Circulating type feed crushing device

A crushing device and circulating technology, which is applied in the field of circulating feed crushing devices, can solve the problems of poor processing refinement and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

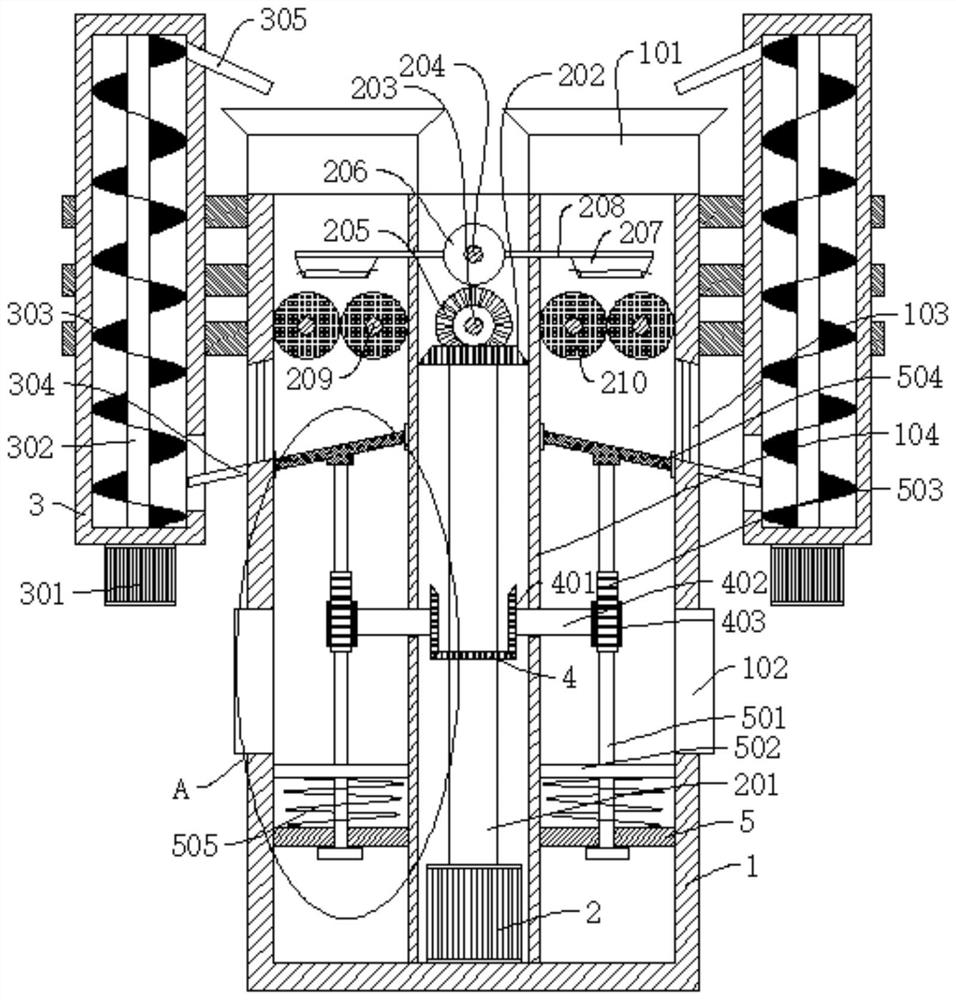

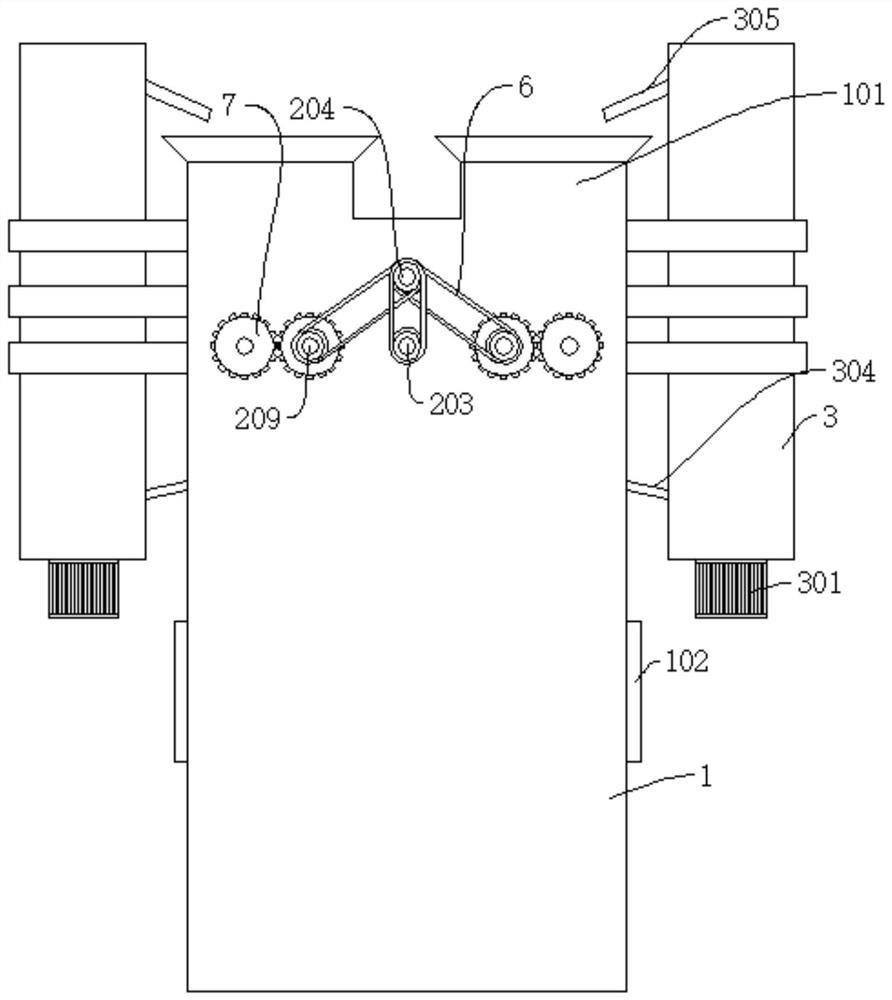

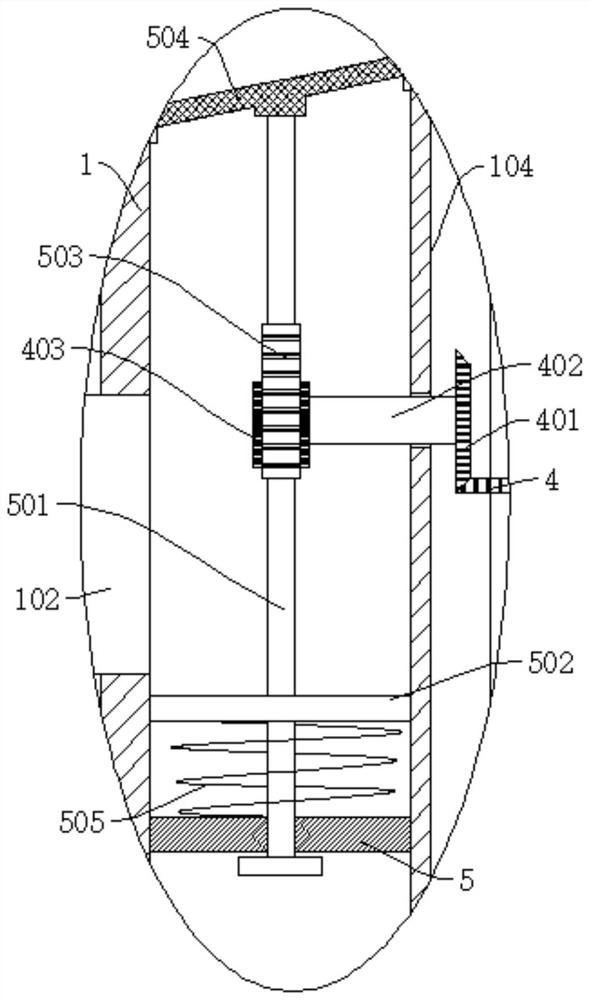

[0024] Reference Figure 1-5 , A circulating feed crushing device, comprising a box body 1, the top of the box body 1 is connected with a feeding port 101, the side wall of the box body 1 is connected with a discharge port 102, and the box body 1 is fixedly connected with two partitions 104, two A partition 104 divides the box 1 into three mutually independent cavities, the inner cavity includes a power cavity between the two partitions 104 and a crushing cavity between the two partitions 104 and the box 1; the crushing device also It includes two sets of crushing rollers 210, the two sets of crushing rollers 210 are respectively rotatably connected in two crushing cavities; a filter screen 504 is used to connect in the two crushing cavities and is located below the two sets of crushing rollers 210; a feeding box 3 , Fixedly connected to the side wall of the box body 1, the conveying box 3 is connected with upwardly conveying material conveying components, and the side wall of ...

Embodiment 2

[0027] Reference Figure 1-5 , A circulating feed crushing device, comprising a box body 1, the top of the box body 1 is connected with a feeding port 101, the side wall of the box body 1 is connected with a discharge port 102, and the box body 1 is fixedly connected with two partitions 104, two A partition 104 divides the box 1 into three mutually independent cavities, the inner cavity includes a power cavity between the two partitions 104 and a crushing cavity between the two partitions 104 and the box 1; the crushing device also It includes two sets of crushing rollers 210, the two sets of crushing rollers 210 are respectively rotatably connected in the two crushing cavities; a filter screen 504 is used to connect in the two crushing cavities and is located below the two sets of crushing rollers 210; a feeding box 3 , Fixedly connected to the side wall of the box body 1, the conveying box 3 is connected with upwardly conveying material conveying components, and the side wall...

Embodiment 3

[0032] Reference Figure 1-5 , A circulating feed crushing device, comprising a box body 1, the top of the box body 1 is connected with a feeding port 101, the side wall of the box body 1 is connected with a discharge port 102, and the box body 1 is fixedly connected with two partitions 104, two A partition 104 divides the box 1 into three mutually independent cavities, the inner cavity includes a power cavity between the two partitions 104 and a crushing cavity between the two partitions 104 and the box 1; the crushing device also It includes two sets of crushing rollers 210, the two sets of crushing rollers 210 are respectively rotatably connected in the two crushing cavities; a filter screen 504 is used to connect in the two crushing cavities and is located below the two sets of crushing rollers 210; a feeding box 3 , Fixedly connected to the side wall of the box body 1, the conveying box 3 is connected with upwardly conveying material conveying components, and the side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com