Automatic shirt under fly sewing machine

A technology of automation equipment and lining, which is applied in the direction of cloth feeding mechanism, clothing part conveyor, sewing machine components, etc., which can solve the problems of difficult hemming, achieve high work efficiency, precise control, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

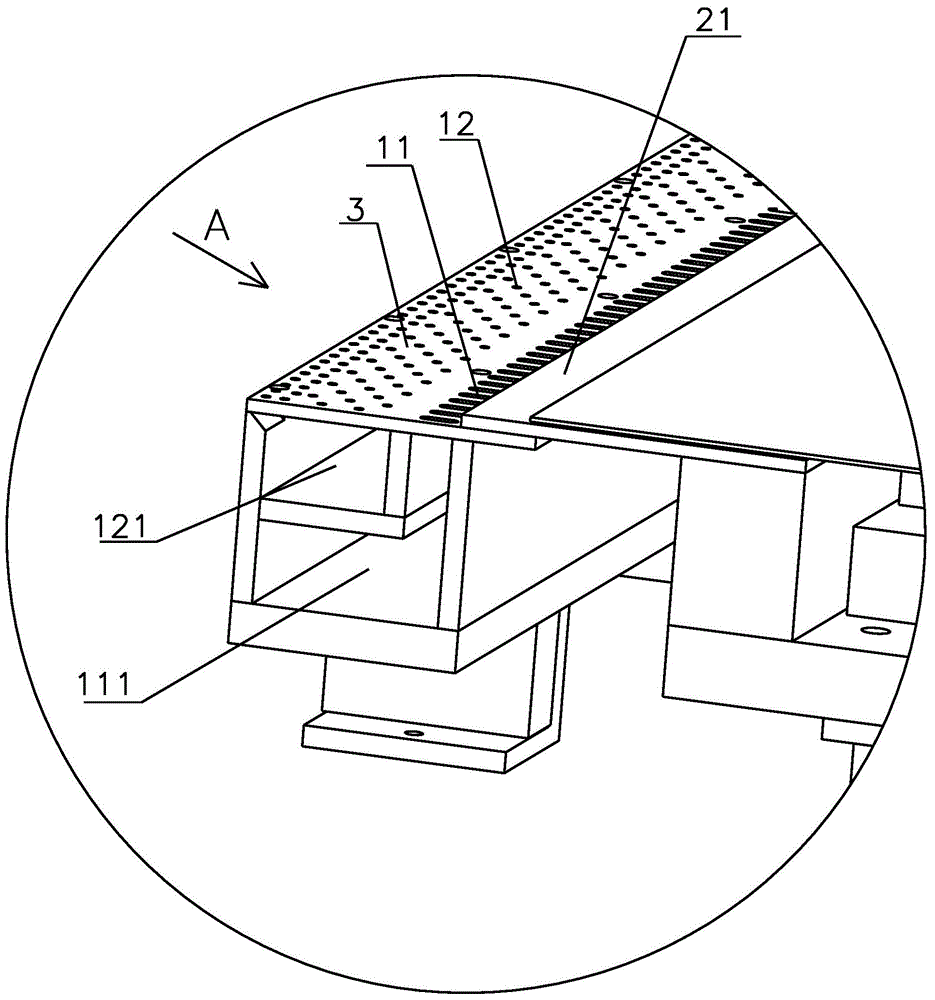

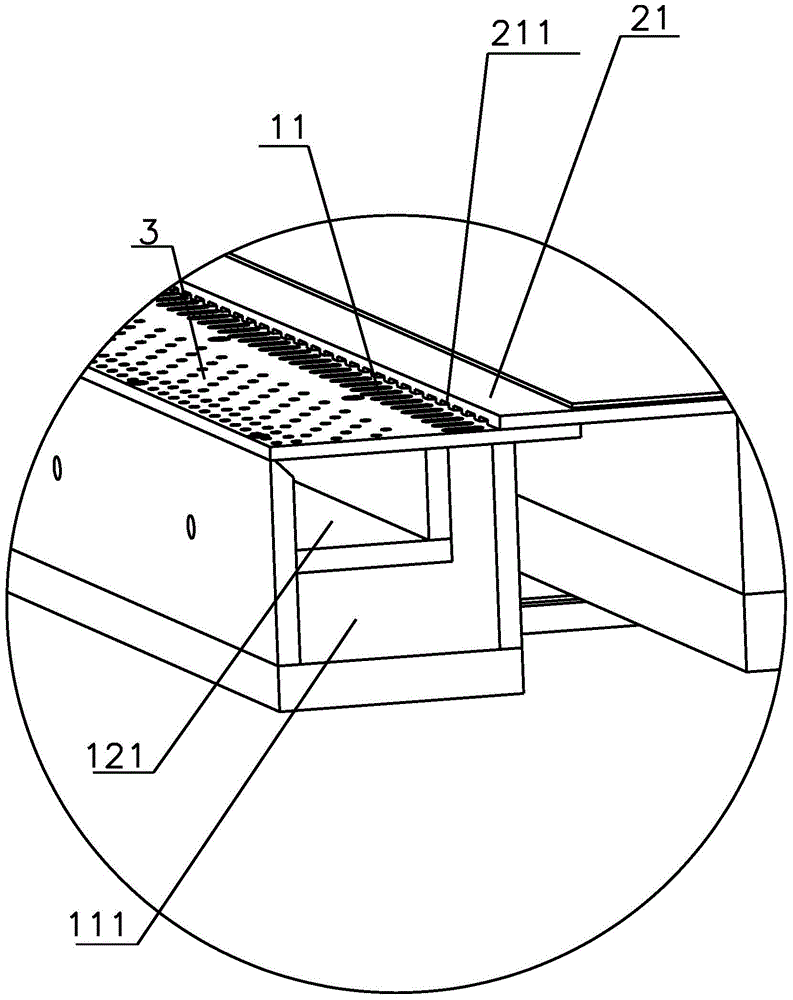

[0043] Such as figure 1 , 2 , 7, a shirt lining machine automation equipment, including a workbench 1 and a hemming mechanism embedded in the workbench 1, the hemming mechanism includes a table panel 3, the upper surface of the workbench 1 and the upper surface of the table panel 3 The surface is even, and the table panel 3 is provided with a first lower air suction area formed by a plurality of lower air suction through holes 12, and a lower air suction chamber 121 communicating with the lower air suction through holes 12 is provided below the table plate 3 , the lower suction air chamber 121 is connected with the suction device, and the right side of the first lower suction area on the table panel 3 is provided with a row of side suction through holes 11. The cover plate 21 of the hole 11, the lower surface of the cover plate 21 is provided with a groove 211, the notch of the groove 211 faces the side suction through hole 11 and covers the side suction through hole 11, and ...

Embodiment 2

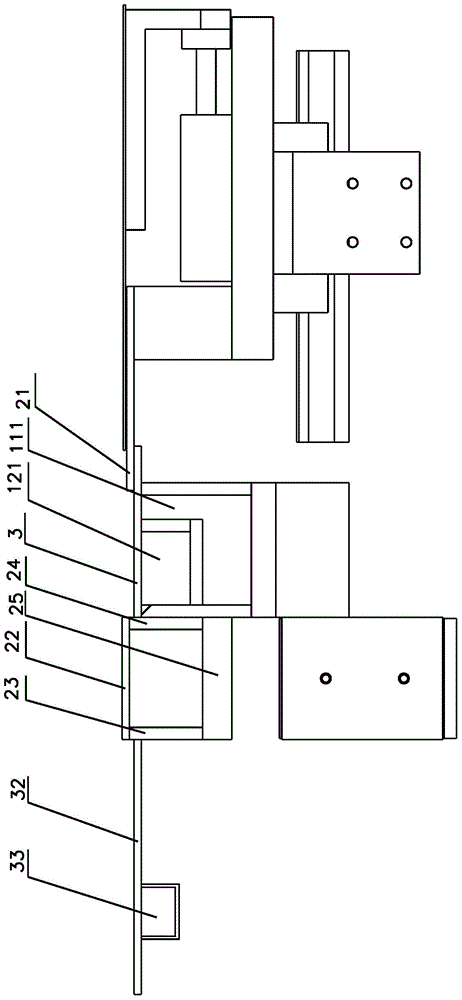

[0046] Such as Figure 3-6 As shown, it is the second embodiment of the present invention, a shirt lining machine automation equipment. On the basis of the first embodiment, the hemming mechanism also includes a side suction that is close to the left side of the table panel 3 and can move up and down. device, the side suction device includes a cuboid-shaped chamber surrounded by a flat plate 22, a left side plate 23, a right side plate 24 and a bottom plate 25, wherein the flat plate 22 is located at the top and can move up and down with the side suction device After being flush with the table panel 3, the upper end faces of the left side plate 23 and the right side plate 24 are fixed on the lower surface of the flat plate 22, and the lower end faces of the left side plate 23 and the right side plate 24 are fixed on the upper surface of the base plate 25, and the right The side plate 24 is close to the left side of the table panel 3, and the upper end surface of the right side...

Embodiment 3

[0062] Such as Figure 7-9 As shown, a shirt lining machine automation equipment, on the basis of the second embodiment, the cover plate 21 will be slightly higher than the surface of the table panel 3, so the groove 211 is actually a small gap, because the hem height of the inner skirt It is very small and can be adjusted as required. The horizontal mop device is installed on the left side of the sewing panel 32, the sewing machine head 5 is installed on the upper surface of the workbench 1, and the left side of the sewing panel 32 is equipped with The X-direction track 31, the transverse mopping device includes a slide plate 41, an L-shaped connecting block 42, a Z-direction cylinder 43 and a Y-direction cylinder 44 that can slide back and forth on the X-direction track 31, and the Z-direction cylinder 43 is fixed on the slide plate 41. One end of the shape connection block 42 is connected with the extended end of the cylinder 43 in Z, the other end of the L shape connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com