Workpiece conveying device and machine tool

A technology of conveying device and workpiece, applied in metal processing machinery parts, manipulators, metal processing and other directions, can solve the problems of shortening the time required for workpiece conveying, shortening the moving time of the sliding body, hindering the acceleration and deceleration of the sliding body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

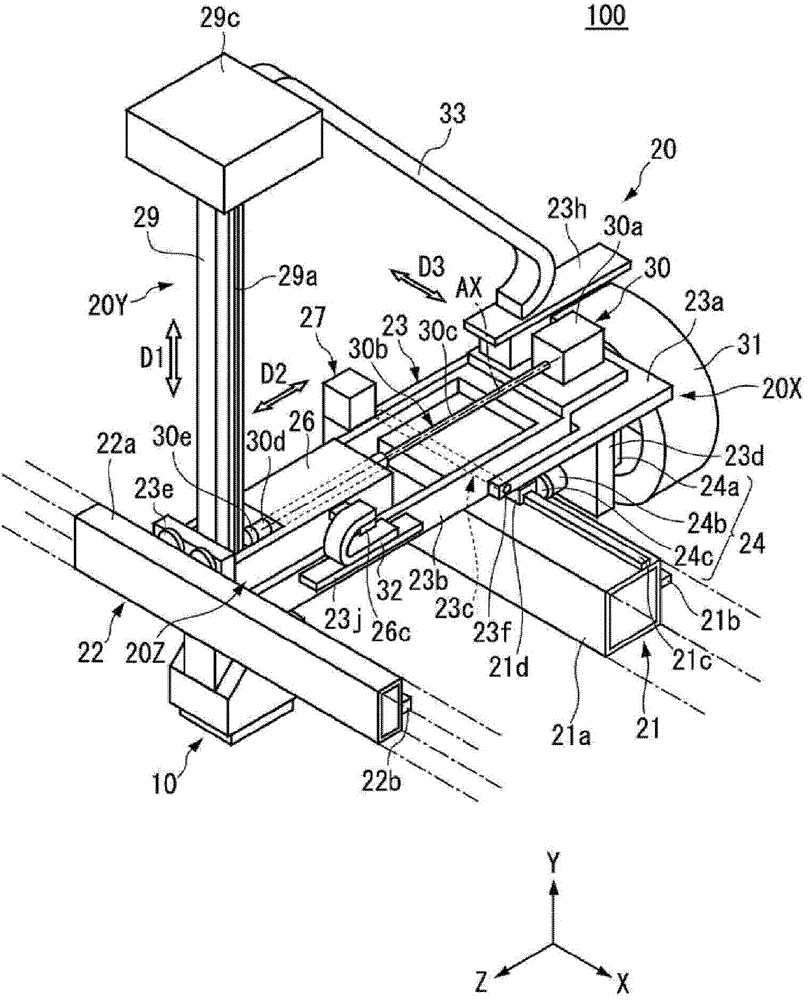

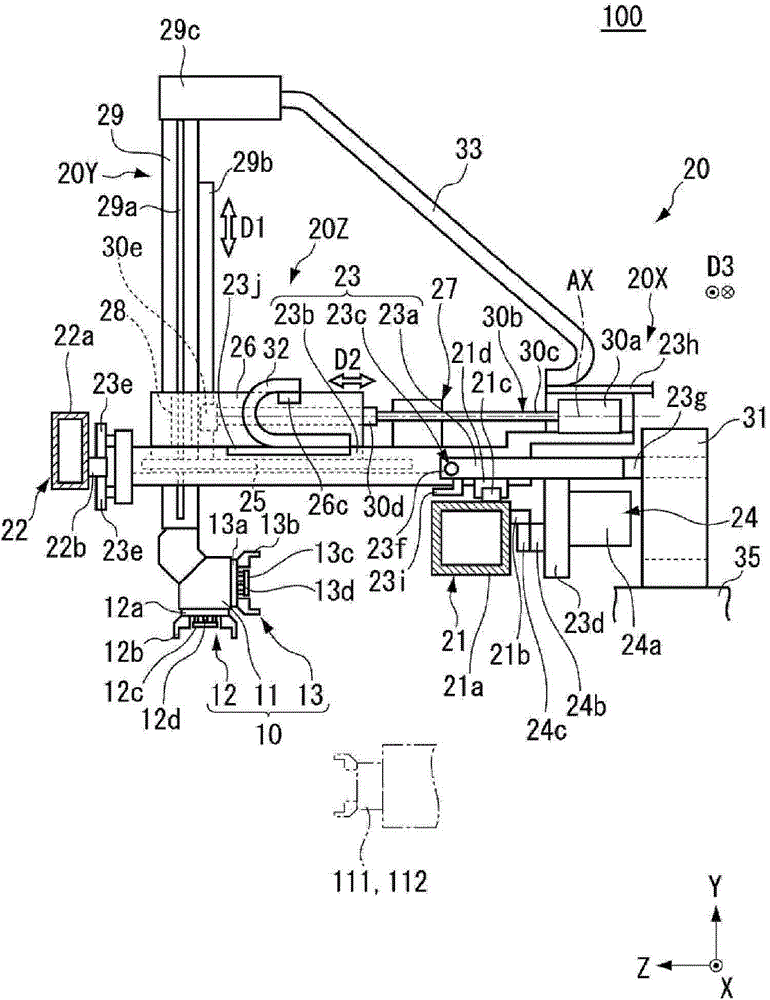

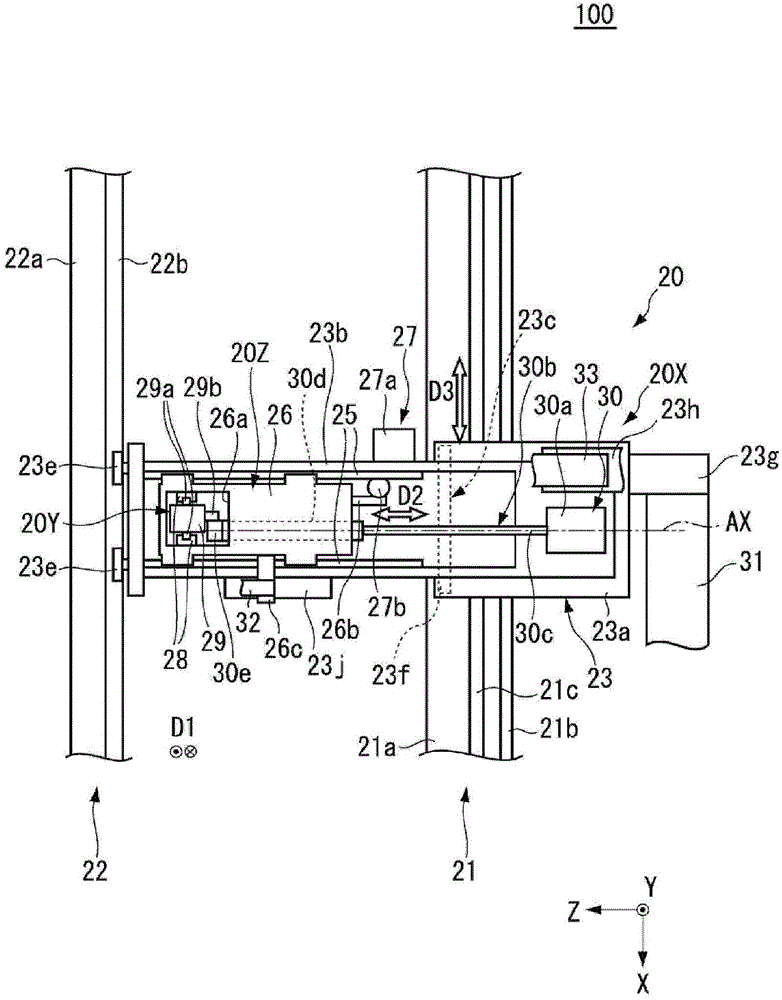

[0025] figure 1 It is a perspective view which shows an example of the workpiece conveyance apparatus 100 which concerns on 1st Embodiment. figure 2 It is a side view showing an example of the workpiece transfer device 100 . image 3 It is a plan view showing an example of the workpiece transfer device 100 . However, in order to easily identify the structure of the workpiece transfer device 100, for example, in Figure 1 ~ Figure 3 In , a part of the workpiece transfer device 100 is shown in cross section, or partially omitted from the illustration.

[0026] Such as Figure 1 ~ Figure 3 As shown, the workpiece transfer device 100 includes a workpiece holding unit 10 and a moving mechanism 20 . The workpiece transfer device 100 is used mounted on, for example, a machine tool described later, and the spindles 111, 112 ( figure 2 The workpiece W is conveyed between the dotted line in ) and the workpiece loading and unloading part (not shown).

[0027] Such as figure 2 A...

no. 2 Embodiment approach >

[0069] Next, a second embodiment will be described. In the second embodiment, a machine tool including the workpiece transfer device 100 described in the first embodiment will be described as an example. In the second embodiment, description will be made using the XYZ rectangular coordinate system common to the first embodiment. However, in the second embodiment, the direction of the rotation shafts of the main shafts 111 and 112 is referred to as the Z direction, and the direction for defining the cutting amount with respect to the workpiece W is referred to as the X direction.

[0070] Figure 8 It is a figure which shows an example of the machine tool 200 which concerns on 2nd Embodiment. Figure 8 The machine tool 200 shown is, for example, a parallel 2-axis lathe. exist Figure 8 In the figure, the +Z side of the machine tool 200 is the front side, and the −Z side is the back side. Also, the ±X sides of the machine tool 200 are side surfaces, and the X direction is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com