Powder coating grinding equipment

A powder coating and equipment technology, applied in the field of powder coating grinding equipment, can solve problems such as waste of raw materials, adhesion, etc., to achieve the effect of avoiding waste, accelerating the falling speed, and realizing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further described in detail through specific implementation methods:

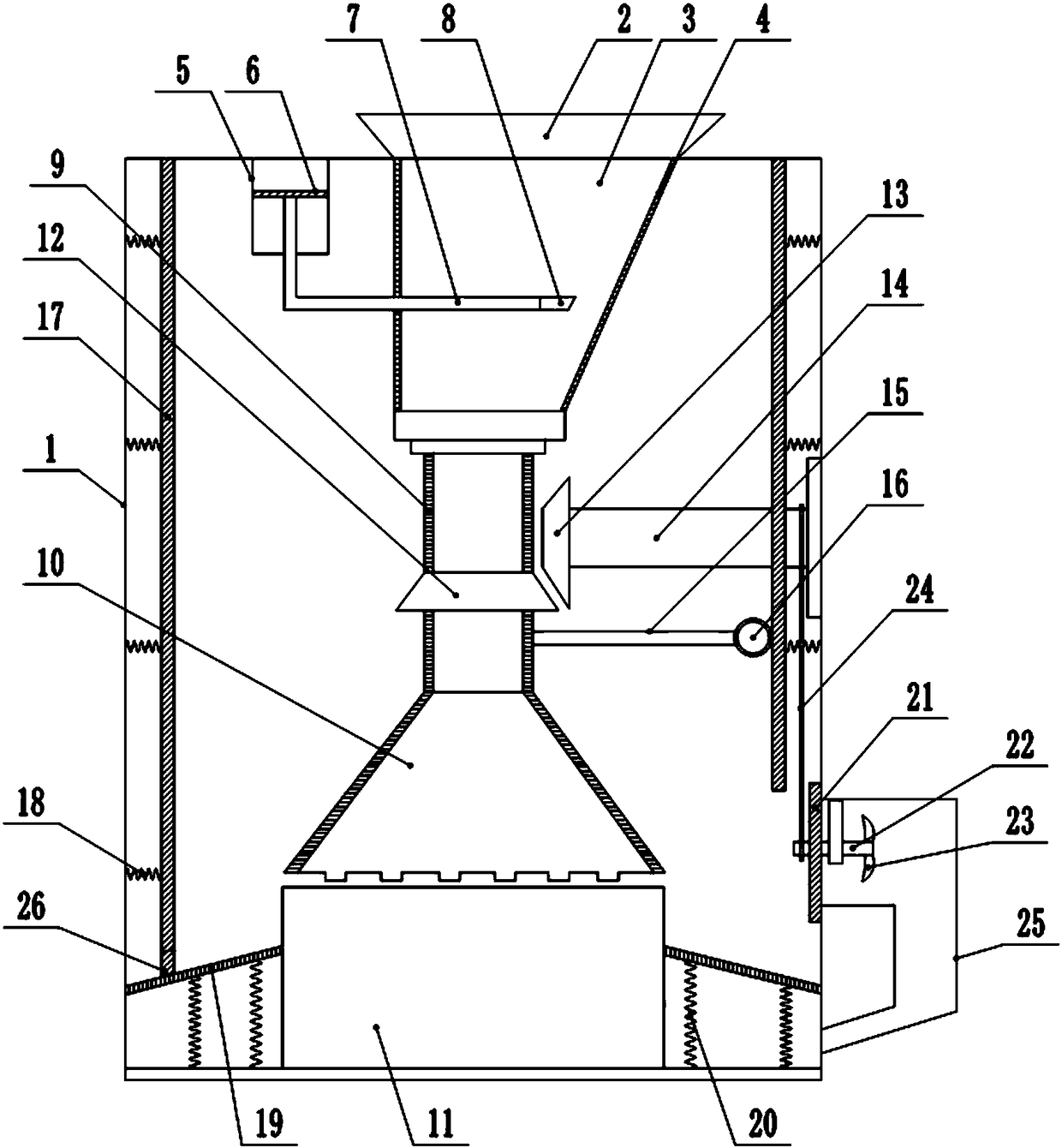

[0018] The reference signs in the drawings of the description include: grinding box 1, feed hopper 2, feed channel 3, inclined side wall 4, cylinder 5, piston 6, feeding rod 7, second wedge block 8, feeding tube 9. Upper grinding disc 10, lower grinding disc 11, first bevel gear 12, second bevel gear 13, horizontal shaft 14, push rod 15, push ball 16, blanking plate 17, shaking spring 18, filter plate 19, support Spring 20, filter screen 21, drive shaft 22, rotating blade 23, belt 24, discharge box 25, first wedge block 26.

[0019] The embodiment is basically as attached figure 1 Shown: grinding equipment for powder coatings, including a grinding box 1, a feeding mechanism and a driving mechanism. The feeding mechanism includes a feeding hopper 2 located on the top of the grinding box 1. The feeding hopper 2 is connected with a feeding channel 3, and the feeding channel The left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com