Special bucket for excavator

A technology for excavators and buckets, applied in the field of excavators, can solve the problems of reducing the effective bucket capacity of the bucket, prolonging the operation cycle time of the excavator, and the soil is not easy to unload and clean, so as to reduce the operation cycle time and improve the effective bucket capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

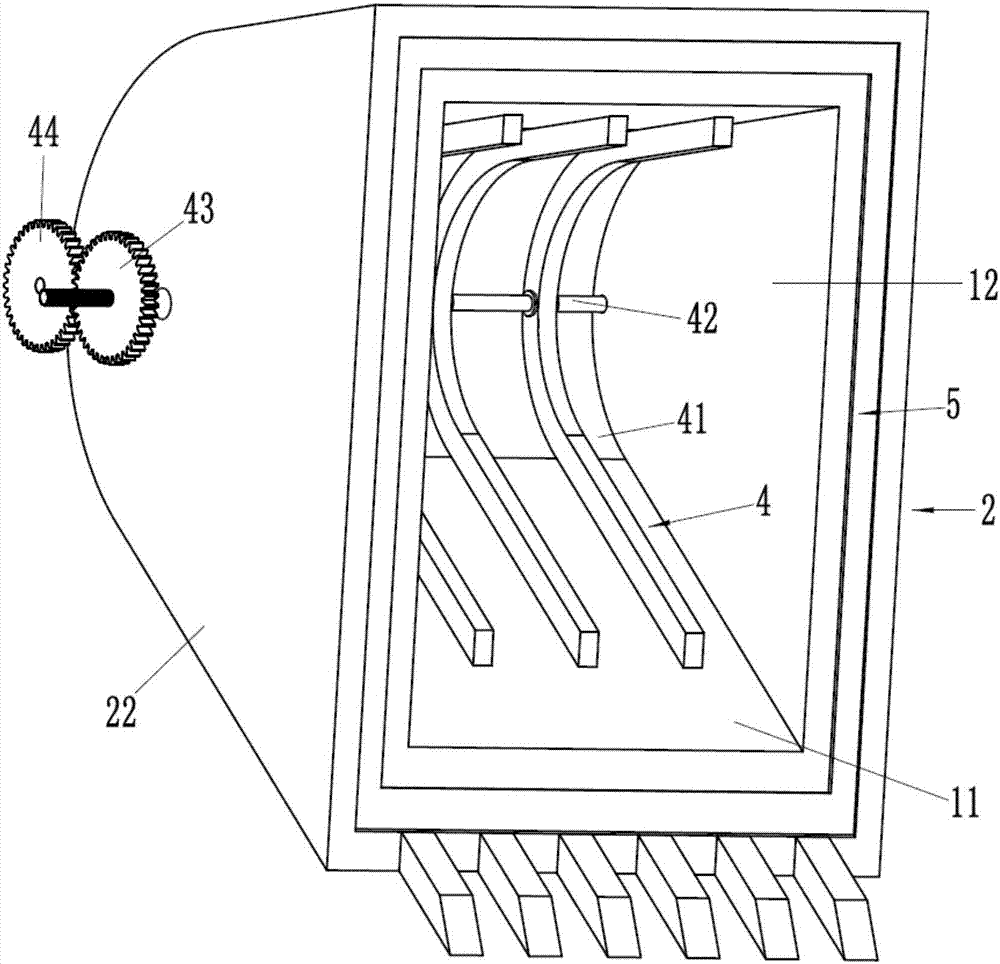

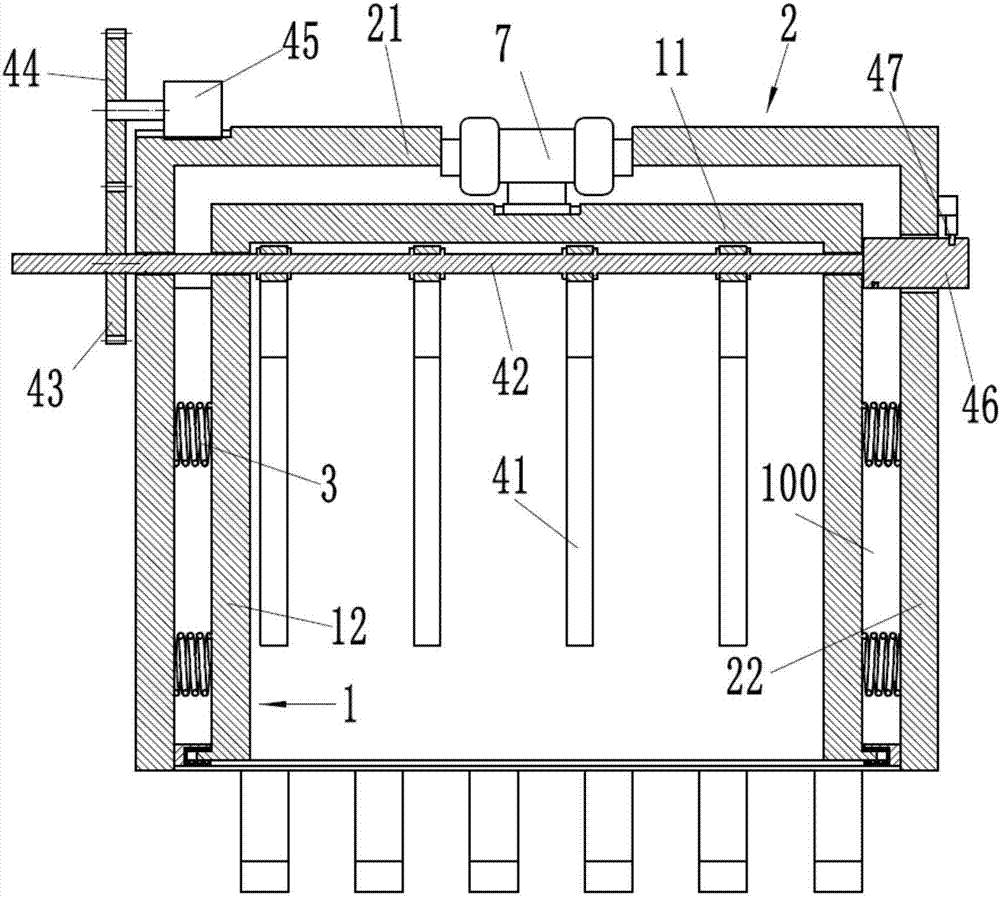

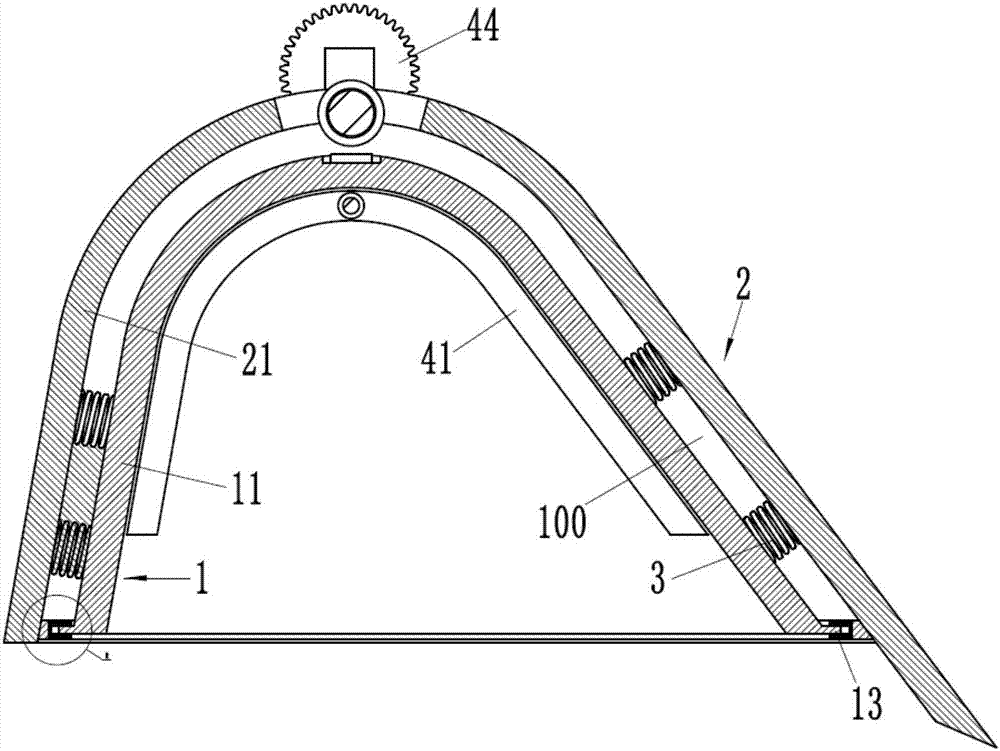

[0024] Examples, see e.g. Figure 1 to Figure 5 As shown, a special bucket for an excavator includes a built-in bucket 1 and an external bucket 2. The intermediate cavity 100 formed by the built-in bucket 1 and the external bucket 2 is provided with several springs 3, and the built-in bucket 1 is floatingly connected in the external bucket 2 by a spring 3, the interior of the internal bucket 1 is provided with a soil scraping mechanism 4, and the openings of the internal bucket 1 and the external bucket 1 are provided with a 100 to prevent soil from entering the middle cavity The seal 5.

[0025] Furthermore, the built-in bucket 1 includes a built-in bucket plate 11 and a pair of built-in side plates 12 fixed on both sides of the built-in bucket plate 11, and the external bucket 2 includes a built-in bucket plate 11 Corresponding external bucket board 21 and a pair of external side boards 22 fixed on both sides of the external bucket board 21, between the built-in bucket boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com