Automobile brake pad steel backing oil immersion device

A technology of brake pads and oil immersion, which is applied to the device and coating of the surface coating liquid, can solve the problems of increased oil immersion cost, inability to remove, and oil waste, etc., and achieves oil immersion cost saving and oil immersion effect. Good, reduce waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

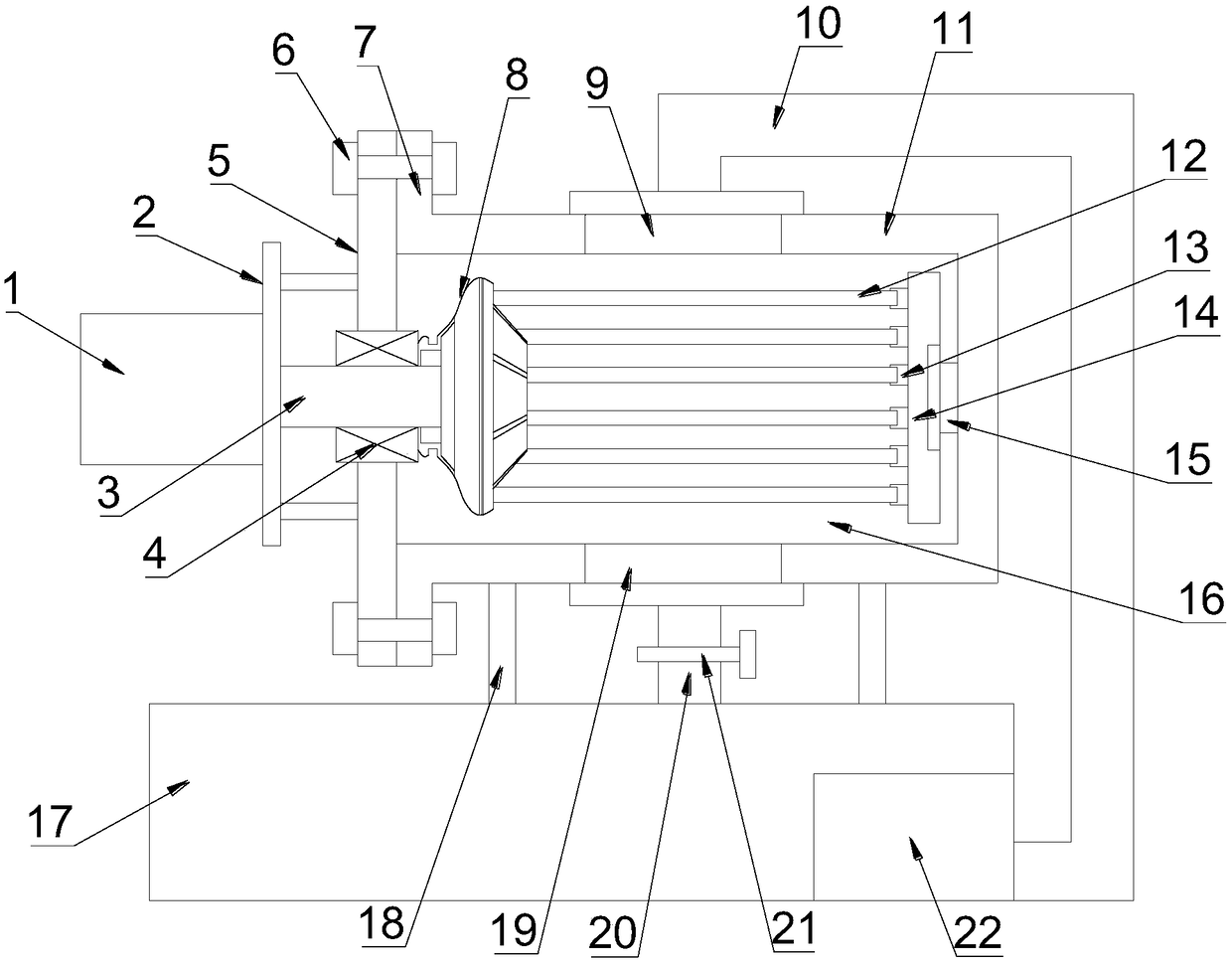

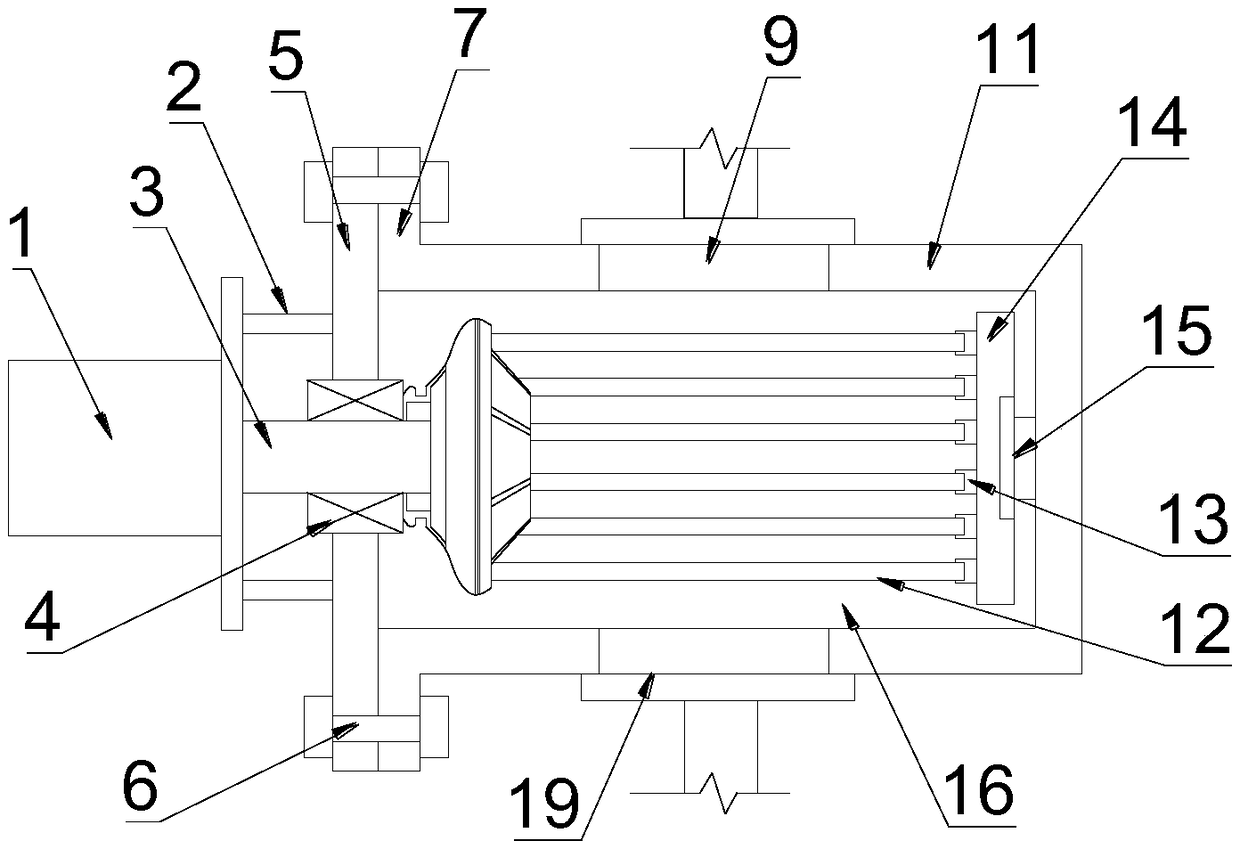

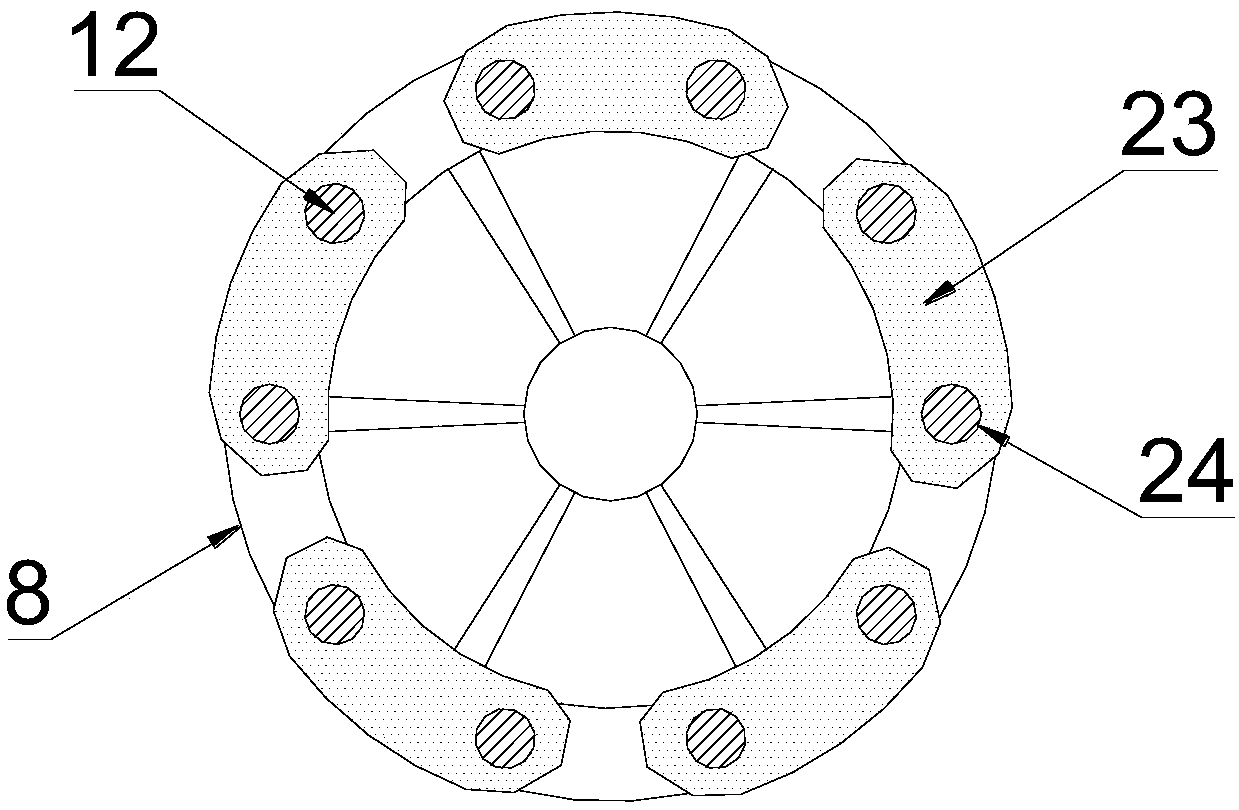

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] see Figure 1-4 , a steel back oil immersion device for automobile brake pads, comprising a sealing cover 5, a rotating drum 8, an oil immersion cylinder 11, an oil immersion rod 12, a rotating disk 14, an oil storage tank 17, an oil pump 22 and a separation sleeve 25, the oil immersion The cylinder 11 is fixed on the top of the oil storage tank 17 through a bracket 18. A flange 7 is welded at one end of the oil-soaked cylinder 11, and the flange 7 is connected to the sealing cover 5 through bolts 6. The connection between the sealing cover 5 and the flange 7 A sealing gasket is provided between them to enhance the sealing performance between the two. The middle part of the sealing cover 5 is provided with a mechanical seal 4, and the drive shaft 3 is mounted inside the mechanical seal 4. The outer end of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com