Flexible automatic assembling machine of mobile communication radio frequency coaxial connector

A radio frequency coaxial, mobile communication technology, applied in the assembly/disassembly, connection, circuit/collector parts and other directions of contacts, can solve the problems of low production efficiency, high resource consumption, difficult control, etc., and achieve hourly production capacity Improvement, reliable guarantee of geometric dimensions and geometric tolerances, reduction of skills and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

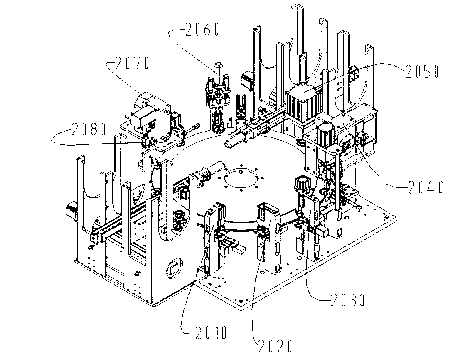

[0076] The structural features and functions of the present invention will be further clearly explained below in conjunction with the accompanying drawings and accompanying drawings and typical specific embodiments.

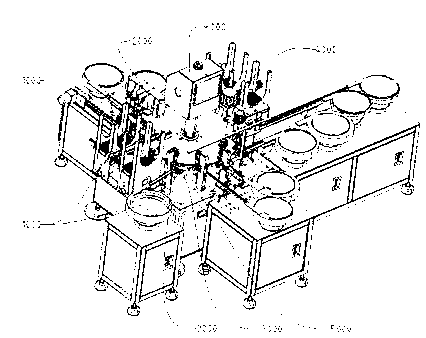

[0077] figure 1 The system composition of the present invention is shown; it includes a loading and unloading system 1000 , an assembly system 2000 , a fixture system 3000 , a rotating worktable system 4000 , a fixed workbench system 5000 , and a man-machine interface control system 6000 .

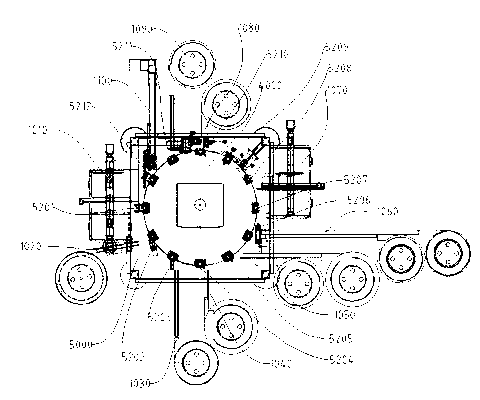

[0078] figure 2 The composition of the loading and unloading system 1000 of the present invention is shown; it includes a main body feeding mechanism 1010, a spring feeding mechanism 1020, a sealing flat gasket feeding mechanism 1030, a screw sleeve feeding mechanism 1040, and a center conductor / front insulator feeding mechanism 1050, the rear insulator / press ring feeding mechanism 1060, the fixed seat feeding mechanism 1070, the spring sleeve feeding mechanism 1080, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com