Two-stage piston type two-stroke engine

A two-stage piston, two-stroke technology, used in engine ignition, engine components, machines/engines, etc., can solve problems such as poor lubrication, reduced cylinder service life, mutual stirring, etc., to improve transmission speed and explosive force, and reduce exhaust emissions. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

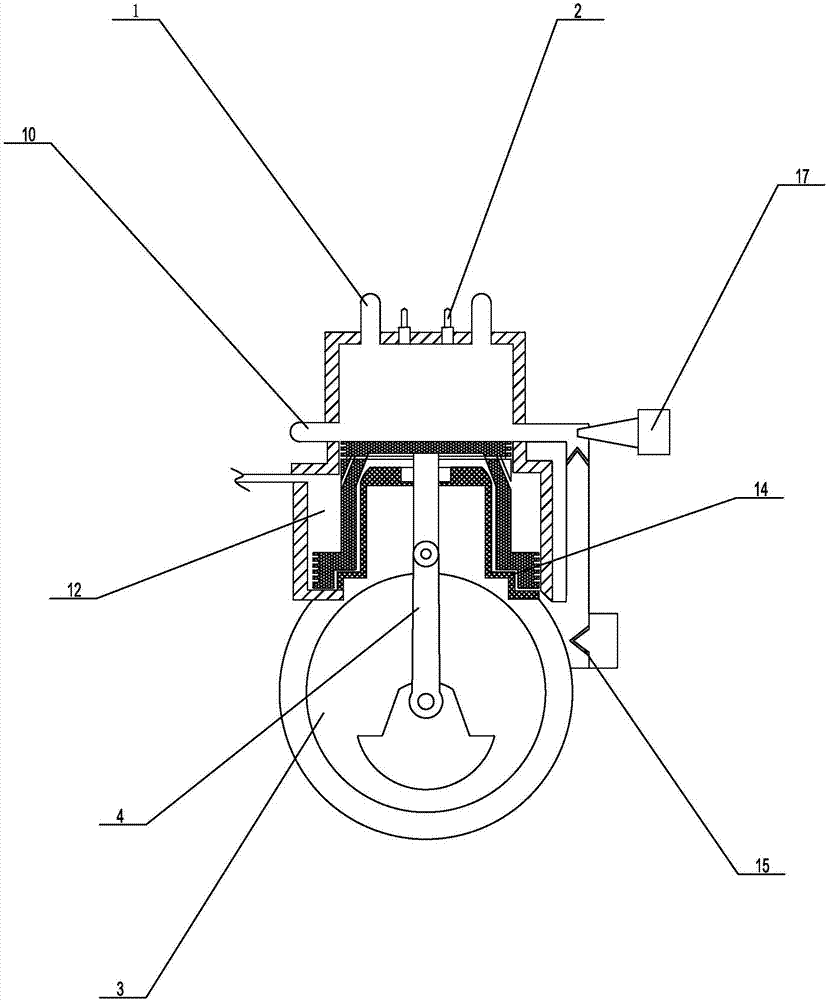

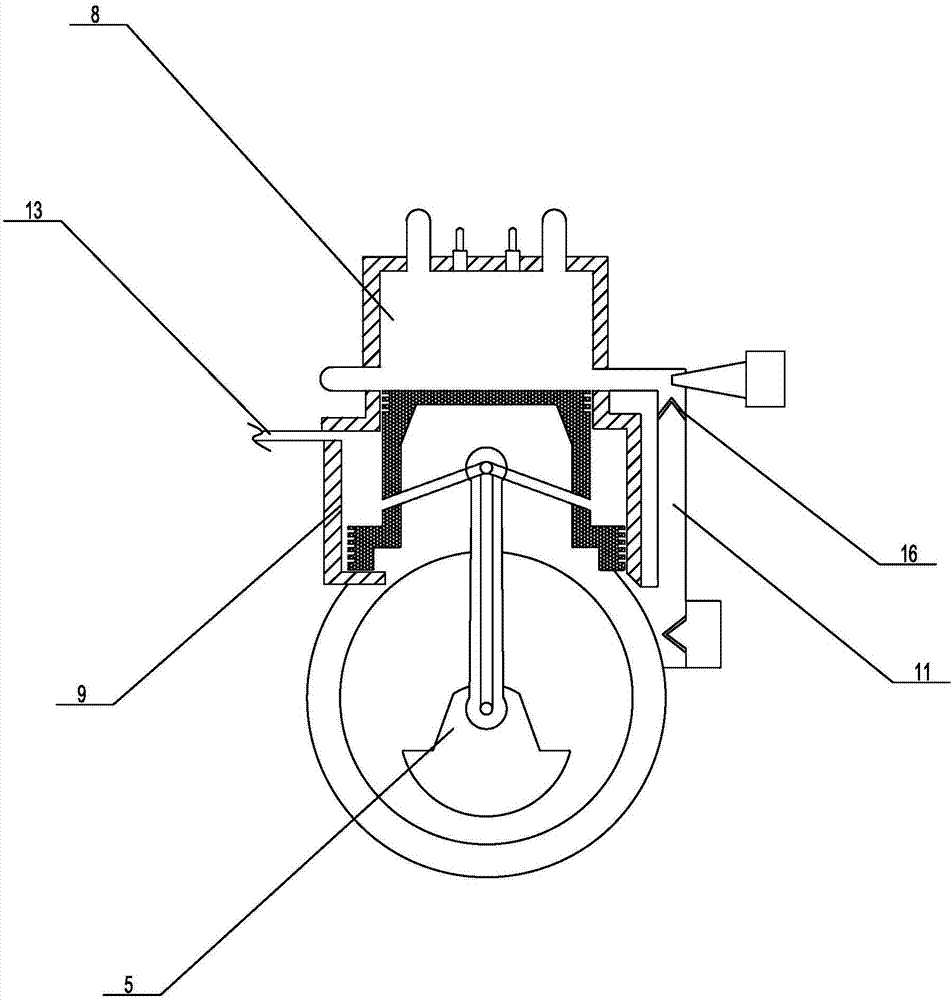

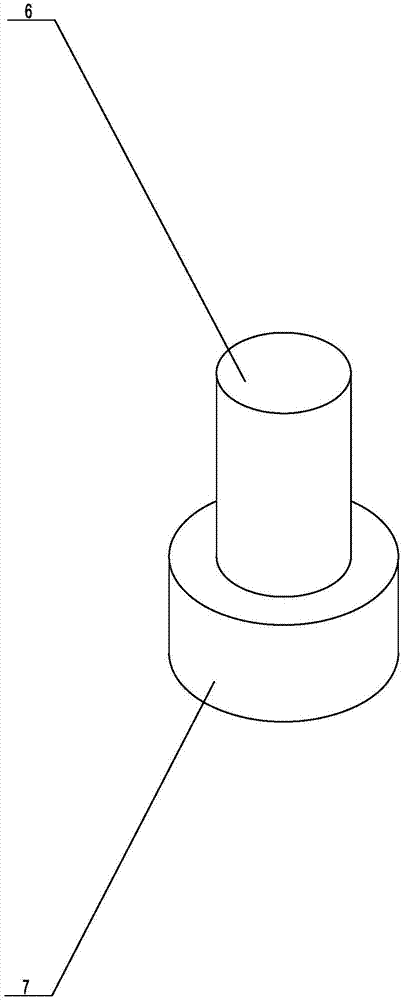

[0018] Such as figure 1 and figure 2 Propose a kind of specific embodiment of the present invention as shown, two-stage piston type two-stroke engine, comprise the cylinder that the top is provided with exhaust valve 1, the piston that is located in the cylinder, the crankcase 3 that is located at the cylinder below, described piston passes through The connecting rod 4 is connected with the crankshaft 5 in the crankcase 3; the piston is a double-stage piston, including a cylindrical and hollow upper-stage piston 6 and a lower-stage piston 7, and the diameter of the lower-stage piston 7 is greater than the diameter of the upper-stage piston 6, Such as image 3 As shown, the top of the upper piston 6 and the top of the lower piston 7 are provided with an air ring and an oil seal ring. The difference between the piston of this embodiment and the traditional piston structure is that the lower piston 7 is provided; the shape of the cylinder is similar to that of the piston. Matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com