Multifunctional conveyor for unloading bulk cargos

A multi-functional conveying and conveying mechanism technology, applied in the direction of loading/unloading, transportation and packaging, etc., can solve the problems of high mechanical cost and maintenance cost, large dust human injury, high labor intensity, etc., to save labor and reduce operating costs , Easy to use and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

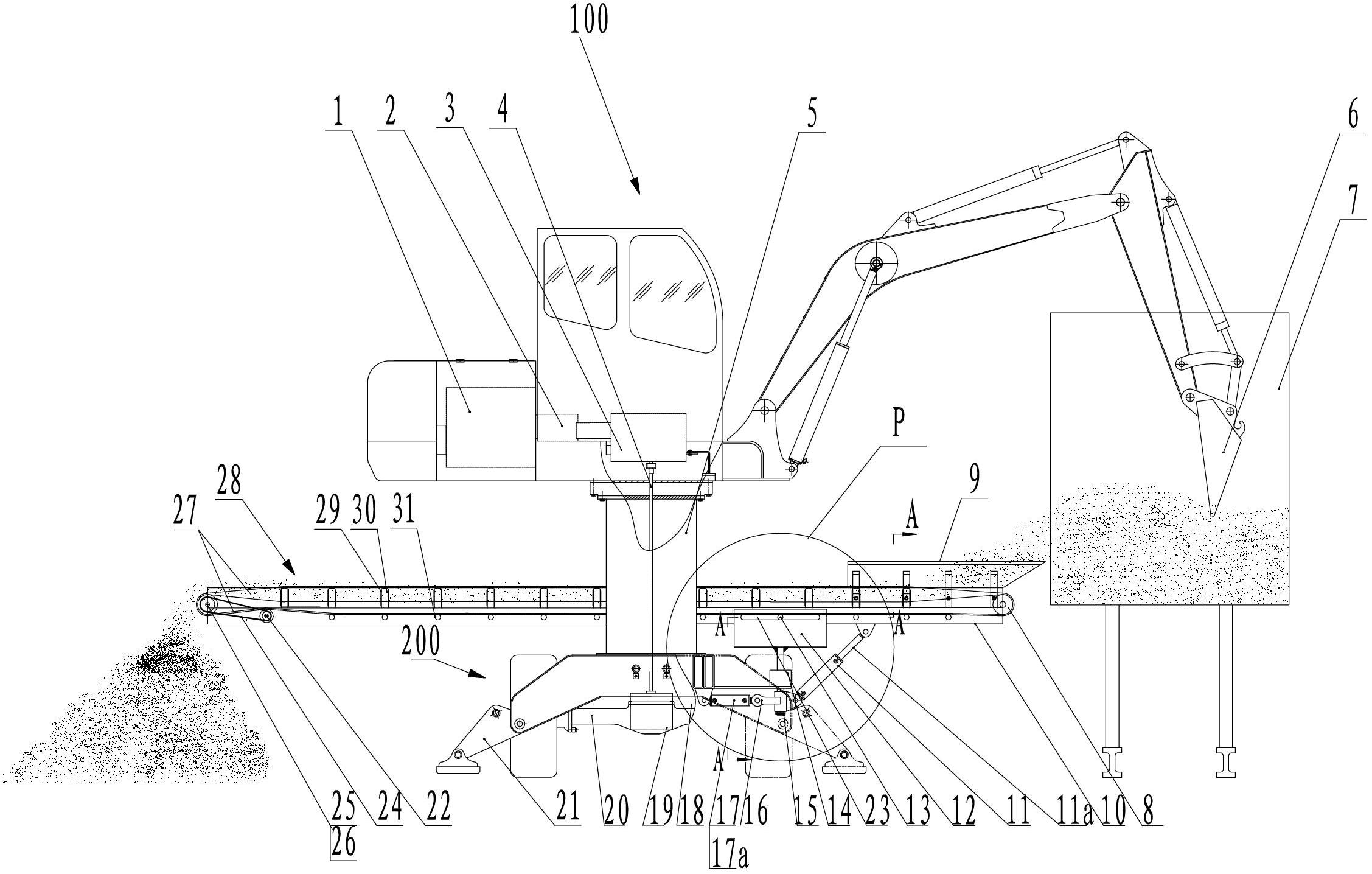

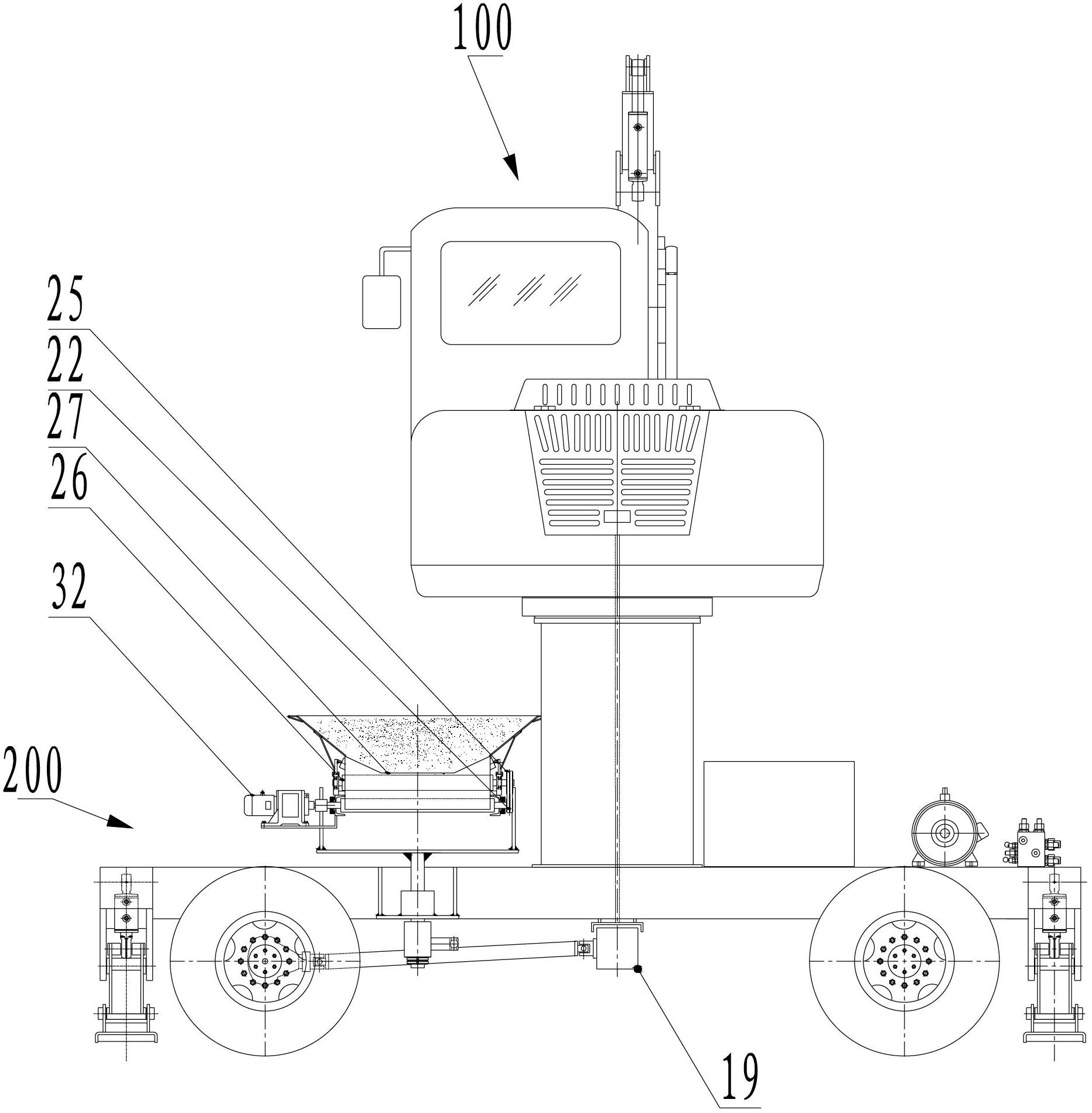

[0015] The present invention provides a multifunctional conveyor for unloading bulk goods. The multifunctional conveyor includes an excavator and a conveying mechanism 28.

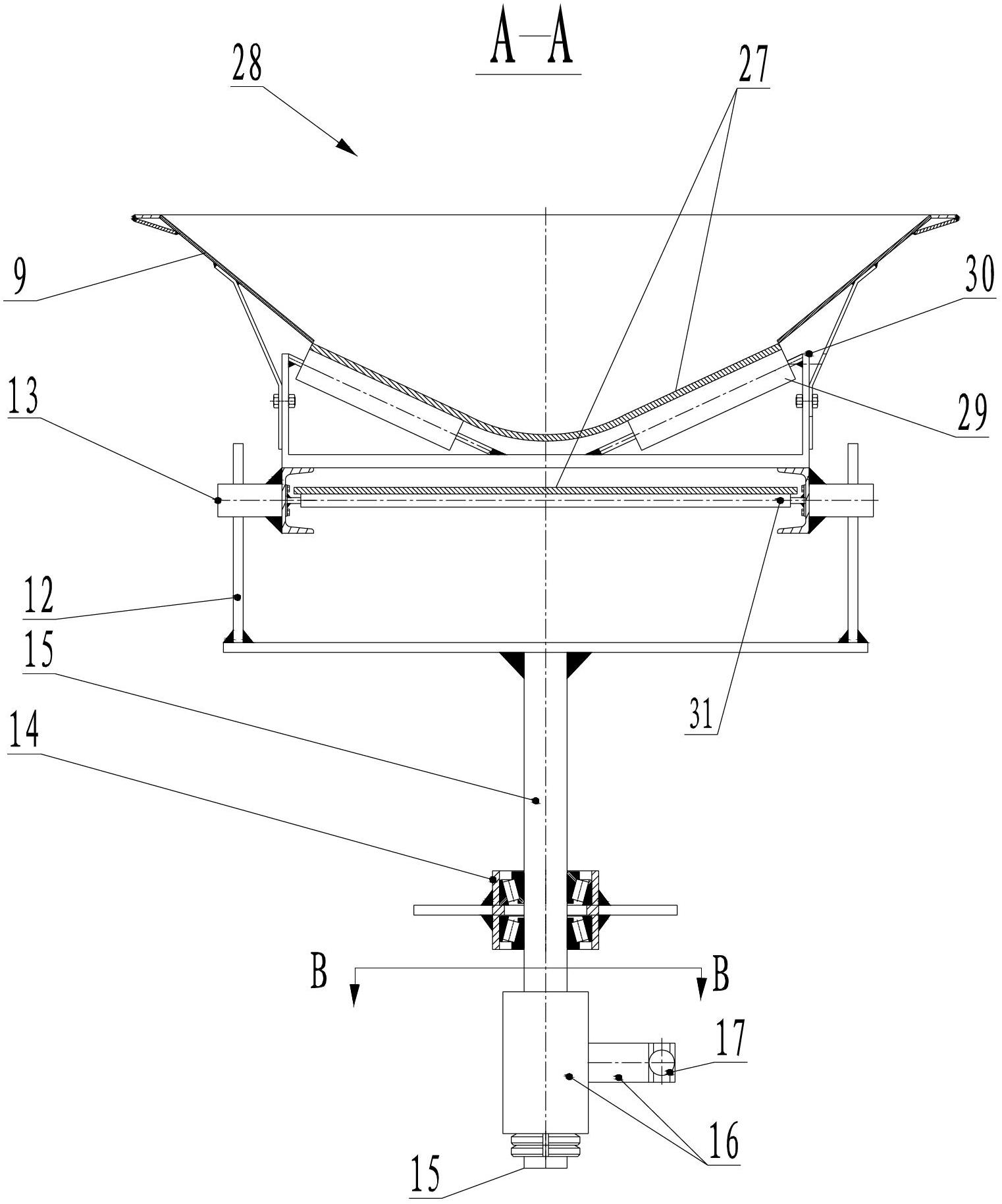

[0016] There is an extended drive shaft 4 between the excavator operating part 100 at the upper part of the excavator and the excavator underframe part 200 at the lower part of the excavator, and the extended drive shaft 4 is connected to the upper transfer case 3 of the excavator operating part 100 And the lower transfer case 19 of the excavator chassis part 200; the conveying mechanism 28 is arranged on the excavator chassis part 200 on the side of the long drive shaft 4, and the conveying mechanism 28 is respectively provided with The horizontal swing mechanism that drives the horizontal rotation and the back and forth movement up and down swing mechanism that moves back an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com