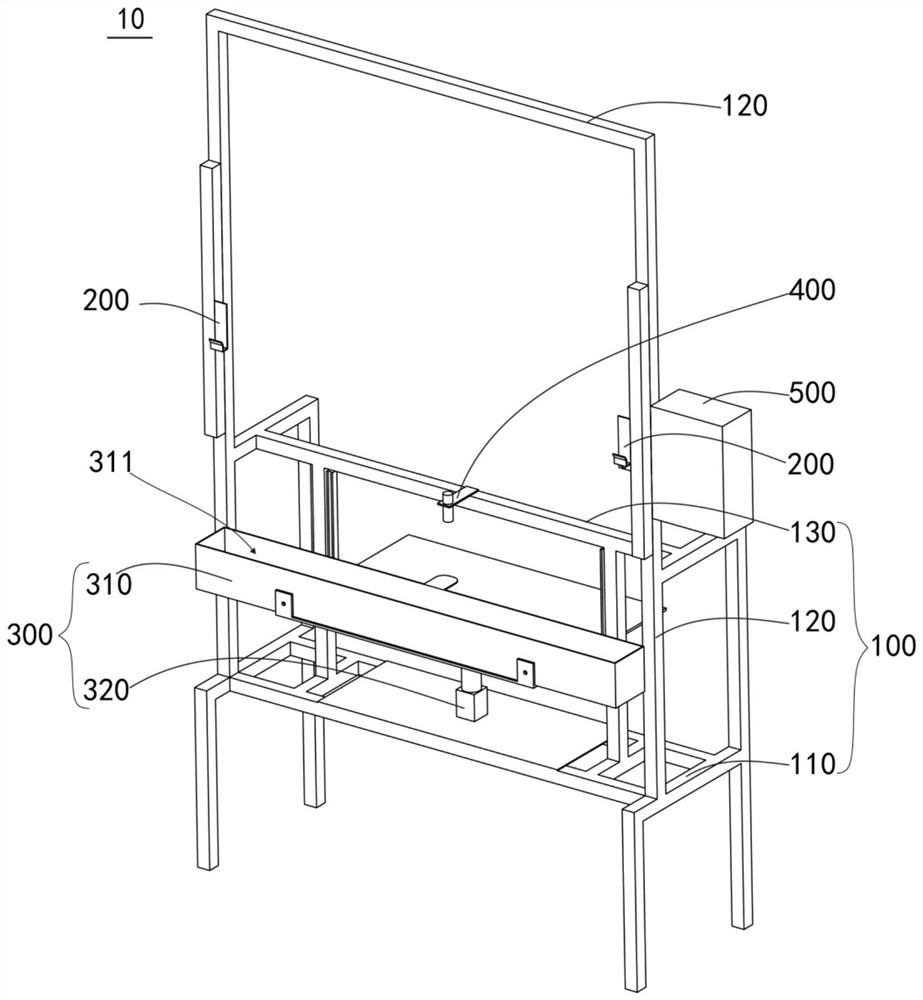

[0050] This embodiment provides an automatic oil immersion device 10 for a rope end around a rope frame.

[0051] see figure 1 As shown, an embodiment of the present invention provides an automatic oil immersion device 10 for rope ends around a rope frame.

[0052] An automatic oil immersion device 10 for a rope end of a rope winding frame, comprising a support mechanism 100 , a rope winding frame hanging mechanism 200 , a rope end oil immersion mechanism 300 , a position detection mechanism 400 and a control mechanism 500 .

[0053] The rope end oil immersion mechanism 300 includes an oil immersion component 310 and a driving component 320 . The oil-soaked component 310 or the rope-wrapping frame hanging mechanism 200 is movably connected to the support mechanism 100 and the oil-soaked component 310 is located below the hanging component. The driving part 320 is connected to the oil-immersed part 310 or the frame hanging mechanism 200 for driving the oil-immersed part 310 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com