Calibration device for welding frame

A calibration and frame technology, applied in the field of automatic welding equipment, can solve problems such as easy to forget a certain point of calibration, low efficiency of calibration work, and high labor intensity of calibration, so as to reduce the dependence on skills and experience and improve calibration Work efficiency, reduce the effect of manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

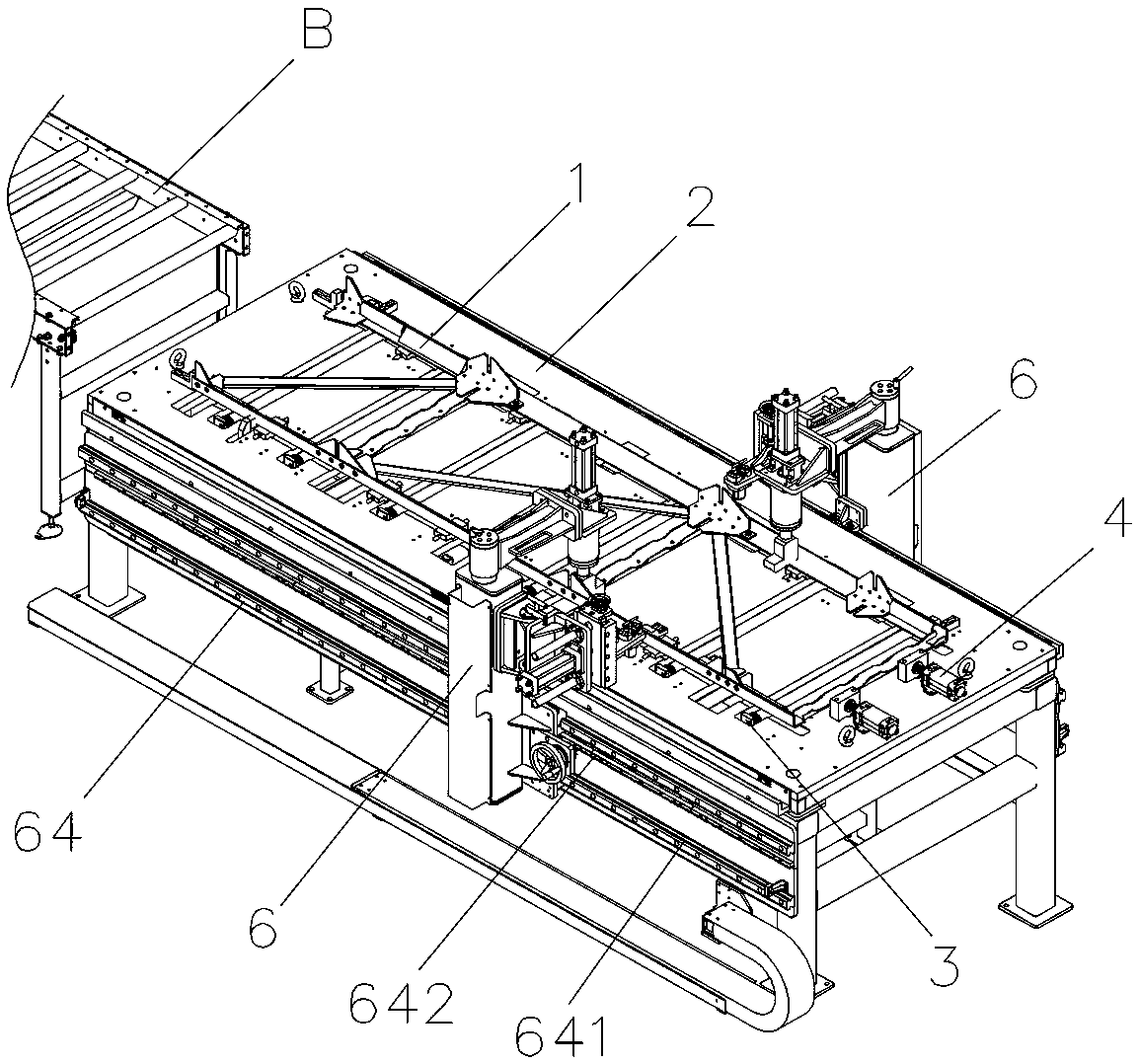

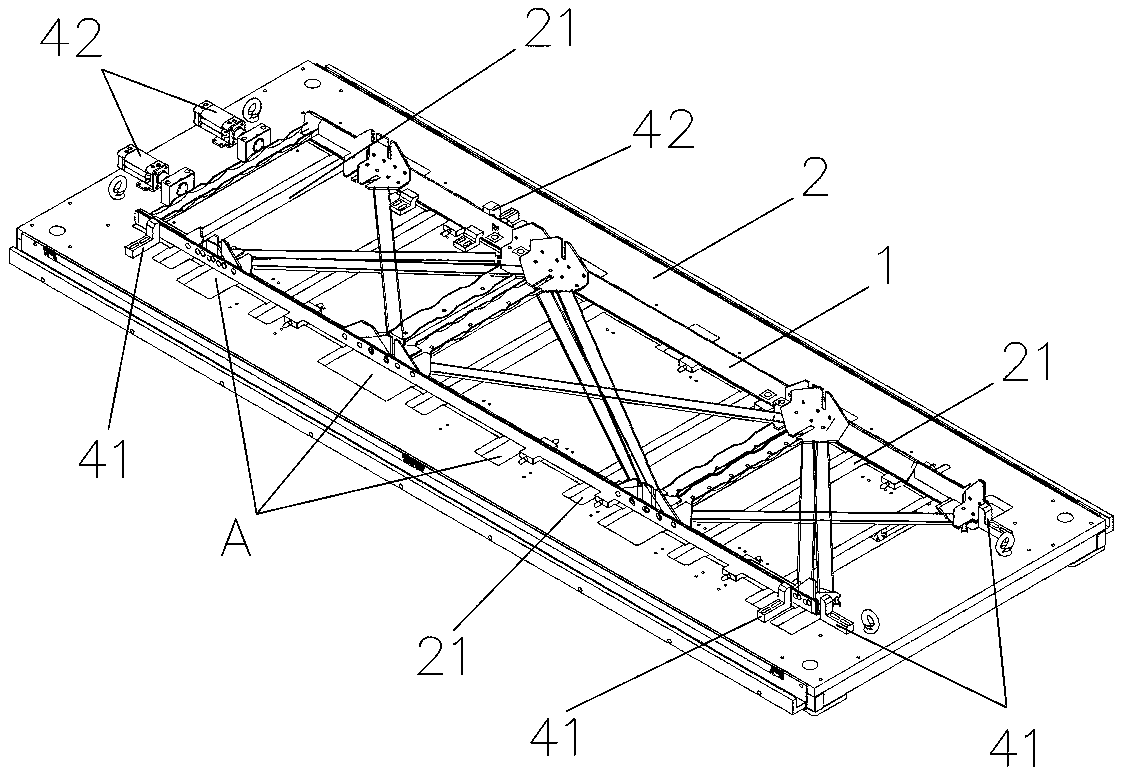

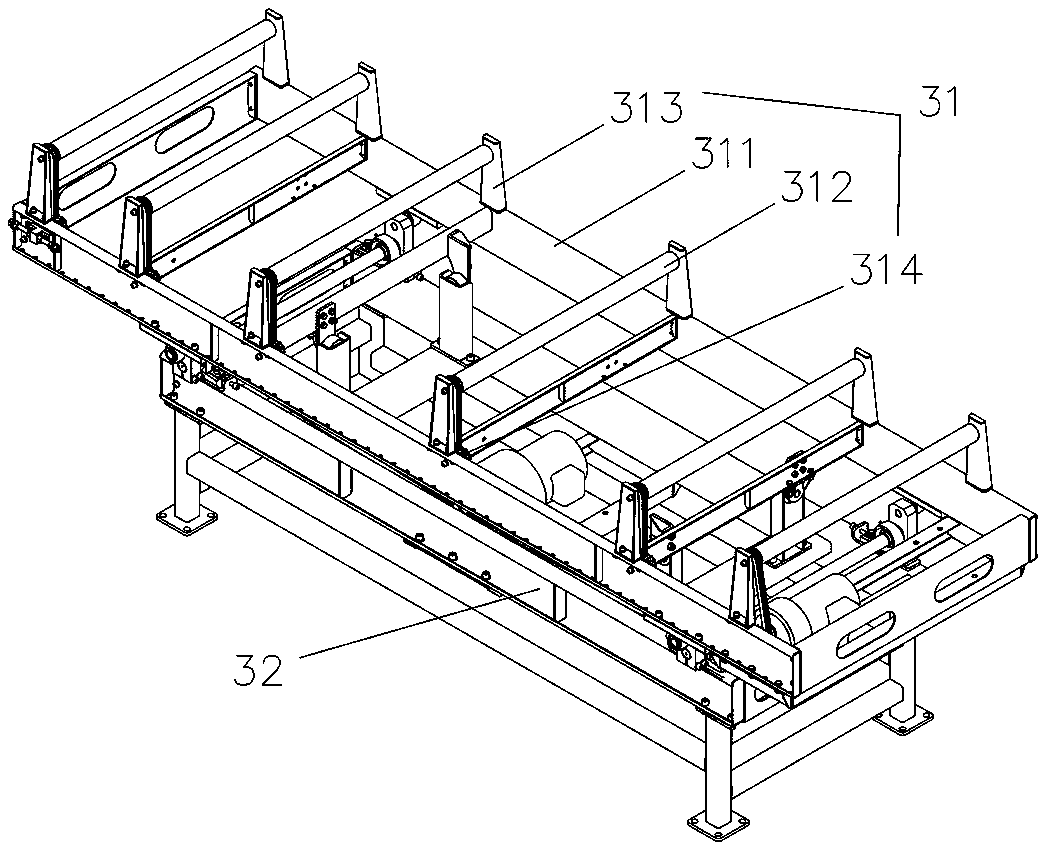

[0045] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention provides a kind of correcting device for welding frame, comprises the frame platform 2 that is used for docking with external transmission mechanism, and frame platform 2 is provided with platform plate, and the height of frame platform 2 is 0.2 meter to between 2 meters. A liftable roller transmission mechanism 3 is provided below the frame platform 2, which is used to transfer the welding frame 1 transmitted by the external transmission mechanism to the frame platform 2 after being raised, and to make the welding frame 1 fall down after falling On the frame platform 2; the frame platform 2 is provided with a positioning and fixing mechanism 4 for adjusting and fixing the position of the welded frame 1 after being dropped; The mob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com