Mining system

A technology for mining machines and mineral deposits, applied in the field of mining systems, can solve problems such as uncontrolled mining areas and huge burdens, and achieve the effects of eliminating needs, simplifying ventilation, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

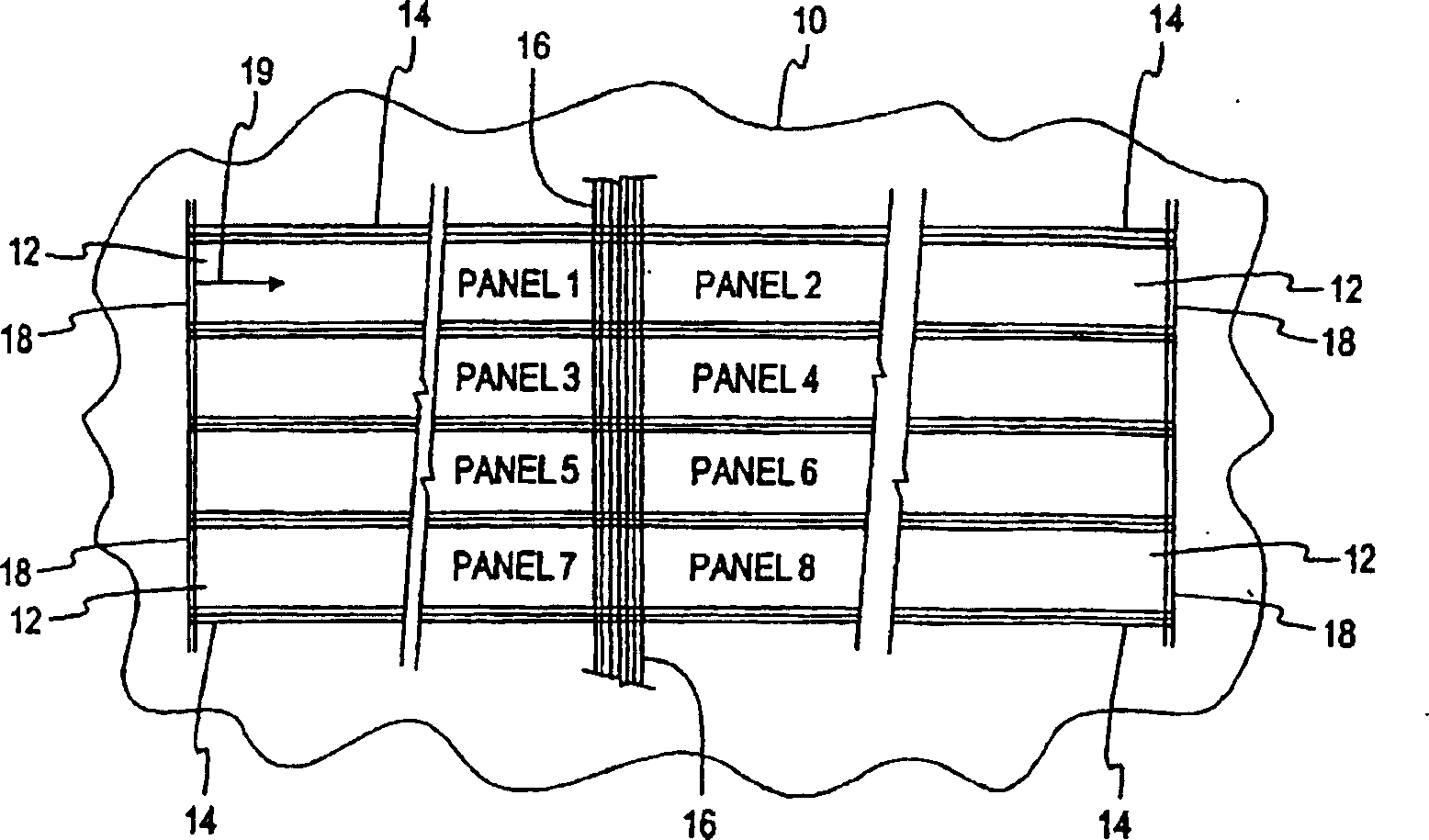

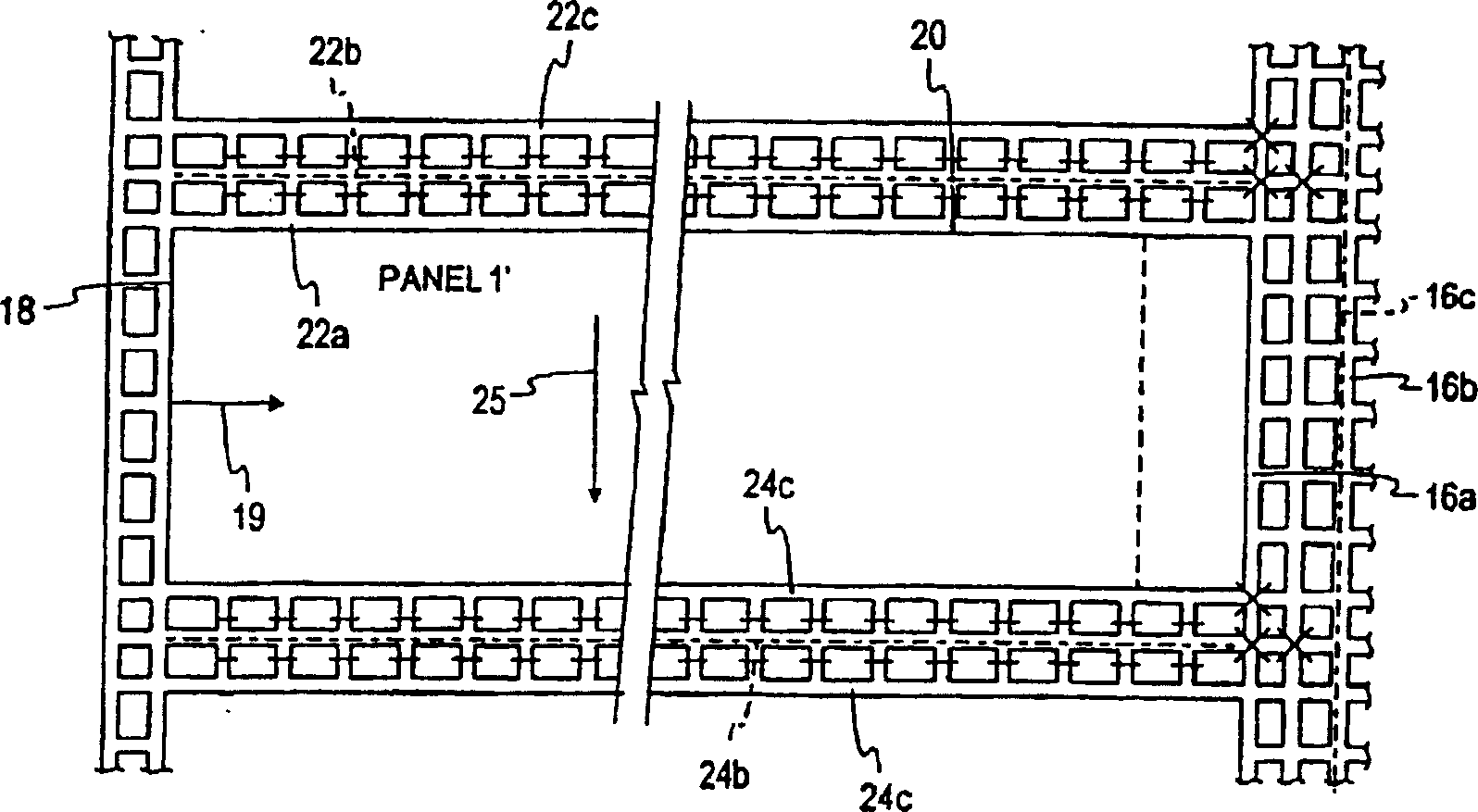

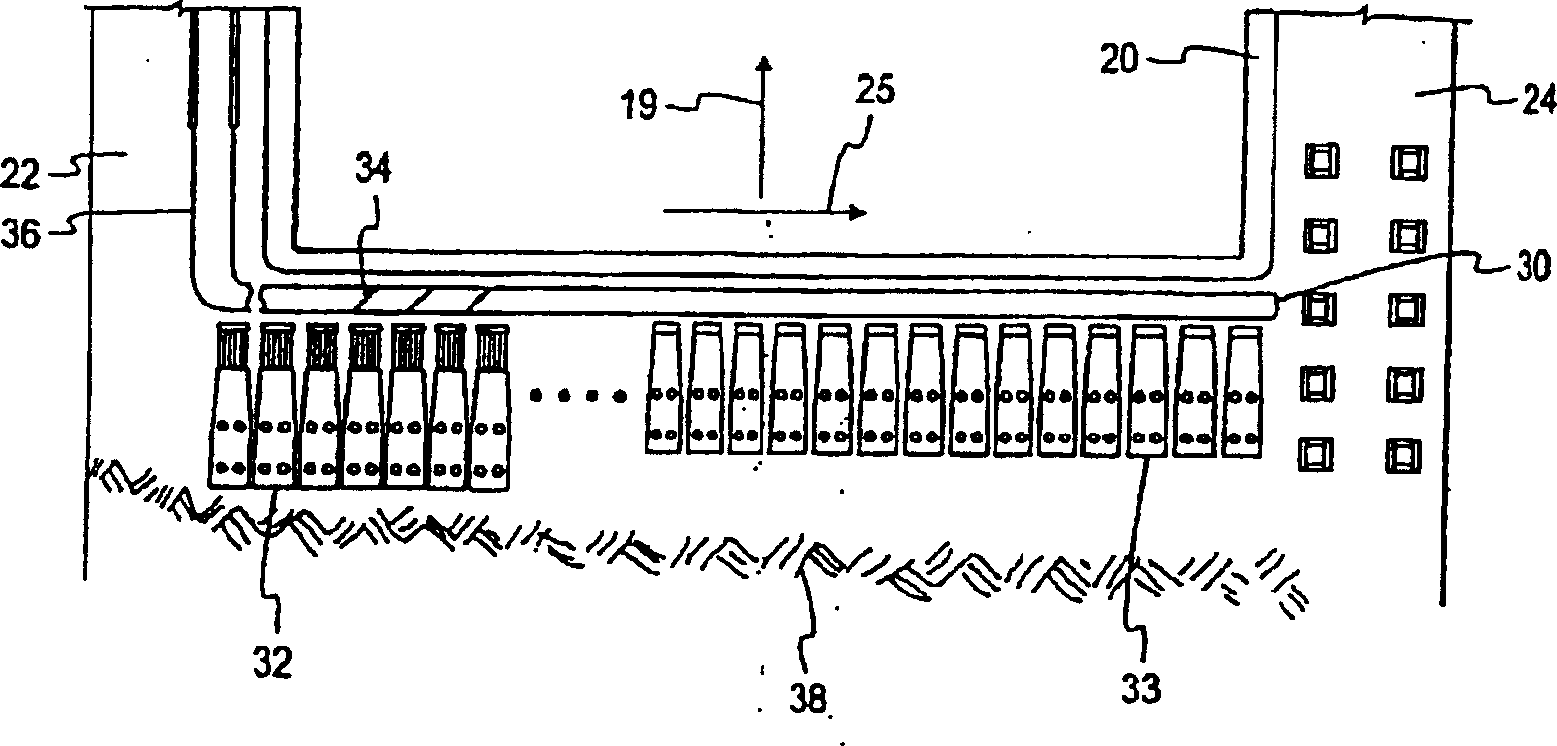

[0045] The present invention provides an economical and convenient mining system suitable for quick and efficient removal of ore deposits from deposits with a minimum of downtime. The ore deposit mining device and method combine open-pit strip mining with underground longwall or shortwall mining techniques. More specifically refer to Figure 5 The mining system of the present invention utilizes open pit strip mining to create stable sides 502 and stepped areas 503 around the deposit 501 to allow the mining system to be inserted underground. However, open-pit strip mining is implemented in stages: starting with zone A between lines a and aN, followed by zone B advancing to lines b and bN, followed by subsequent open-pit steep-slope strips, each strip increasing by approximately 200 feet to 500 feet to the end of deposit 501. Typically, the width of the stepped area 503 is between 80 and 100 feet.

[0046] Also refer to Figure 5a , the mining system begins constructing an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com