Underground blind tunnel ventilation system

A single-headed roadway and ventilation system technology, which is applied in the field of ventilation systems, can solve problems such as difficult discharge, increased equipment and maintenance costs, energy consumption, and greater safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

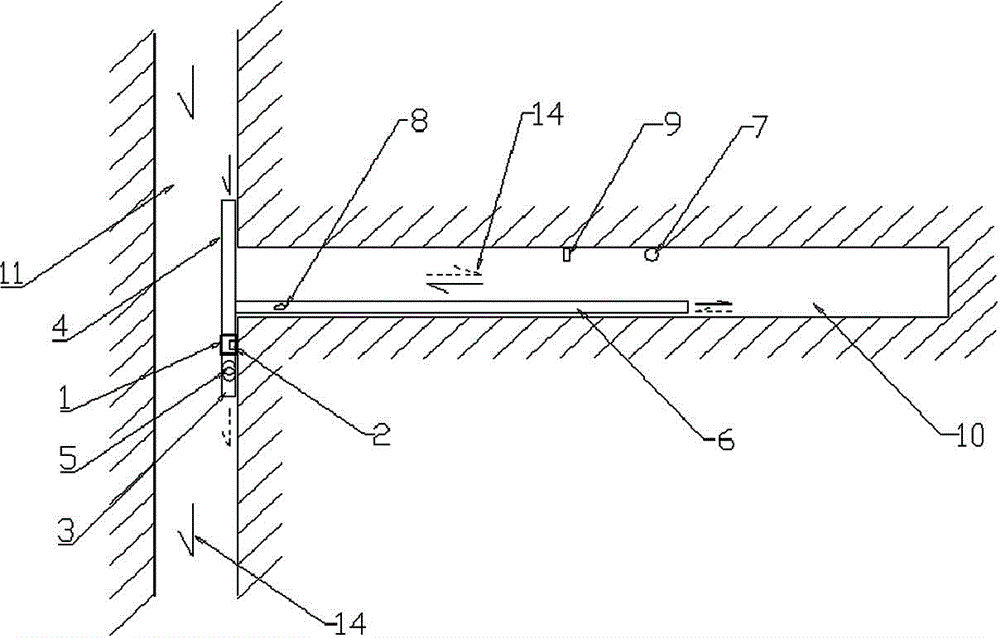

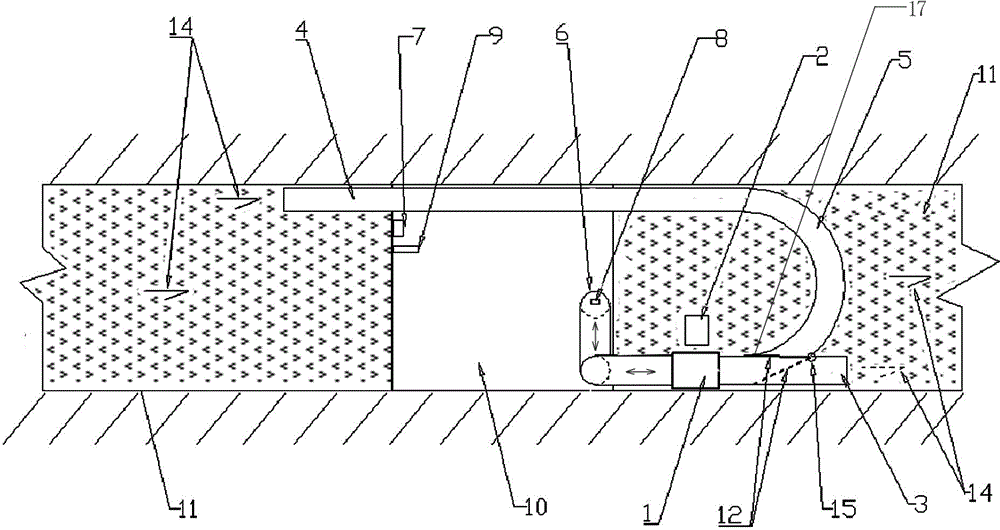

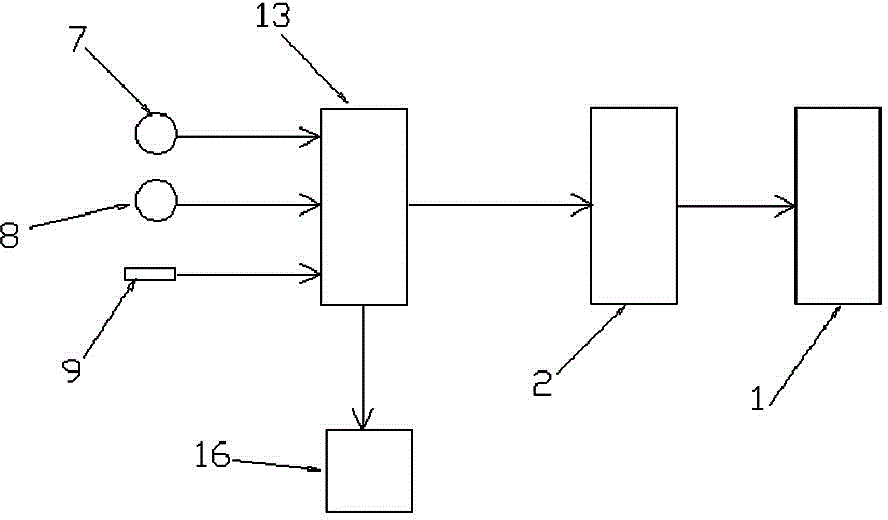

[0022] see figure 1 , figure 2 and image 3 . The system includes ventilation facilities and detection and control facilities.

[0023]The ventilation facilities include: in the side alley 11 outside the entrance of the single-ended alleyway 10, a local fan 1 is arranged, and one end of the local fan 1 is connected with a branch fan 3 and a branch fan 4, wherein the branch fan 4 passes through the bend The cylinder 5 is placed on the top of the horizontal alley 11, and extends across the single-headed alleyway 10 to the upstream air inlet direction of the wind flow. The outlet of the branch air cylinder 3 is located in the downstream return air direction of the air flow. Road conversion valve plate 12 and its valve plate rotating pair 15, the valve plate rotating pair 15 is equipped with a valve plate drive unit 16 connected with the fan control module 13; Nearby drainage duct 6;

[0024] The detection and control facilities include a smoke sensor 7 arranged in the singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com