Cabinet type clothes dryer control method and cabinet type clothes dryer

A control method and clothes dryer technology, which are applied to household clothes dryers, textiles, papermaking, washing devices, etc., can solve the problems of poor wrinkle removal effect, stiff clothes, poor user experience, etc., and achieve good wrinkle removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

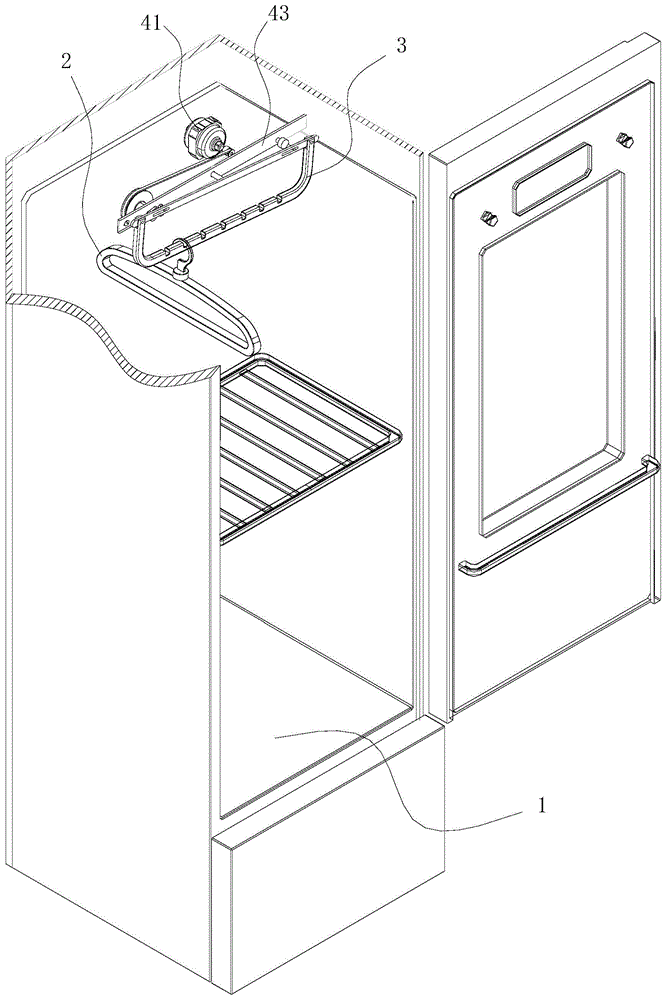

[0029] The preferred embodiment discloses a control method for a cabinet-type clothes dryer and a cabinet-type clothes dryer for realizing the control method. The control method is to apply force in the up and down direction to the item to be dried, make the item to be dried reciprocate in the up and down direction, and shake the item to speed up the drying speed and eliminate the wrinkles of the item to be dried. Among them, the "up and down direction" is only a concept of relative position, not a specific limitation on the method; and "reciprocating motion in the up and down direction" can be the movement with only the up and down direction, or it can have both the up and down direction motion component and the horizontal plane Movement component.

[0030] The items to be dried in the cabinet dryer (mainly including clothes, bed sheets, quilt covers, quilts, etc.) are usually suspended vertically, and the wrinkles are stretched by their own gravity during the drying process....

Embodiment 2

[0040] This preferred embodiment discloses a control method for a cabinet-type clothes dryer and a cabinet-type clothes dryer for realizing the control method. The control method is basically the same as that of the preferred embodiment 1, but the specific procedure and shaking frequency of the control method are not limited, as long as an up-down force can be applied to the item to be dried during the drying process to make it reciprocate in the up-down direction.

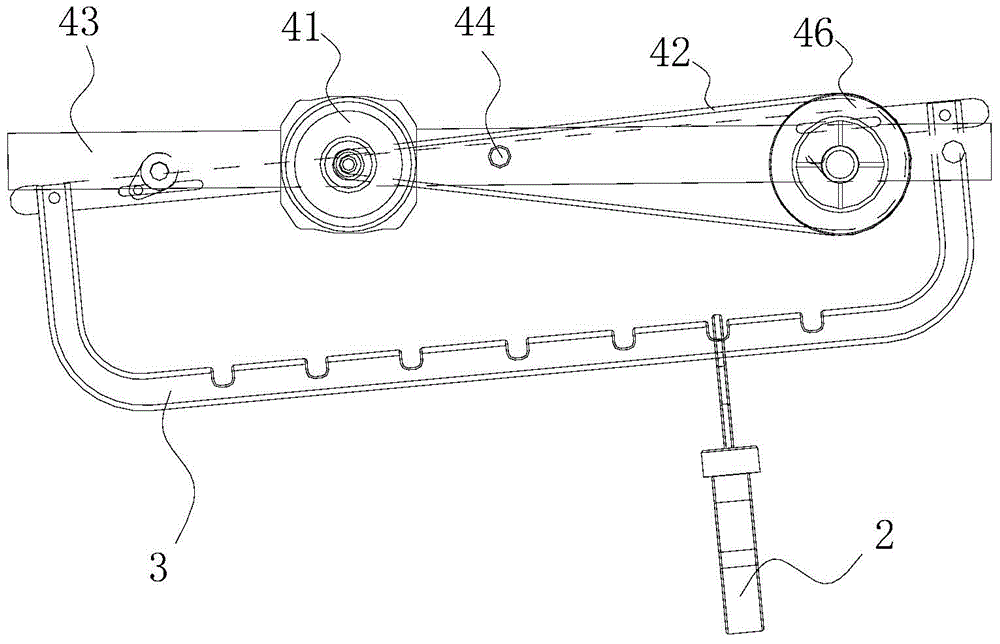

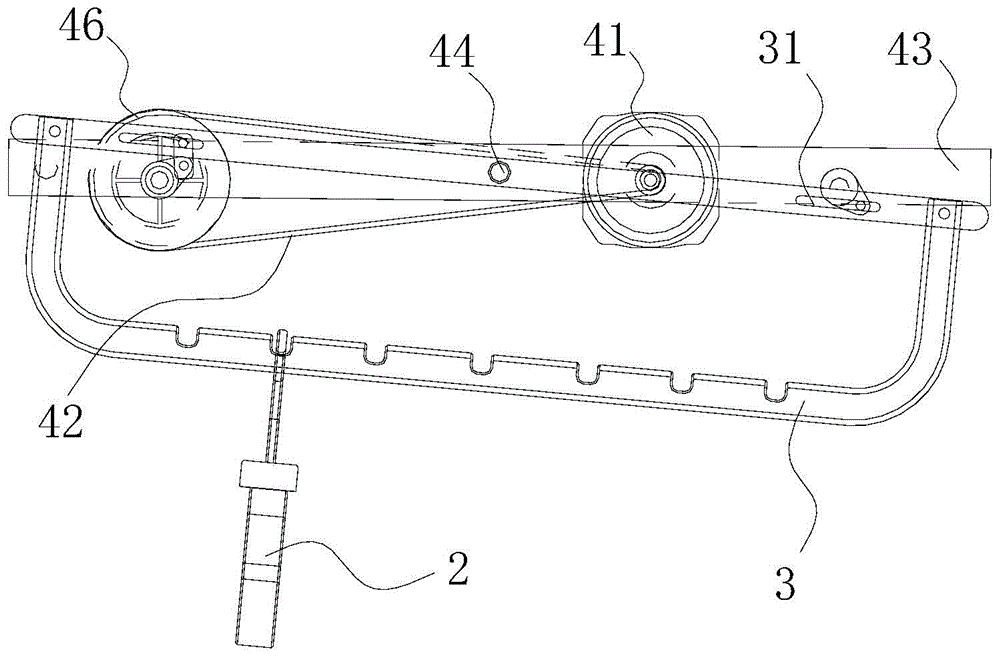

[0041] The structure of the cabinet type clothes dryer used to realize the above control method is basically the same as that of the preferred embodiment 1, including a hollow cabinet body, a support rod for placing clothes hangers is arranged inside the cabinet body, a drive device is connected to the support rod, and the drive device The support rod can be driven to reciprocate in the up and down direction.

[0042]The difference is that the specific structure of the driving device is not limited, as long as it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com