Improved gear oil immersion equipment

A gear and oil immersion technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of high randomness, difficult to guarantee the quality of oil immersion, and increase the labor intensity of workers, so as to reduce labor intensity and reduce oil immersion. Good effect and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

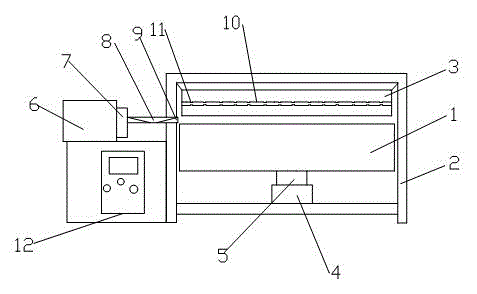

[0015] Such as figure 1 As shown, an improved gear oil immersion equipment of the present invention includes an oil tank 1 and a bracket 2 for supporting the oil tank 1. The oil tank 1 can move up and down along the bracket 2. Above the oil tank 1, there is a The gear shelf 3, the bottom of the oil tank 1 is provided with a driving device for driving the oil tank 1 to move up and down, the driving device includes a cylinder A4 and a cylinder arm A5, and the cylinder arm A5 is in contact with the bottom of the oil tank 1. The up and down movement of A4 then drives the tank body 1 to move up and down to complete the oil immersion operation, which is beneficial to reduce the work intensity of the staff and improve work efficiency. The lifting time of the cylinder A4 is controlled by the electric control box 12, so as to accurately control the soaking time of the gears and obtain a relatively stable and better oil soaking effect.

[0016] In order to save resources, and also to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com