Patents

Literature

61results about How to "Reduce skills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

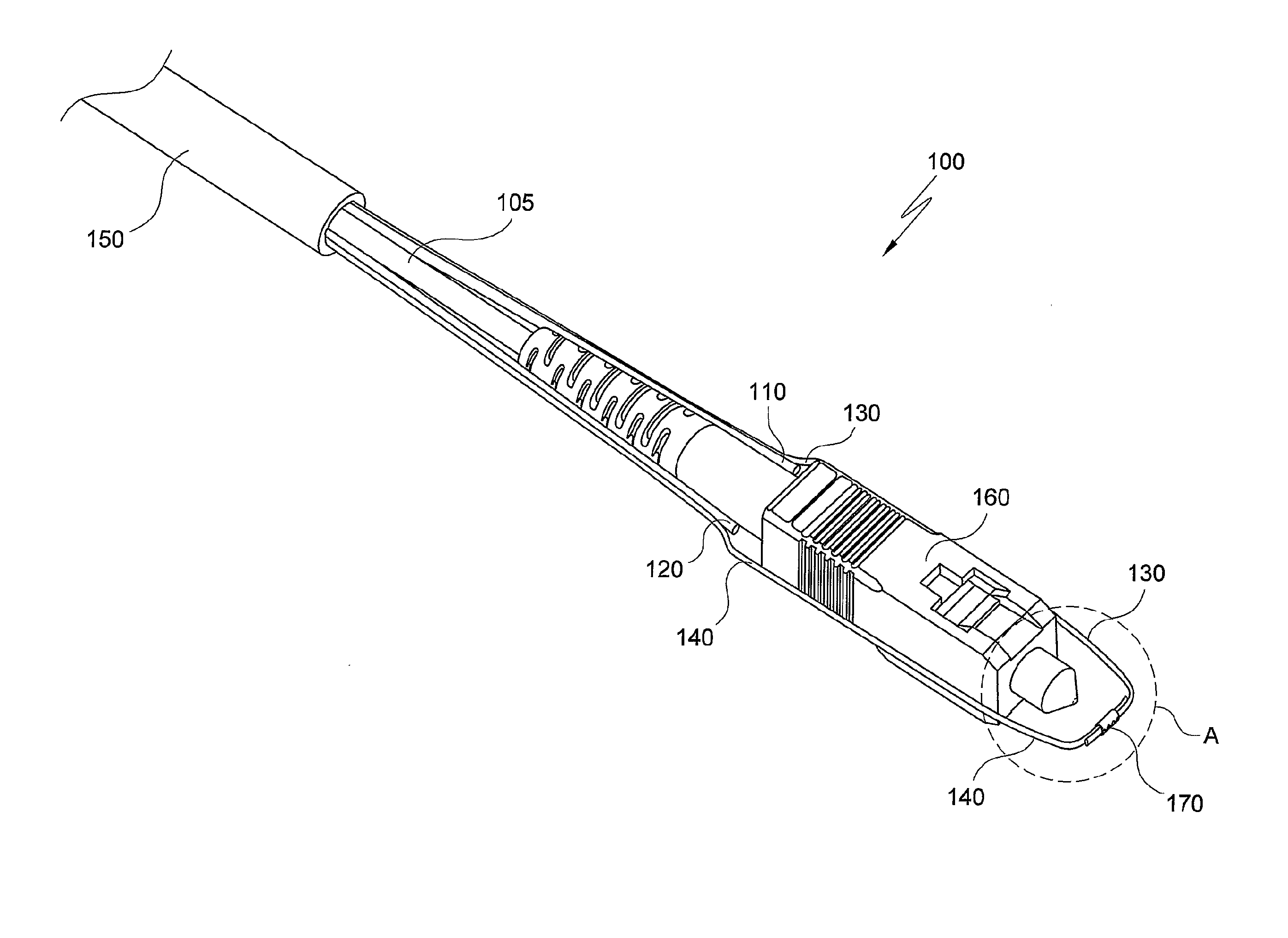

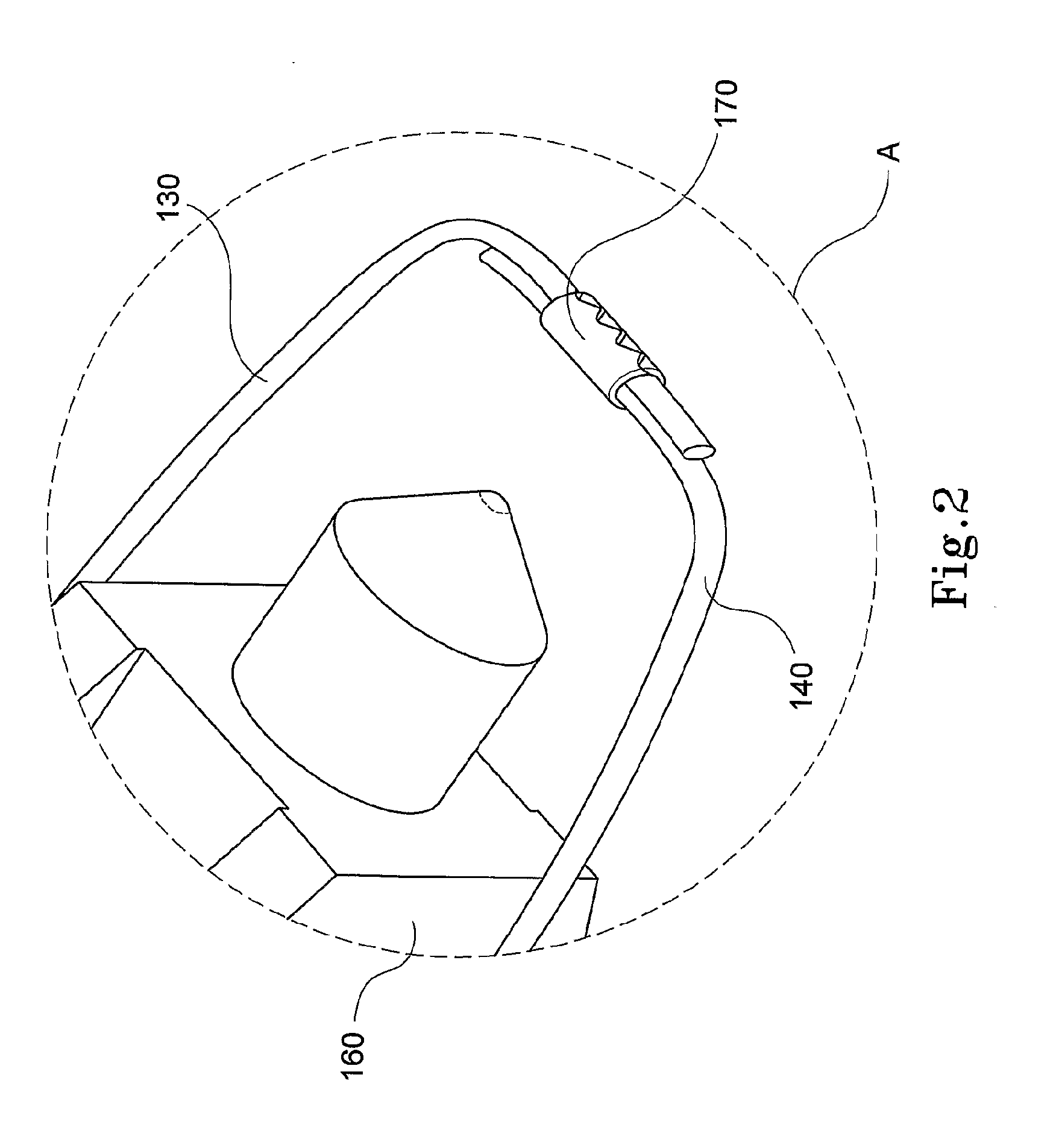

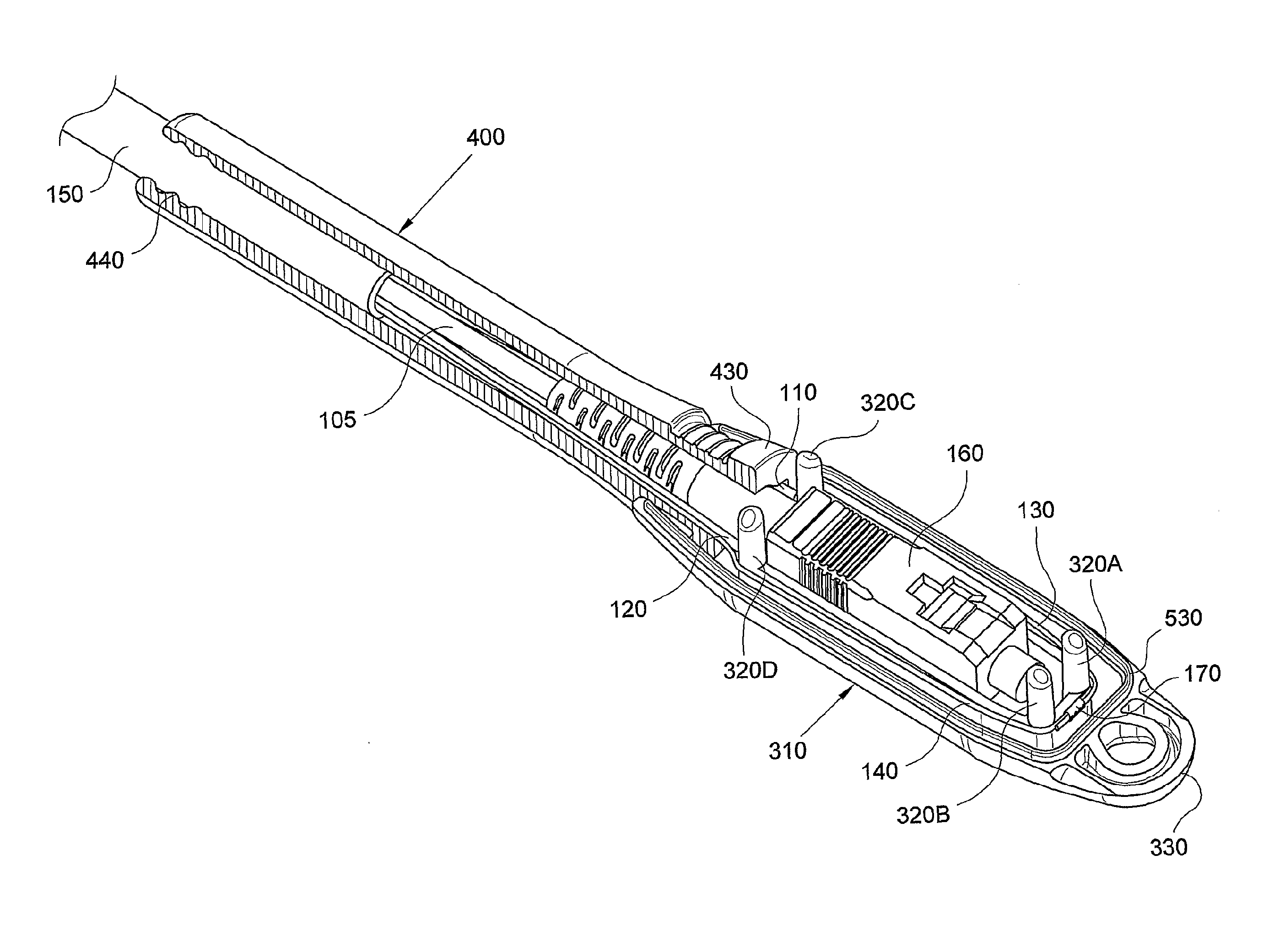

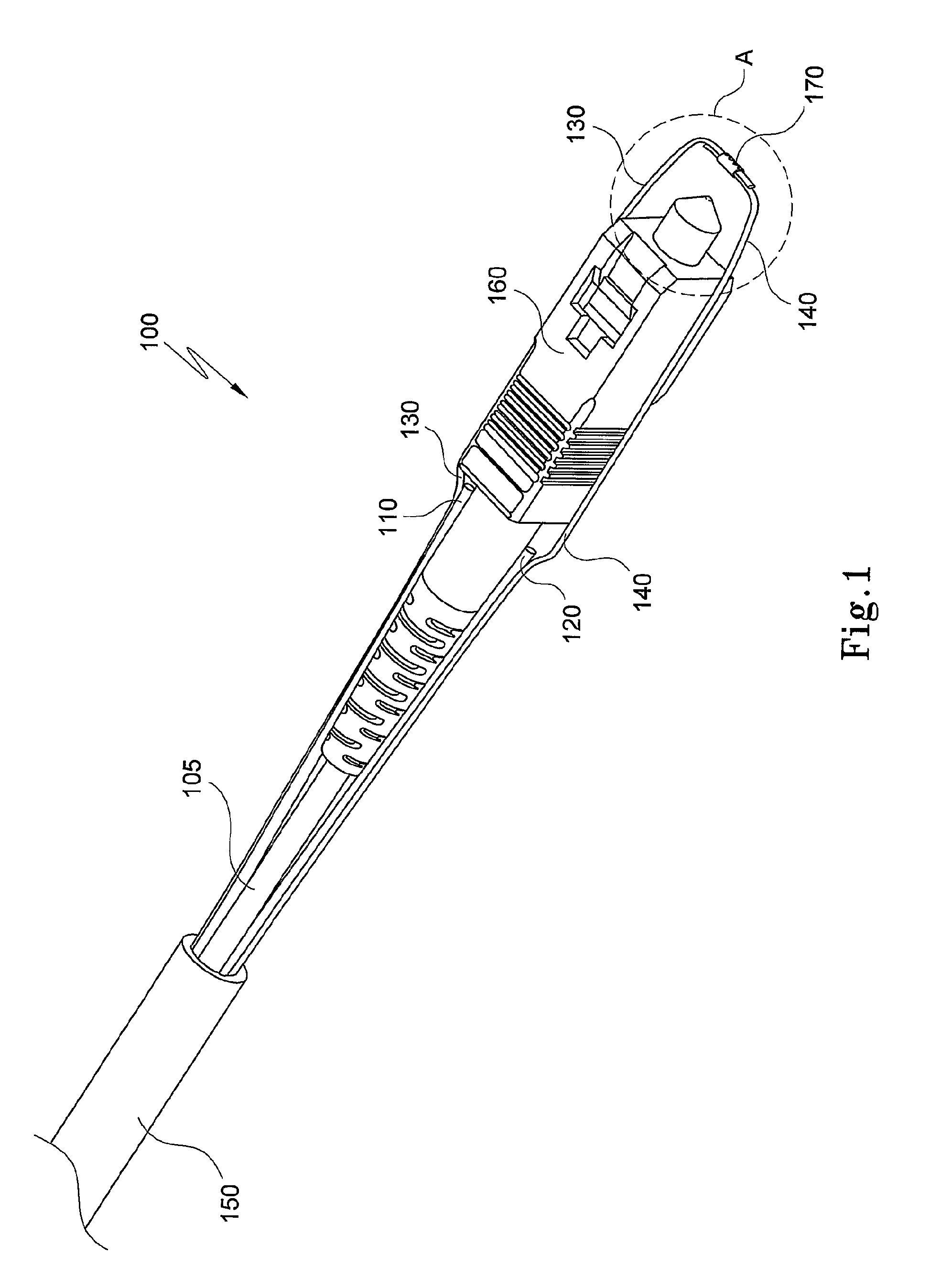

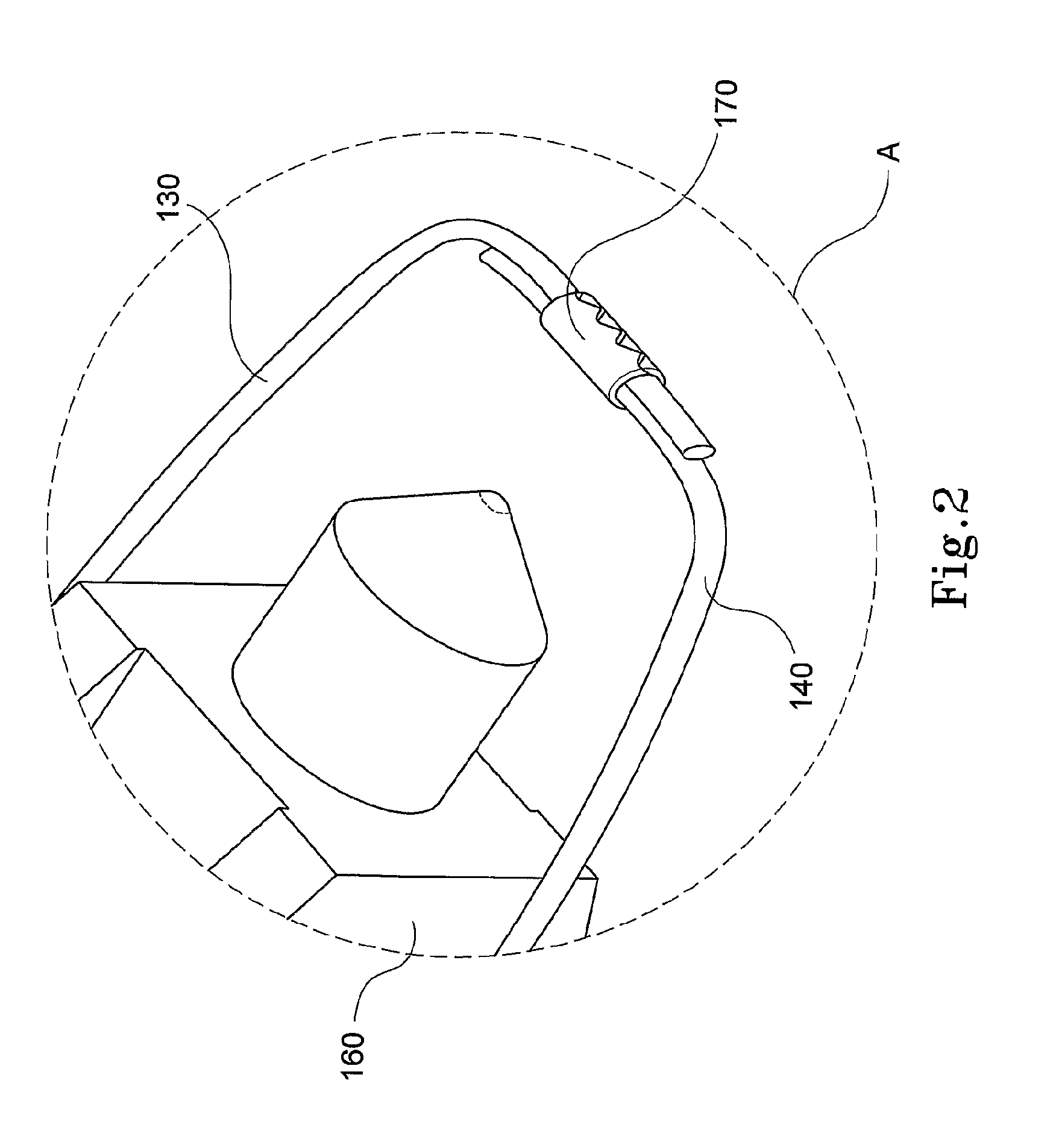

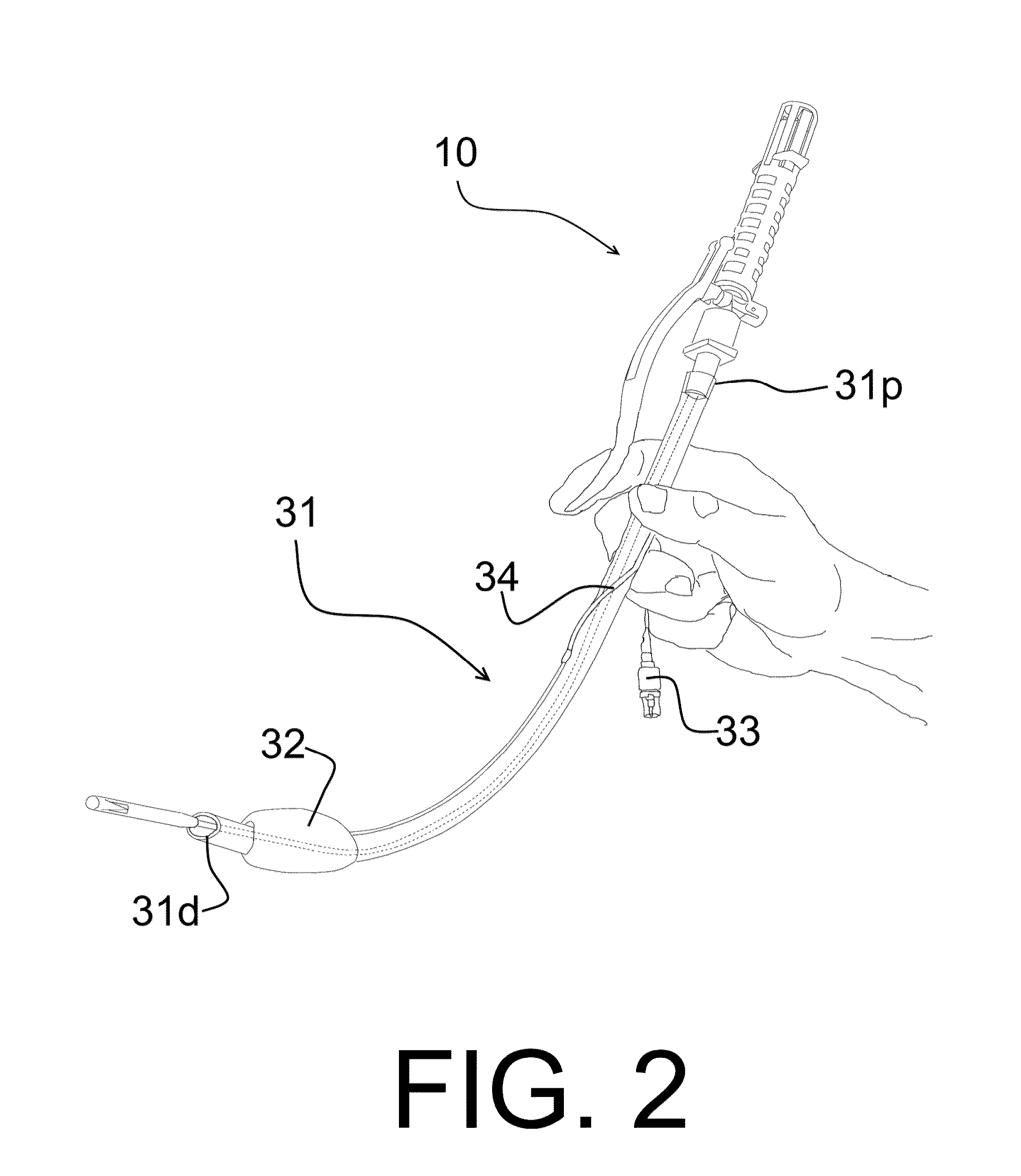

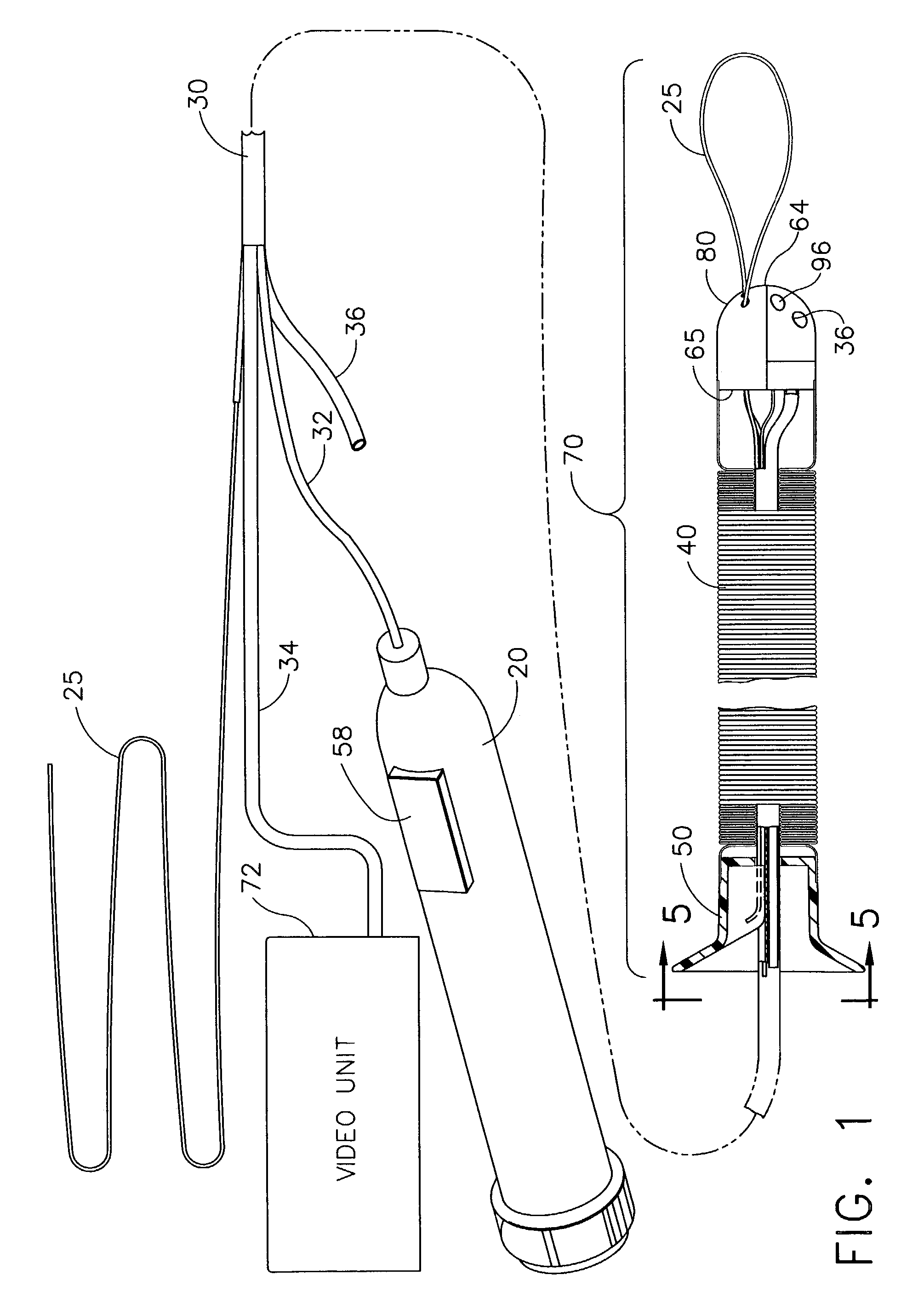

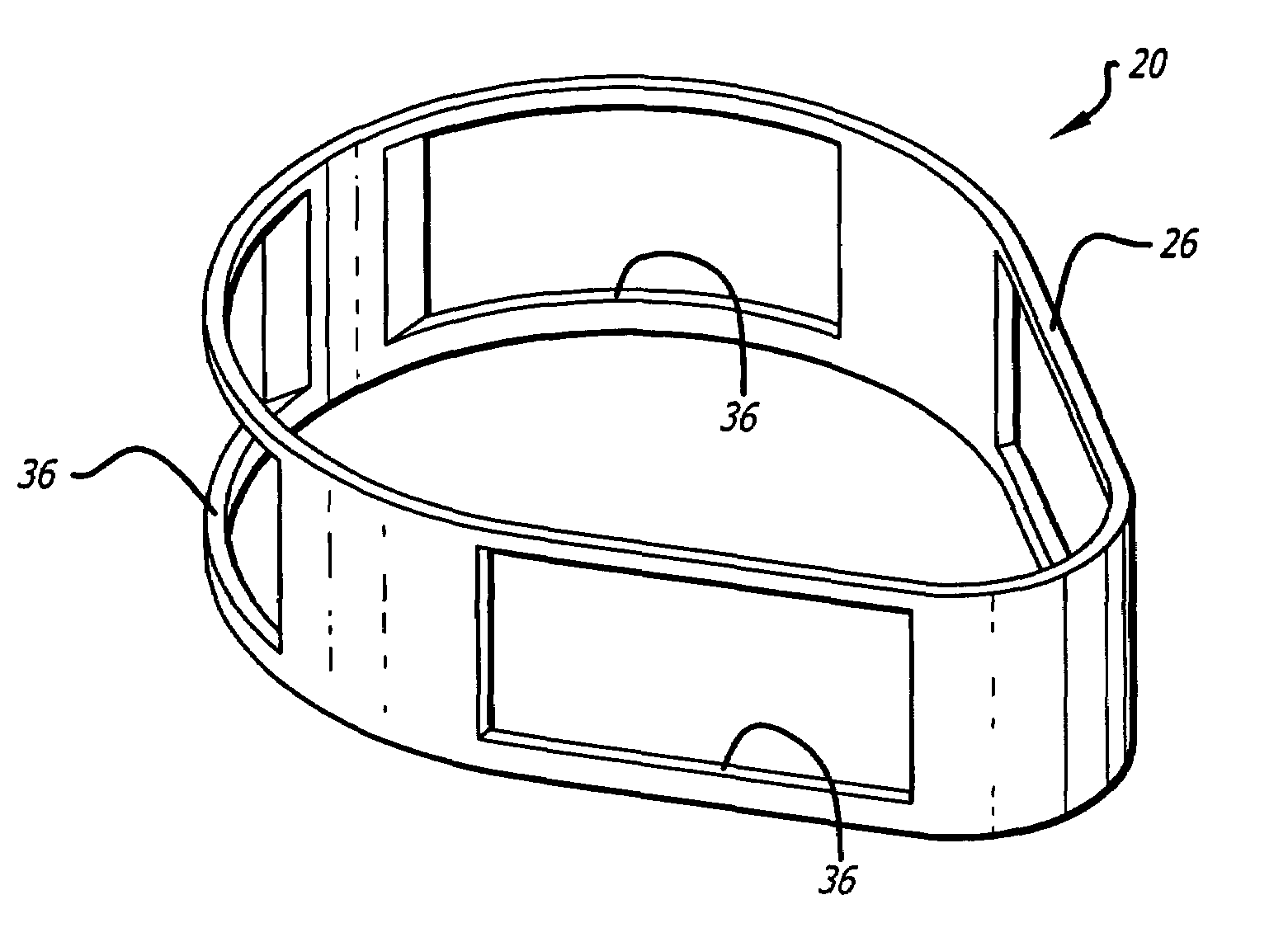

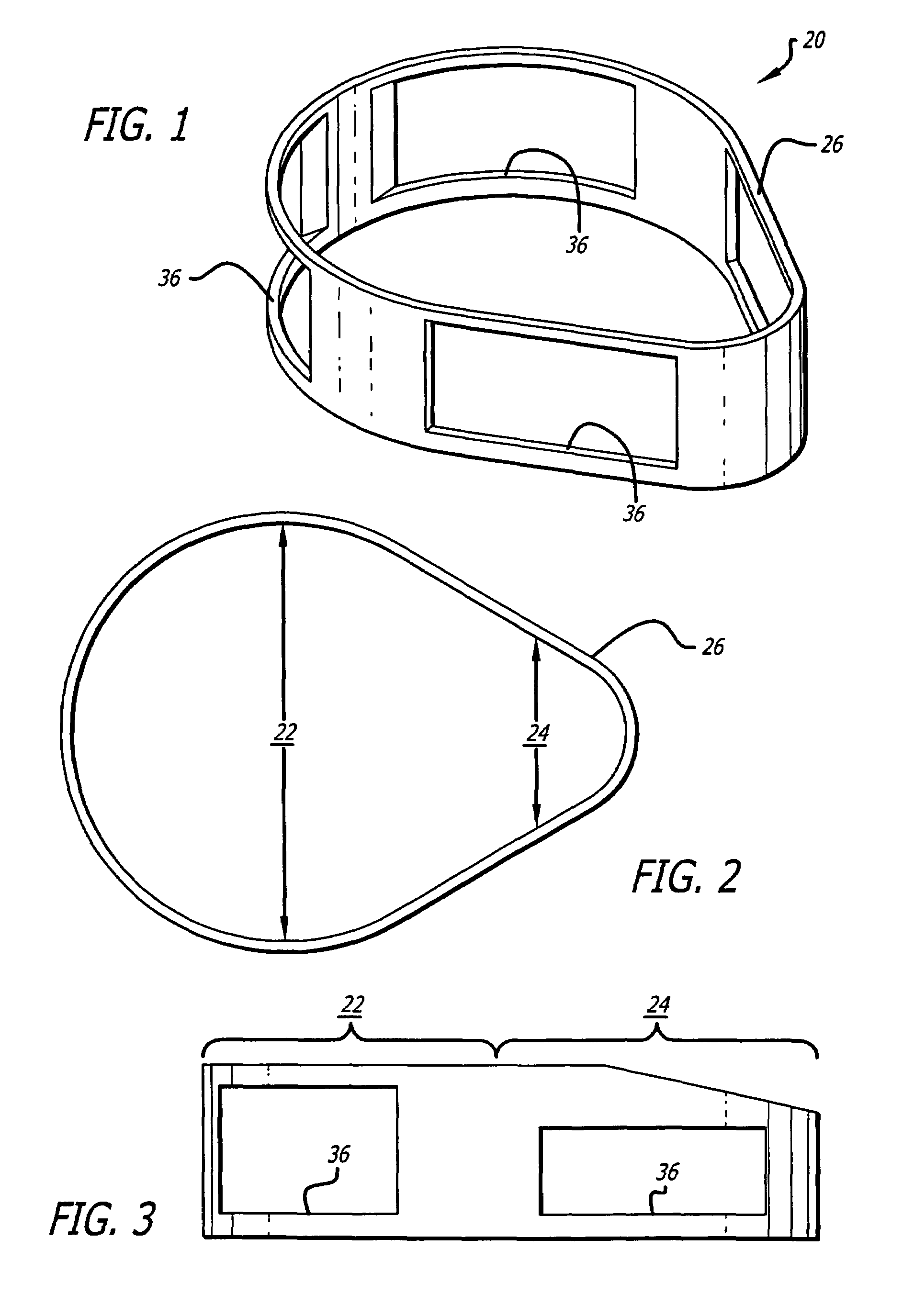

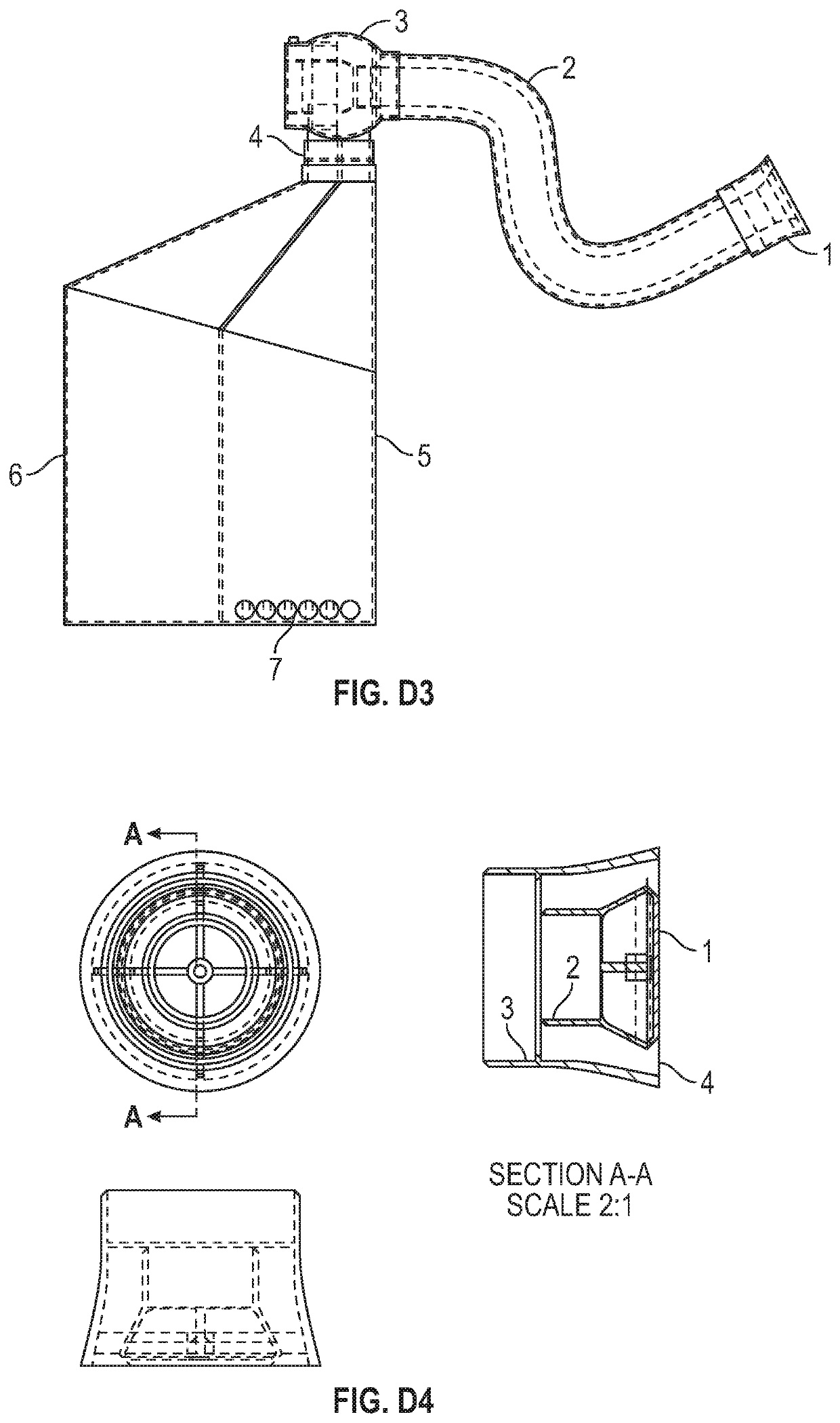

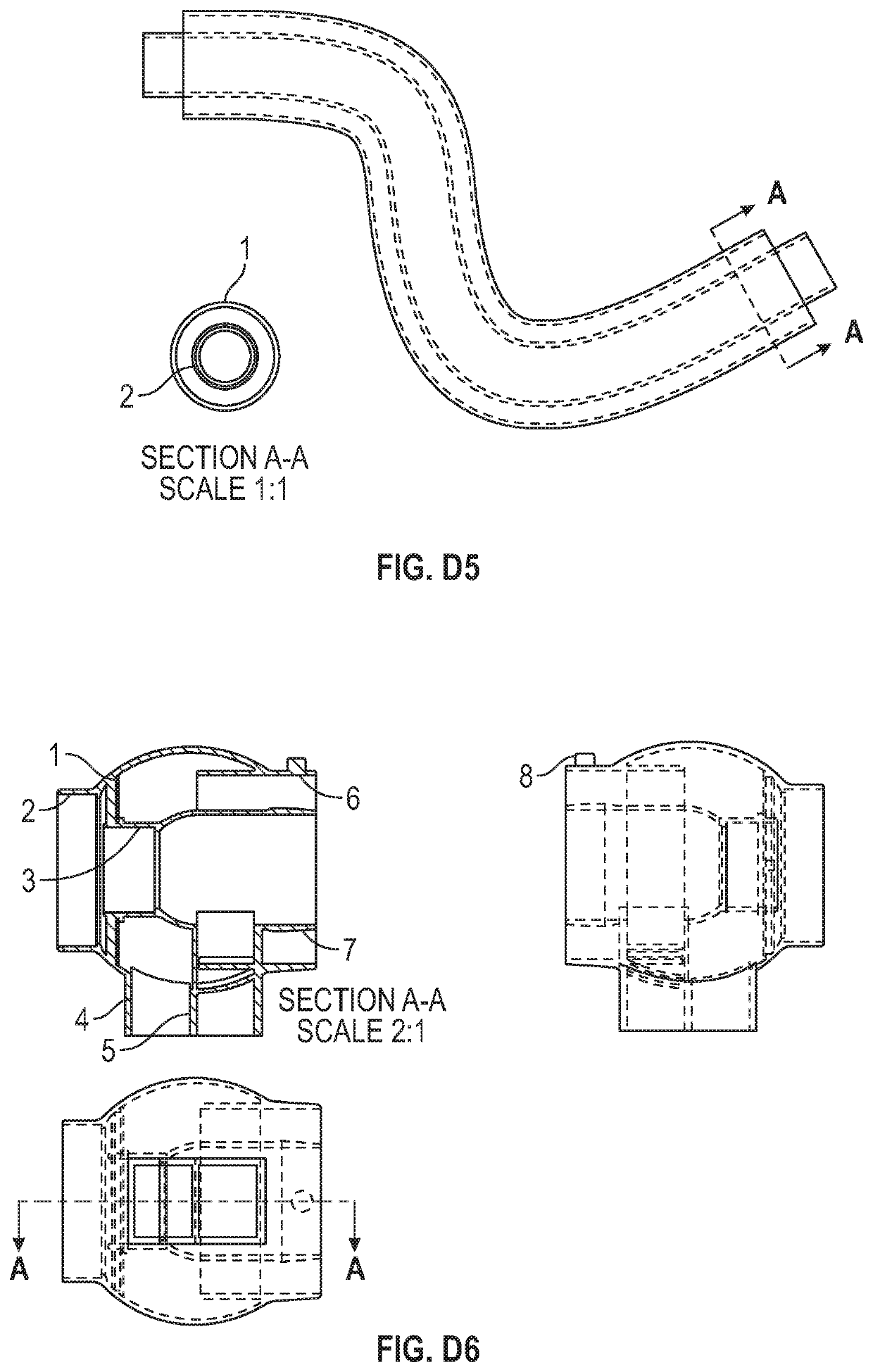

Hauling shroud for hauling fibre optic cable along a conduit

ActiveUS20100202748A1Reduce dimensionStreamlined shapeWaterborne vesselsFilament handlingFiberCatheter

A hauling shroud, a cable termination and methods of hauling a fibre optic cable with a pre-connected optic termination along a conduit. The hauling shroud protects the optic termination when being hauled along the conduit. The hauling shroud includes a first housing member and a second housing member such that the first housing member and the second housing member can be joined together to enclose the optic termination. At least one anchoring member is used, for example, connecting pins, such that at least one strengthening element of the fibre optic cable engages with the anchoring member inside an internal cavity formed within the hauling shroud. Alternatively, at least two strengthening elements of the fibre optic cable are attached together to form a loop which engages with the at least one anchoring member, e.g., the connecting pins. This prevents any hauling forces from being applied to the optic termination.

Owner:PRYSMIAN AUSTRALIA

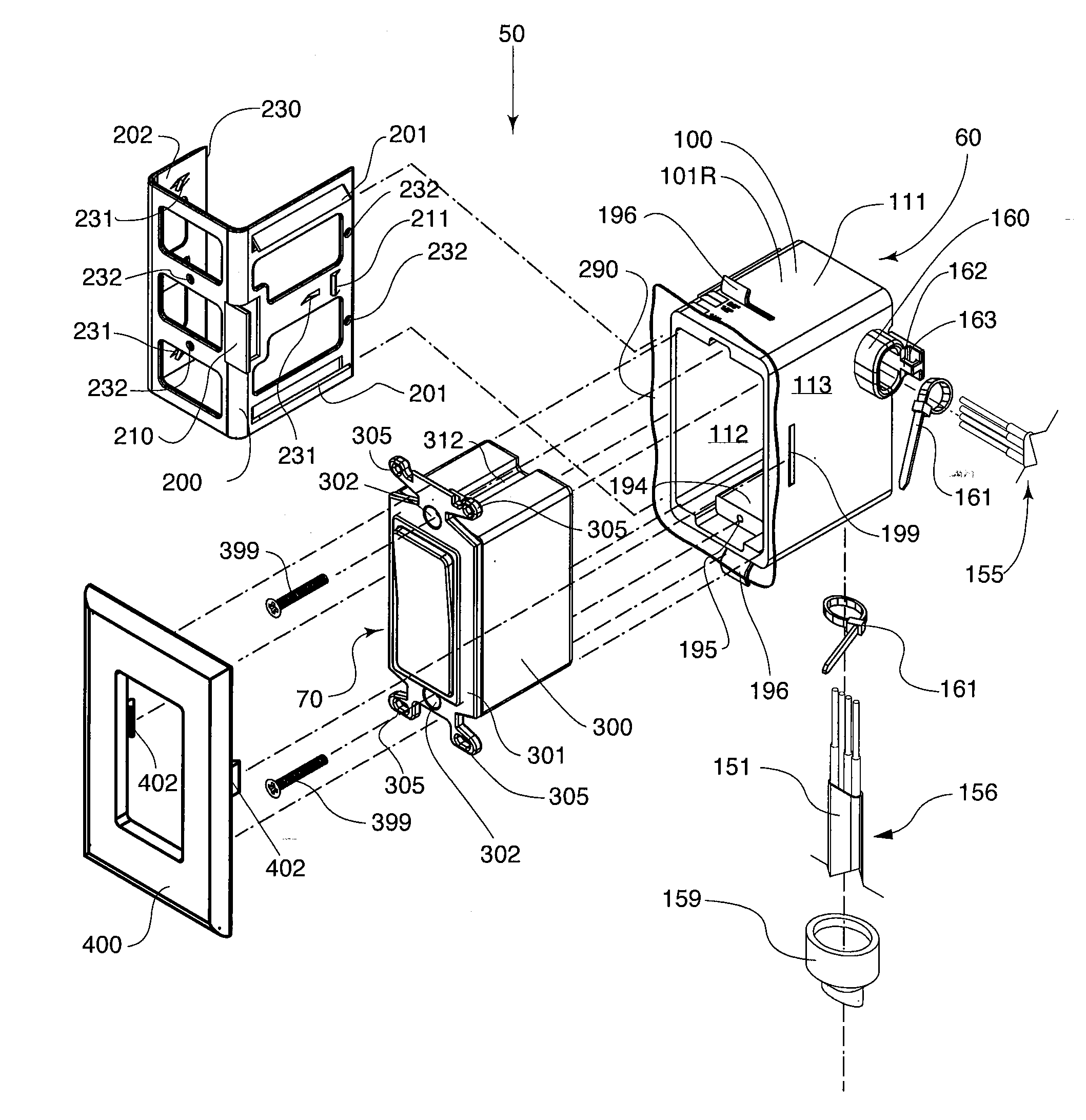

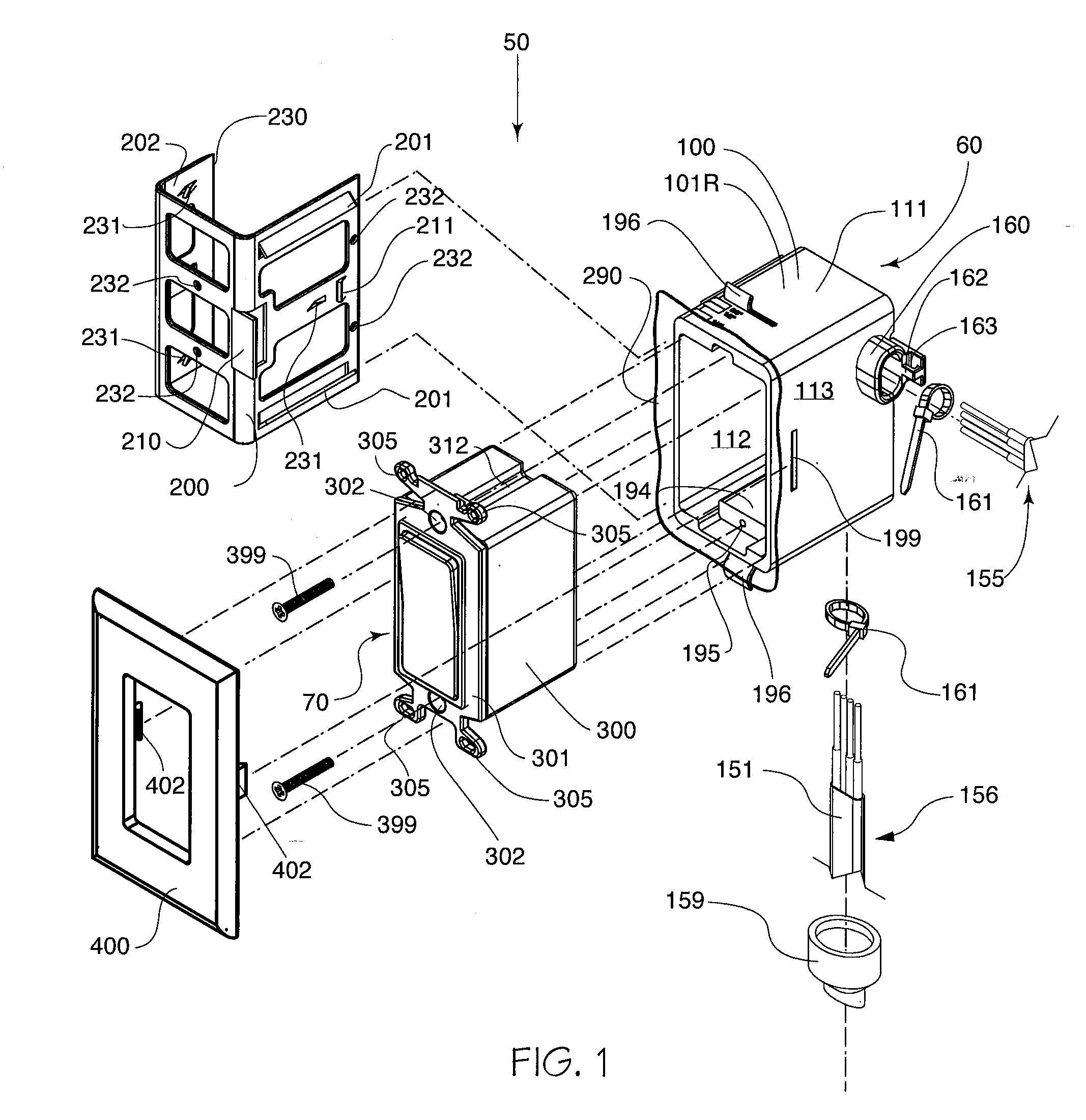

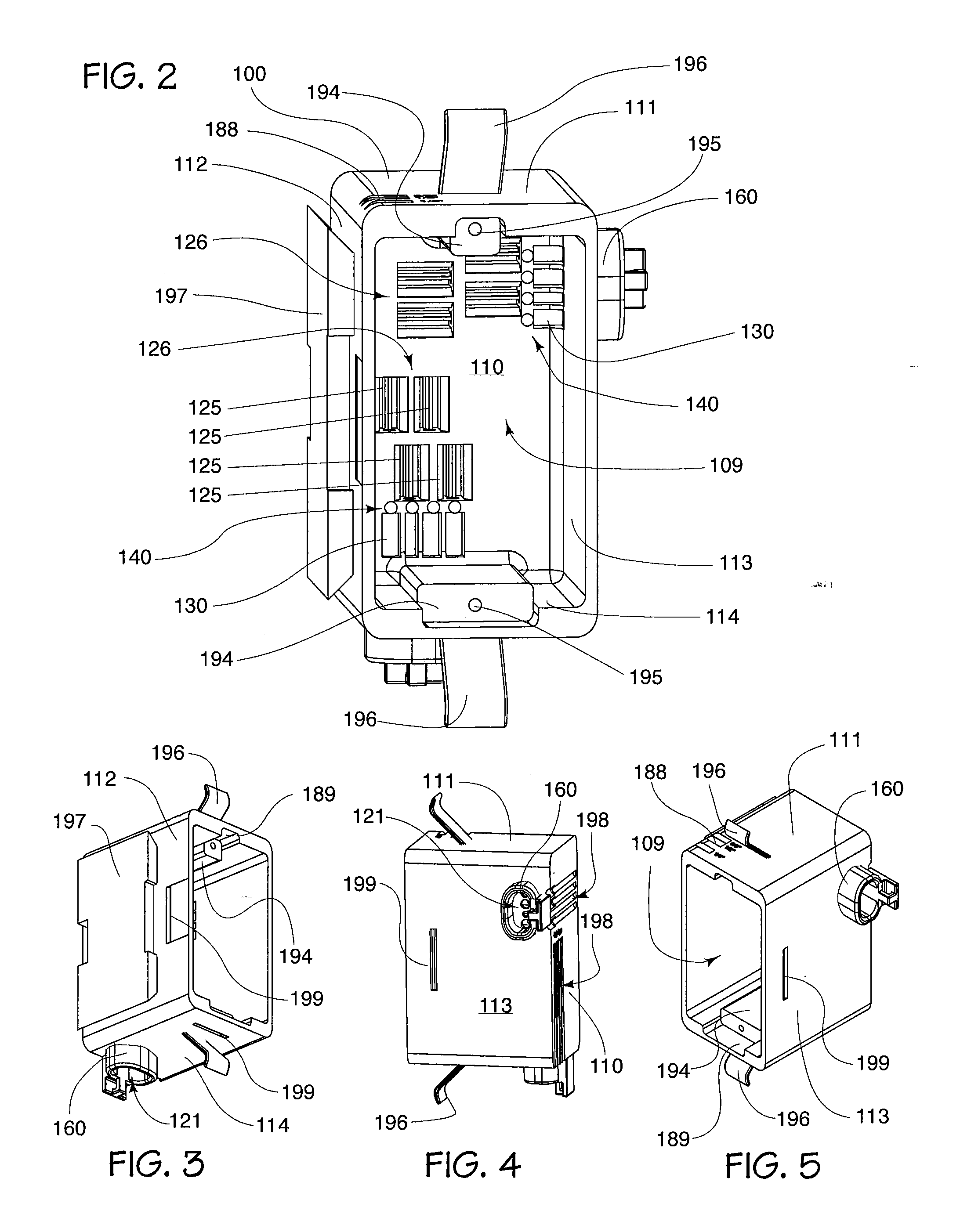

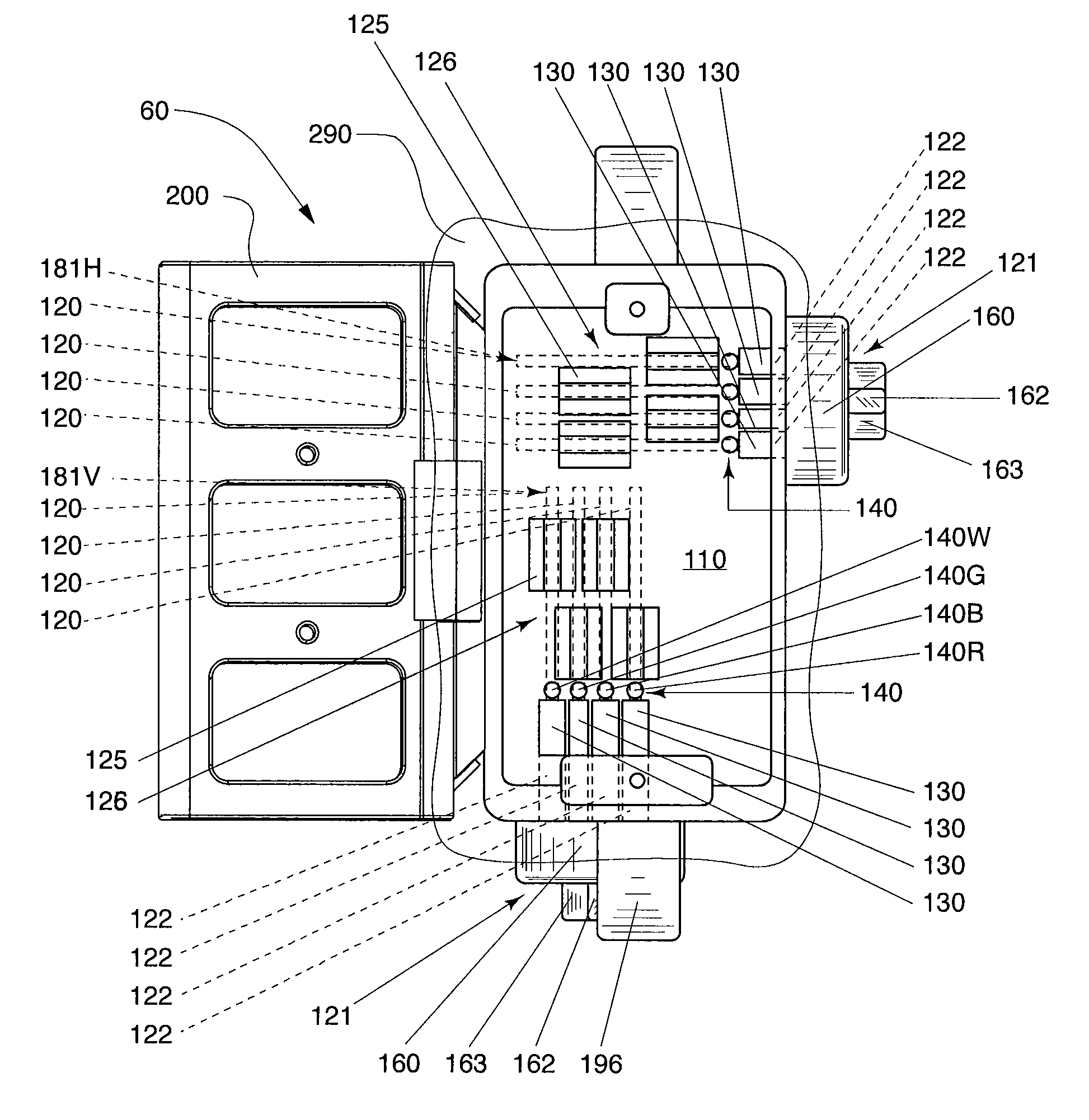

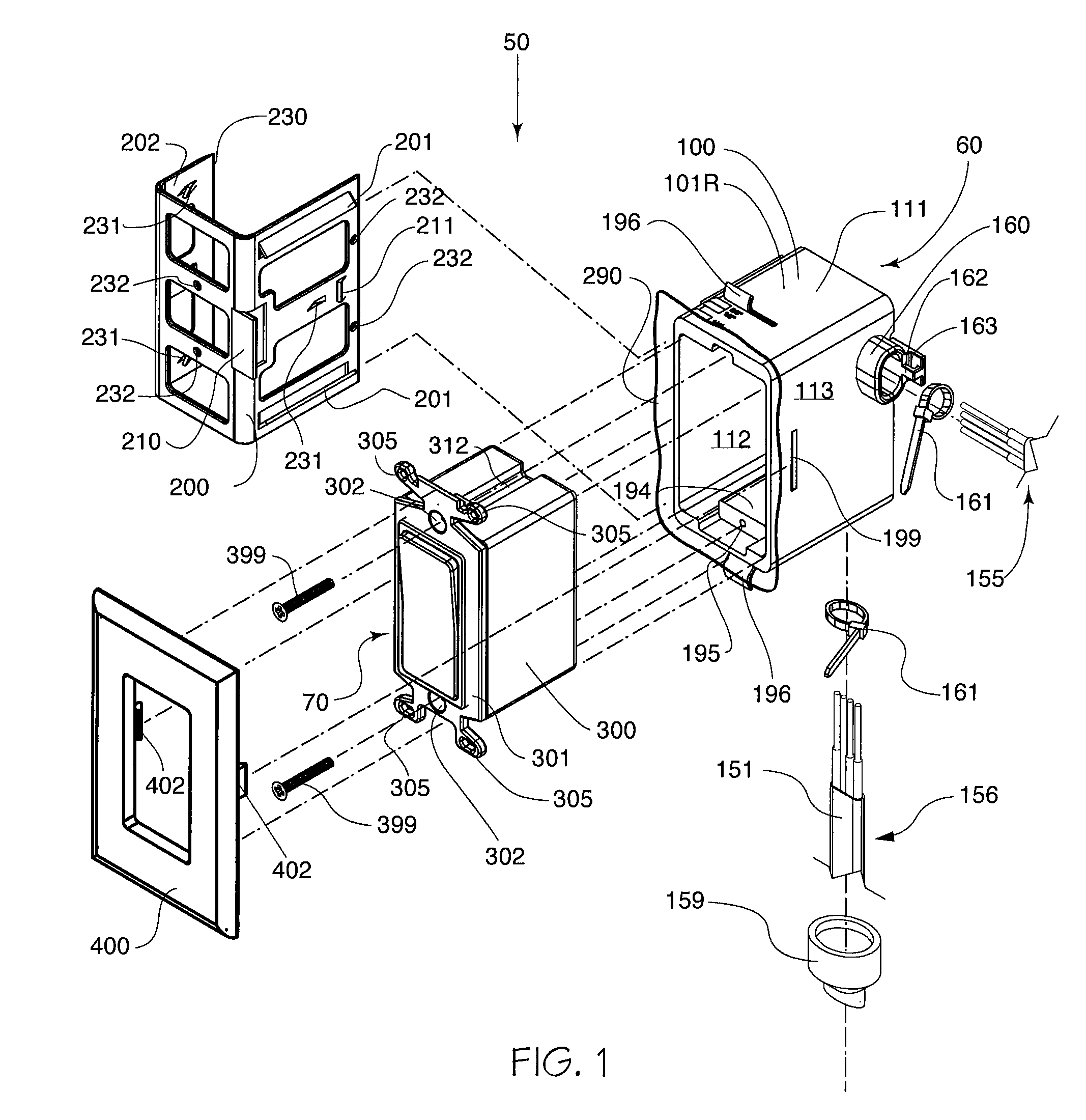

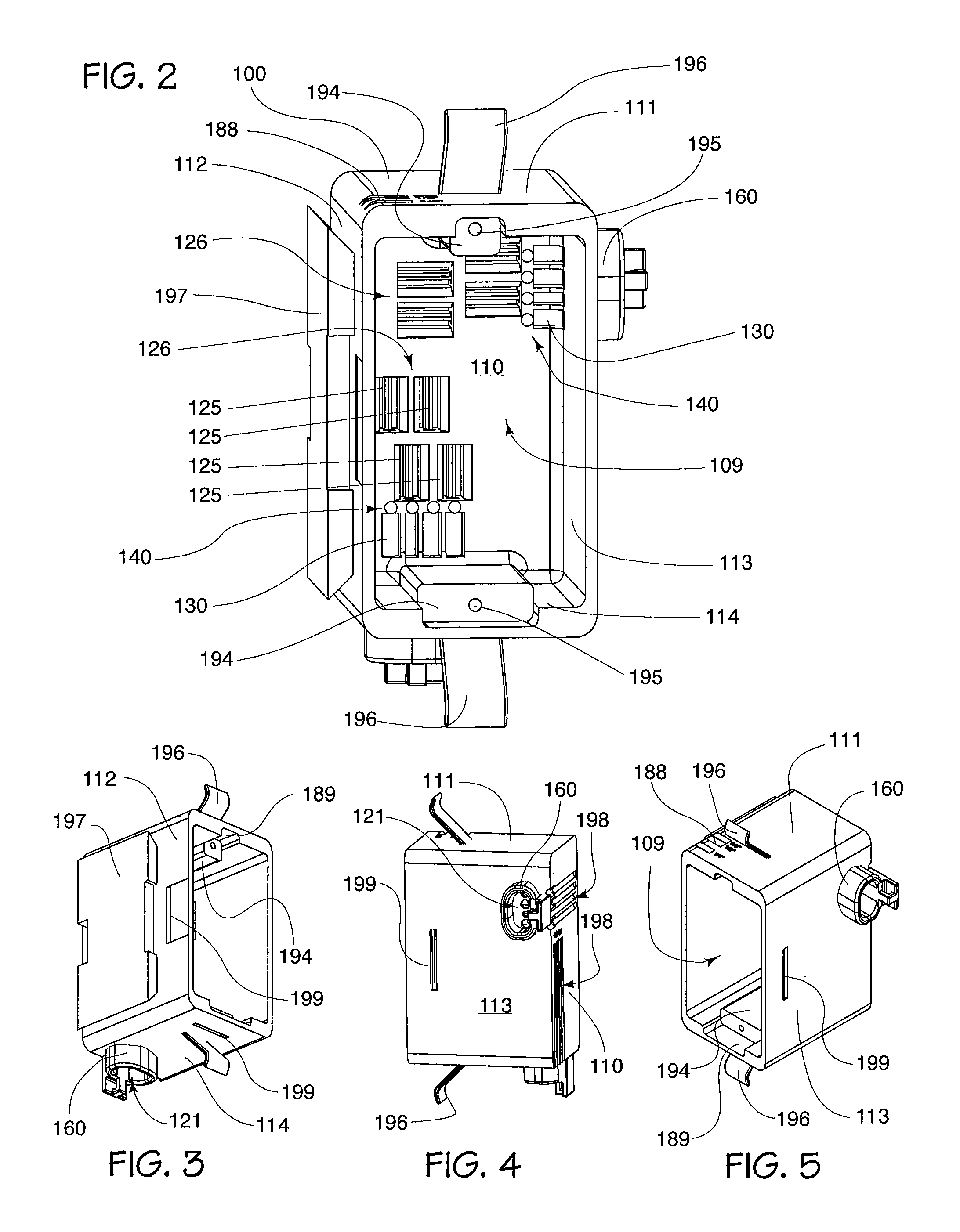

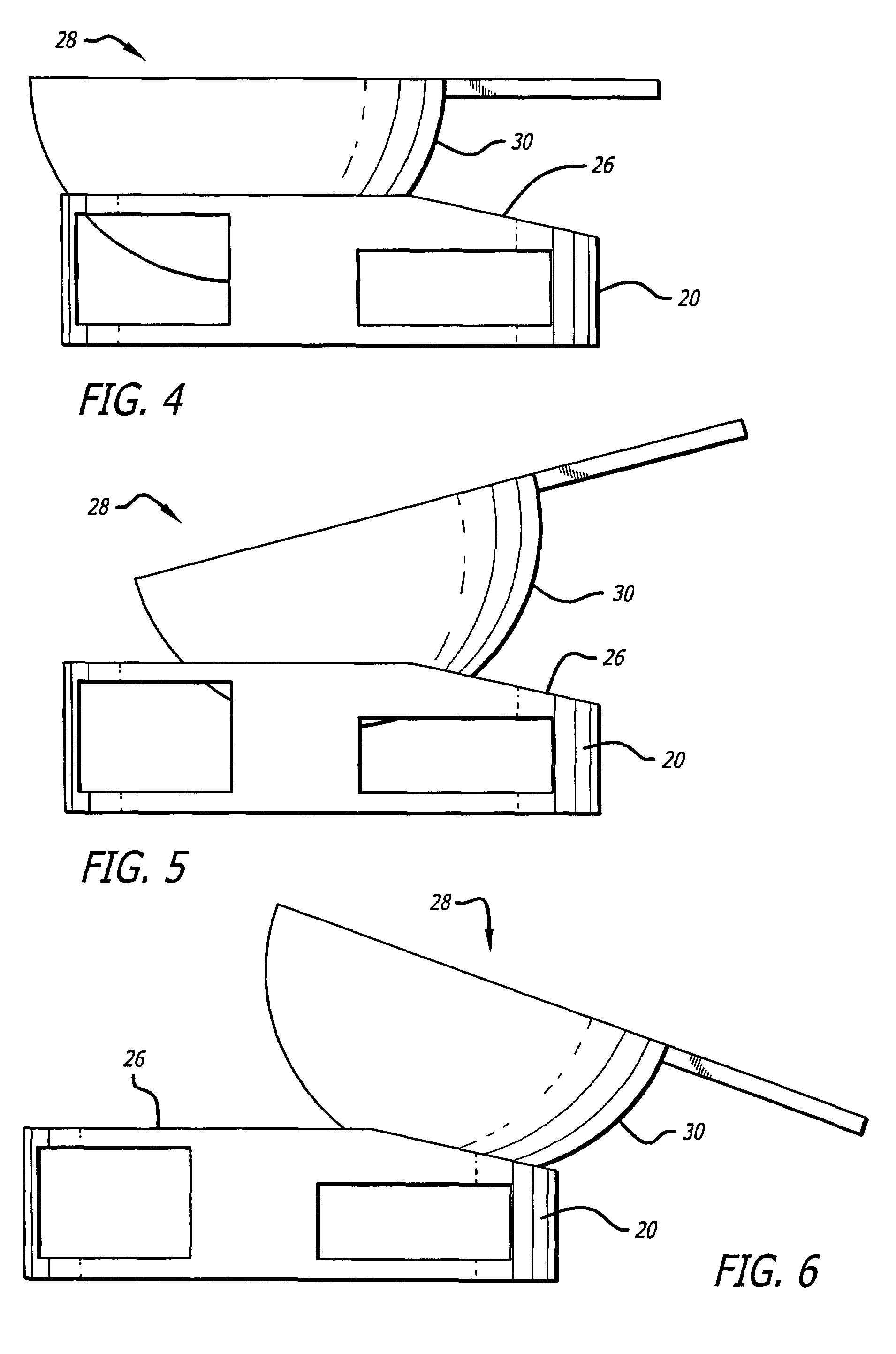

Electrical apparatus having quick connect components

InactiveUS20090107693A1Reduce labor costsReduce skillsBus-bar/wiring layoutsMachine supportsElectricityElectrical devices

Methods and apparatuses for power distribution improve and can standardize electrical connections between electrical cables and the multitude of electrical switches, receptacles, and fixtures of known technology. The invention can include modular hardware components such as junction boxes, electrical devices, adaptors, a / b switches, etc. that simplify both installation and inspection requirements at the job site. Optional color coding can facilitate proper wiring of the components. The invention allows field wiring to be completed more quickly and accurately thereby advantageously reducing associated costs and increasing safety.

Owner:THE WEST END DESIGN GROUP

Electrical apparatus having quick connect components

InactiveUS7767905B2Reduce skillsLow experience requirementBus-bar/wiring layoutsMachine supportsElectricityElectrical devices

Methods and apparatuses for power distribution improve and can standardize electrical connections between electrical cables and the multitude of electrical switches, receptacles, and fixtures of known technology. The invention can include modular hardware components such as junction boxes, electrical devices, adaptors, a / b switches, etc. that simplify both installation and inspection requirements at the job site. Optional color coding can facilitate proper wiring of the components. The invention allows field wiring to be completed more quickly and accurately thereby advantageously reducing associated costs and increasing safety.

Owner:THE WEST END DESIGN GROUP

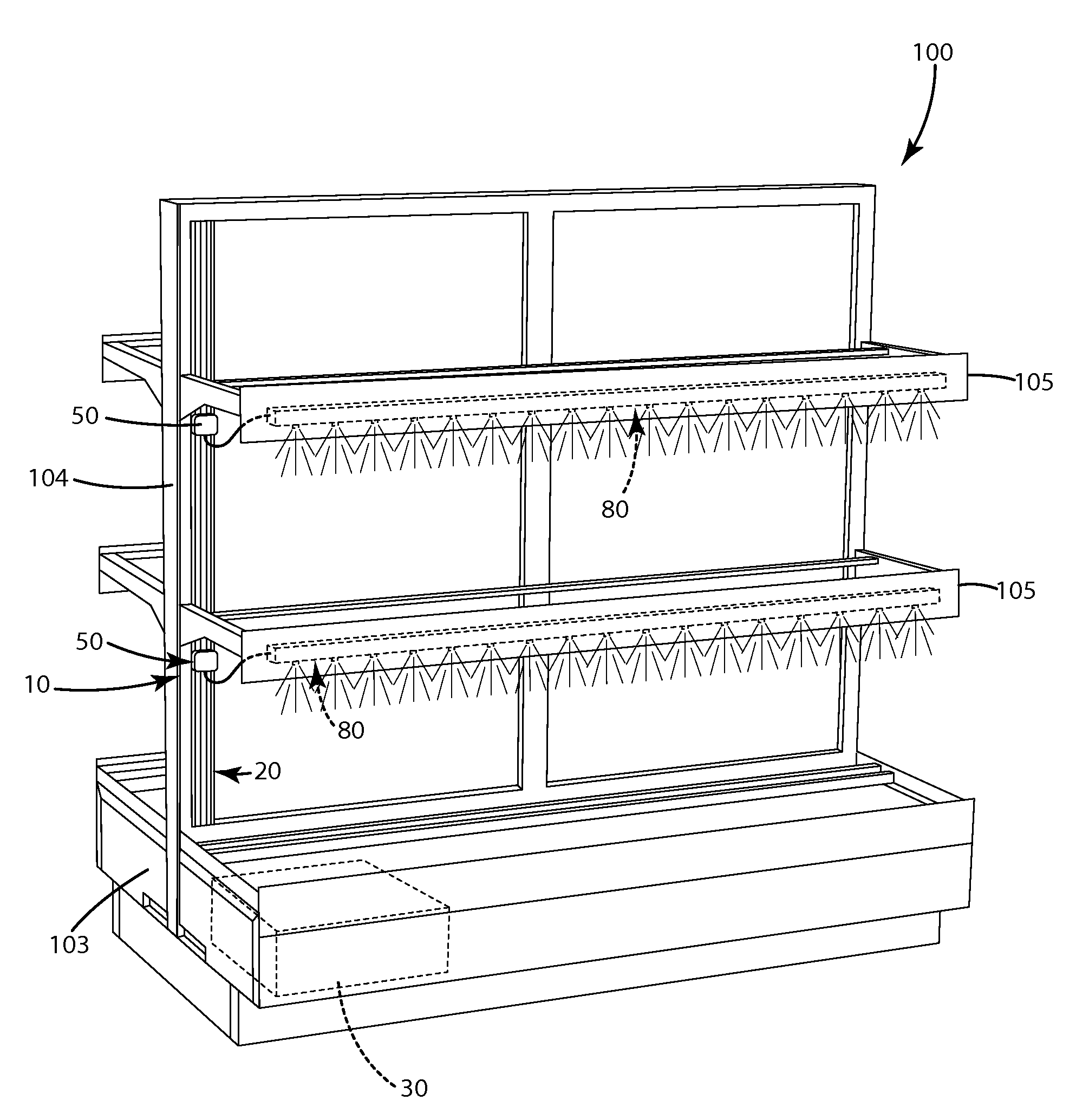

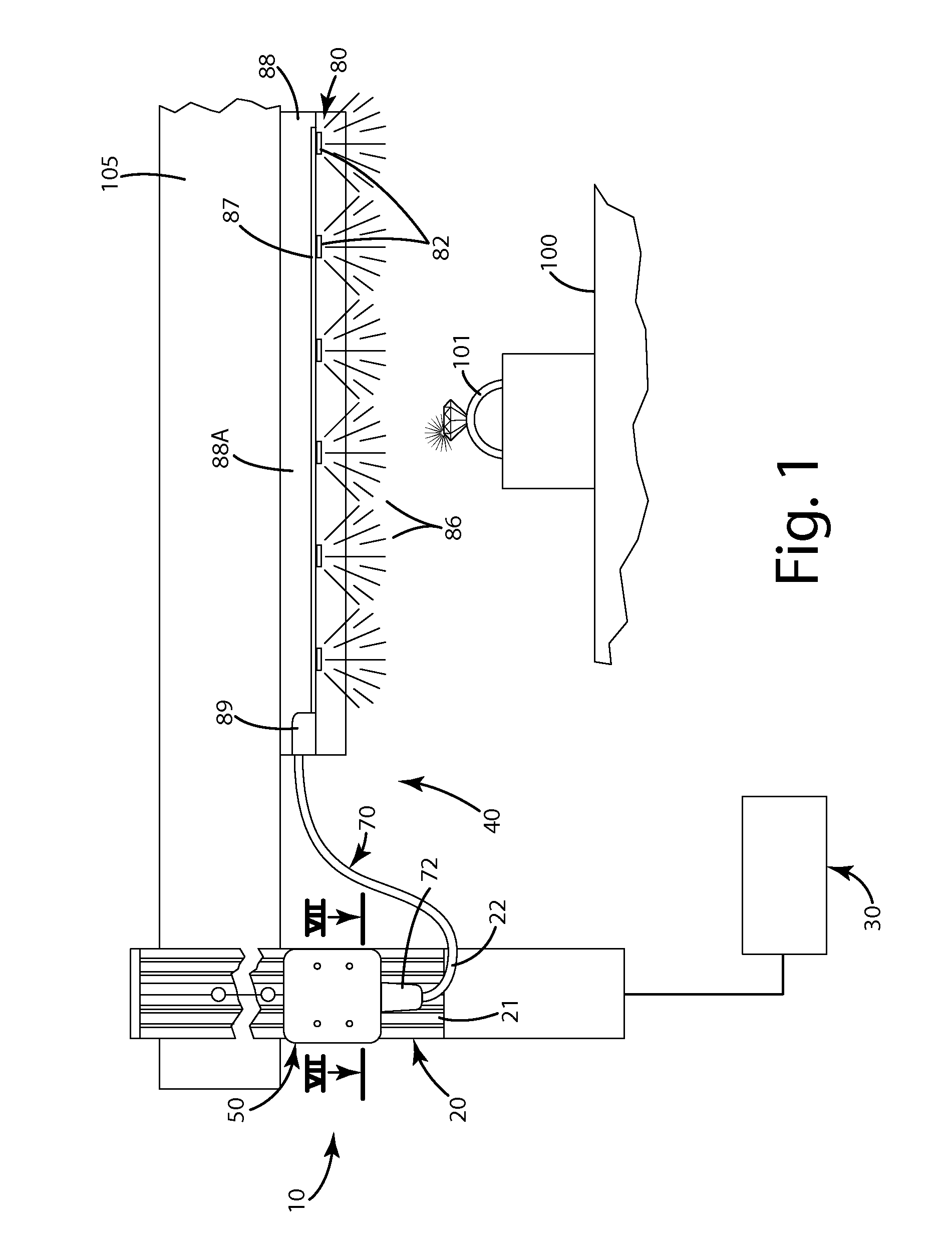

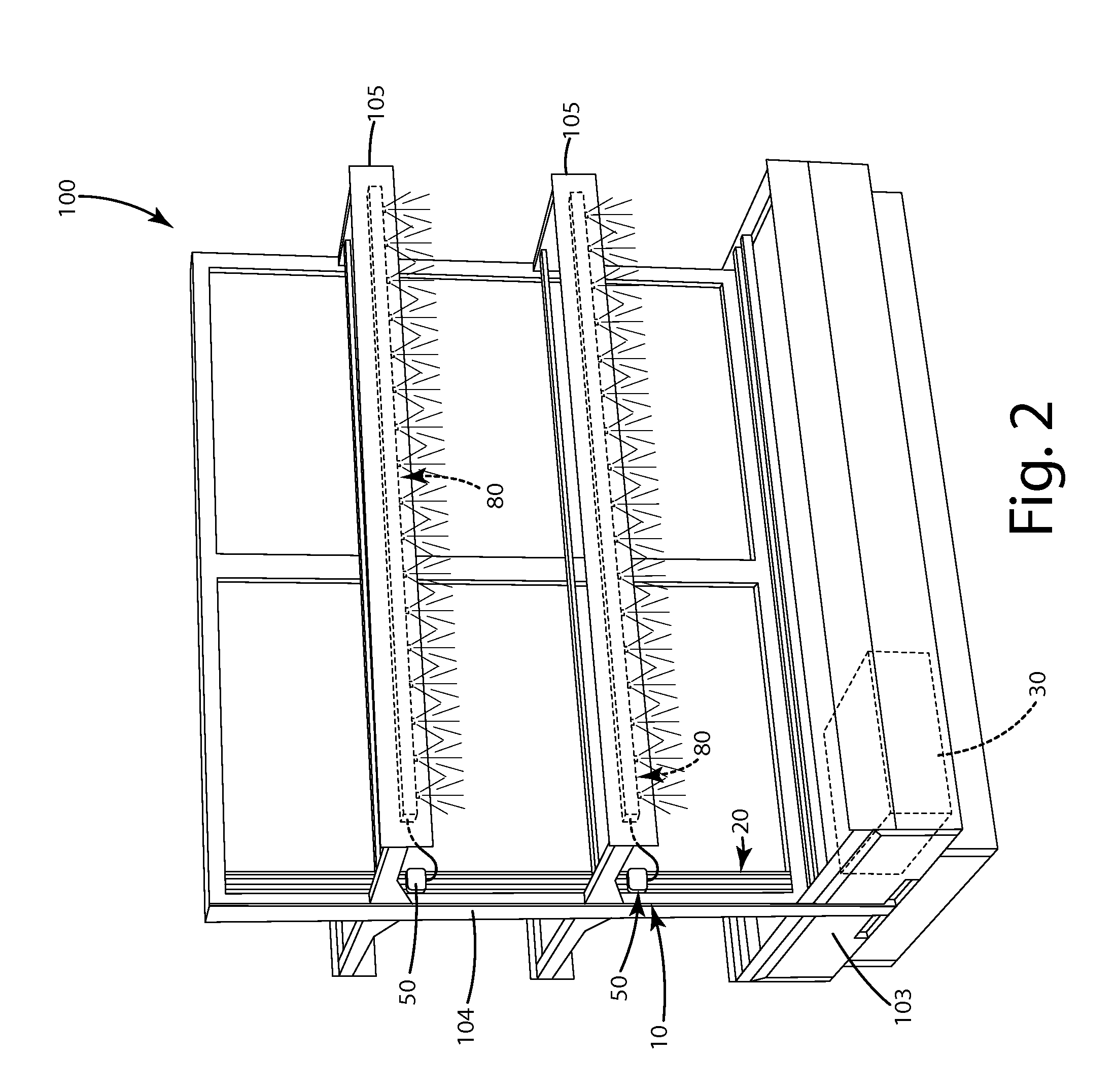

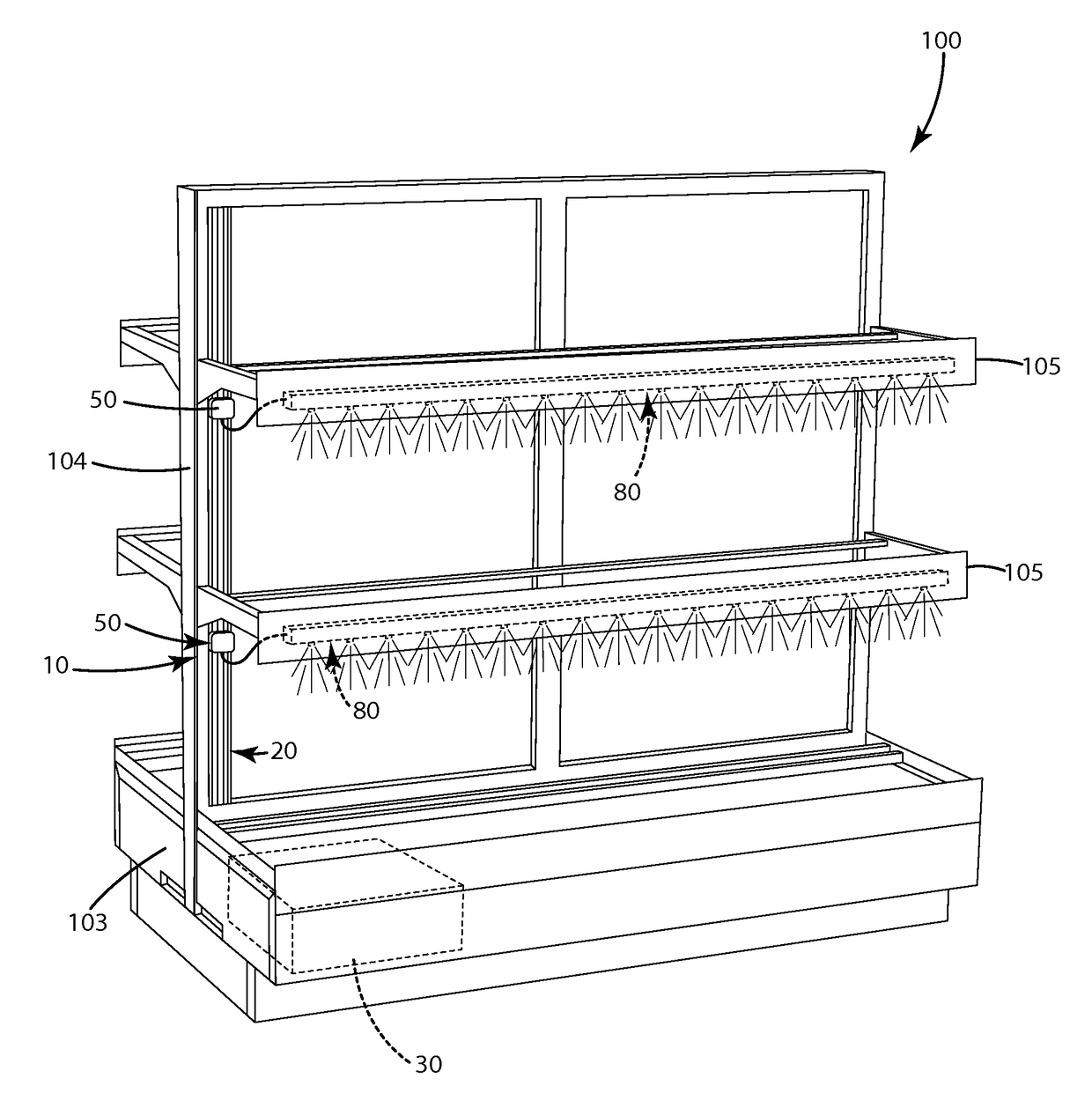

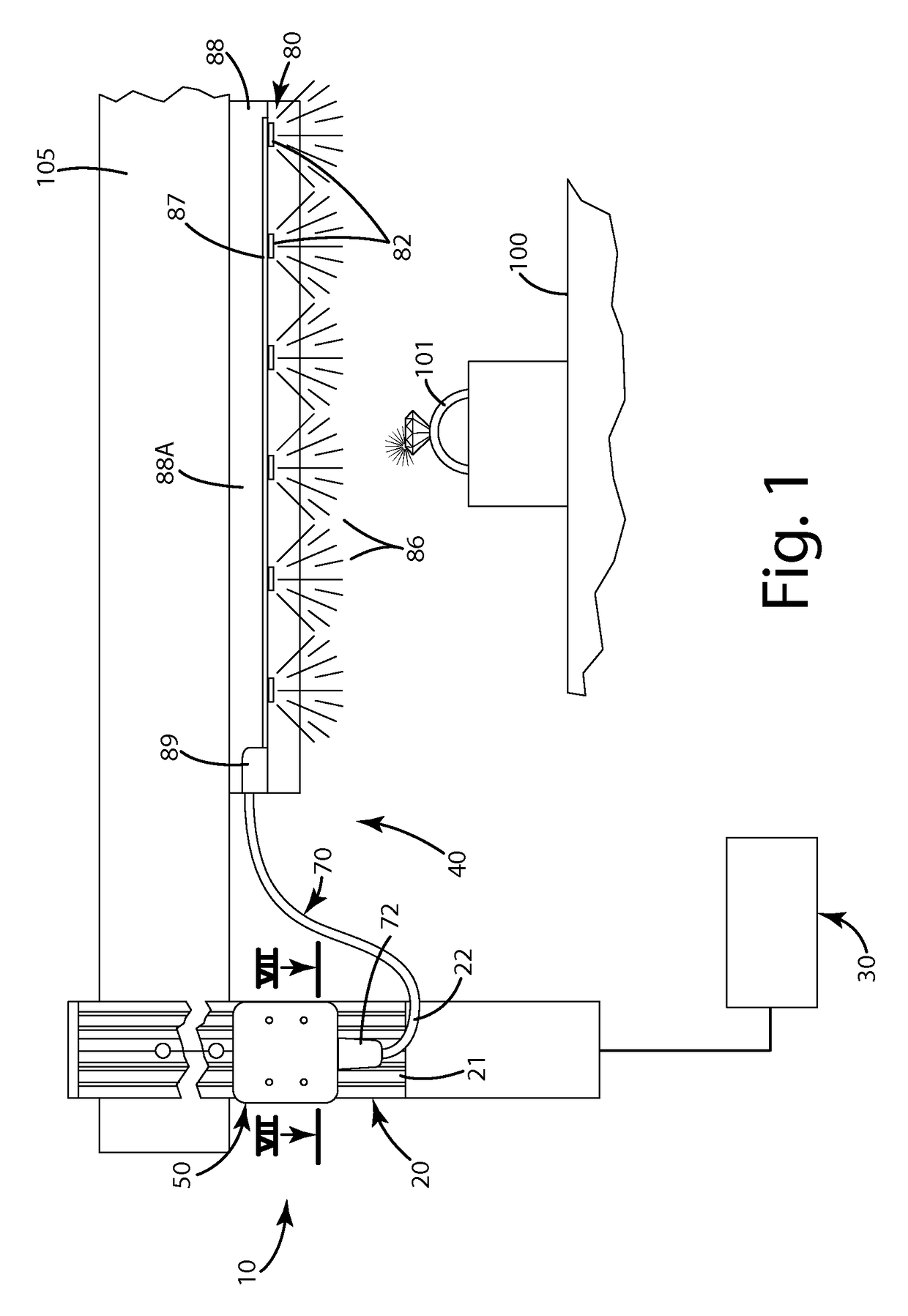

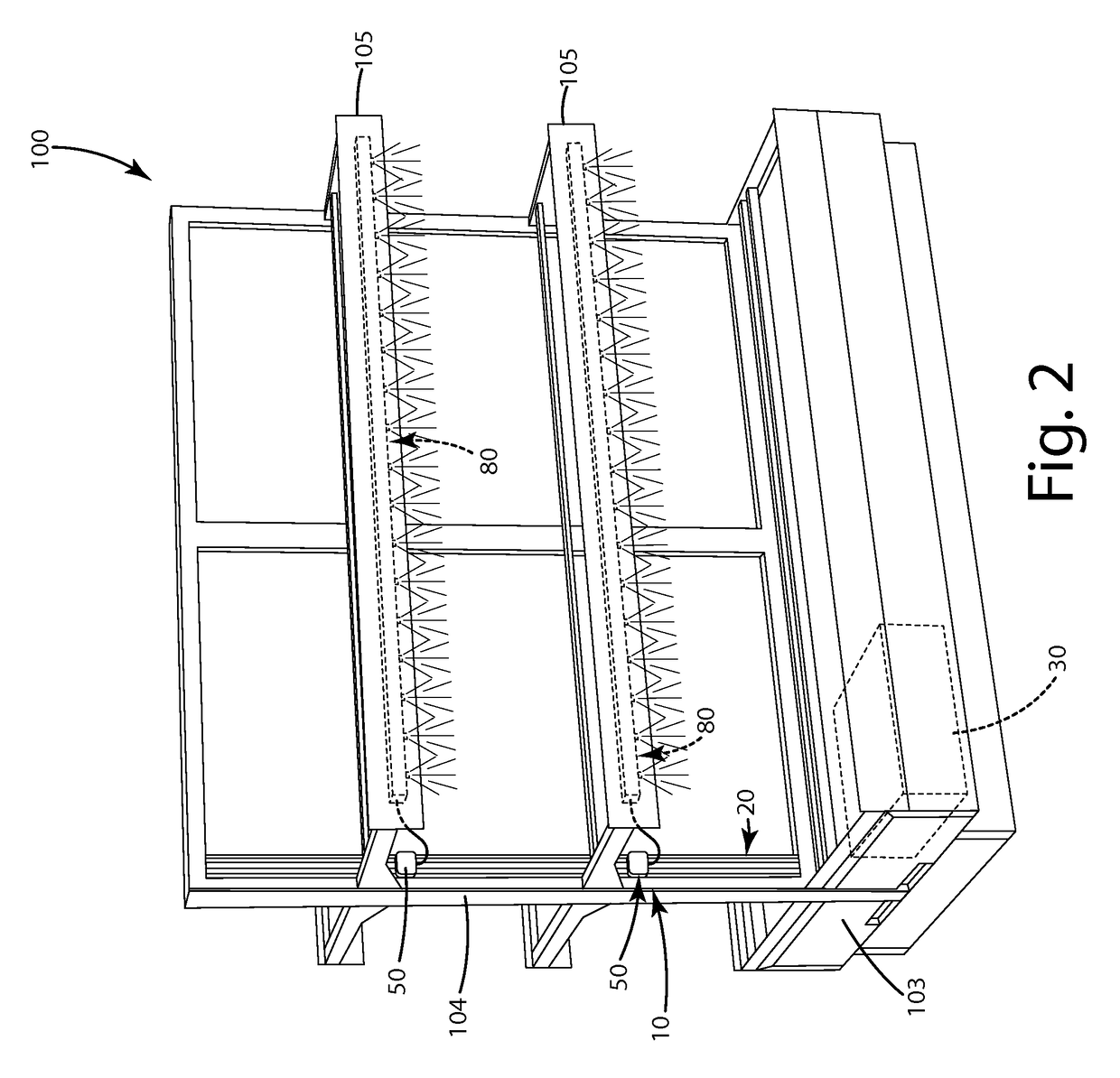

Display lighting system

ActiveUS20160061429A1Reduce orientation errorPrecise positioningMechanical apparatusLighting support devicesElectricityLow voltage

A lighting system including a low voltage frame, a puck magnetically joinable with the frame, a lighting array, and an elongated electrical connector joining the puck and the lighting array. The puck can be selectively positioned along the low voltage frame in a variety of different locations. The puck can be constructed from a polymeric material molded over electrical connectors, and optionally a power feed, such as a cable jack. The electrical connectors can be magnetized so that the electrical connectors are magnetically attracted to power rails on the low voltage frame to establish electrical coupling of the connectors to the power rails, while physically securing the puck in a fixed location along the low voltage frame. The power rails can be constructed from magnetic stainless steel, optionally coated with black oxide from a hot black oxide coating process.

Owner:AMSTORE

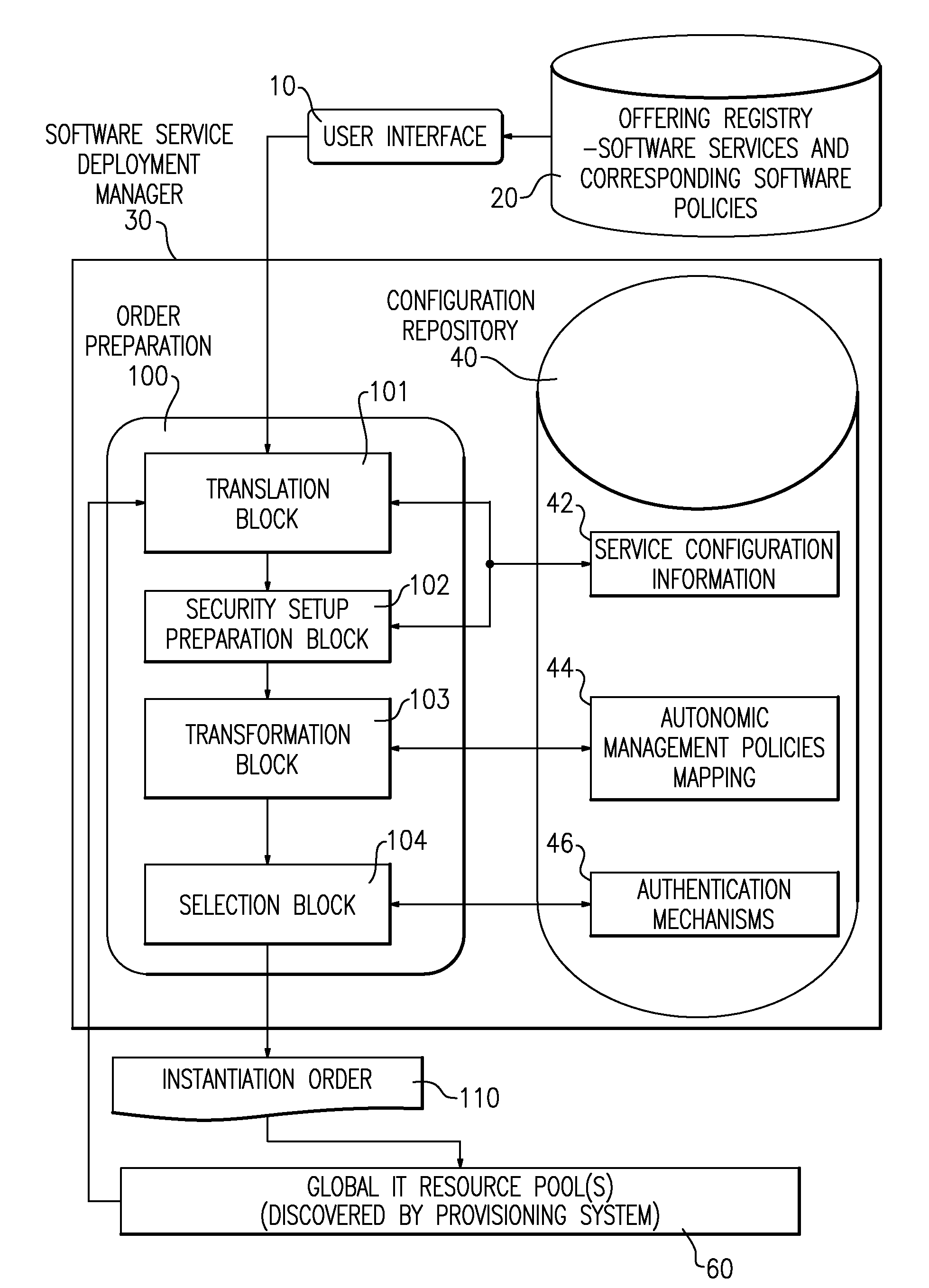

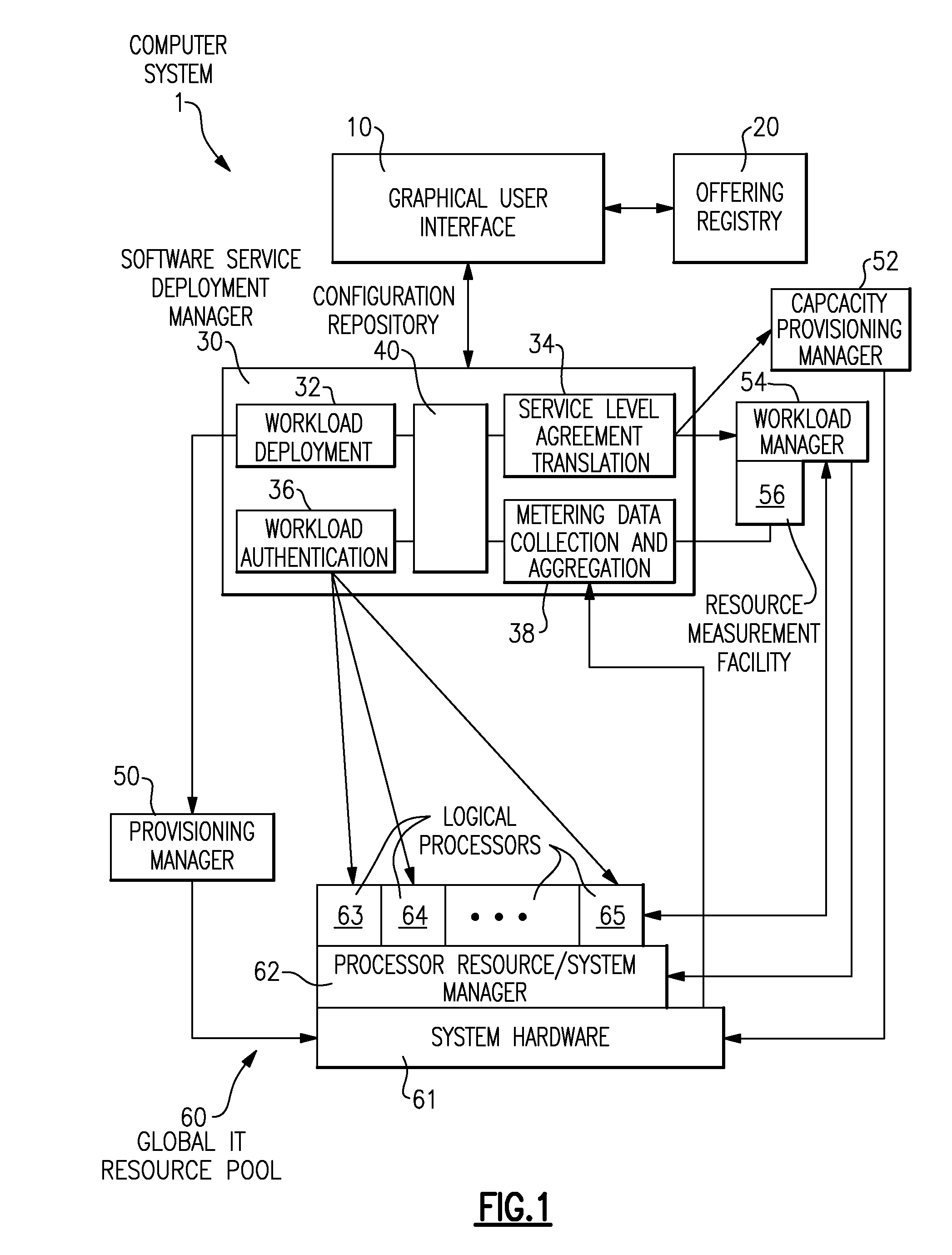

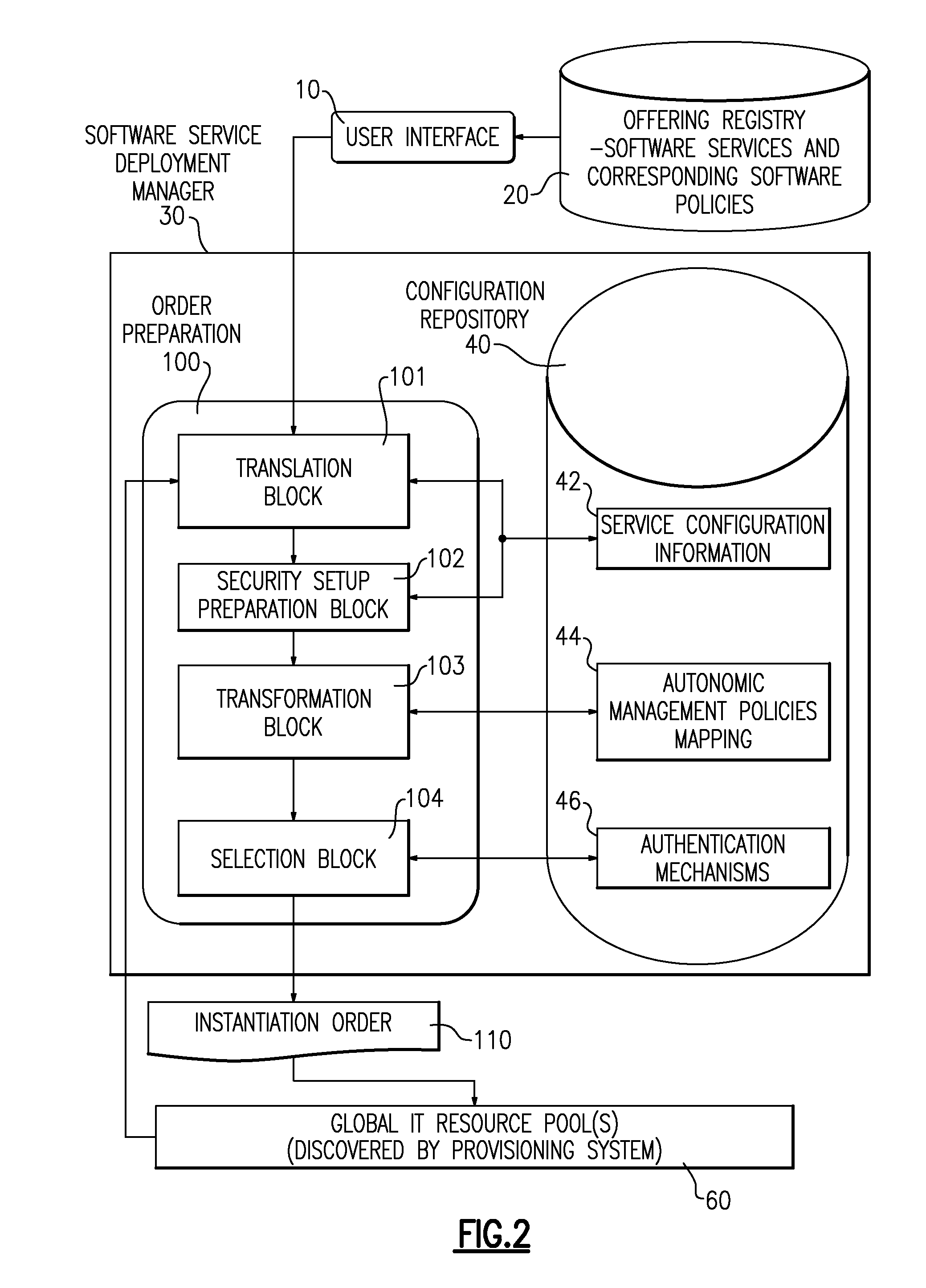

Method, Arrangement, Computer Program Product and Data Processing Program for Deploying a Software Service

ActiveUS20090307685A1Detail informationEasy to useProgram loading/initiatingMemory systemsComputerized systemSoftware as a service

Deploying a software service. A defined software service offering is selected from a plurality of defined software service offerings. An instantiation order for deploying the selected defined software service offering on a corresponding computer system is generated. Each defined software service offering comprises a software service definition and at least one defined software policy. One selected from the group consisting of the software service definition, the software policy, and a combination thereof, provides a hardware configuration for the software service, a software configuration for the software service, and a managing policy for the software service. The instantiation order of the software service for execution on the computer system is created based on the hardware configuration, the software configuration and the managing policy.

Owner:IBM CORP

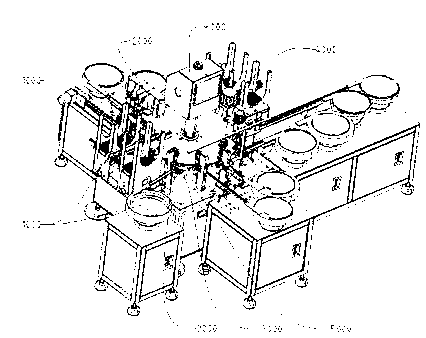

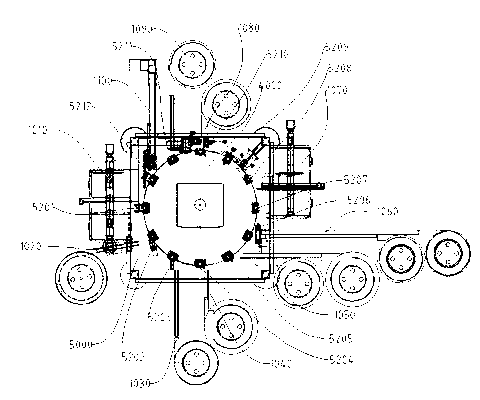

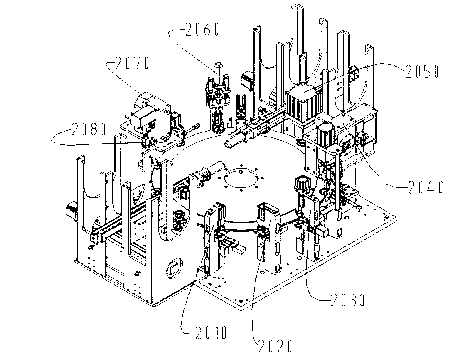

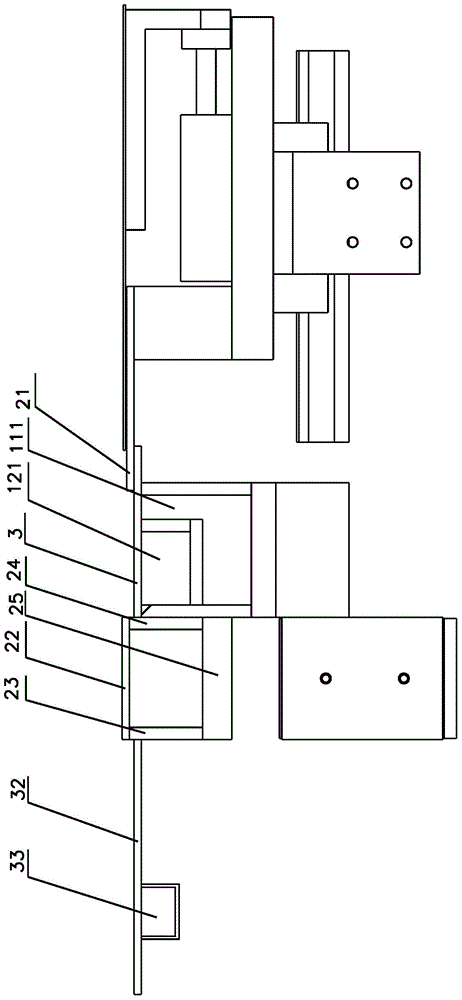

Flexible automatic assembling machine of mobile communication radio frequency coaxial connector

ActiveCN103124038AReliable guarantee of geometric dimensions and shape and position tolerancesReduced skills and labor intensityContact member assembly/disassemblyRadio frequencyHuman–machine interface

The invention discloses a flexible automatic assembling machine of a mobile communication radio frequency coaxial connector. The flexible automatic assembly machine comprises a feeding and discharging system, an assembling system, a tool clamp system, a rotary working disc system, a fixed workbench system and a human-machine interface control system. The conventional manual work is substituted by the flexible automatic assembling machine, so that the production efficiency is greatly increased, the operating skill and the labor intensity are reduced, the floor area is reduced, the consistency of product quality is guaranteed, and the product quality is improved. The feeding and discharging system, the assembling system, the tool clamp system and the PLC (Programmable Logic Control) system have adjustability or convertibility, can adapt to connector production objects of different types and specifications and have the characteristics of flexibility and flexible automation. The flexible automatic assembling machine of the mobile communication radio frequency coaxial connector comprehensively realizes high unity of compactness, reliability, safety, accuracy, fastness, flexibility, convenience and economy of the entire machine, and therefore, realizes new breakthrough in the national and international mobile communication radio frequency coaxial connector manufacturing industry.

Owner:江苏吴通物联科技有限公司

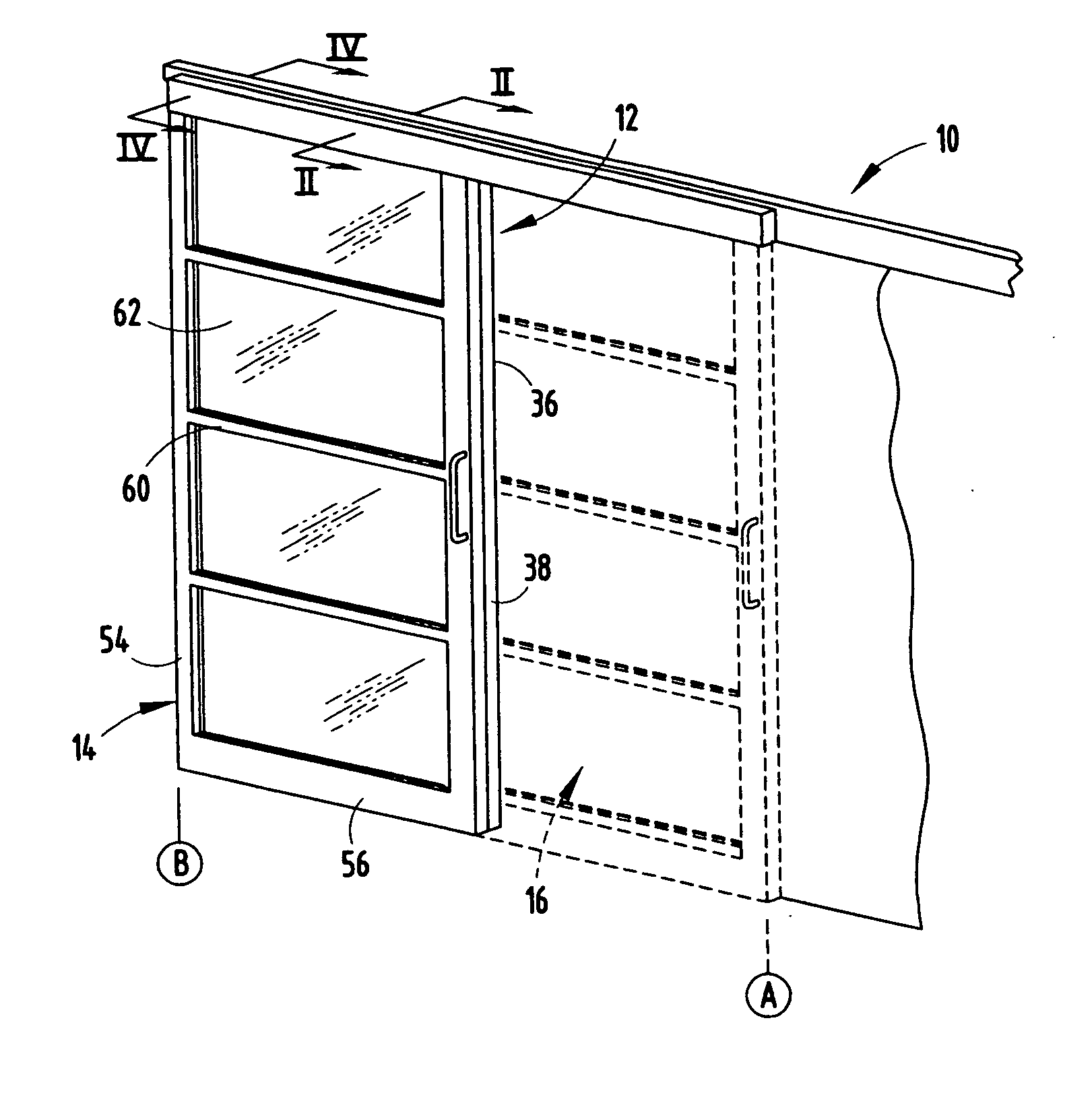

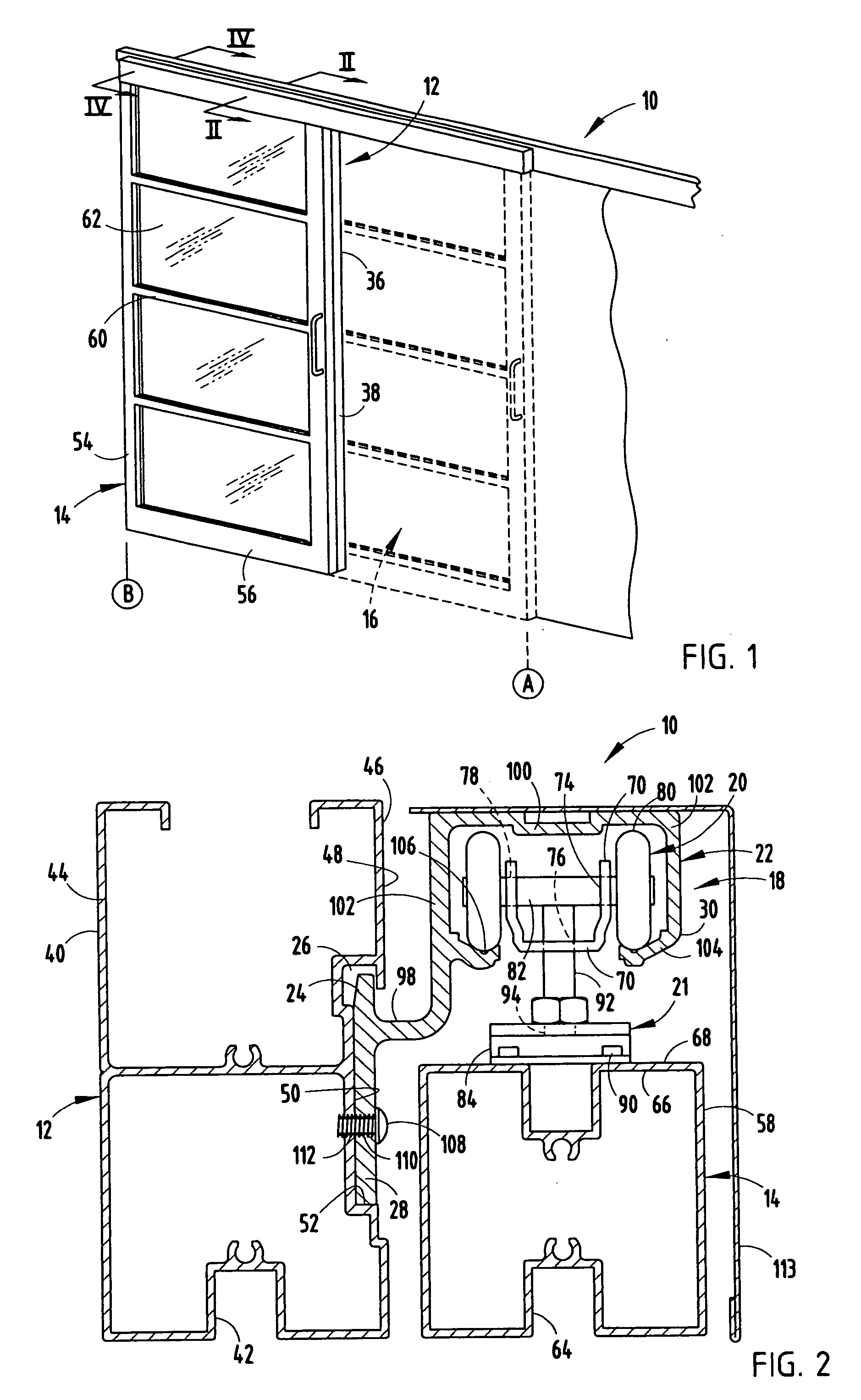

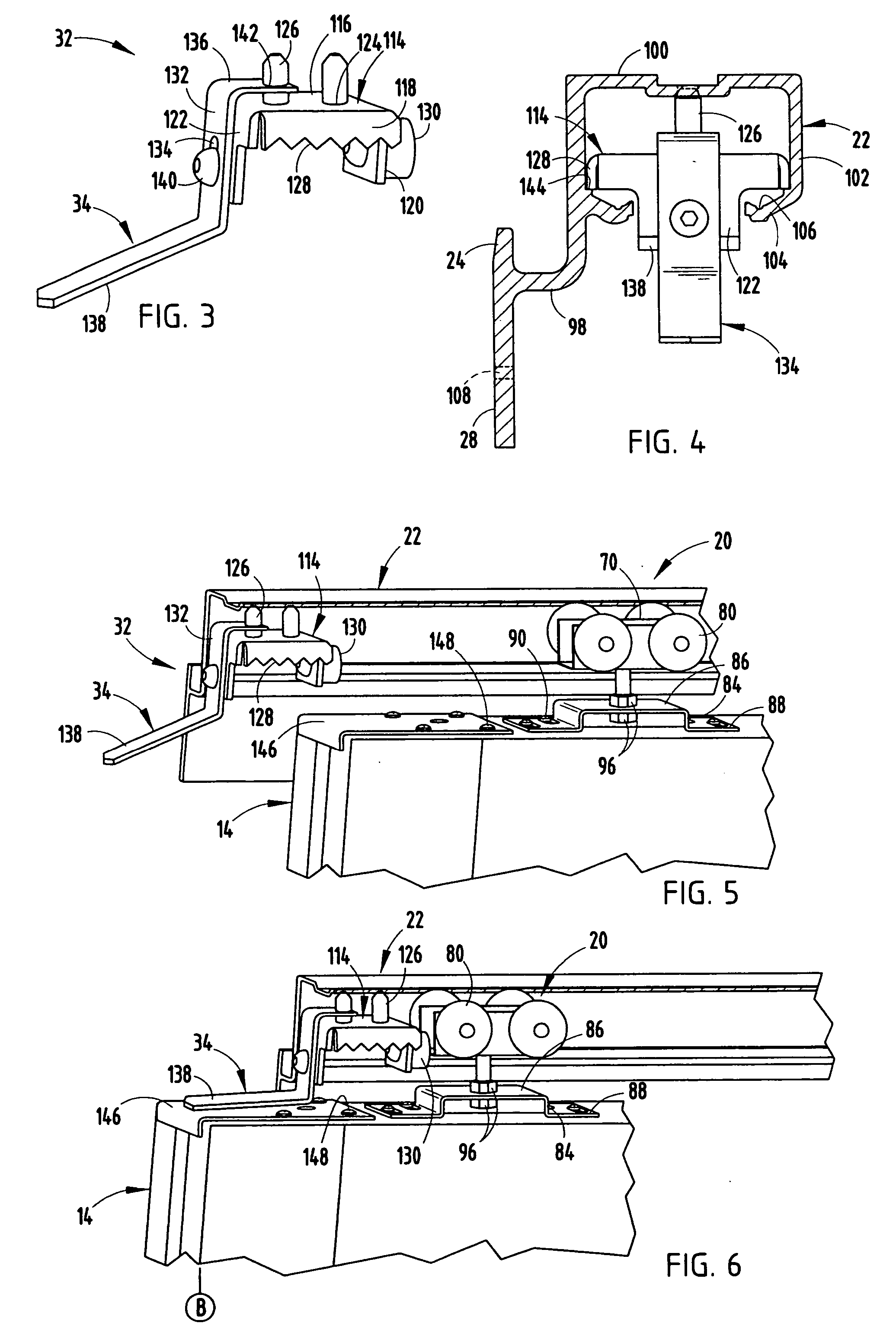

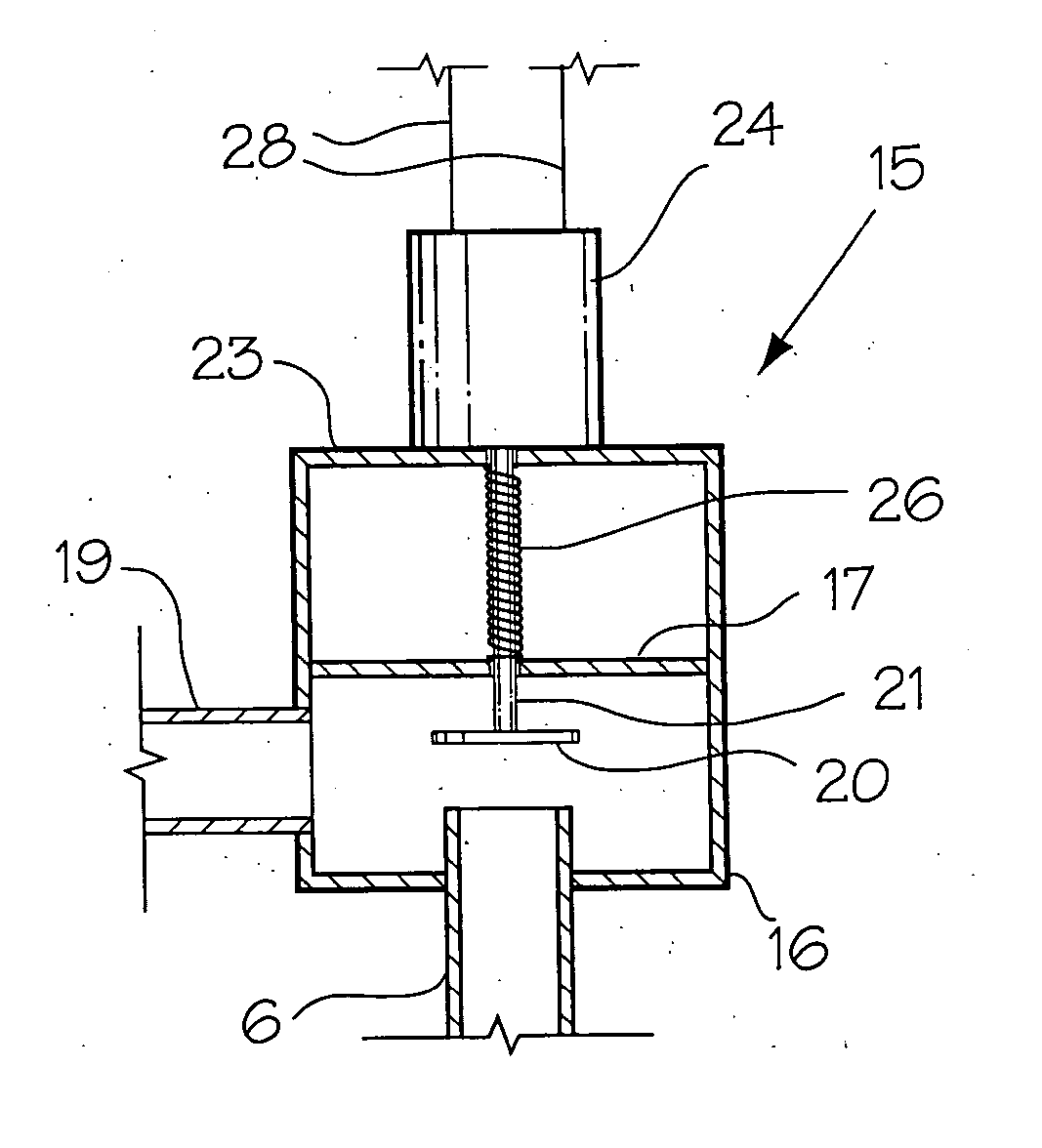

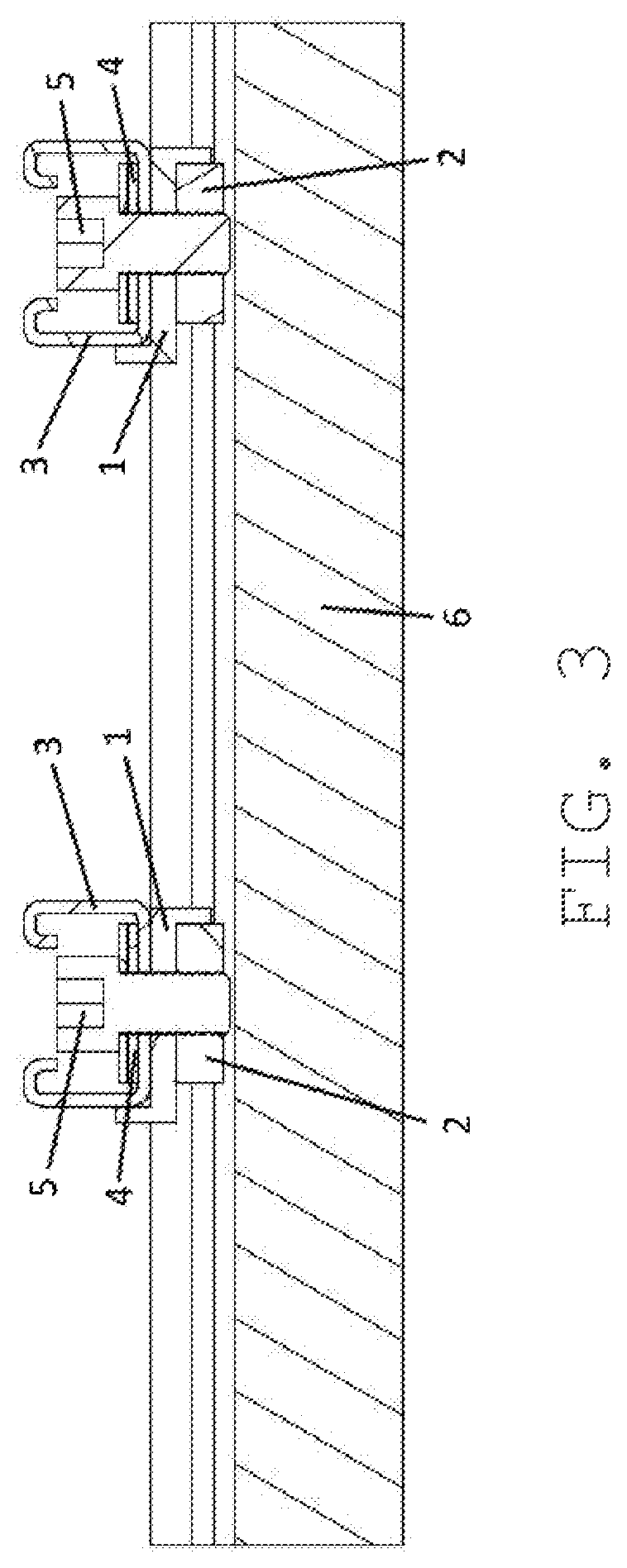

Partition panel assembly

InactiveUS20060277850A1Shorten speedReduce skillsBuilding braking devicesPublic buildingsSurface plateEngineering

A partition panel assembly includes a stationary panel member having an exposed surface including a longitudinally-extending, downwardly-exposed channel, and a door member slidably supported from the stationary panel member for movement between a closed position and an open position. The partition panel assembly also includes a door member support assembly comprising a roller assembly operably coupled to the door member, and a support member having an upwardly-extending arm received within the channel of the stationary panel member, a downwardly-extending arm abutting the exposed surface of the stationary panel member, and a track member supporting the roller of the roller assembly such that the door member is slidably supported from the stationary panel member. The partition panel assembly further includes a decelerator assembly including a spring member secured to the track member and adapted to frictionally engage the door member when the door member is proximate the open or closed position, thereby decreasing a velocity of the door member prior to the door member reaching a fully opened or closed position.

Owner:STEELCASE INC

Hauling shroud for hauling fibre optic cable along a conduit

ActiveUS8577199B2Streamlined shapeEasy accessOptical fibre/cable installationCable installation apparatusFiberEngineering

A hauling shroud, a cable termination and methods of hauling a fiber optic cable with a pre-connected optic termination along a conduit. The hauling shroud protects the optic termination when being hauled along the conduit. The hauling shroud includes a first housing member and a second housing member such that the first housing member and the second housing member can be joined together to enclose the optic termination. At least one anchoring member is used, for example, connecting pins, such that at least one strengthening element of the fiber optic cable engages with the anchoring member inside an internal cavity formed within the hauling shroud. Alternatively, at least two strengthening elements of the fiber optic cable are attached together to form a loop which engages with the at least one anchoring member, e.g., the connecting pins. This prevents any hauling forces from being applied to the optic termination.

Owner:PRYSMIAN AUSTRALIA

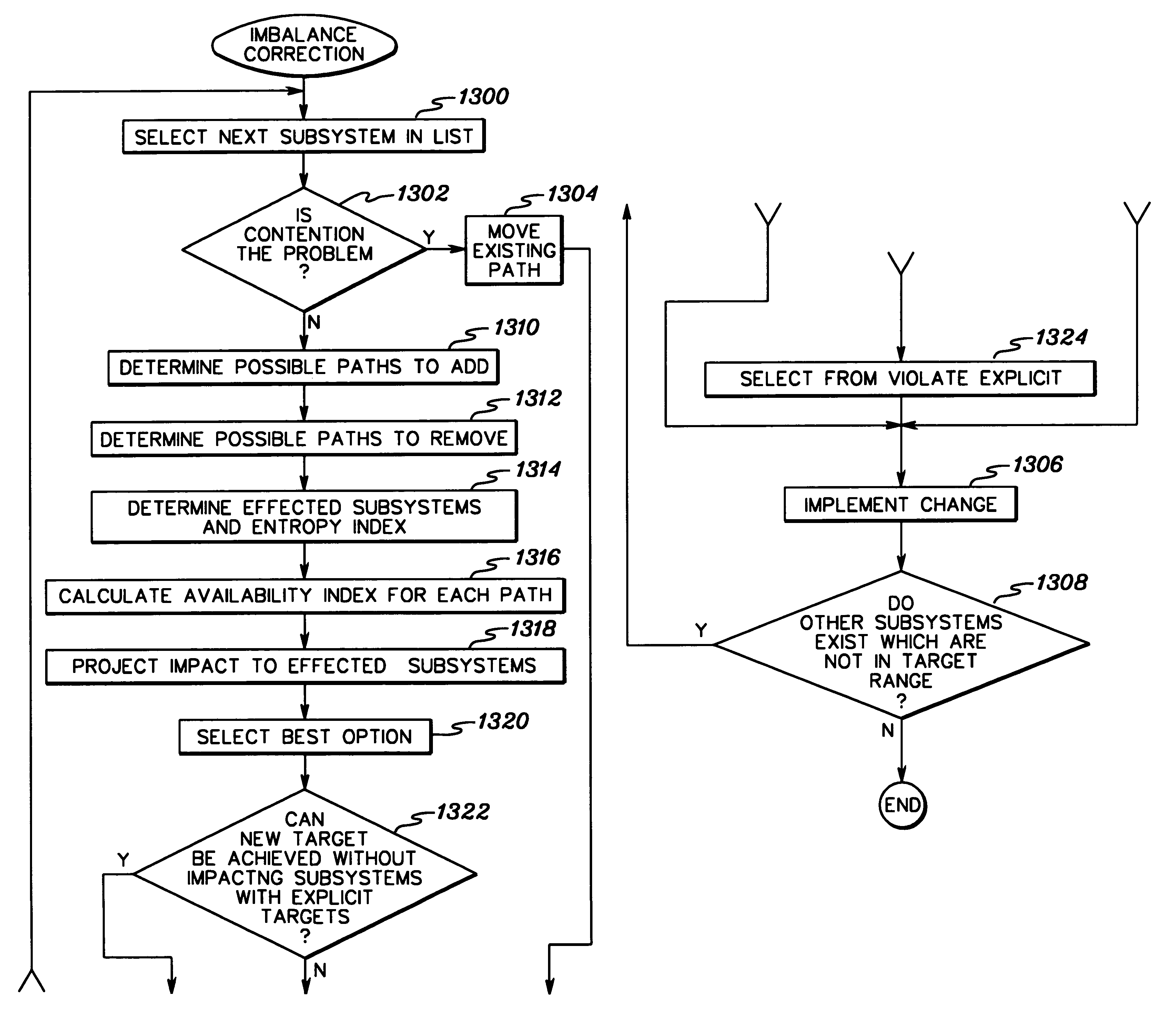

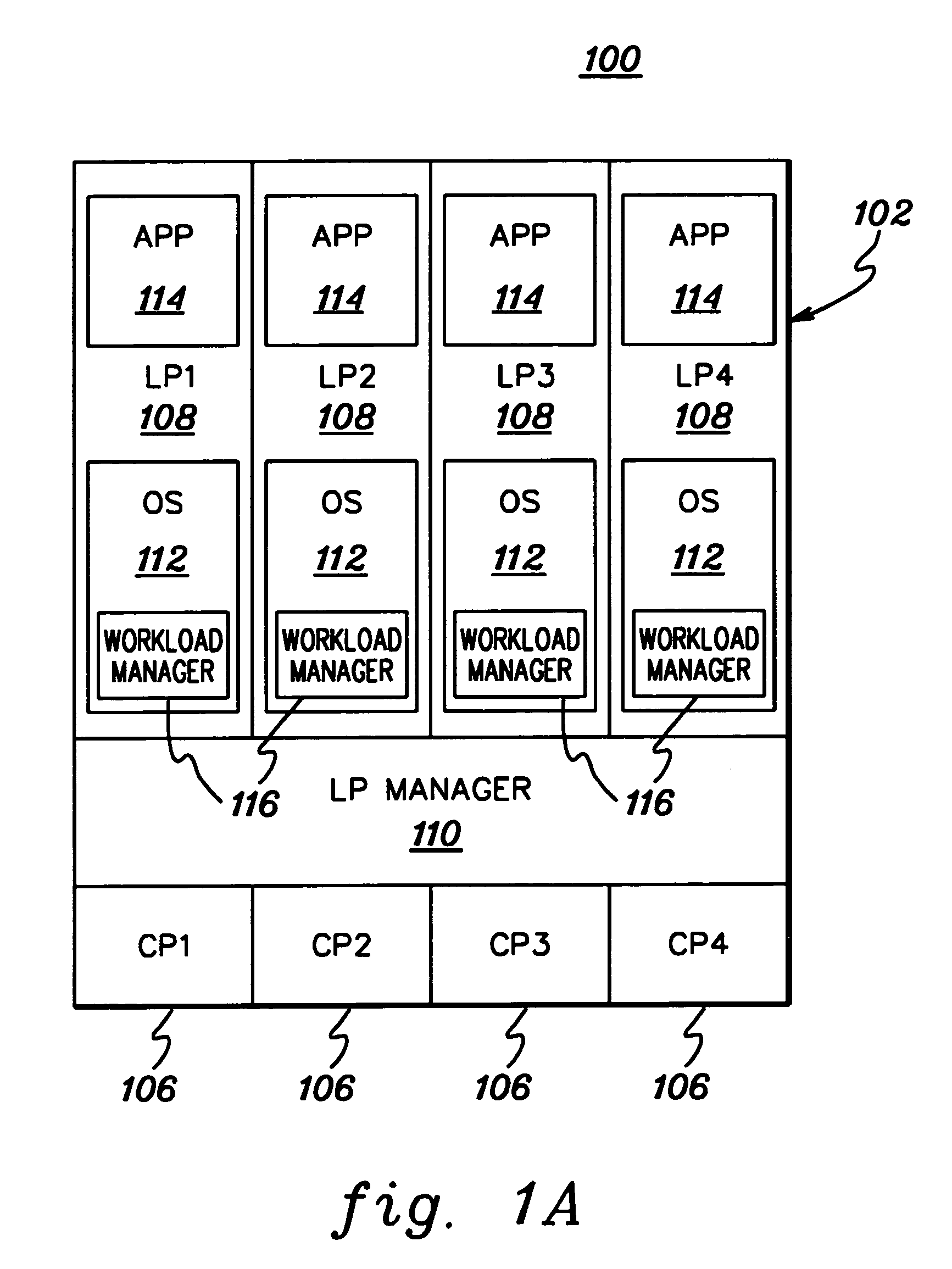

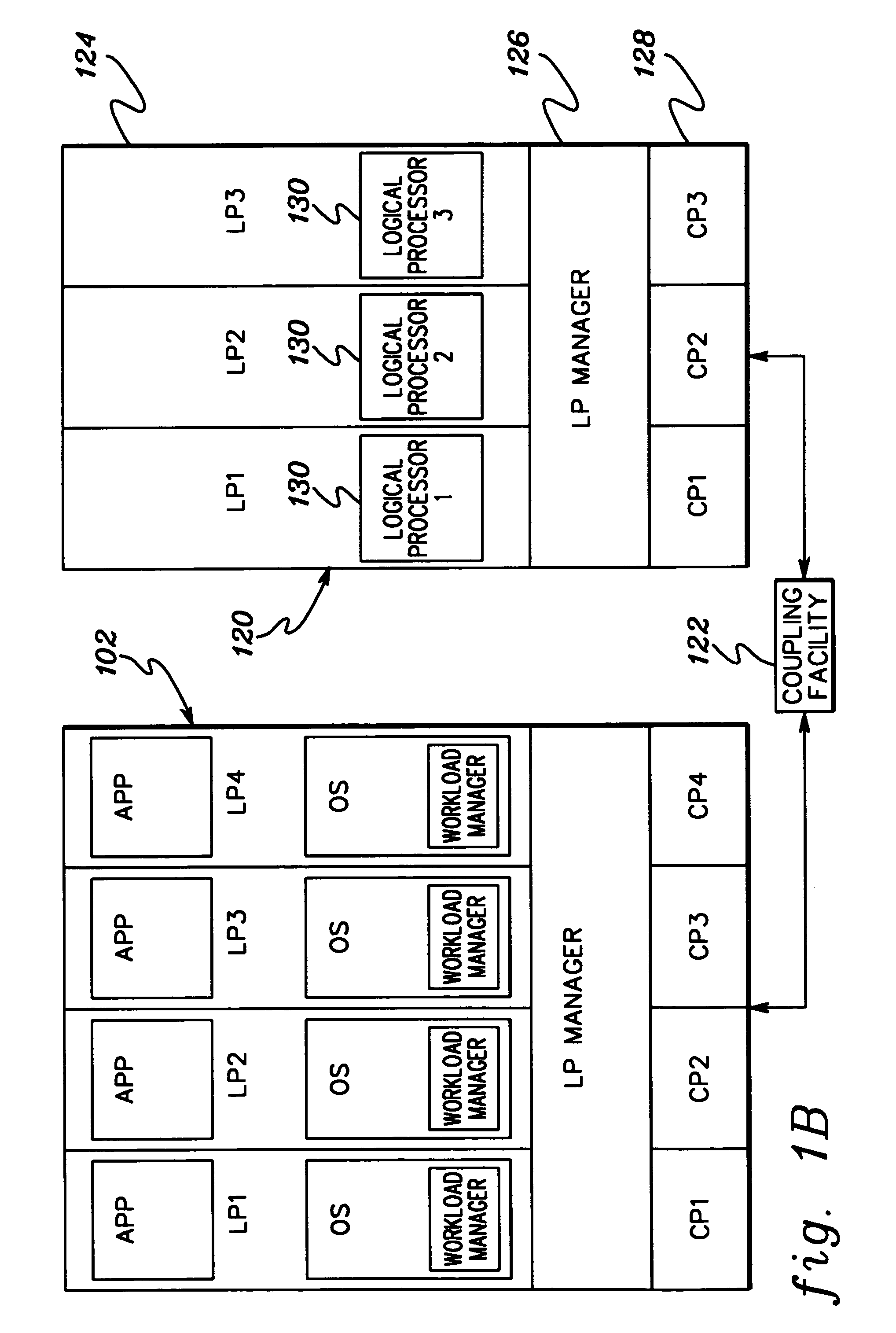

Method, system and program products for managing I/O configurations of a computing environment

InactiveUS7568052B1Reduces skillEnhance system availabilityResource allocationMemory systemsInput/outputReal-time computing

Owner:IBM CORP

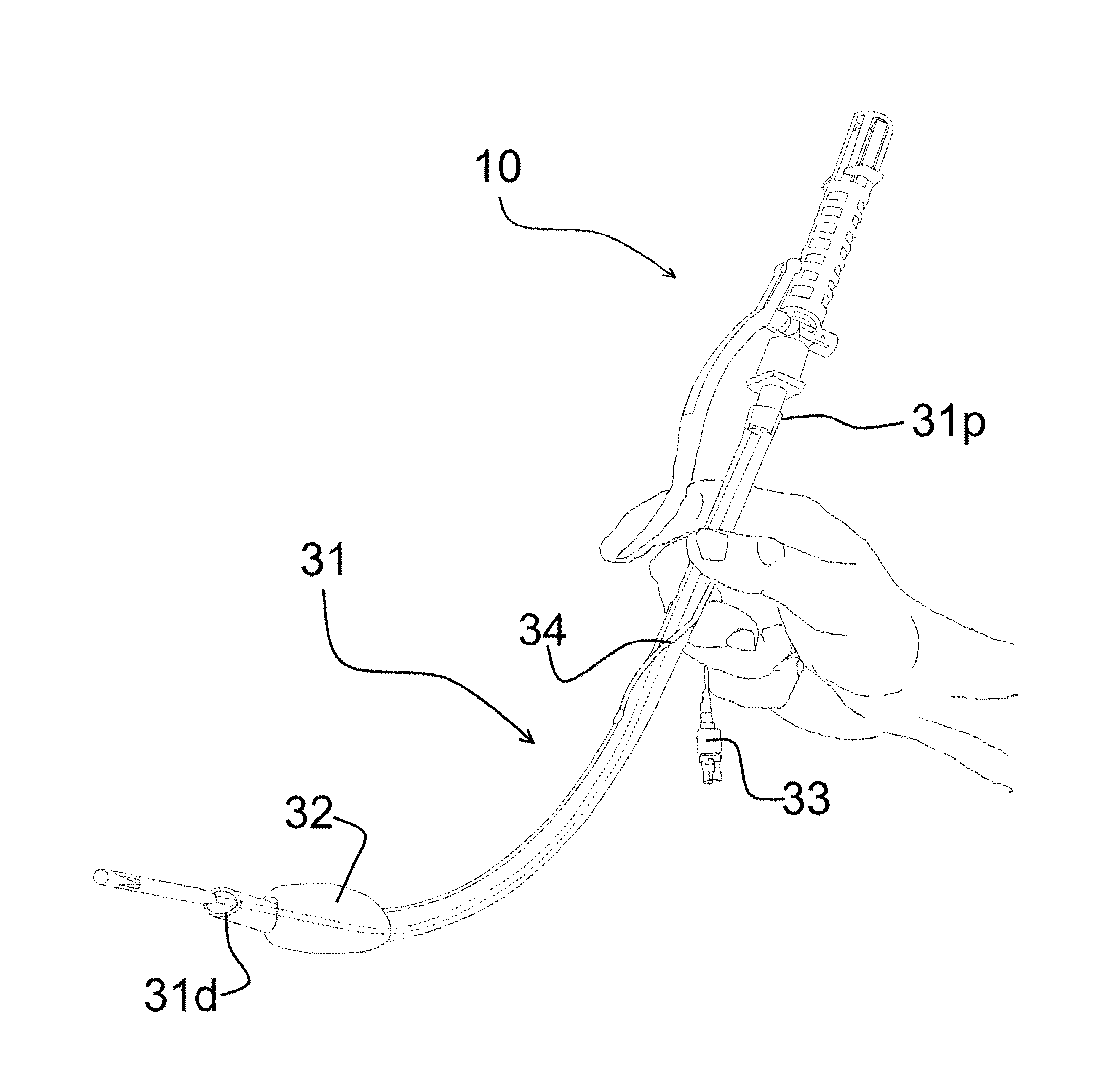

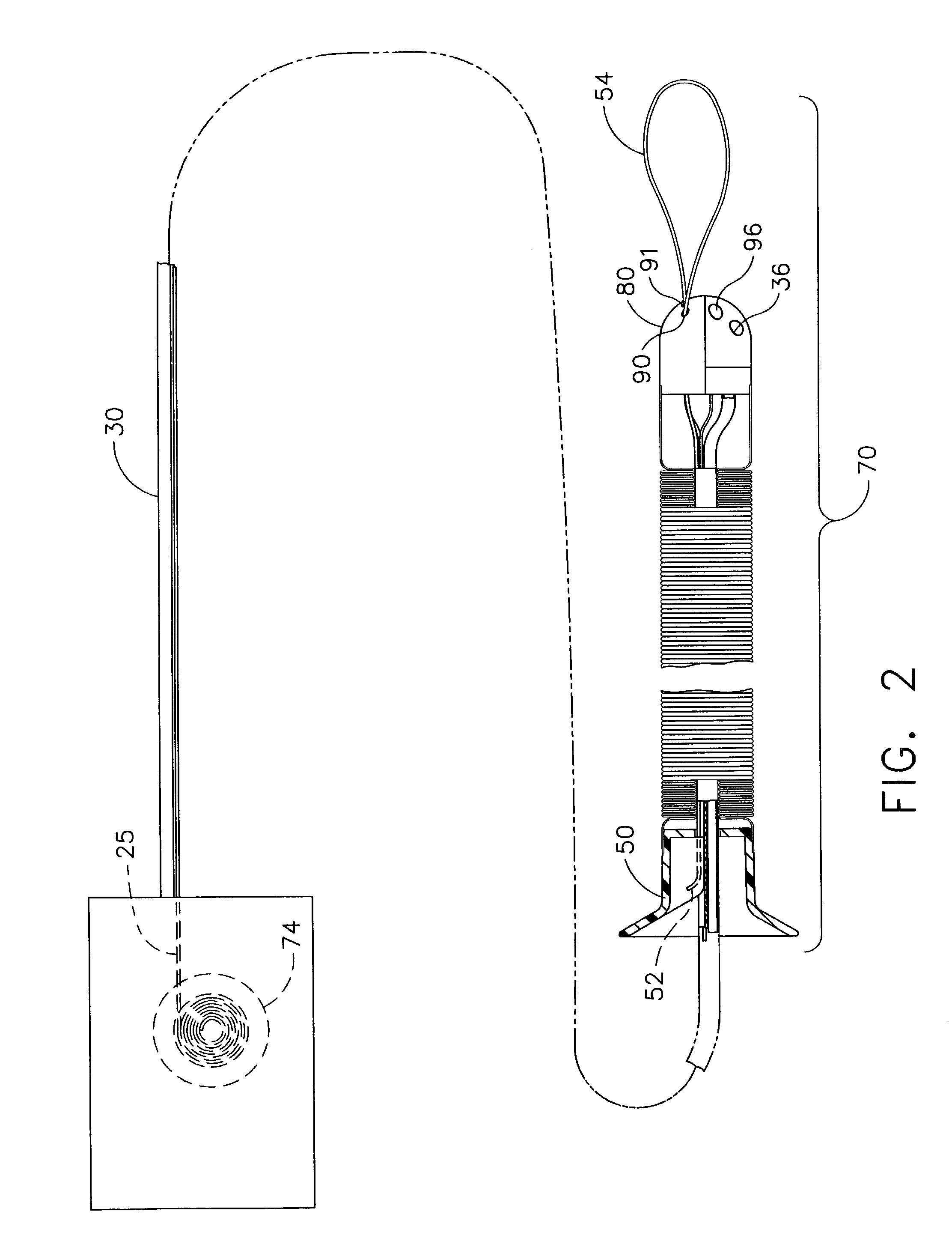

Combined laryngo-tracheal anesthetic and stylet device

ActiveUS20140360494A1Shorten the timeLiability exposure for consequently reducedBronchoscopesLaryngoscopesCatheterAnesthetic

A laryngo-tracheal anesthetic device is provided, said device comprising a malleable conduit with a first end and a second end, wherein the second end is designed to enter a patient, a device for pressurizing anesthetic, wherein the device is adapted to receive a cartridge of anesthetic, a substrate actuated by a finger of a user for releasing anesthetic from the reservoir into the malleable tube; and a nozzle at the second end of the malleable tube.

Owner:GUIDANCE AIRWAY SOLUTIONS LLC

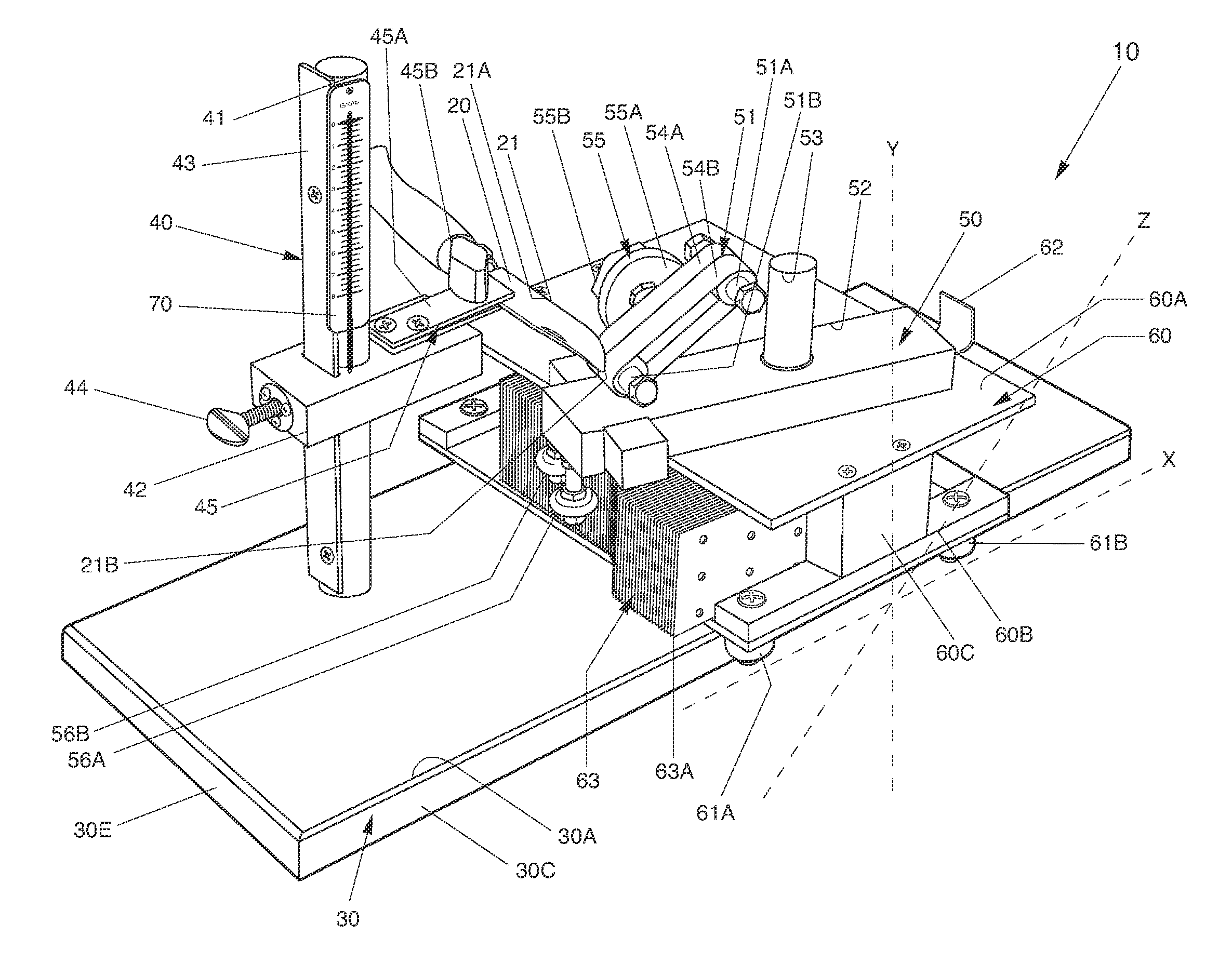

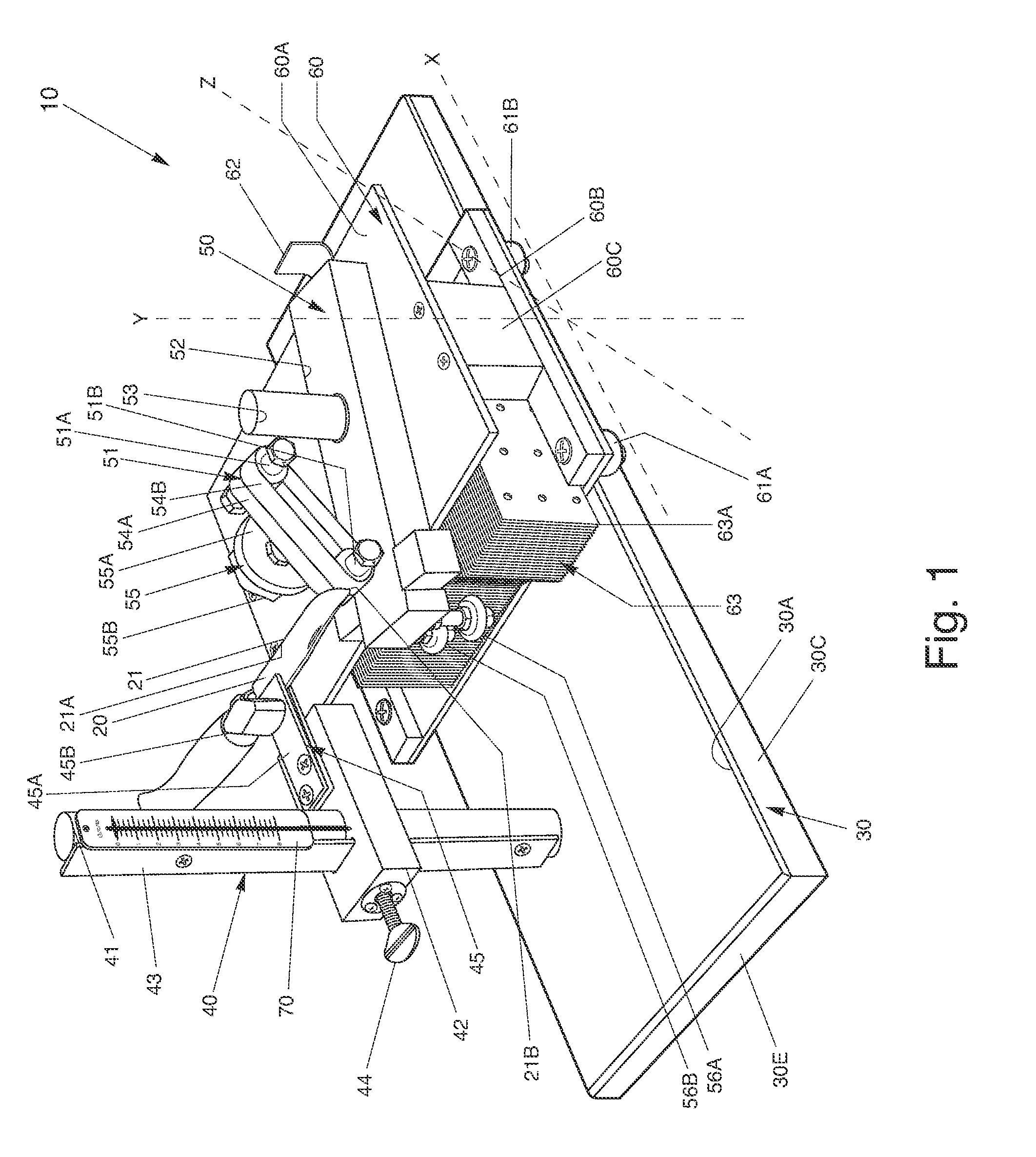

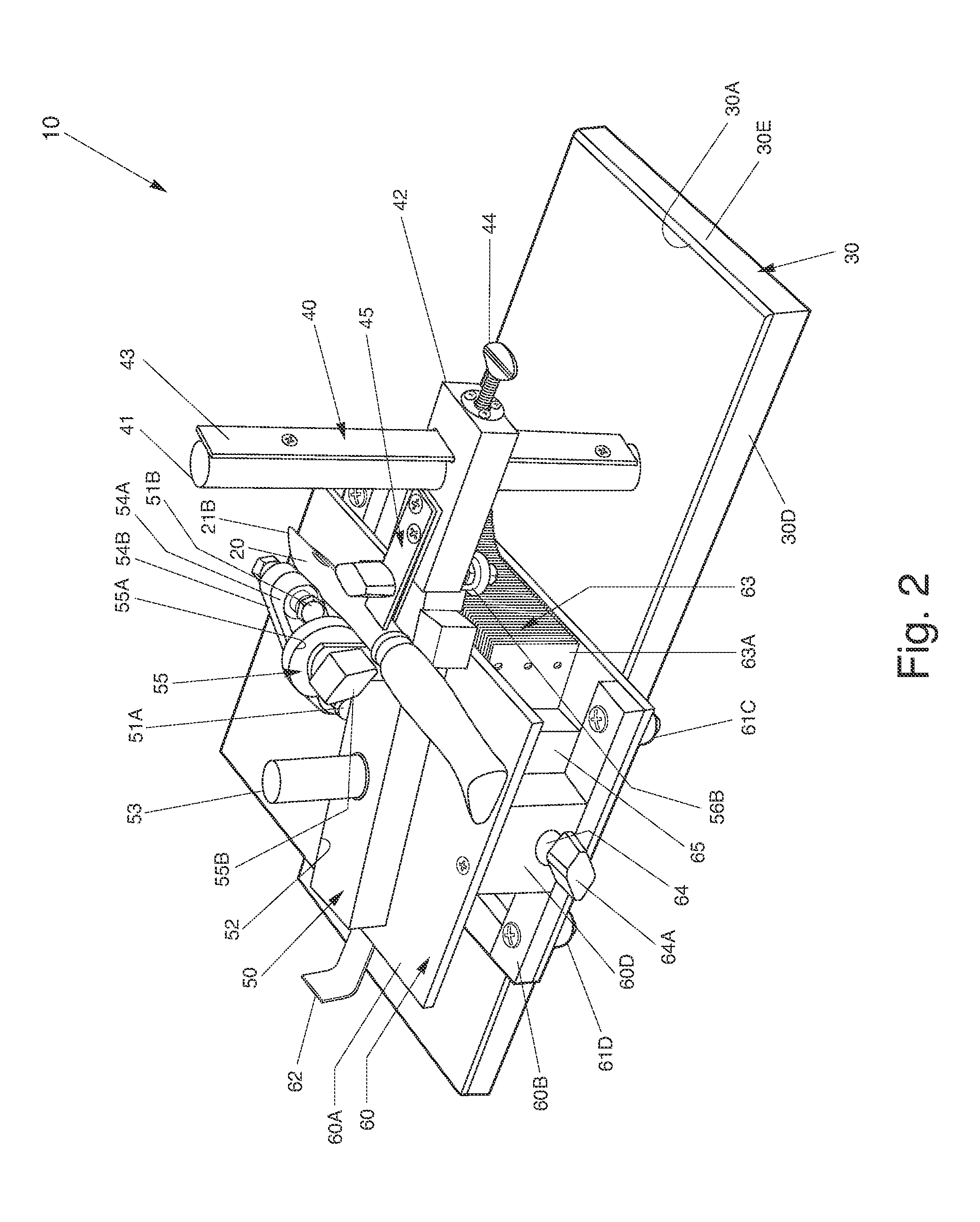

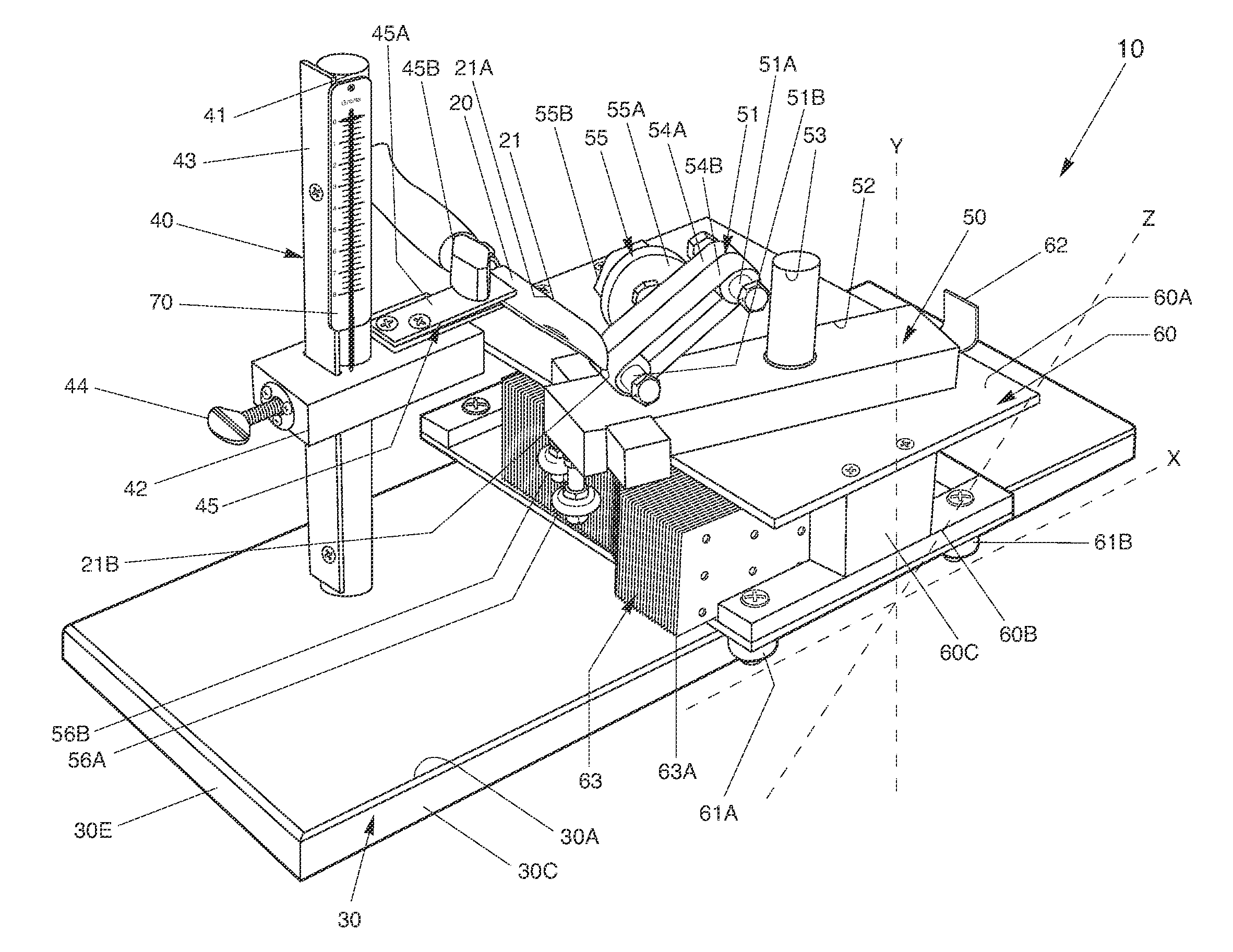

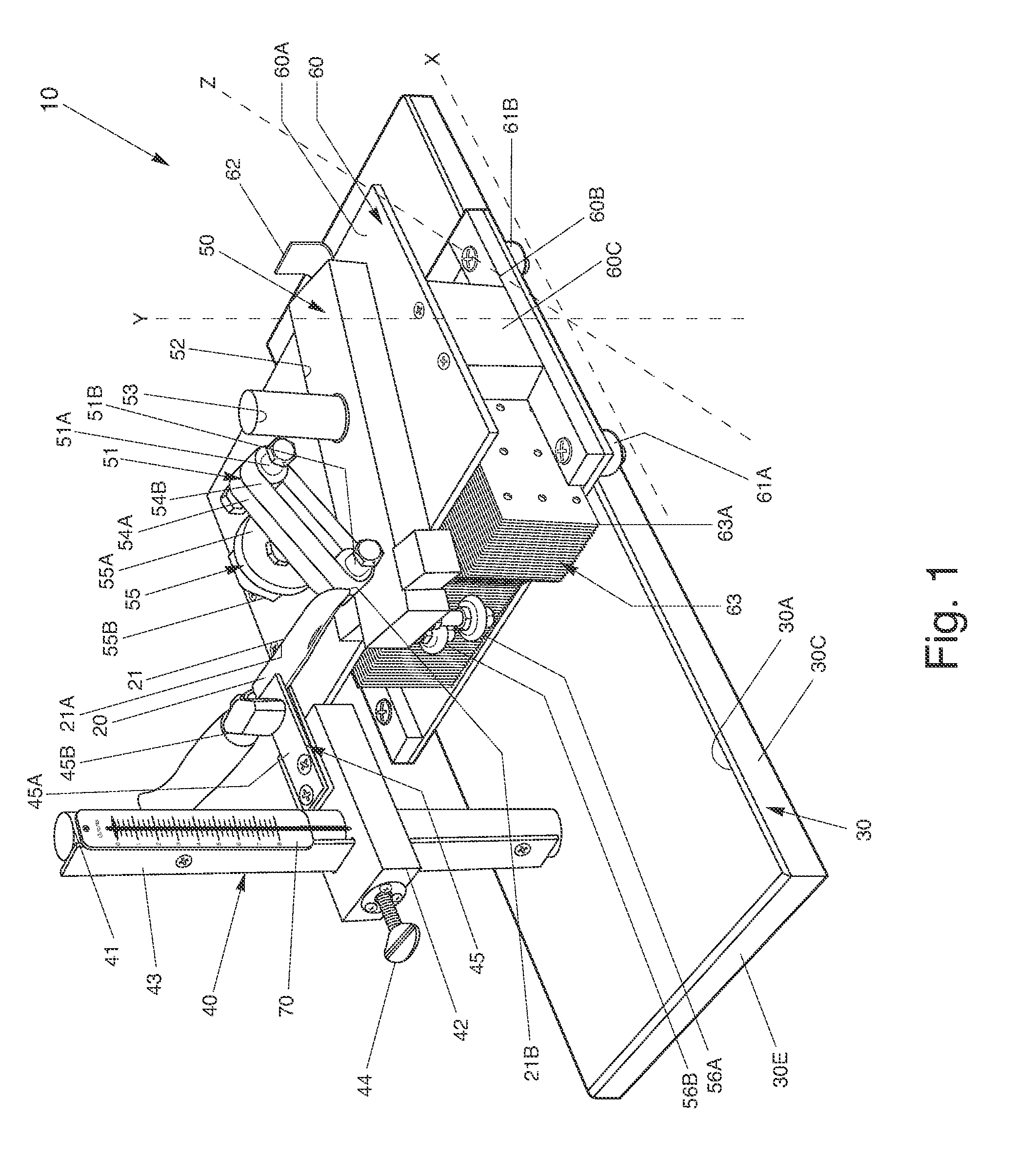

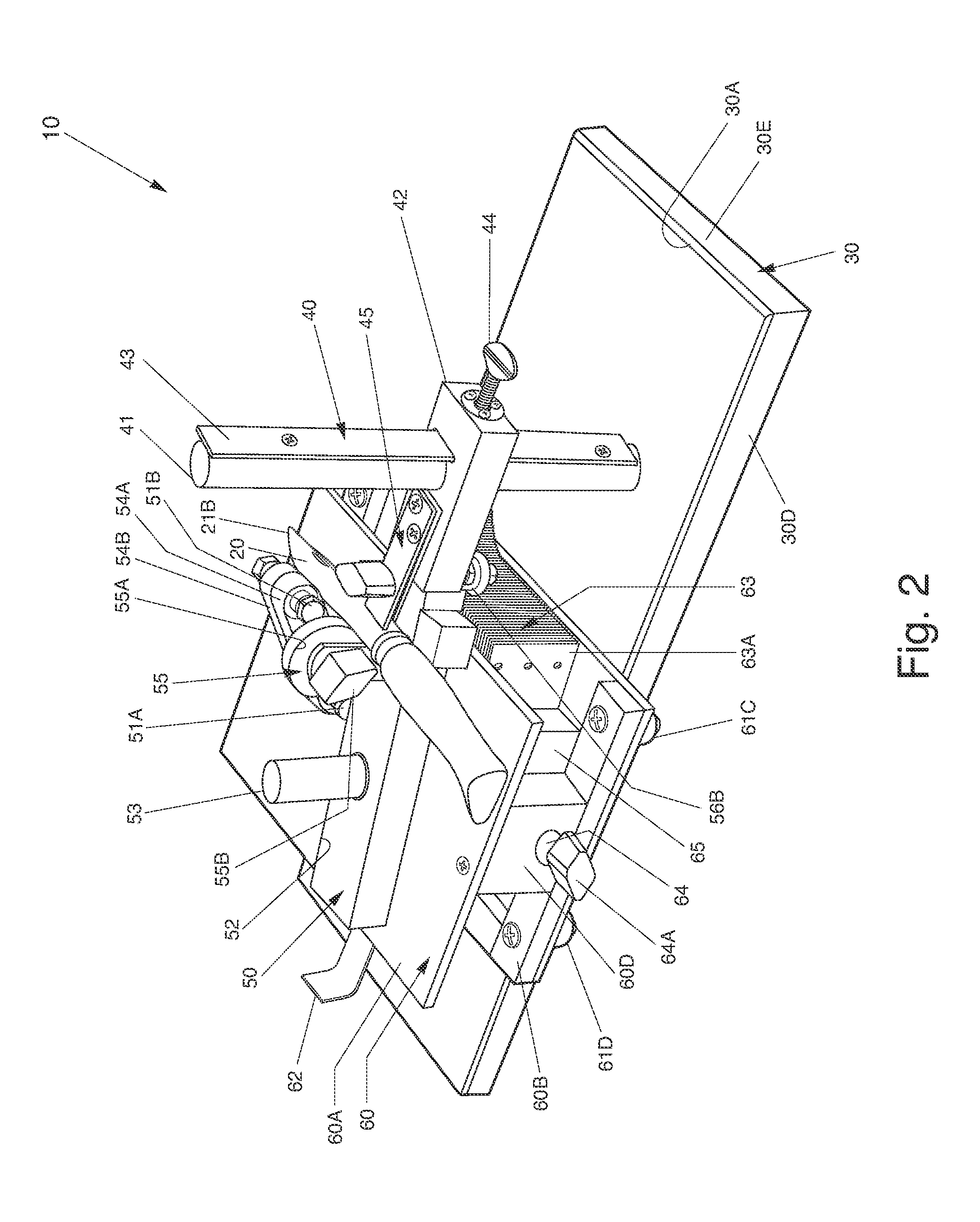

Blade sharpening device with blade contour copying device

InactiveUS7413504B2Prevent overheating and damageProvide consistencyEdge grinding machinesBelt grinding machinesEngineeringKnife blades

The present invention provides a blade sharpening device designed for sharpening a blade for a uniform sharpening of the edge thereof. The blade sharpening device contains a base having a guide slidably movable relative to the base. The guide includes a material that receives an impression of a blade defining a blade contour. A blade holder is attached to the base for securing the blade while being sharpened. A carriage contains an elongated structure for interacting with the material of the guide which has received an impression of the blade defining a blade contour. The guide defines a sharpening path substantially aligning with the blade contour. The carriage also has an abrasive surface for sharpening the blade. In operation, the guide and carriage direct the movement of the abrasive surface along the contour of the blade for a uniform sharpening of the edge thereof.

Owner:LYTINAS MICHAEL

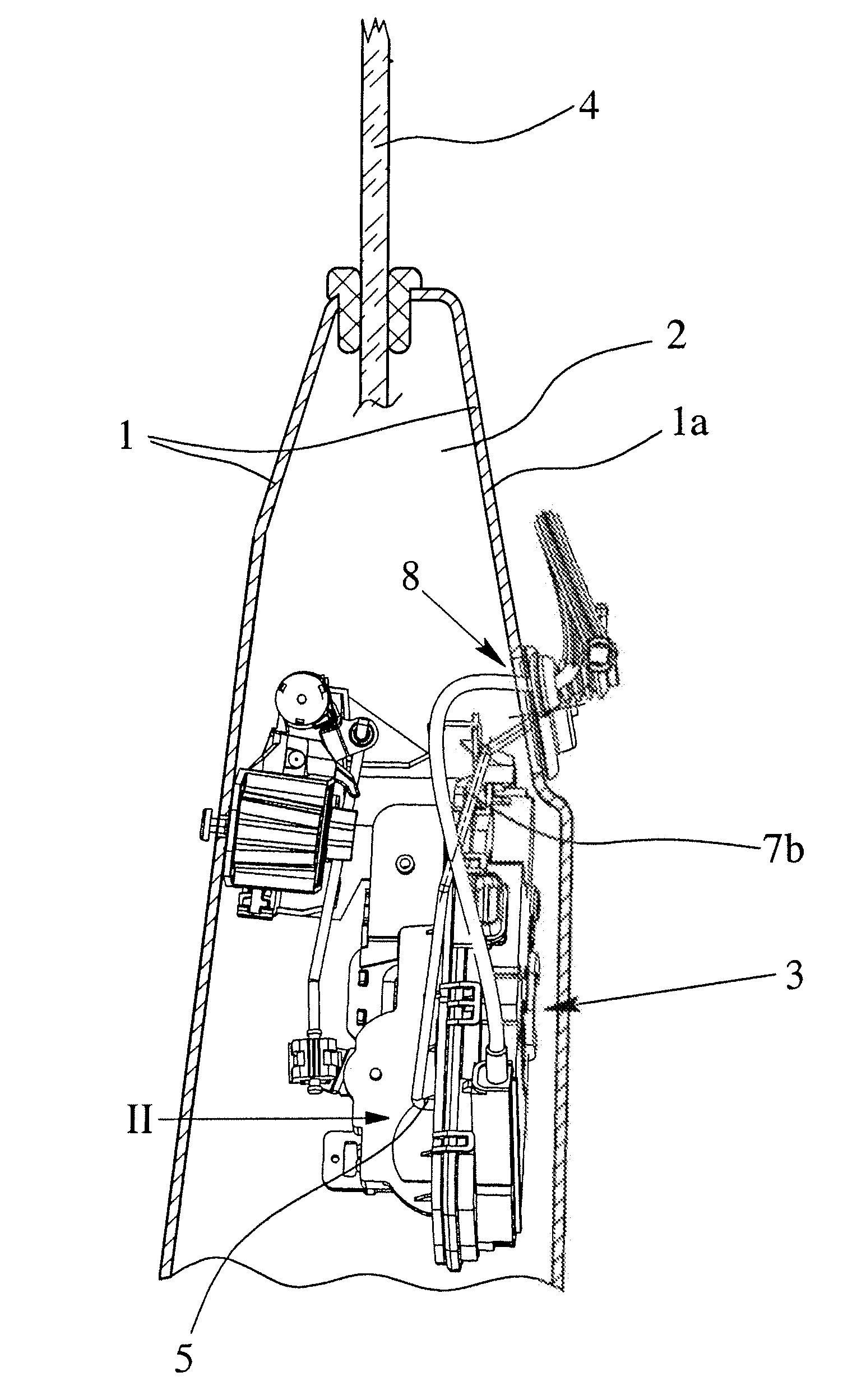

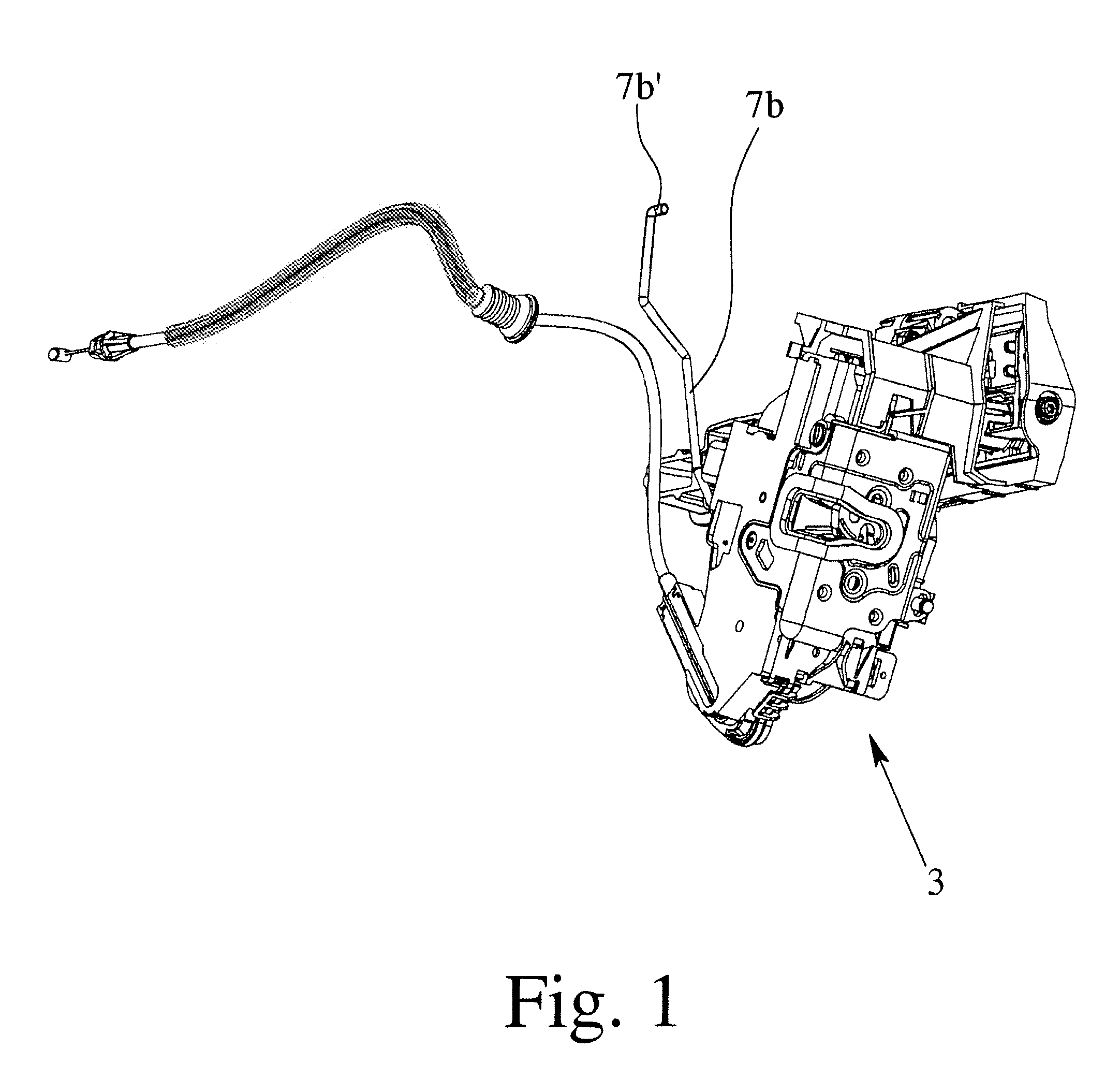

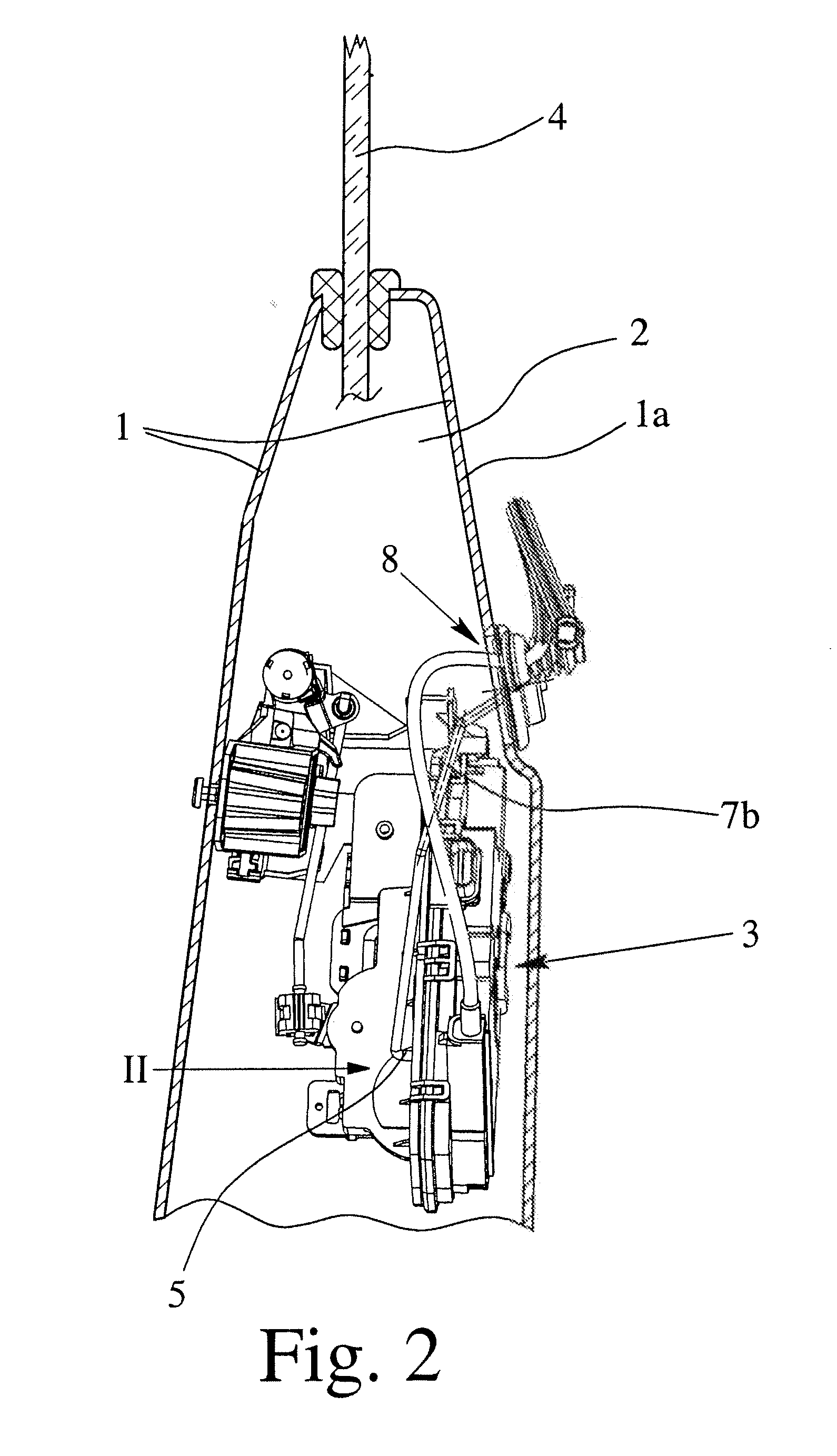

Method for mounting a motor vehicle door lock

A motor vehicle door and to a motor vehicle door lock and a method for mounting the motor vehicle door lock in a motor vehicle door, the motor vehicle door lock having an inside locking lever, and when installed, being located in a hollow space of the door and coupled to an inside safety element via a connecting rod that extends through a passage opening in an inside wall segment of the door body. To facilitate installation, the connecting rod is formed of two segments, a lower connecting rod segment extending through the passage opening and being connected to a an upper connecting rod segment at a location that is outside of the hollow space in proximity to the passage opening.

Owner:BROSE SCHLIESSSYSTEME GMBH & CO KG

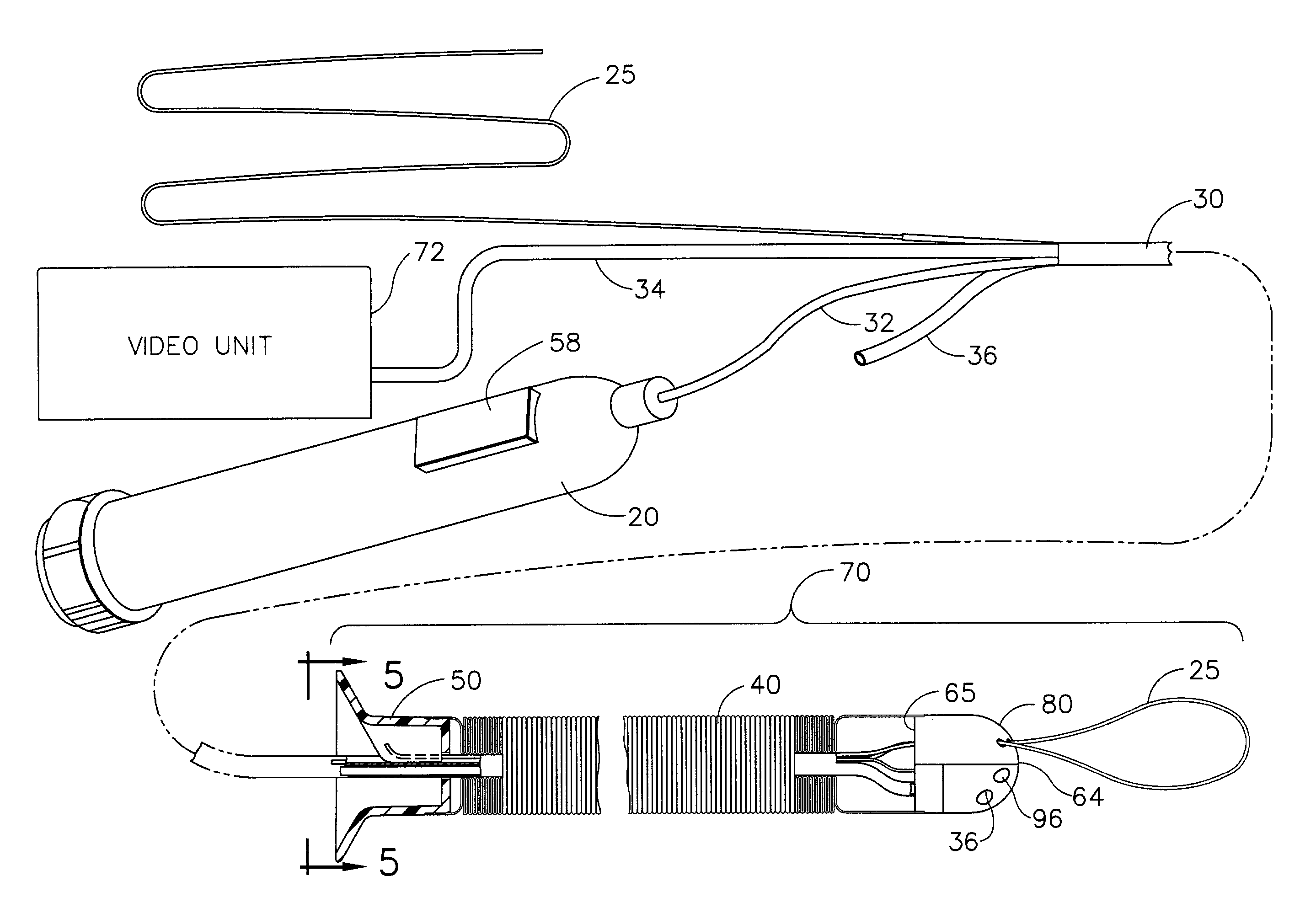

Locally-propelled, intraluminal device with cable loop track and method of use

A medical device for performing medical procedures inside a lumen (such as the GI tract) of a patient is provided comprising a capsule, a cable, and a propulsion means. The cable can have one end anchored to the patient, and can extend from this anchored portion to the capsule. The cable can include a loop forward (distal) of the capsule in the GI tract. The propulsion means is operably connected to the cable to vary the length of cable between the anchored end and the capsule, so that the capsule is repositioned inside the GI tract of the patient.

Owner:ETHICON ENDO SURGERY INC

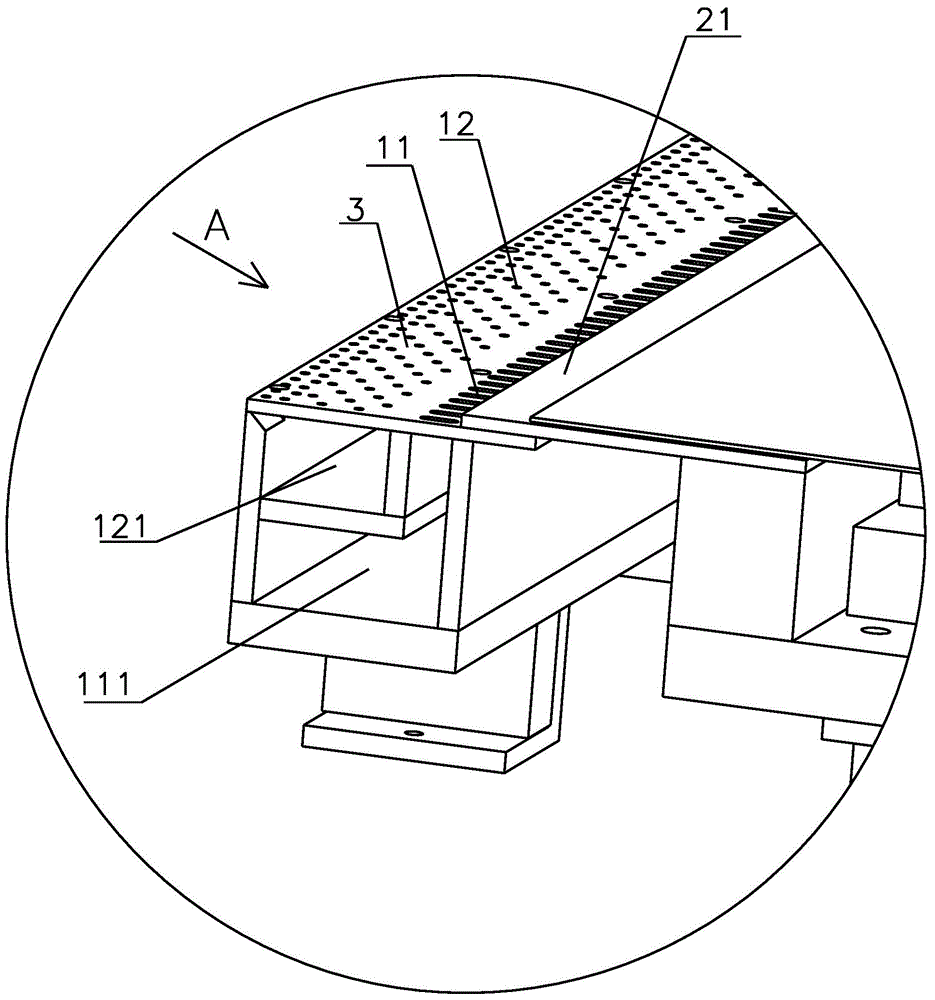

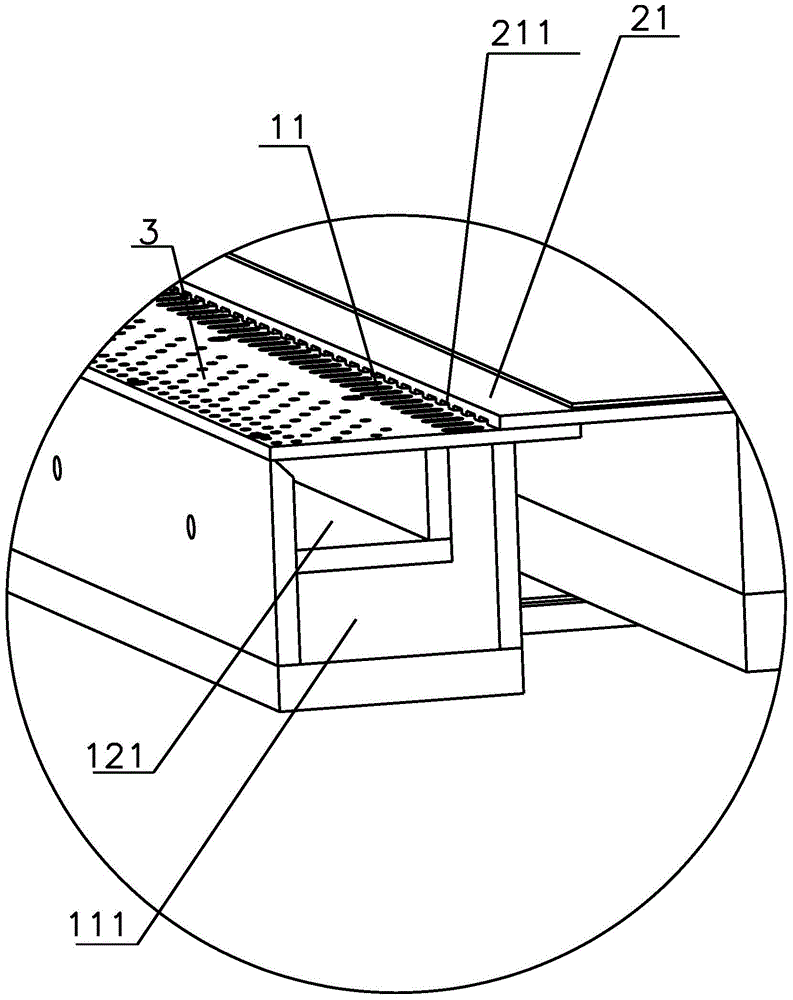

Automatic shirt under fly sewing machine

ActiveCN105177875ASolve the positioning problemSolving Sewing DifficultiesWorkpiece carriersWork-feeding meansSewing machineSurface plate

The invention relates to an automatic shirt under fly sewing machine which comprises a worktable and an edge folding mechanism. The edge folding mechanism comprises a table top plate, the table top plate is provided with a first low air suction area formed by multiple lower air suction through holes, a column of side air suction through holes is formed in the right side of the first low air suction area on the face plate, a cover plate capable of covering the side air suction through holes is arranged on the upper surface of the table top plate, grooves are formed in the lower surface of the cover plate, the groove openings of the grooves face the side air suction through holes and cover the side air suction through holes, one end of each groove extends to the edge of the cover plate close to the center of the table face plate, and a transverse cloth dragging device and a sewing machine head are further installed on the worktable. The automatic shirt under fly sewing machine is provided with the cover plate with the grooves formed in the lower surface on the table with the holes, so that lower air suction is changed into side air suction, the edge of a fabric is folded, and the fabric is erected at the position provided with the grooves at the edge position of the cover plate to form a folded edge.

Owner:中山市阿米达机电设备有限公司

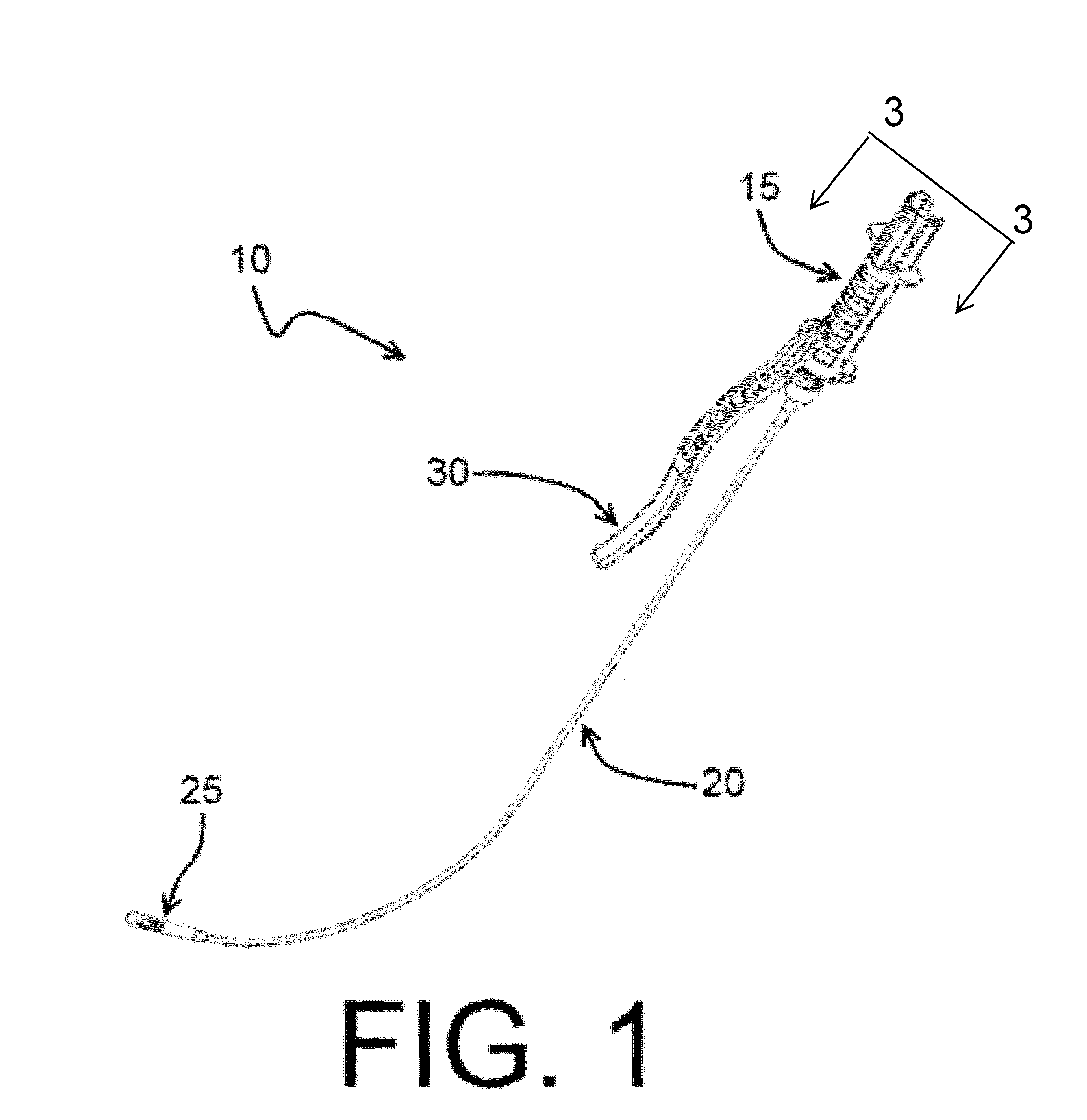

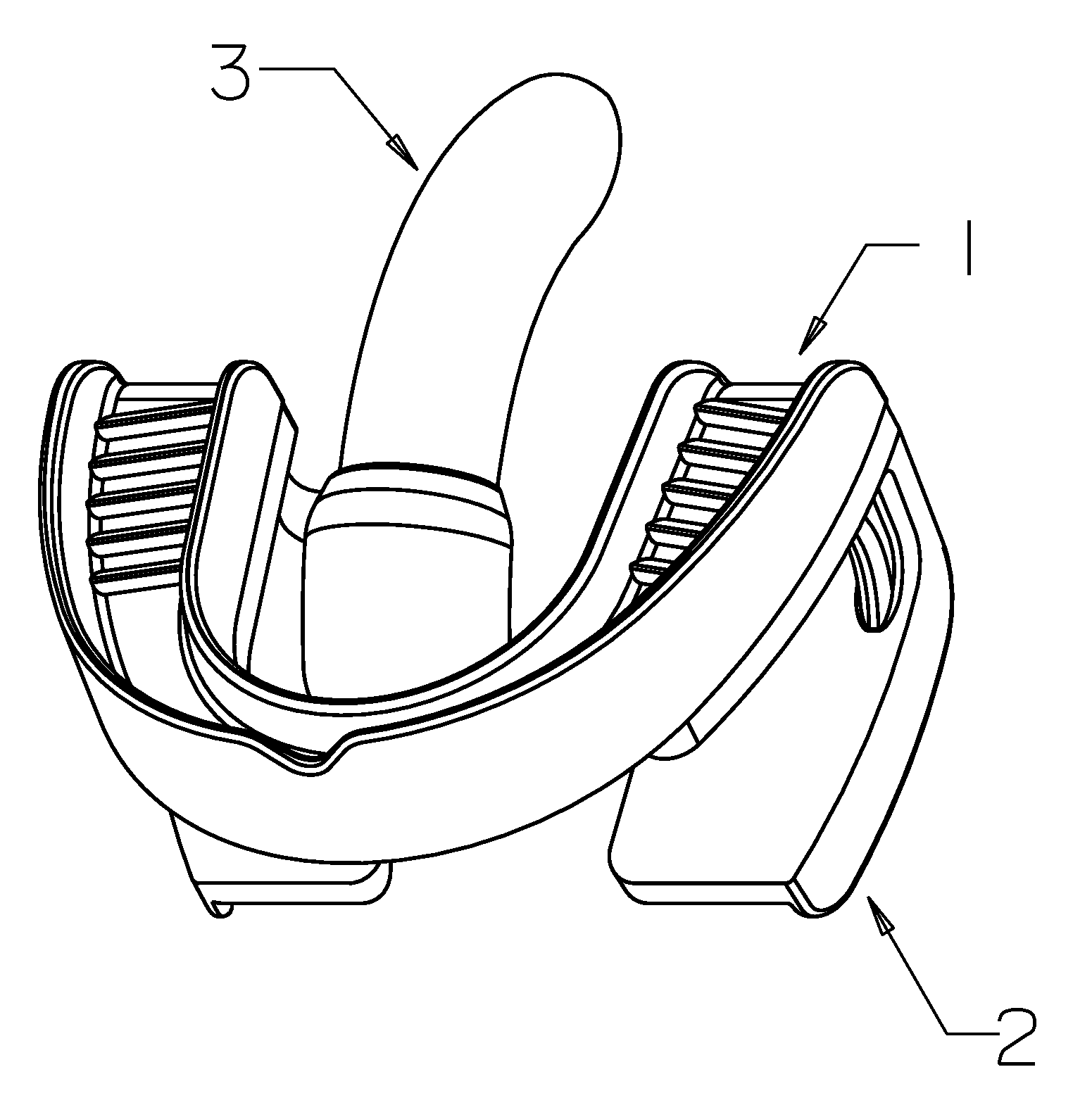

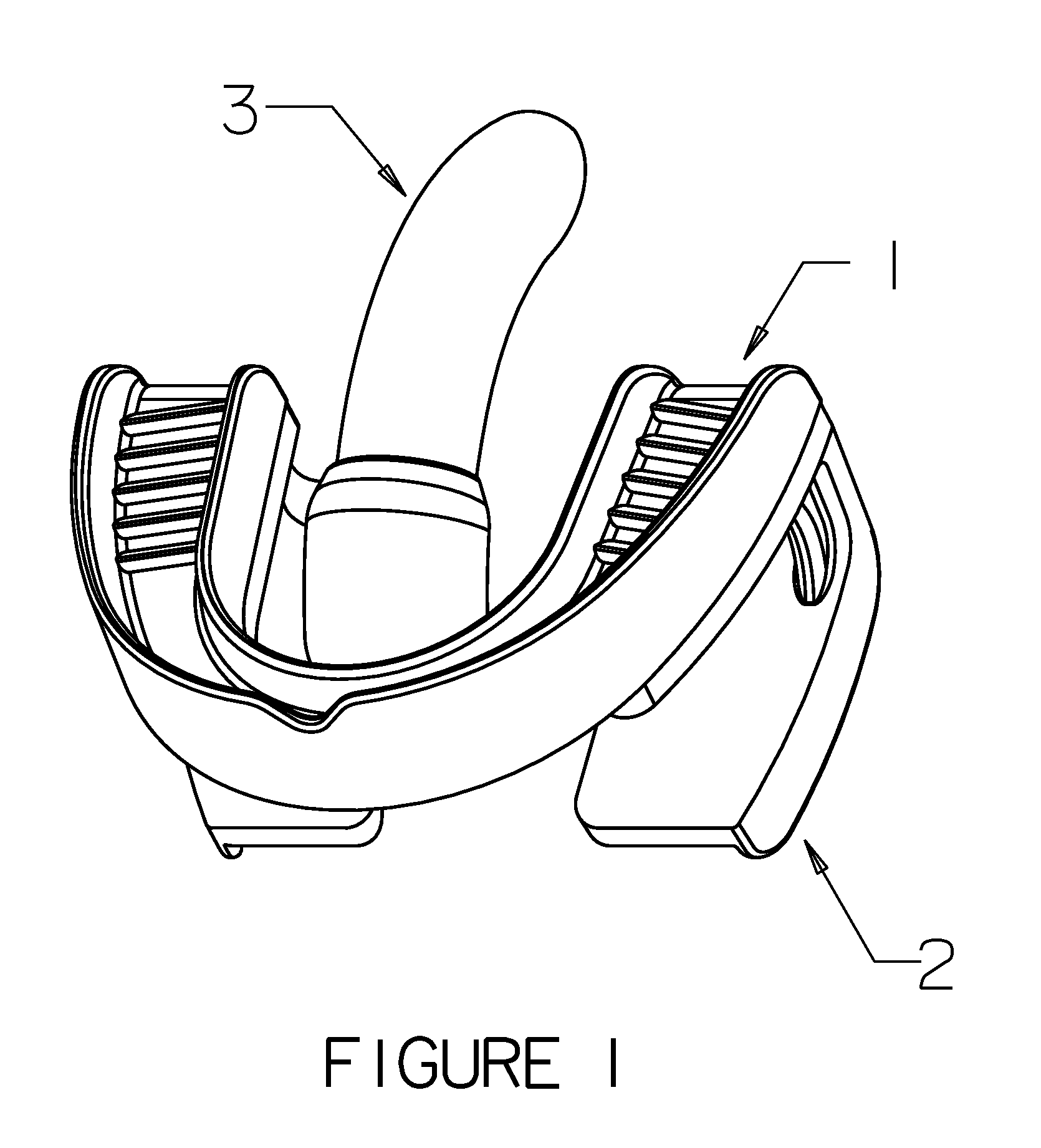

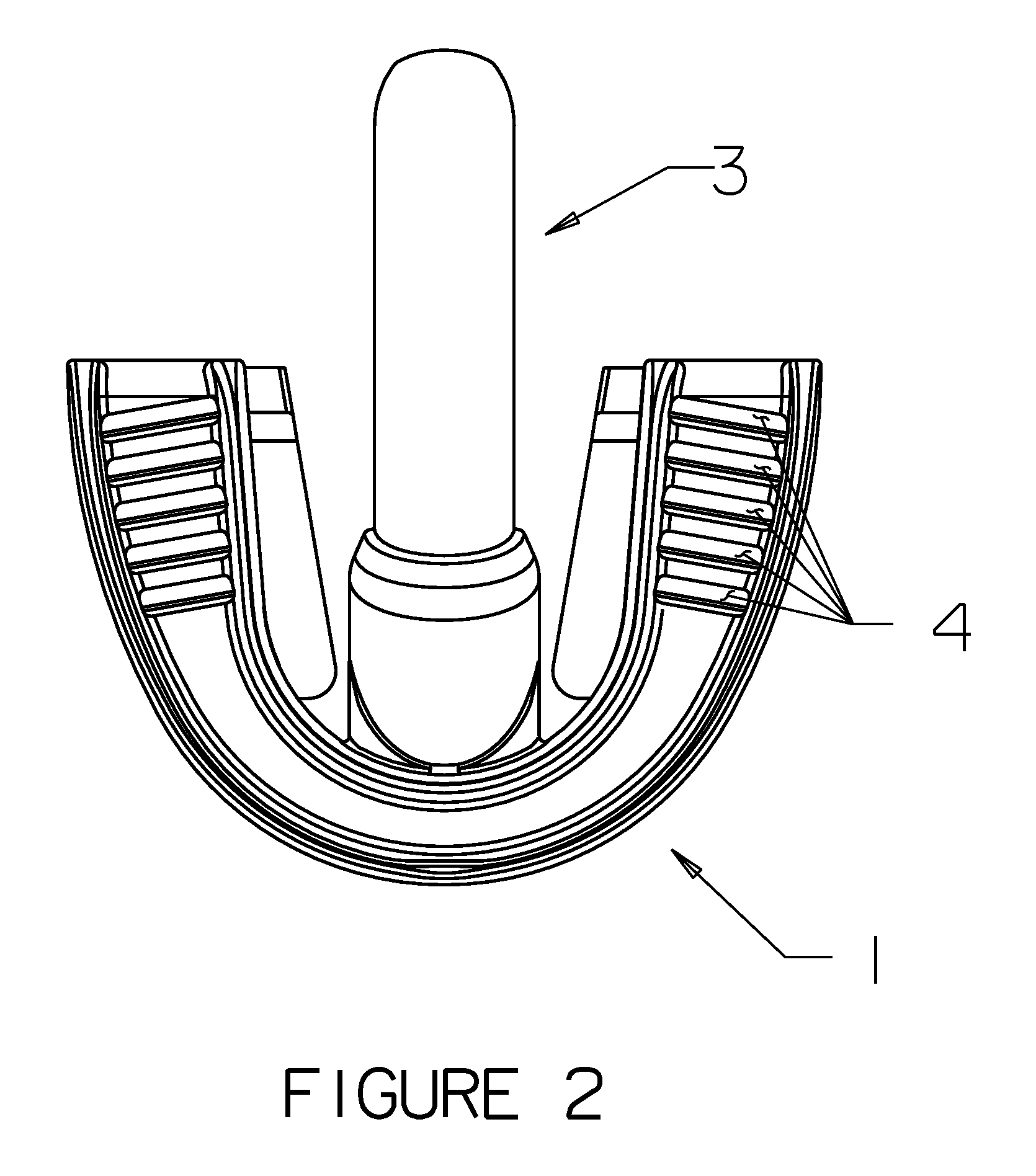

Rapid orotracheal intubation guide

InactiveUS8104467B2Easy to disassembleFast and accurate intubationTracheal tubesTeeth fillingTracheal tubeIntratracheal intubation

A rapid orotracheal intubation guide device is disclosed that facilitates orotracheal intubation or direct orotracheal visualization without resting the device on the subject's tongue and that, during a bronchoscopic intubation, automatically ejects the endotracheal tube from the device as the endotracheal tube is advanced coaxially over a bronchoscope previous placed through the guide, thereby providing a mid-line entry of the bronchoscope and endotracheal tube, higher intubation success rate by lower skilled operators, and easy removal of the device from the patient's oral cavity.

Owner:HANU SURGICAL DEVICES

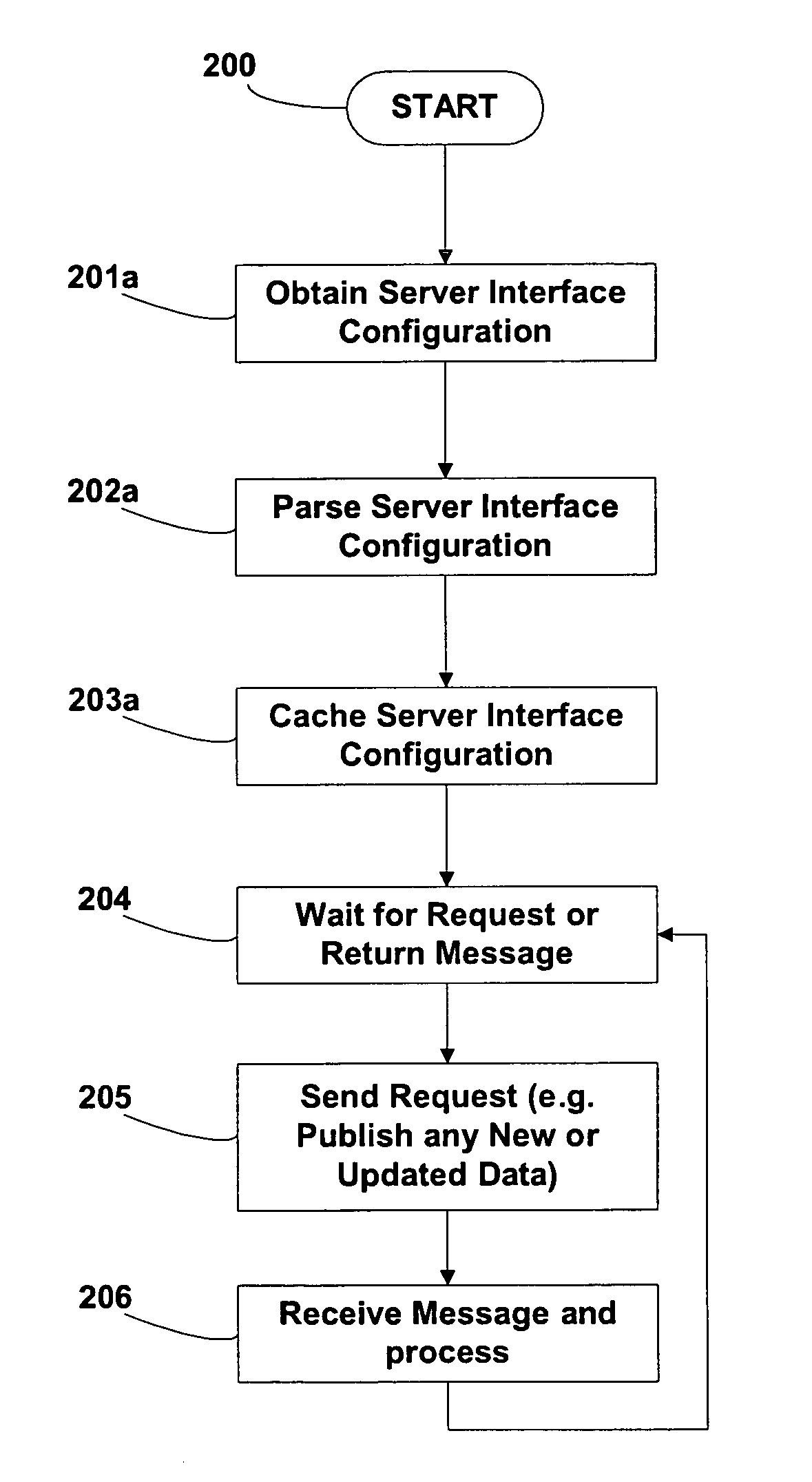

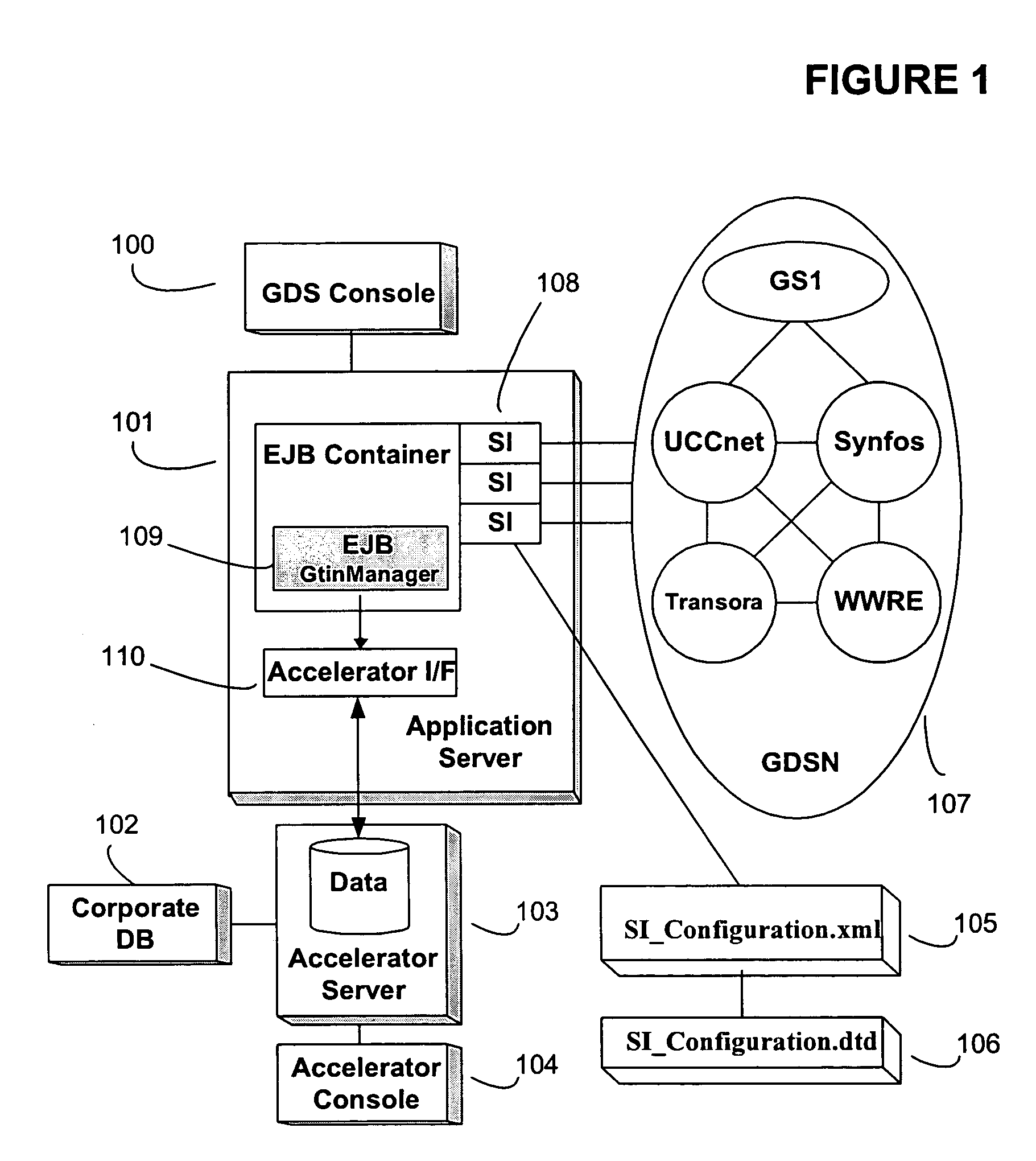

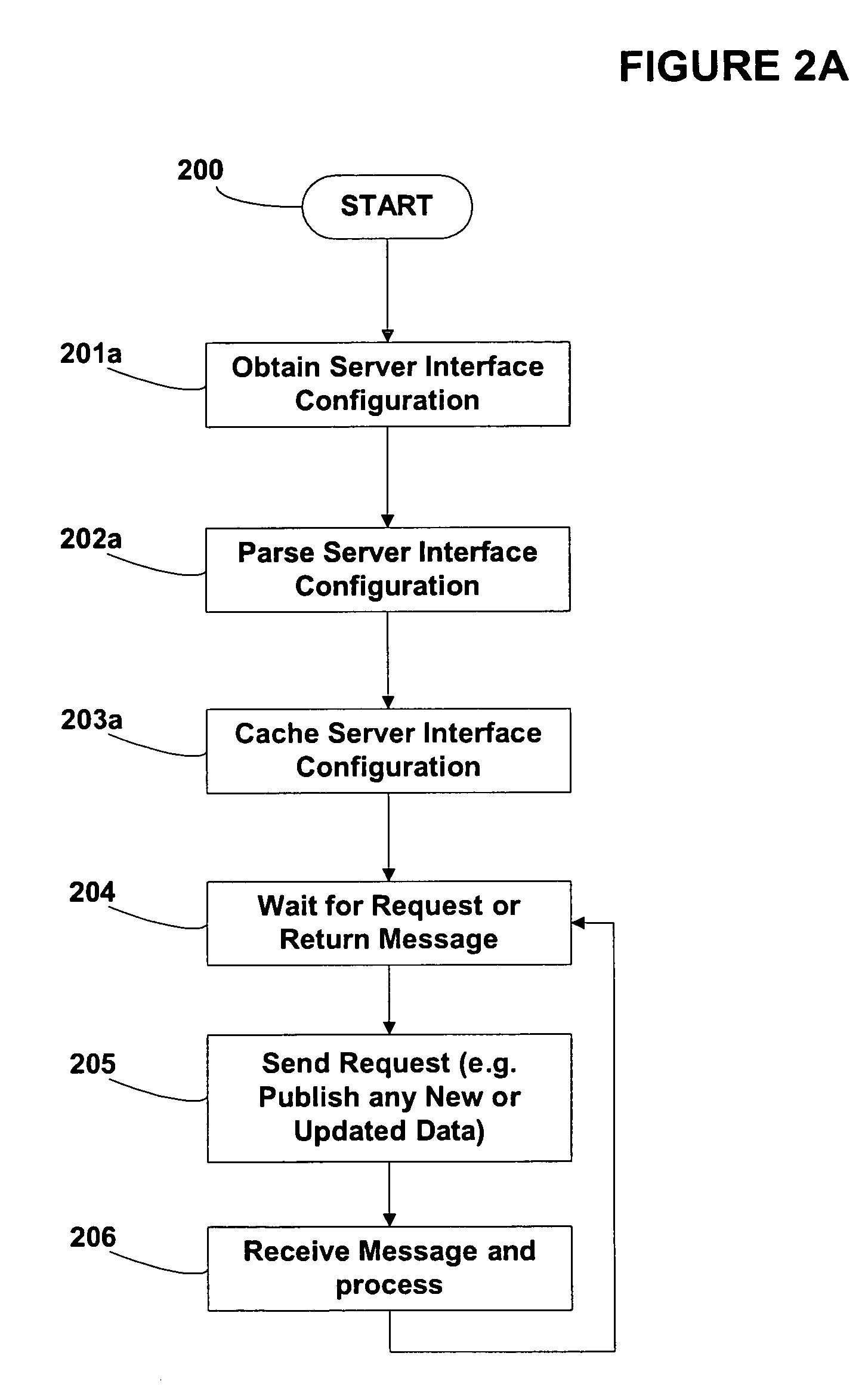

System and method for dynamically modifying synchronized business information server interfaces

ActiveUS7738497B2Quick couplingReduce skillsDigital computer detailsDatabase distribution/replicationApplication serverRunning time

One or more embodiments of the invention enable data that is synchronized between businesses to be transferred to any desired data pool or data pool version in a format that may be declaratively specified and dynamically altered to meet the needs of the specific data pool or data pool version. The data pool vendor utilized by a company or the attributes and formats used in communicating with a particular data pool may change over time and embodiments of the invention are capable of automatically detecting and altering the data and format of the data to be transferred to and from the data pool. The server interface configuration may comprise an XML file in one embodiment of the invention. The XML file may be parsed with any compliant schema based or DTD based XML parser and sent to the server interface for dynamic update using JMS for example. The server interface itself may be implemented or make use of a Resource Adapter configured to operate within the Java Connector Architecture of the Enterprise JavaBeans specification. In at least one embodiment of the invention an N-tier architecture may be employed comprising an Application Server. The server interface accepts an incoming server interface configuration request and utilizes information derived from the XML configuration file in order to add or remove data attributes or alter the format of the data attributes that are transferred to and from each data pool. In this embodiment of the invention, data pools may be switched by at run-time without recompiling and redistributing the application.

Owner:SAP AG

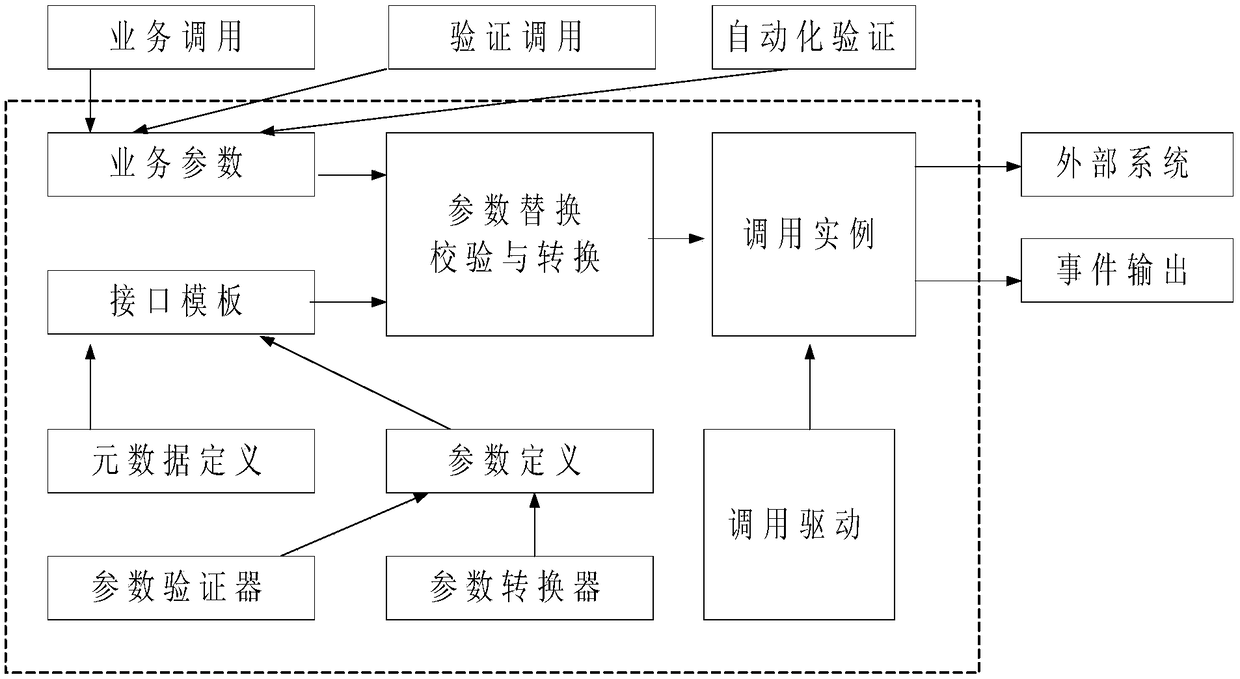

An API gateway management system and method thereof

ActiveCN109460223AImprove development efficiencyImprove applicabilityCreation/generation of source codeSoftware engineeringWorkload

The invention discloses an API gateway management method. The method comprises following steps of metadata definition and parameter definition are performed on API of an access system; Combined with metadata definition and parameter definition, the interface template is formed. Interface templates dynamically bind business variables, and synthesize dynamic specific business parameters through external systems; Combined with interface template and dynamic business parameters, API parameters are replaced and a calling instance is formed by computer. The invocation instance invokes the external system through the invocation driver, as well as the event output. The invention adopts the API gateway management method and the system based on the method, Many APIs are templated with complex interfaces, informationized and combined with dynamic data parameters to form templated calling instances, which have high development efficiency. With the accumulation of various APIs, the system applicability is higher, which reduces the workload of development and testing, and saves human cost.

Owner:SHENYANG LINKTECH INFORMATION TECH CO LTD

Blade sharpening device with blade contour copying device

InactiveUS20080096477A1Prevent overheating and damageProvide consistencyEdge grinding machinesBelt grinding machinesEngineeringKnife blades

The present invention provides a blade sharpening device designed for sharpening a blade for a uniform sharpening of the edge thereof. The blade sharpening device contains a base having a guide slidably movable relative to the base. The guide includes a material that receives an impression of a blade defining a blade contour. A blade holder is attached to the base for securing the blade while being sharpened. A carriage contains an elongated structure for interacting with the material of the guide which has received an impression of the blade defining a blade contour. The guide defines a sharpening path substantially aligning with the blade contour. The carriage also has an abrasive surface for sharpening the blade. In operation, the guide and carriage direct the movement of the abrasive surface along the contour of the blade for a uniform sharpening of the edge thereof.

Owner:LYTINAS MICHAEL

Wok support ring and devices for imparting a rocking motion to a wok

A wok support ring supports the weight of a wok and food items to be cooked in the wok and imparts a rocking motion to the wok as it is moved in a back and forth motion by the worker. A wok rocking device includes the use of a wok support base which moves in a rocking motion via cam tracks with roller followers. When the worker pulls the wok in a back and forth motion, the rollers follow the cam track to cause the wok to rise rapidly and then rock forward near the end of the stroke. A wok rocking device also can utilize movable linkages attached to a wok support base in order to create the rocking motion needed to mix and fold the food items within the wok.

Owner:PANDA RESTAURANT GROUP

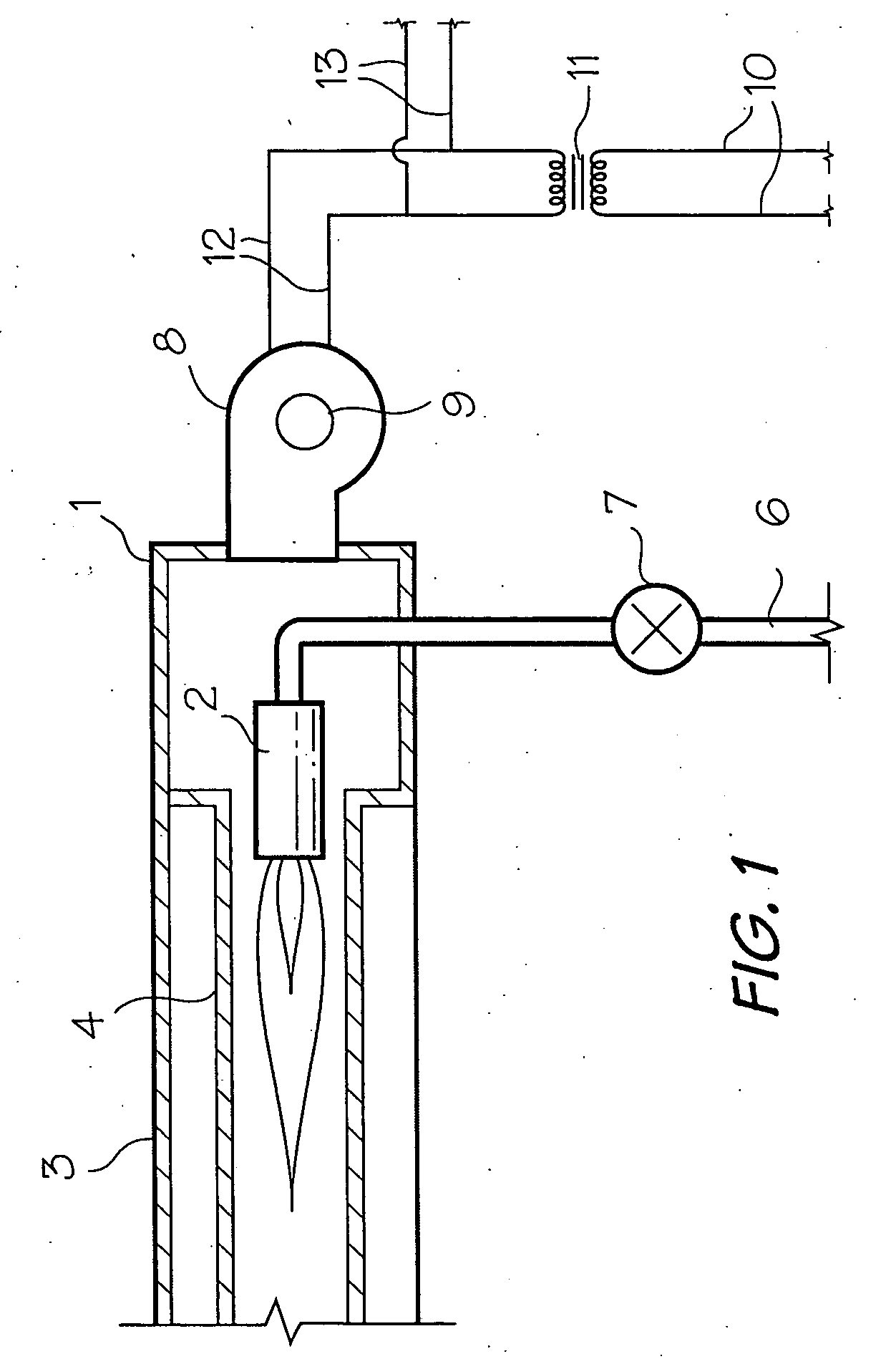

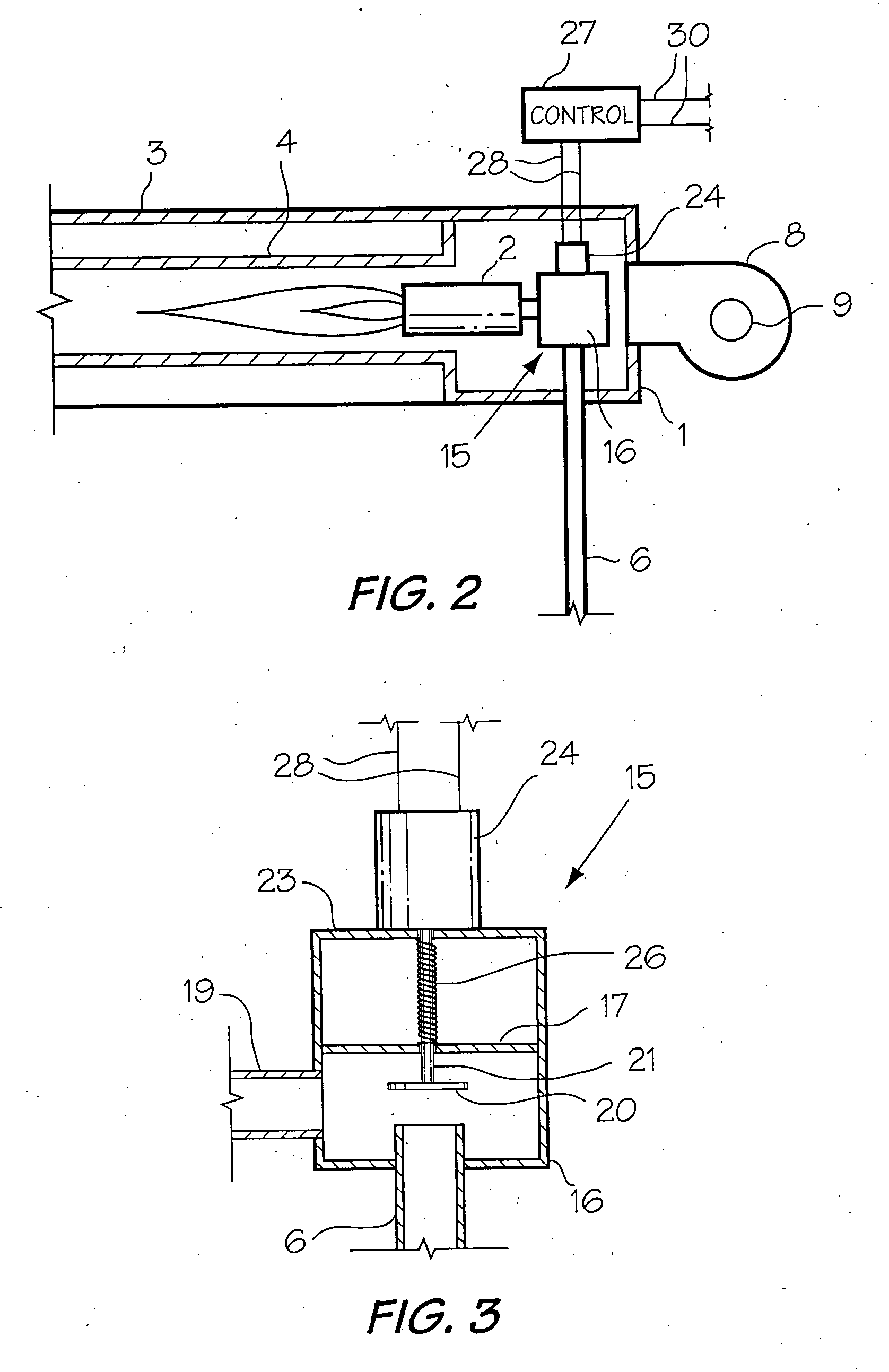

Radiant tube heater assemblies

InactiveUS20060081238A1Operational securityEasy to installDomestic stoves or rangesHot-air central heatingElectrical controlVolt

A variable input, radiant tube heater includes the usual housing containing a burner tube, a reflector connected to the housing, a fuel line into the housing and a pressure regulator in the fuel line. The blower is operated by a 24 volt motor and a transformer remote from the heater. Fuel flow is regulated by a regulator including a valve in the fuel line, a valve operator and an electrical control connected to the operator. For outdoor use heaters are supported by a modular frame including hollow beams, posts for supporting the beams and saddles for interconnecting the beams and mounting them on posts.

Owner:VANCAK JOHN

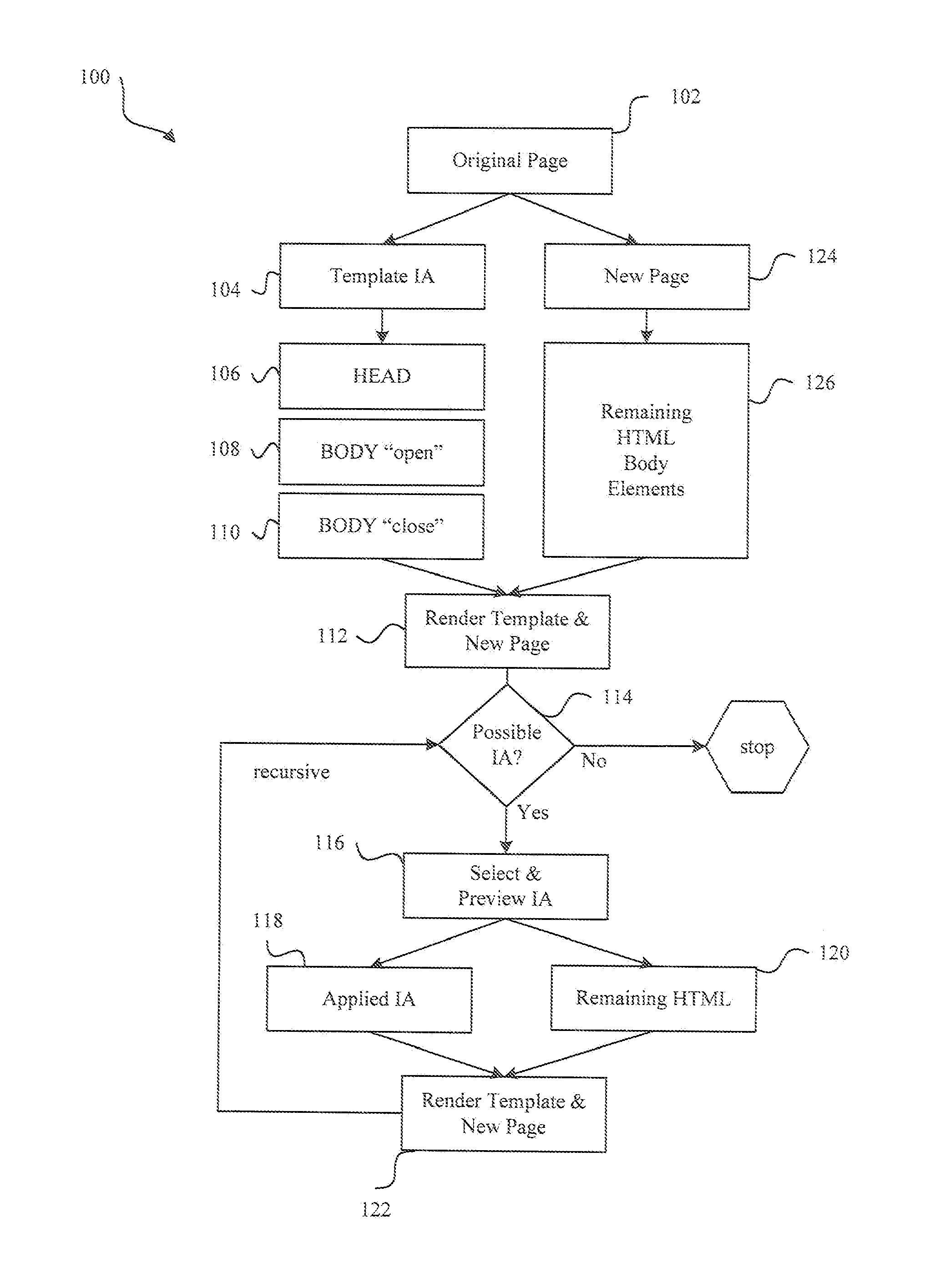

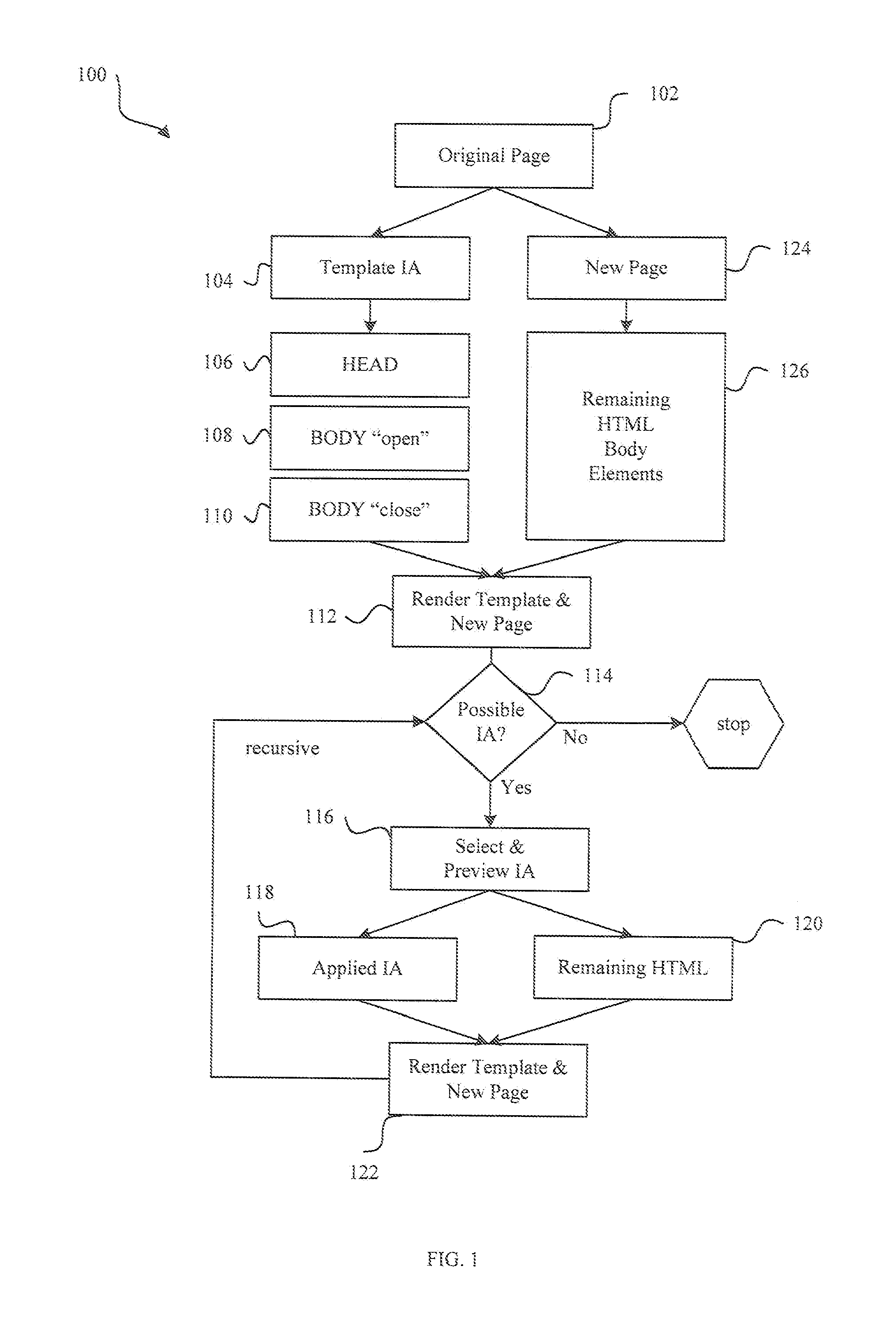

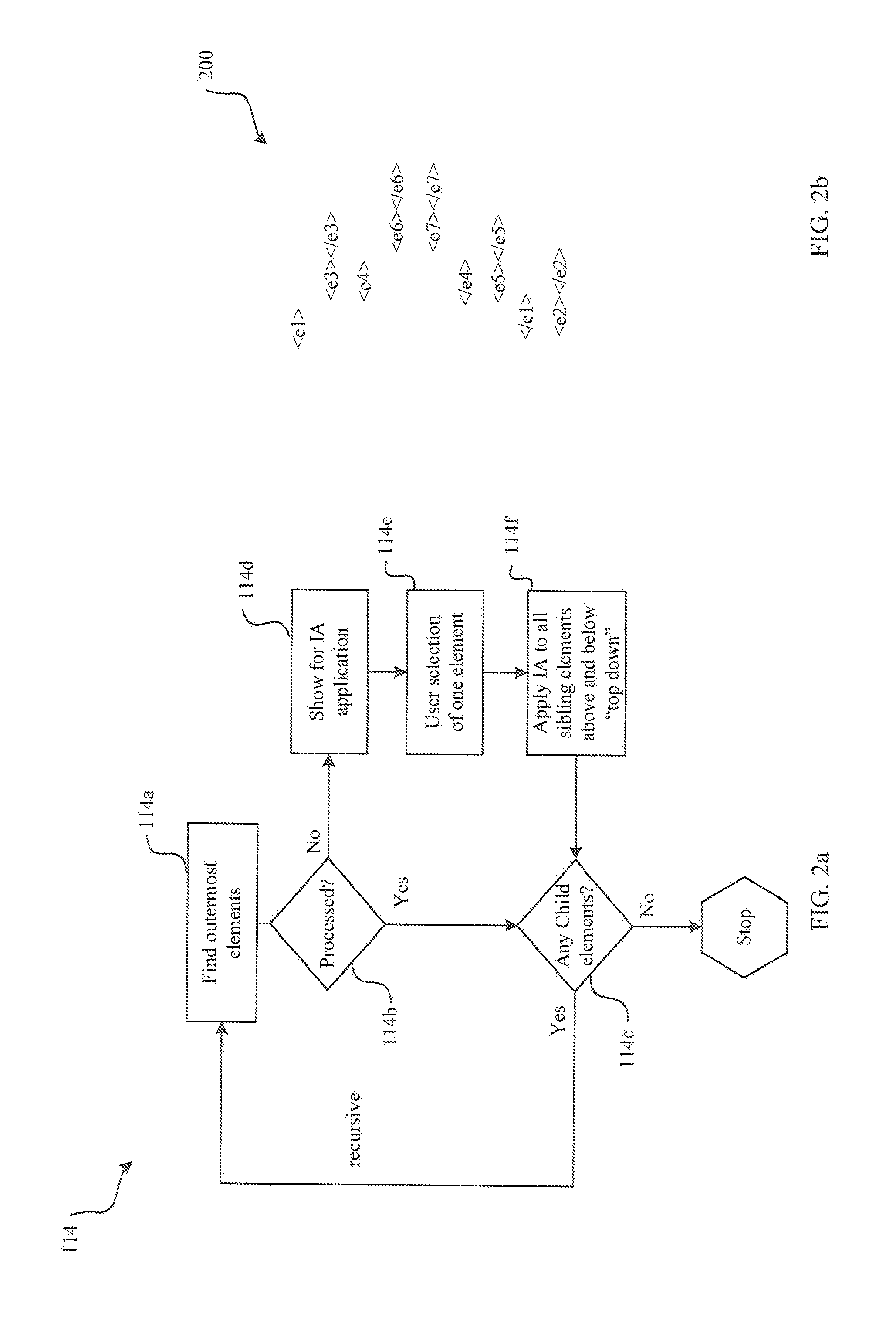

Lossless application of new information architecture to existing websites, web pages, and online content

InactiveUS20140101533A1Avoid lostReduce skillsNatural language data processingWebsite content managementLook and feelWeb page

A method and system that applies an information architecture (IA) to an existing website, set of web pages, or other online content. The method and system may allow a user to apply IA to web pages in situ, and through a visual point and click process. This prevents the loss of content and / or look and feel as IA changes are being applied, provides immediate visual feedback to the user, dramatically reducing the skill required to make IA choices, and makes subsequent content migration and / or “reassembly” of websites or pages unnecessary.

Owner:PERCUSSION SOFTWARE

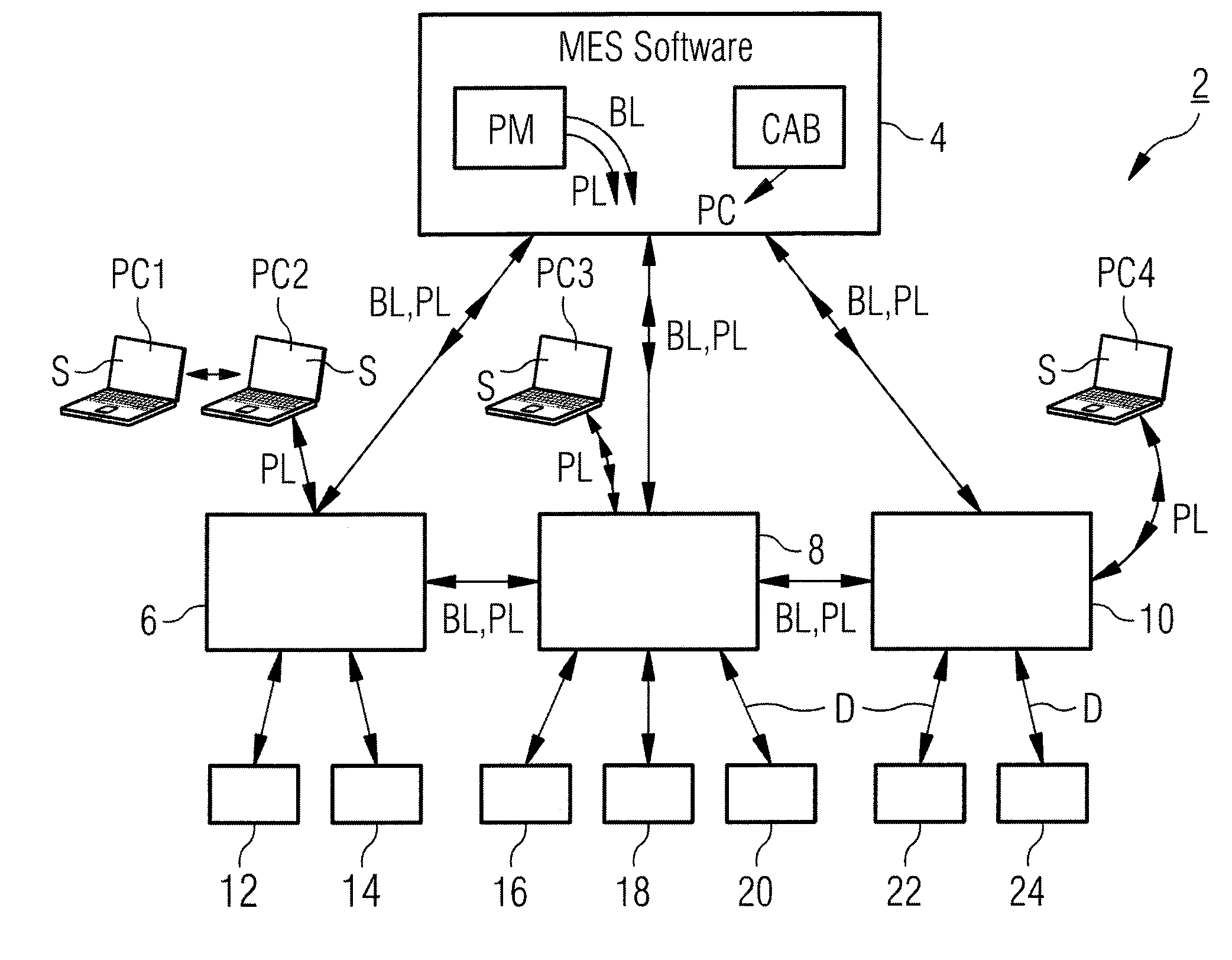

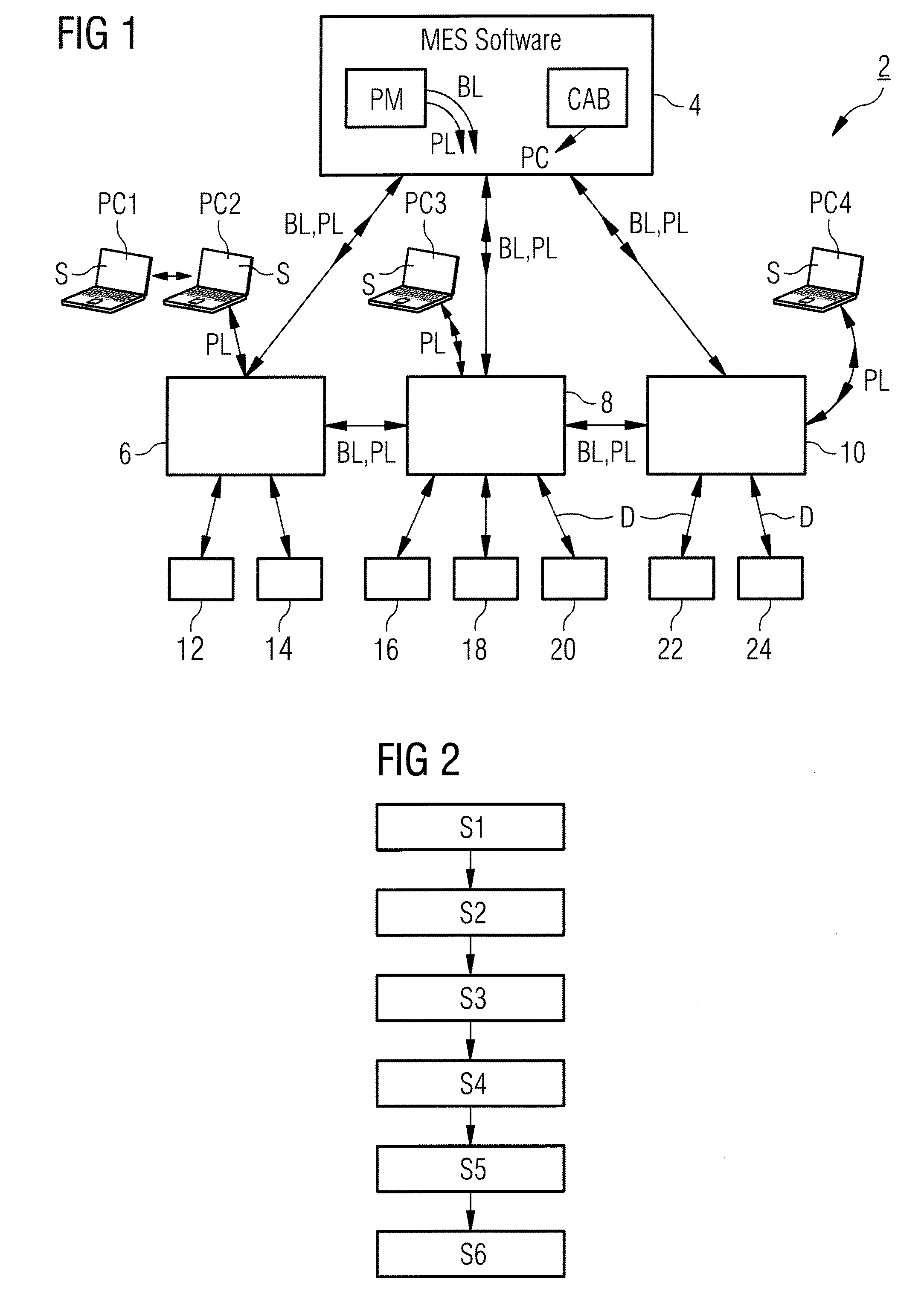

System and method for handling a data refresh procedure in a production execution system

InactiveUS20090019368A1Reduces the system workloadReduce developmentSpecific program execution arrangementsMemory systemsGraphicsGraphical user interface

A system for handling a data refresh procedure in a production execution system includes a network having data processing units running a MES software for controlling and monitoring a production process operating production components. A production modeler within the MES software defines a business logic that includes a plant model of the production process and the operating procedures for the production components in a graphical environment. A client application builder within the MES software provides a WEB based graphical user interface for generating cross-functionality graphic screens that form part of the network as presentation clients and display data stemming from the production components and being manipulated by the production modeler, where required. The production modeler defines a presentation logic operating the cross-functionality graphic screens, and updates the data at the presentation clients exclusively when the business logic requires the update to the presentation logic.

Owner:SIEMENS AG

Display lighting system

ActiveUS9596950B2Reduce errorsPrecise positioningMechanical apparatusLighting support devicesElectricityLow voltage

A lighting system including a low voltage frame, a puck magnetically joinable with the frame, a lighting array, and an elongated electrical connector joining the puck and the lighting array. The puck can be selectively positioned along the low voltage frame in a variety of different locations. The puck can be constructed from a polymeric material molded over electrical connectors, and optionally a power feed, such as a cable jack. The electrical connectors can be magnetized so that the electrical connectors are magnetically attracted to power rails on the low voltage frame to establish electrical coupling of the connectors to the power rails, while physically securing the puck in a fixed location along the low voltage frame. The power rails can be constructed from magnetic stainless steel, optionally coated with black oxide from a hot black oxide coating process.

Owner:AMSTORE

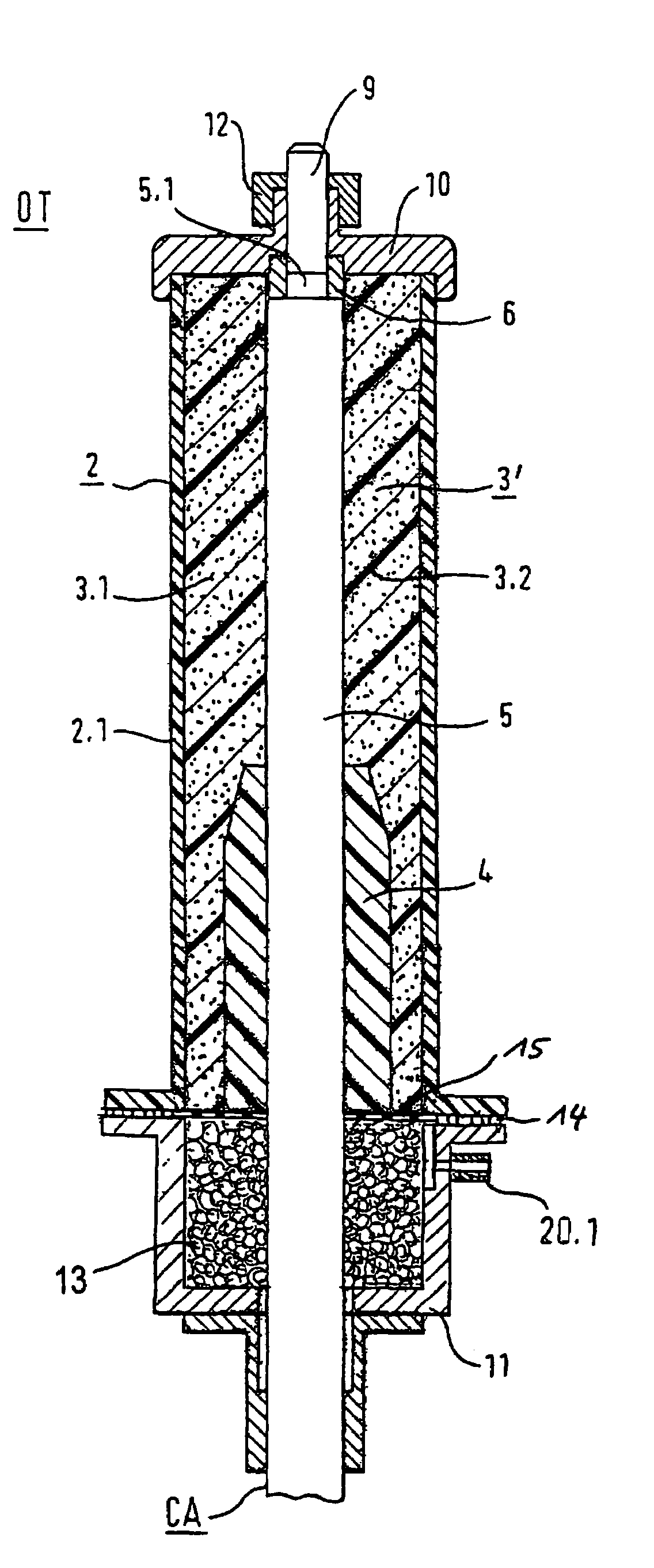

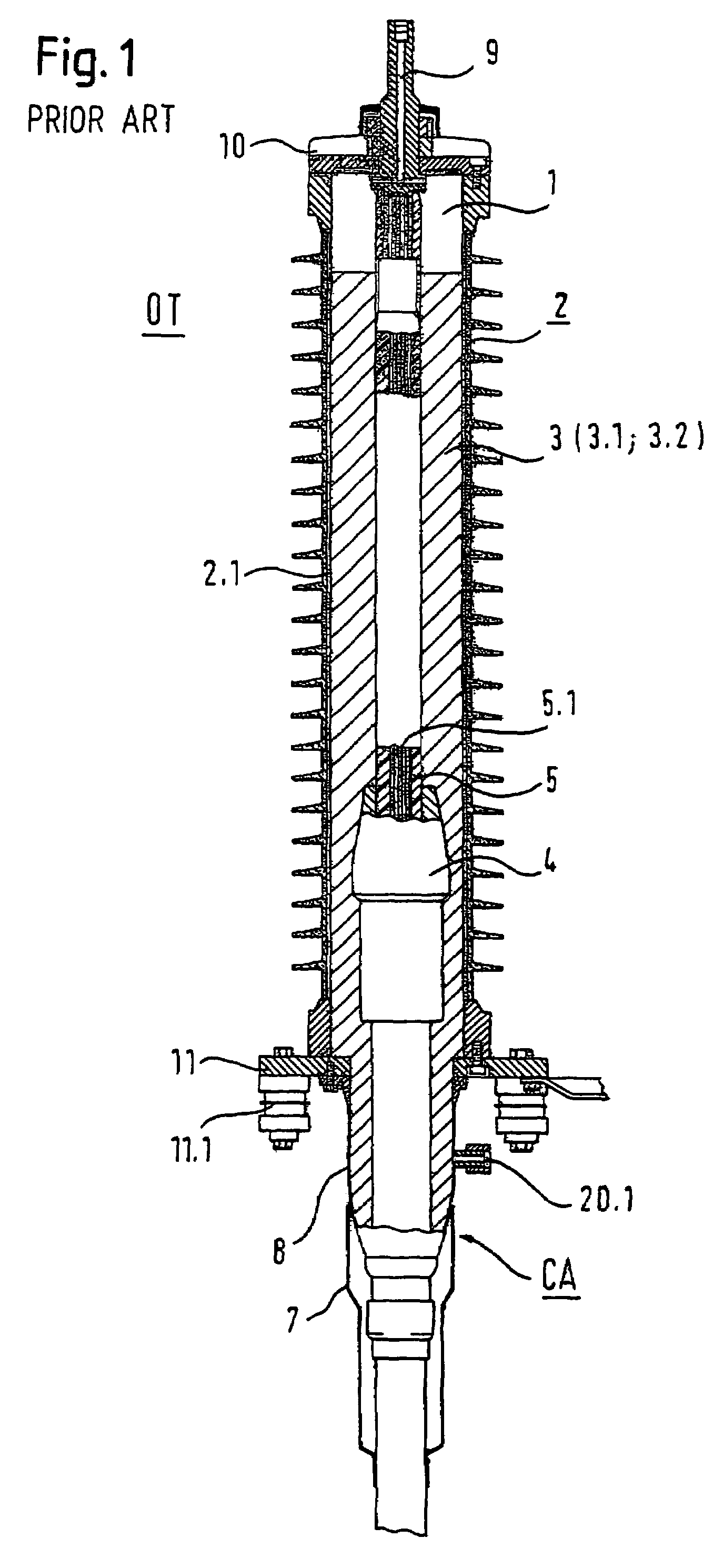

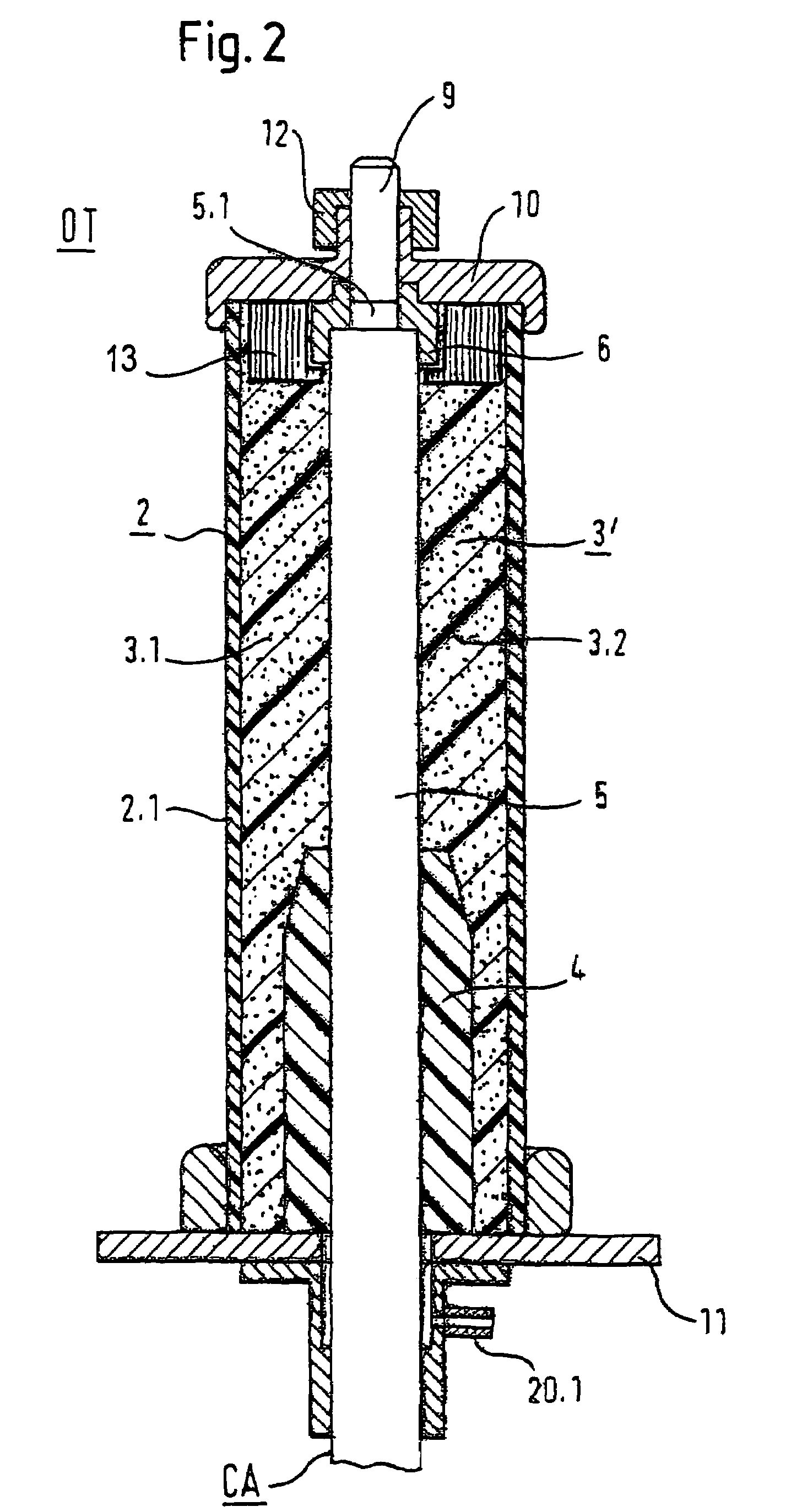

Method and arrangement for a termination of an electrical cable

InactiveUS7361836B2Improve reliabilityReduce skillsElectrically conductive connectionsCable junctionsElectrical conductorVolume variation

A method of building a cable termination is provided. The termination has an outer insulator body, a substantially longitudinally extended interior member having the electrical cable to be terminated, having a conductor for carrying load, an insulating material filled in a cavity between the outer insulator body and the interior member and means for accommodating volume expansions of the insulating material filled within the cavity. The cavity is created by introducing the interior member into the insulator body, filling the insulating material into the cavity and sealing the termination. A volume change compensation member having a predetermined volume to accommodate volume expansions of the insulating material within the cavity is placed into the cavity. Respective terminations are also provided.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

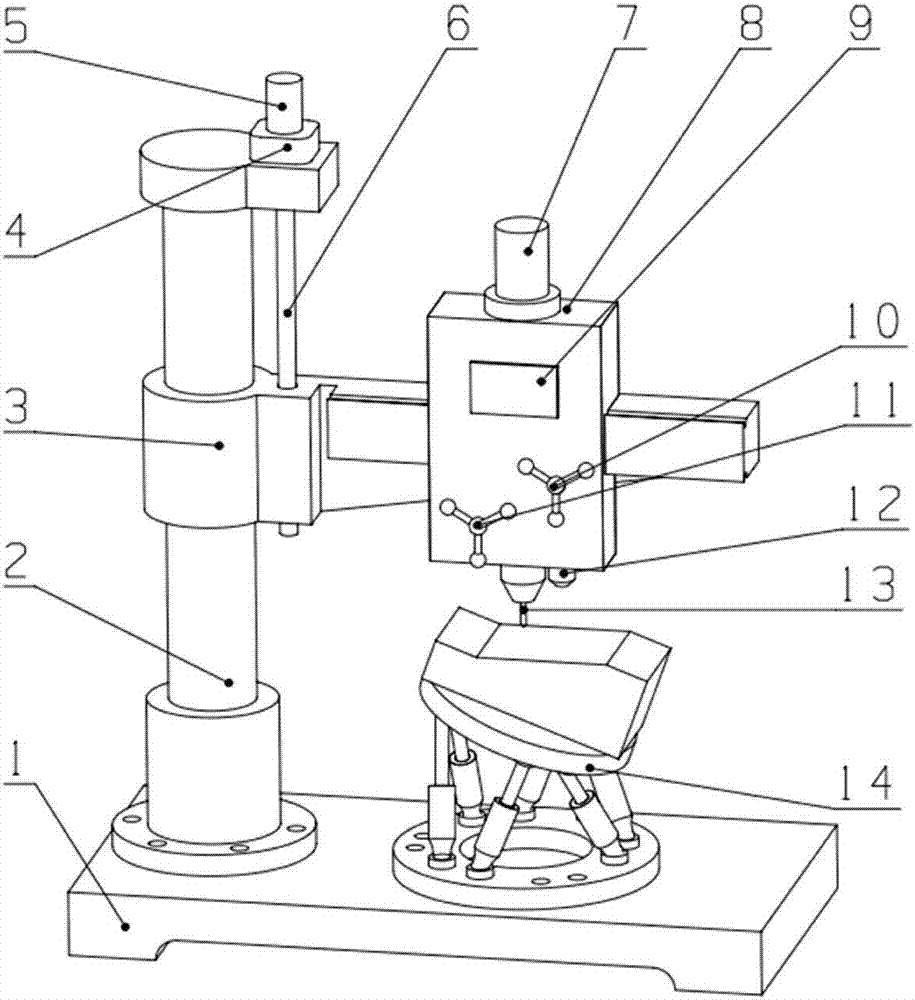

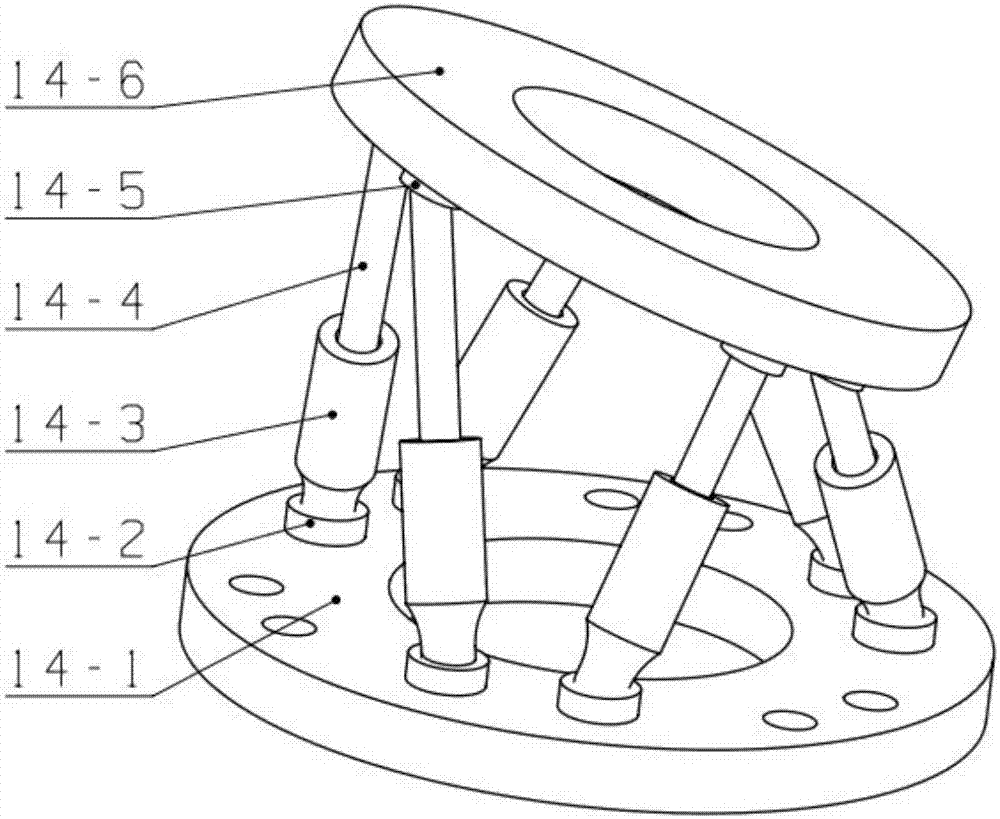

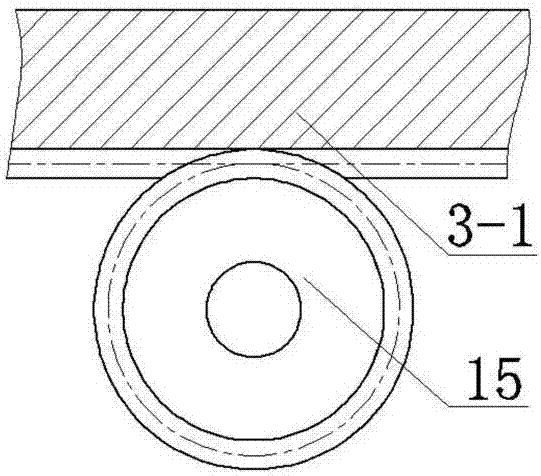

Intelligent drilling machine based on six-degree-of-freedom parallel robot

InactiveCN107030307AReal-time detection of location informationGuaranteed to be always verticalLarge fixed membersBoring/drilling machinesMachined surfaceRelative motion

The invention discloses an intelligent drilling machine based on a six-degree-of-freedom parallel robot, belongs to the technical field of intelligent drilling machines and aims to solve the problems of poor manual positioning accuracy, low manual positioning efficiency and poor drilling accuracy in the prior art. The intelligent drilling machine comprises a base, a stand column, a rocker arm, a spindle box, a drill bit, displacement sensors, the six-degree-of-freedom parallel robot and a controller, wherein the lower end of the stand column is fixedly connected with the base; one end of the rocker arm is arranged on the stand column in a sleeving mode and the rocker arm can move up and down relative to the stand column; the spindle box moves leftwards and rightwards relative to the rocker arm; the drill bit extends out of the lower end of the spindle box, is connected with a spindle in the spindle box and is capable of performing rotational motion and feeding motion; the displacement sensors are fixed to the lower end of the spindle box, the outer cylindrical surface of the end, extending out of the spindle box and connected with the drill bit, of the spindle is fit with the displacement sensors, and the position information of a to-be-machined surface of a workpiece is acquired in real time through the displacement sensors; the six-degree-of-freedom parallel robot is fixed to the base and corresponds to the drill bit in position, and the workpiece is arranged on a movable platform of the six-degree-of-freedom parallel robot; and the controller is disposed in the spindle box and electrically connected with the six-degree-of-freedom parallel robot and the displacement sensors.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Intelligent postnatal rehabilitation device, realization method thereof and rehabilitation instrument

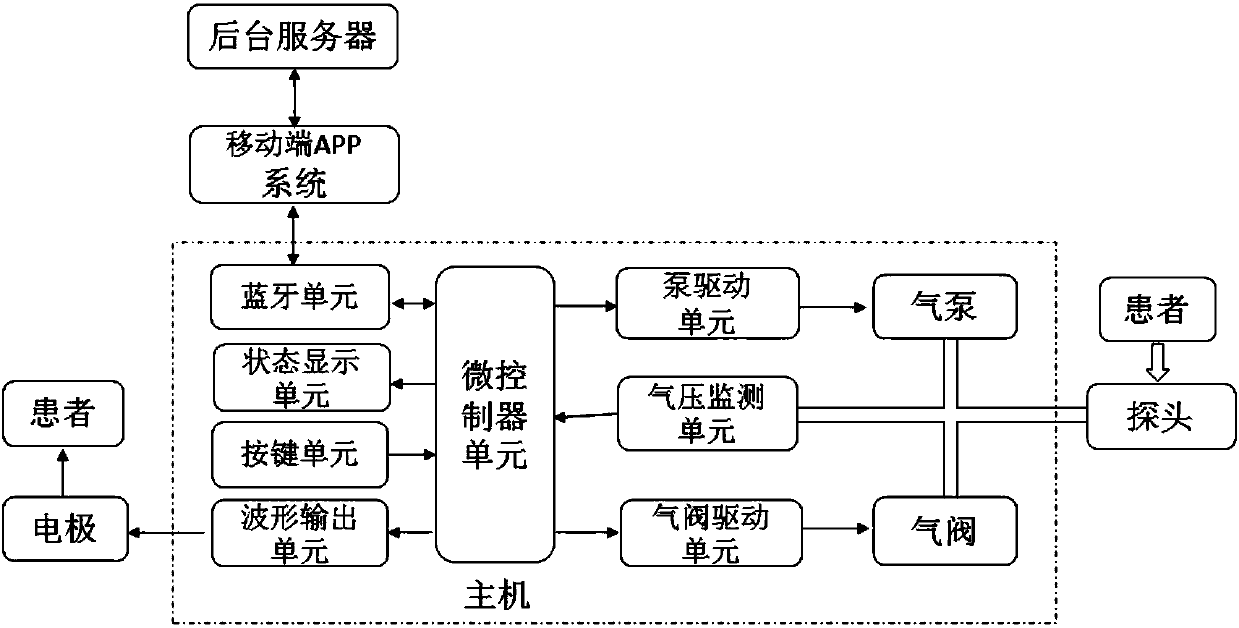

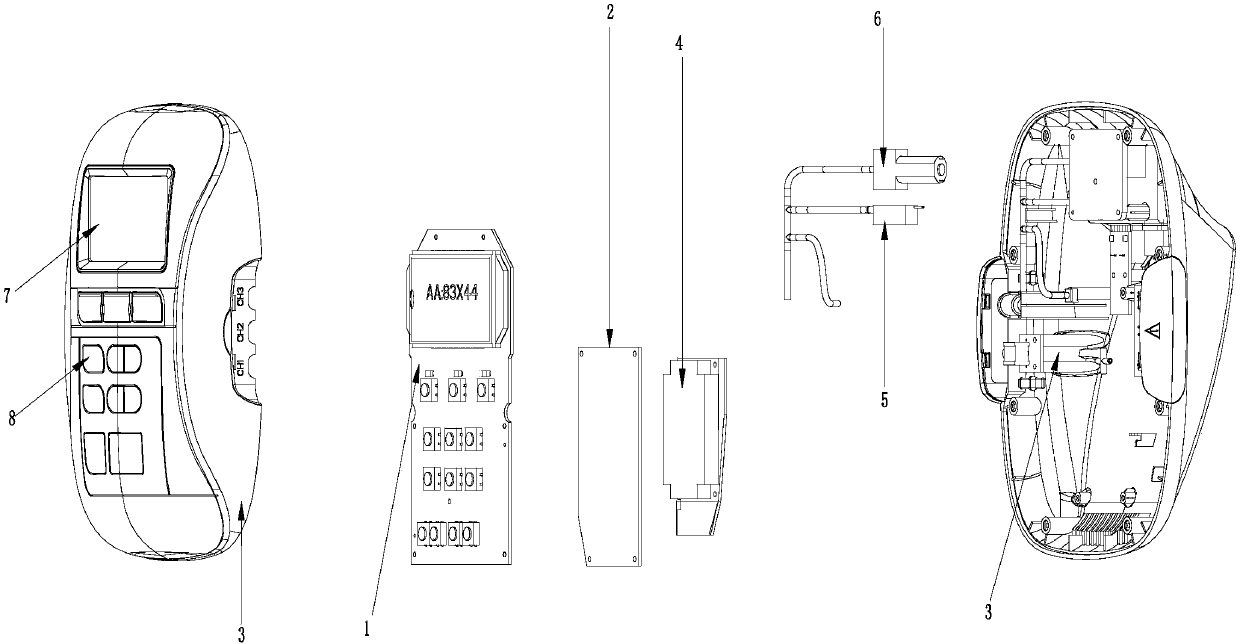

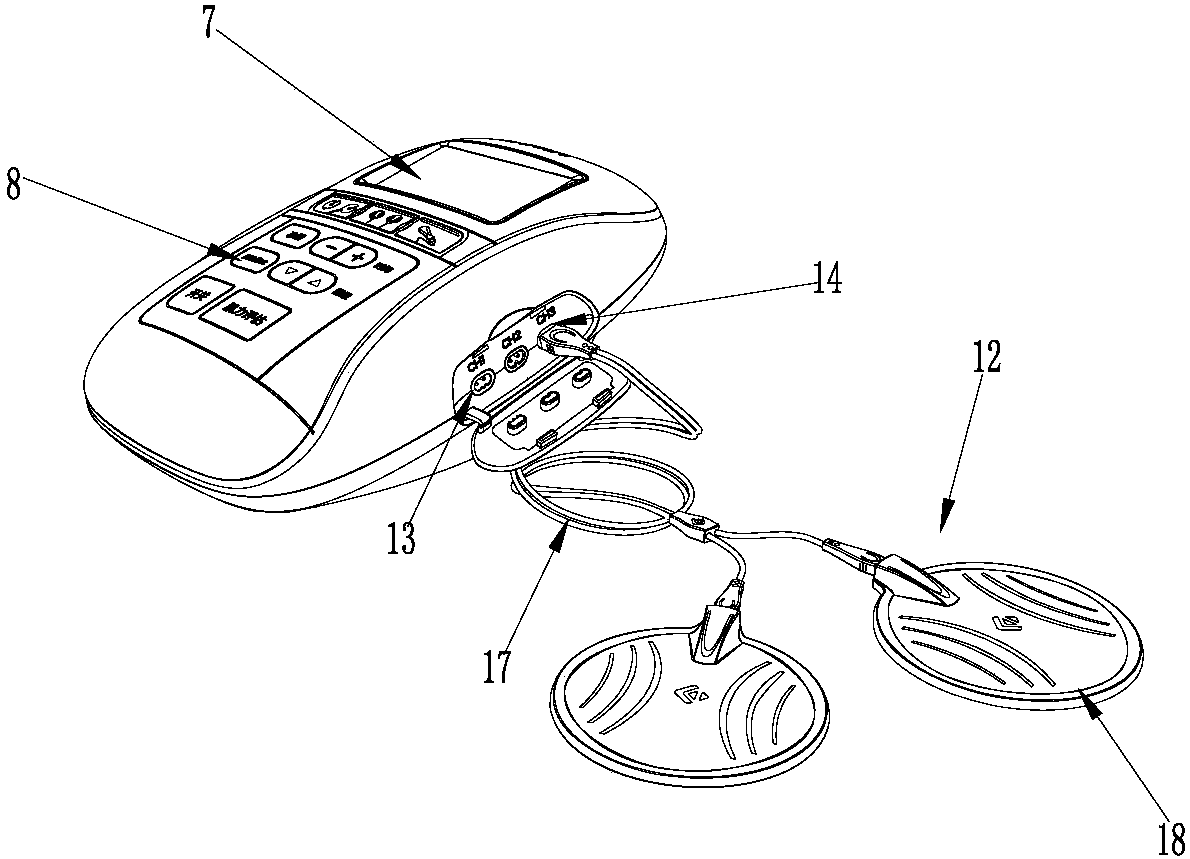

PendingCN107929942AAchieve recoveryLow comprehensionElectrotherapyTelemetric patient monitoringMicrocontrollerValve actuator

The invention discloses an intelligent postnatal rehabilitation device, a realization method thereof and a rehabilitation instrument. The device comprises a host and a mobile terminal and background server capable of Bluetooth communication with the host; the mobile terminal comprises a mobile-end APP system; the host comprises a microcontroller unit, and a button unit, a Bluetooth unit, a state display unit, a waveform output unit, a pump driving unit, an air pump, an air valve driving unit, an air valve, an air pressure monitoring unit, an electrode and a probe electrically connected with the microcontroller unit; the electrode is electrically connected with the waveform output unit; and the air pump, the air valve and the air pressure monitoring unit are in air passage connection with the probe. Via the device, method and instrument, electrical stimulation treatment and biofeedback treatment can be carried out, patients can be managed, and the treatment efficiency can be improved greatly.

Owner:深圳德佳智联科技有限公司

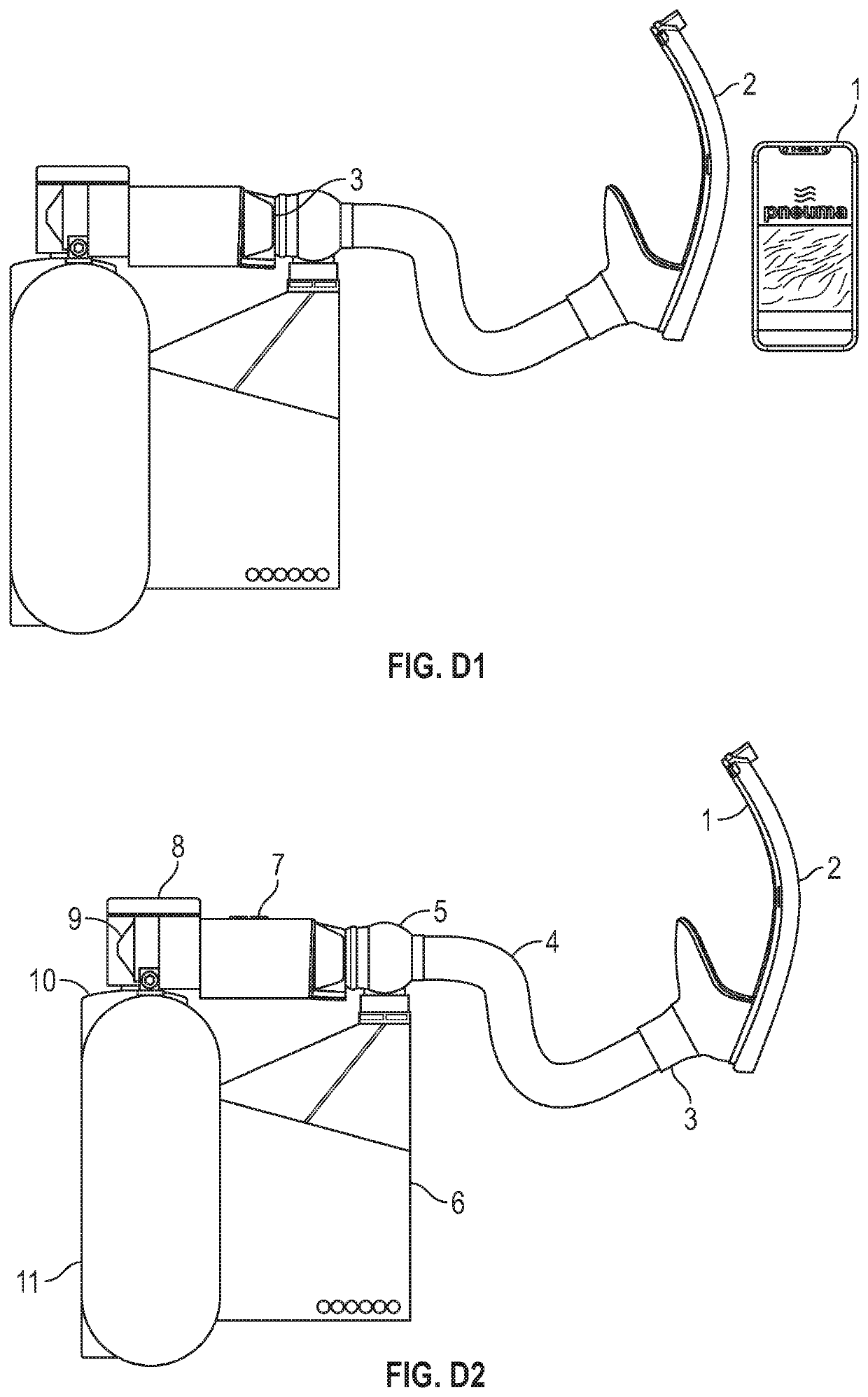

Automated Recreational Closed Circuit Breathing Device

PendingUS20200001956A1Increase pressure insideReduce water pressureRespiratory masksFire rescueBiologyElectronics

A highly automated, fully-closed circuit rebreather and methods for operating the device by users with limited training and limited skill development are disclosed. Advanced sensors, electronics, software, assembly methods, and disposable cartridges dramatically reduce the skills required for assembly, operation, and maintenance of the unit. The use of the rebreather apparatus is primarily for recreational diving applications, but may be used for additional applications where the presence of breathable air may be absent or limited, such as hazardous duty applications, high altitude applications, no-atmosphere or low-atmosphere applications, and the like.

Owner:VARIS CORP

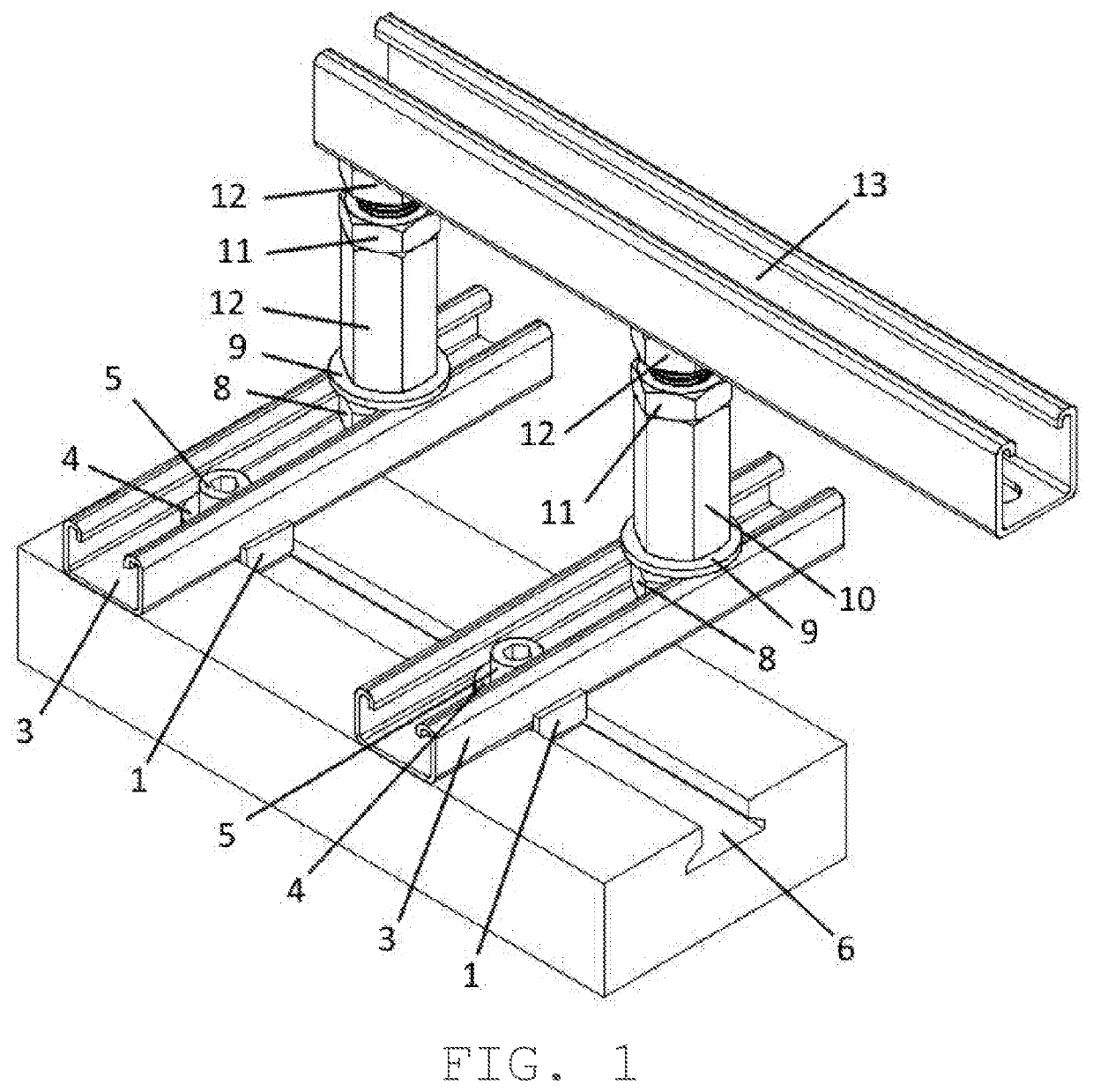

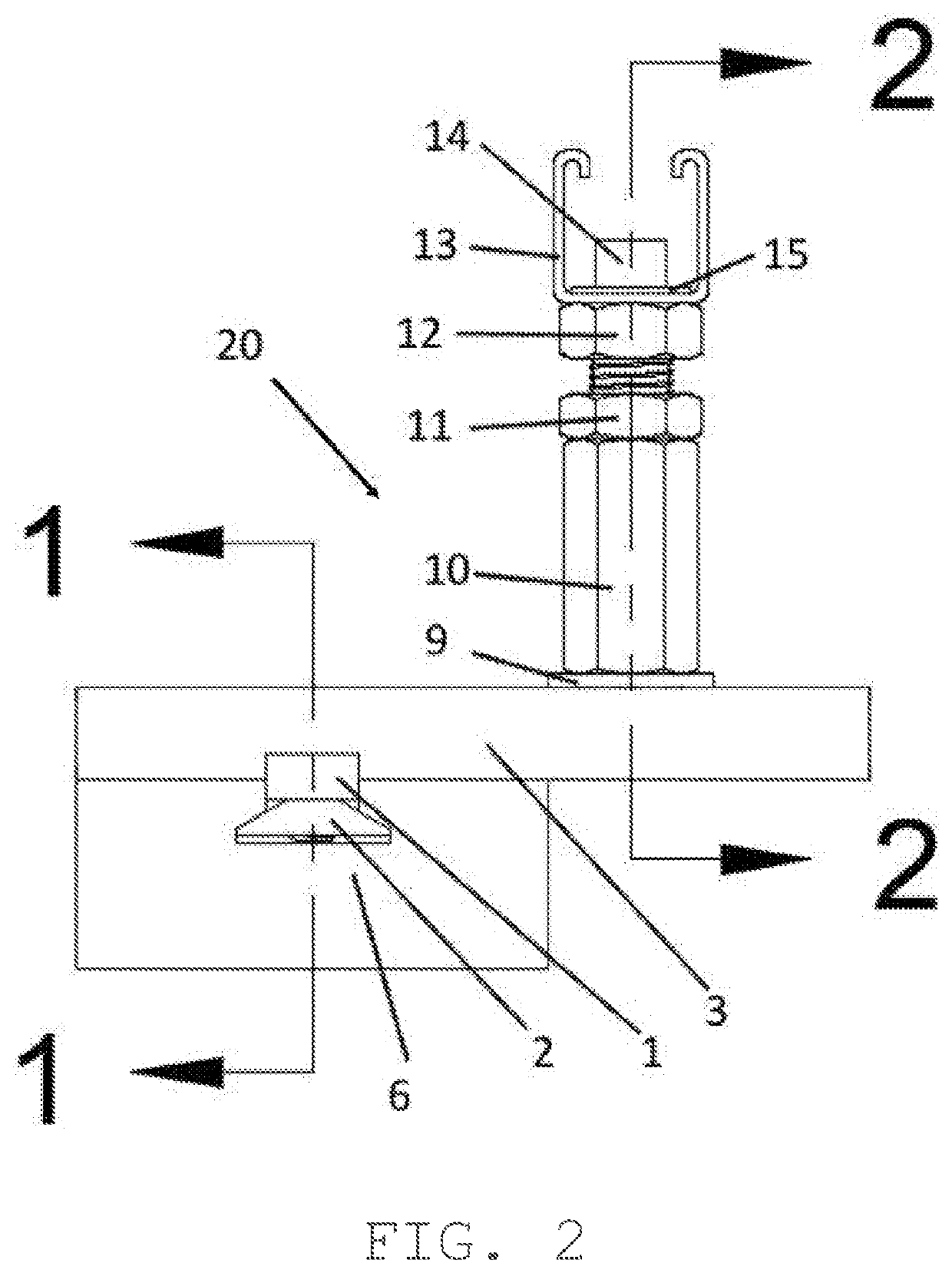

EZ Speedy Fence Mount

ActiveUS20190381614A1Reduce the time required for installationReduce skillsGuide fencesWork benchesControl theoryBearing surface

The invention allows for alignment perpendicular to a track engaged by a securing nut. An opposing tooth key type aligner has two functions: keeps the second track perpendicular to the first track and allows the securing nut to always be correctly oriented to engage with the track. A bolt clamps the securing nut to the track to lock the position of the invention. A second axis perpendicular to the lower track is created with a second track. A bolt connected to a coupler nut engages with the middle track to create a third axis perpendicular to both previous axes. A washer provides a neutral bearing surface between the coupler nut and second track. An elevation bolt sets the vertical position of the object to be mounted. A bolt can be used to fasten an object to the end of the elevation bolt.

Owner:SUHLING ROBERT JAMES

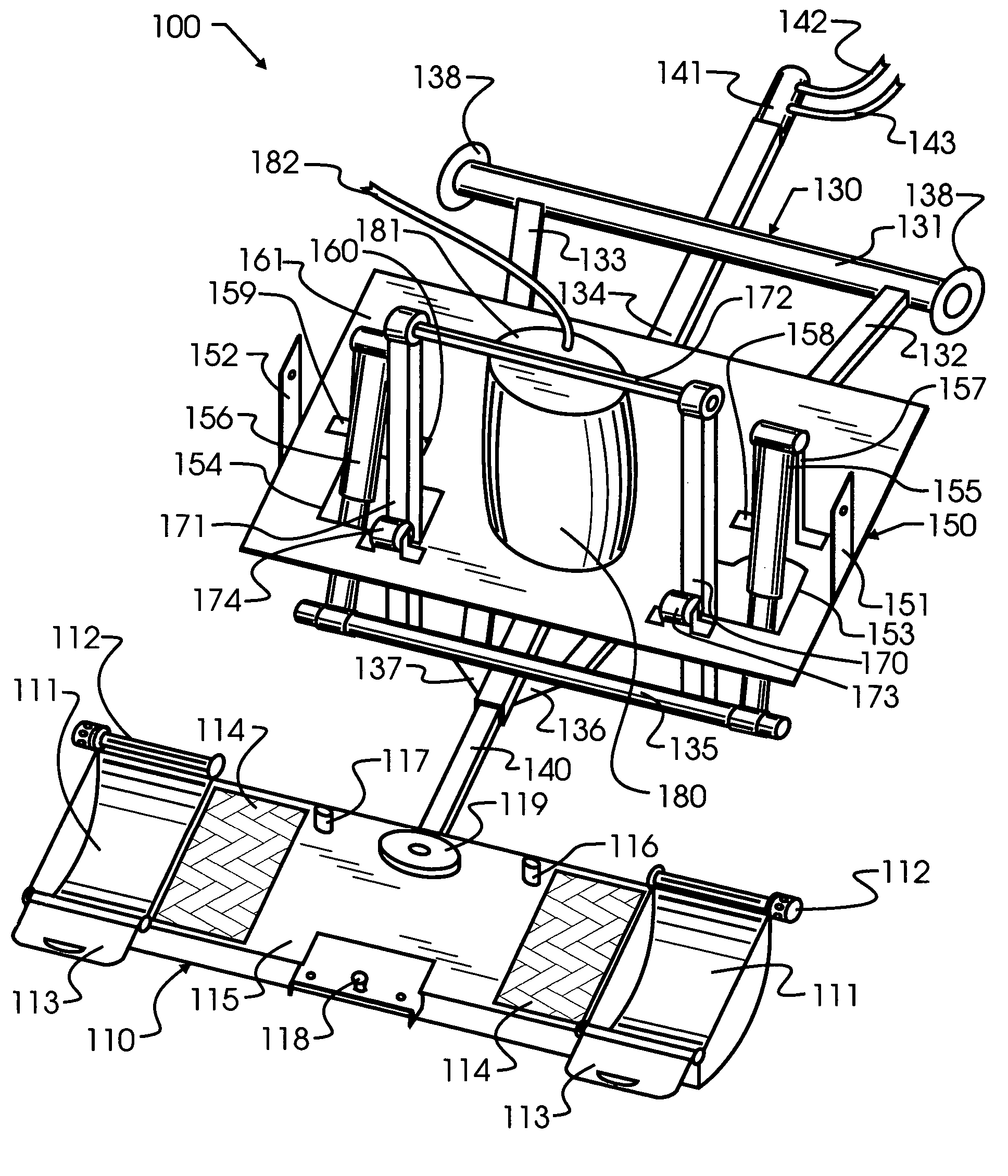

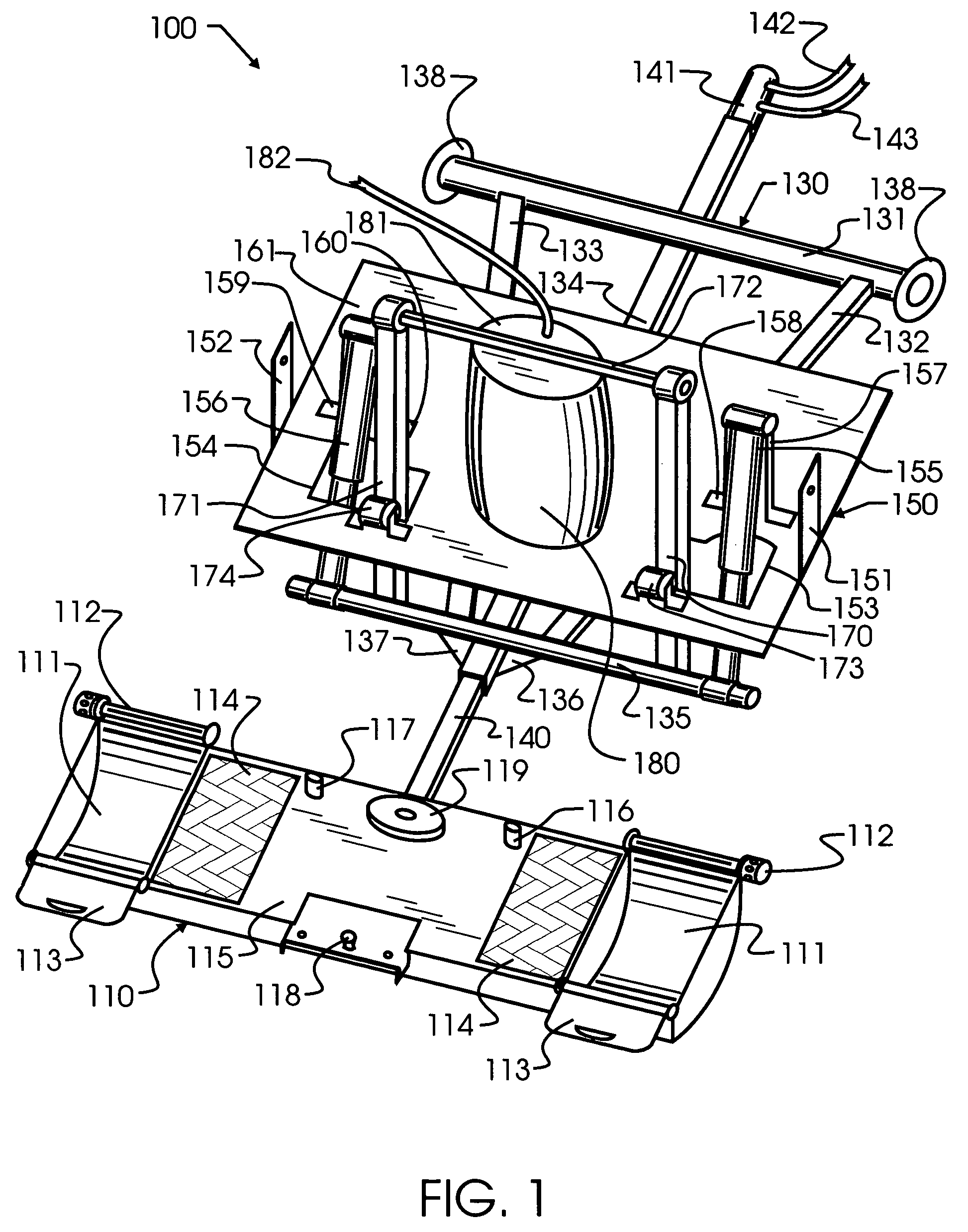

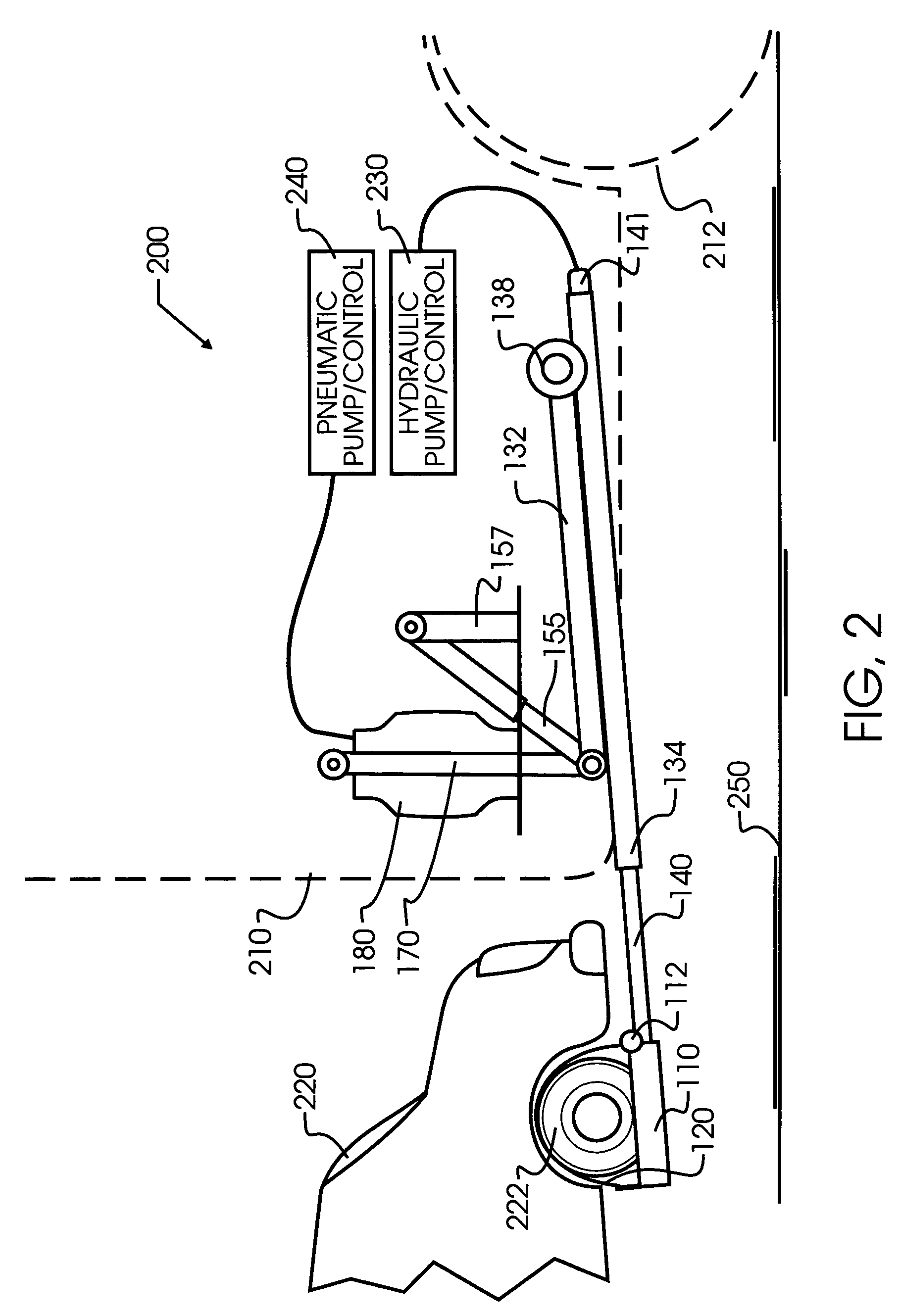

Vehicular towing apparatus using air lift

InactiveUS7448839B2Tow connectionReduce the amplitudeItem transportation vehiclesStorage devicesMarine engineeringAirbag deployment

A vehicular towing apparatus incorporates an air bag in association with shock absorbers and a tow bar. The air bag may be selectively inflated and deflated, allowing the tow bar to be raised and lowered at will. In addition, the tow bar may be extended or retracted as desired. Several platform attachments enable the towing apparatus to be used alternatively as an automobile tow bar, a support for motorcycles or bicycles, or other items that may be supported upon a platform. The towing apparatus retracts under the vehicle, and may also serve as a vehicle step or standard trailer ball attachment point.

Owner:TRANSPORT SYST HLDG CO LLC +2

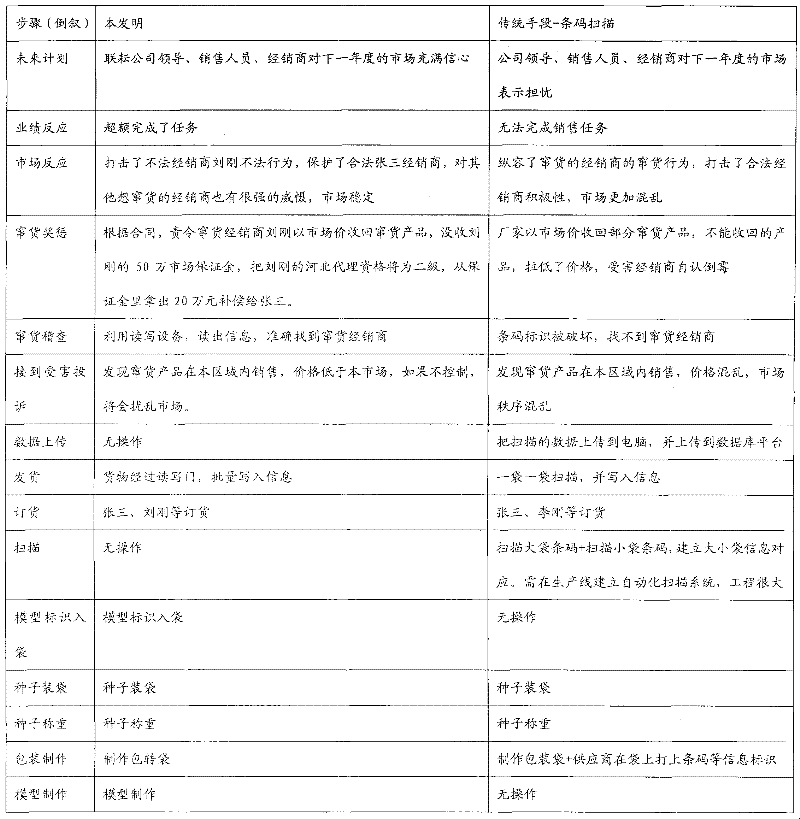

Goods fleeing and damage preventing method for identifying non-fixed position

InactiveCN102402708AAvoid destructionImprove reading and writing accuracyCo-operative working arrangementsCommerceElectronic identificationFixed position

The invention discloses a method for making a goods fleeing and damage preventing model identifier for identifying a non-fixed position. An electronic identifier is made into the model identifier, and export read-write equipment is made into door-like read-write equipment. The identifier is randomly placed in a small seed packing bag and mixed together with the seeds. The identifier has no fixed position requirement, and the required position is not fixed; and when the seeds are delivered, information for judging whether goods flee and the like is written into a memory in the model identifier through a read-write door. After the seeds are circulated to the market, because the dealer cannot find the information identifier, the information identifier cannot be destroyed, the information identifier is prevented from being destroyed, and the goods fleeing preventing technical means is not destroyed; and during market inspection, the goods fleeing information is read by using general read-write equipment, and whether the goods flee is judged. By the method, the position of the information identifier is not fixed, the color and the shape of the information identifier are similar to those of a protected agricultural resource, the information identifier mixed with the agricultural seeds is not easily identified, and loading and acquisition of the information identifier are ensured.

Owner:王赤坤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com