Drying and screening device used before soil improvement

A soil improvement and screening device technology, applied in the directions of drying gas arrangement, sieving, drying, etc., can solve the problems of reducing soil quality and failing to achieve complete separation of soil and impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

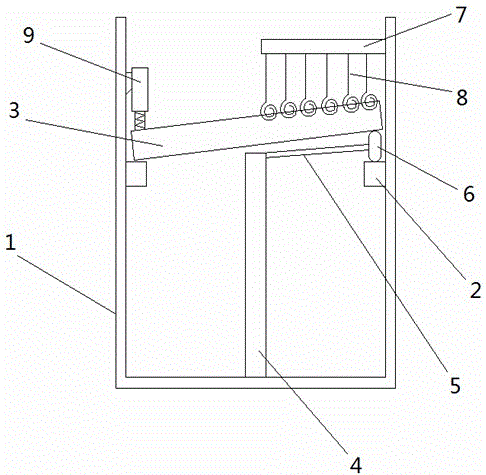

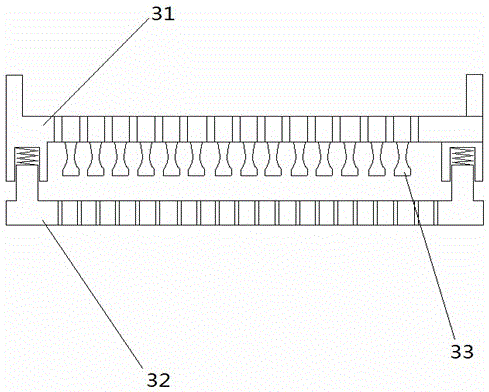

[0038] As shown in the figure, a drying and screening device before soil improvement includes a cylinder structure 1, an annular step 2 is arranged on the inner wall of the cylinder structure 1, and a circular filter screen 3 is arranged on the annular step 2 to filter The size and diameter of the sieve 3 is the same as that of the annular step 2, and there are some holes evenly distributed on the filter sieve 3;

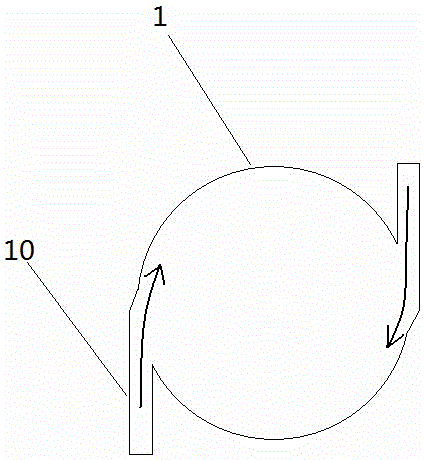

[0039] The active rotating rod 4 and the driven rotating rod 5 are arranged in the cylinder structure 1. One end of the driving rotating rod 4 and one end of the driven rotating rod 5 are connected and perpendicular to each other to form a "7" shape. The other end of the driving rotating rod 4 Connect the central position of the inner bottom of the cylinder structure 1 to realize rotation. The other end of the driven ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com