Hot dip galvanizing equipment with smoke prevention and dust control thermal insulation device

A technology of smoke and dust removal and heat preservation device, applied in the metallurgical field, can solve the problems of heavy pollution and high energy consumption, and achieve the effects of easy operation and control, reducing production costs and solving heavy pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

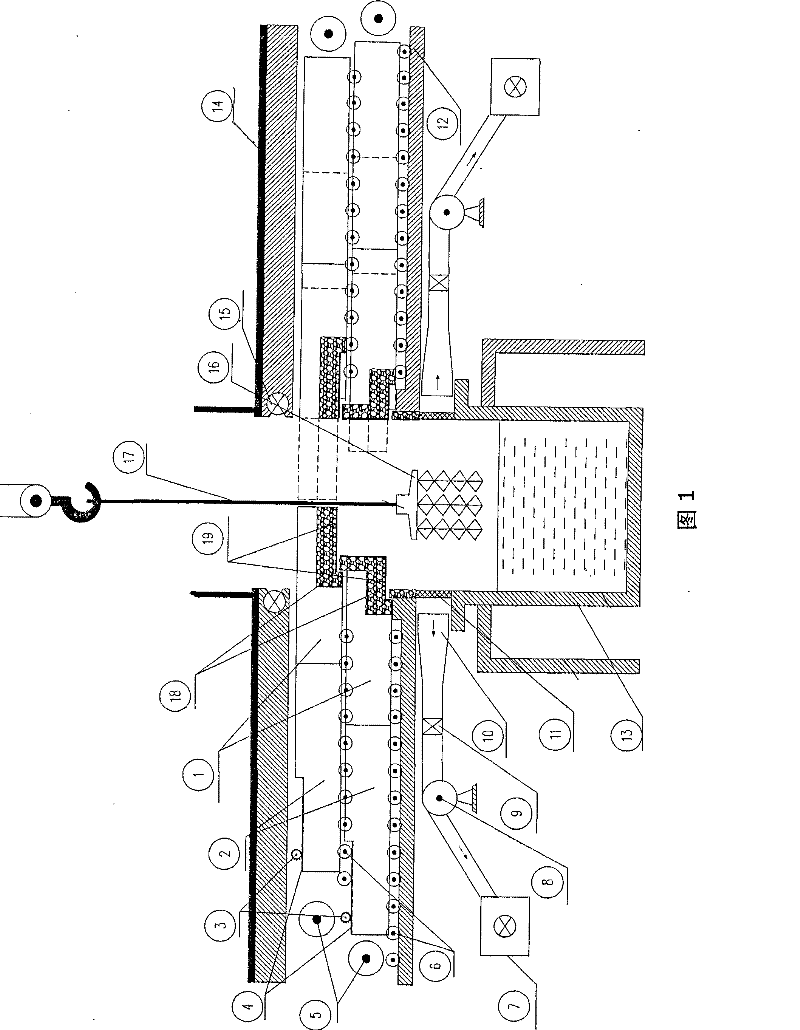

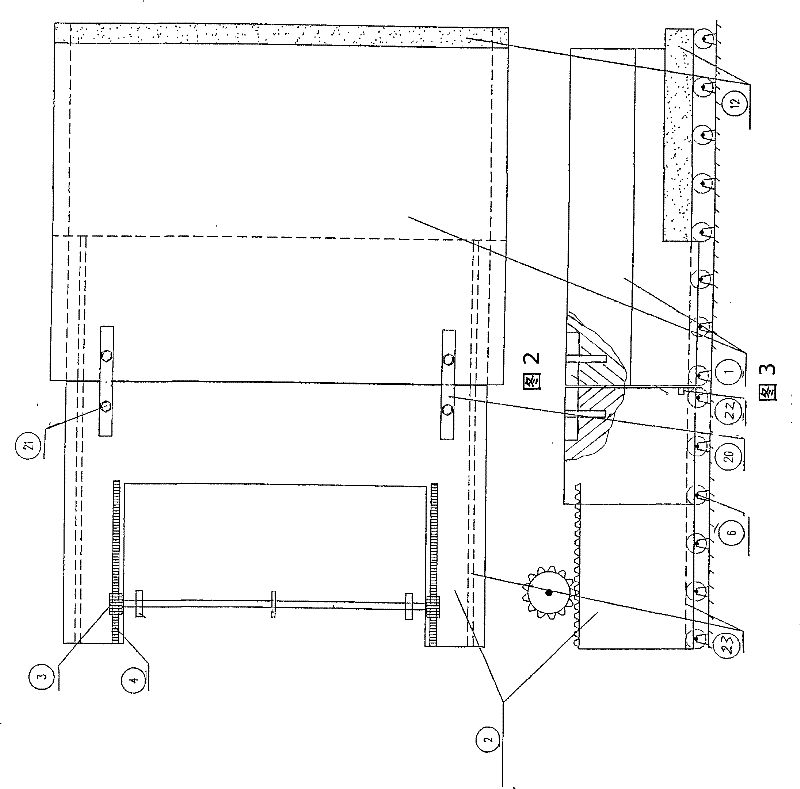

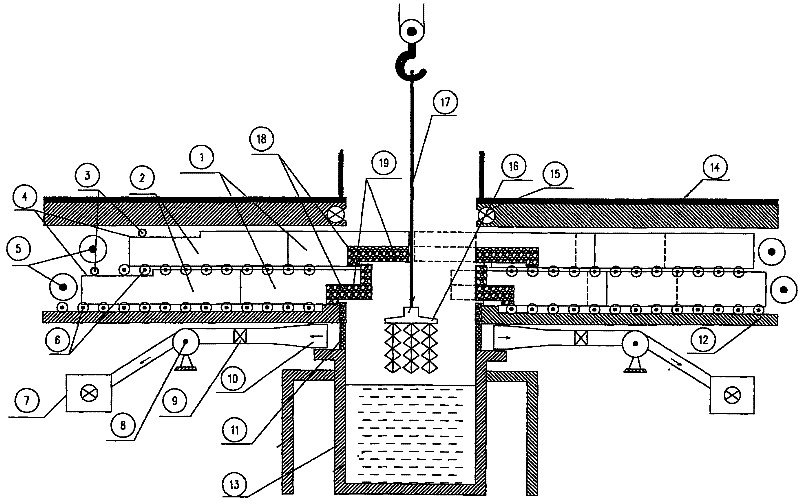

[0018] refer to figure 1 , A frame is set above the mouth of the zinc pot 13 to form a cover vehicle running surface 12 and a worker's operating platform pedal 14. According to the length of the zinc pot and the width of the selected cover car, determine the number of cover cars on each side. Packing wheel 6 is installed symmetrically on the vertical pot mouth both sides of the pot mouth on the cover car walking surface, and each cover car has two rows of pack wheels. refer to figure 1 , figure 2 , image 3 , each cover car has the same structure, and is divided into two groups and arranged on both sides of the pot mouth. Cover plate car is made up of two sections of cover plate part 1 and walking part 2, and two sections are connected as a whole by connecting plate 20 on the upper end surface of cover plate car and connecting plate pin 21 and the docking pin 22 of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com