Method for excavating subway station through middle steel pipe vertical columns

A technology for steel pipe columns and subway stations. It is applied in the direction of earthwork drilling, underground chambers, pillars/brackets, etc. It can solve the problems of difficult organization and many excavation steps, optimize the construction process, reduce the construction process, and improve the construction efficiency. The effect of digging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

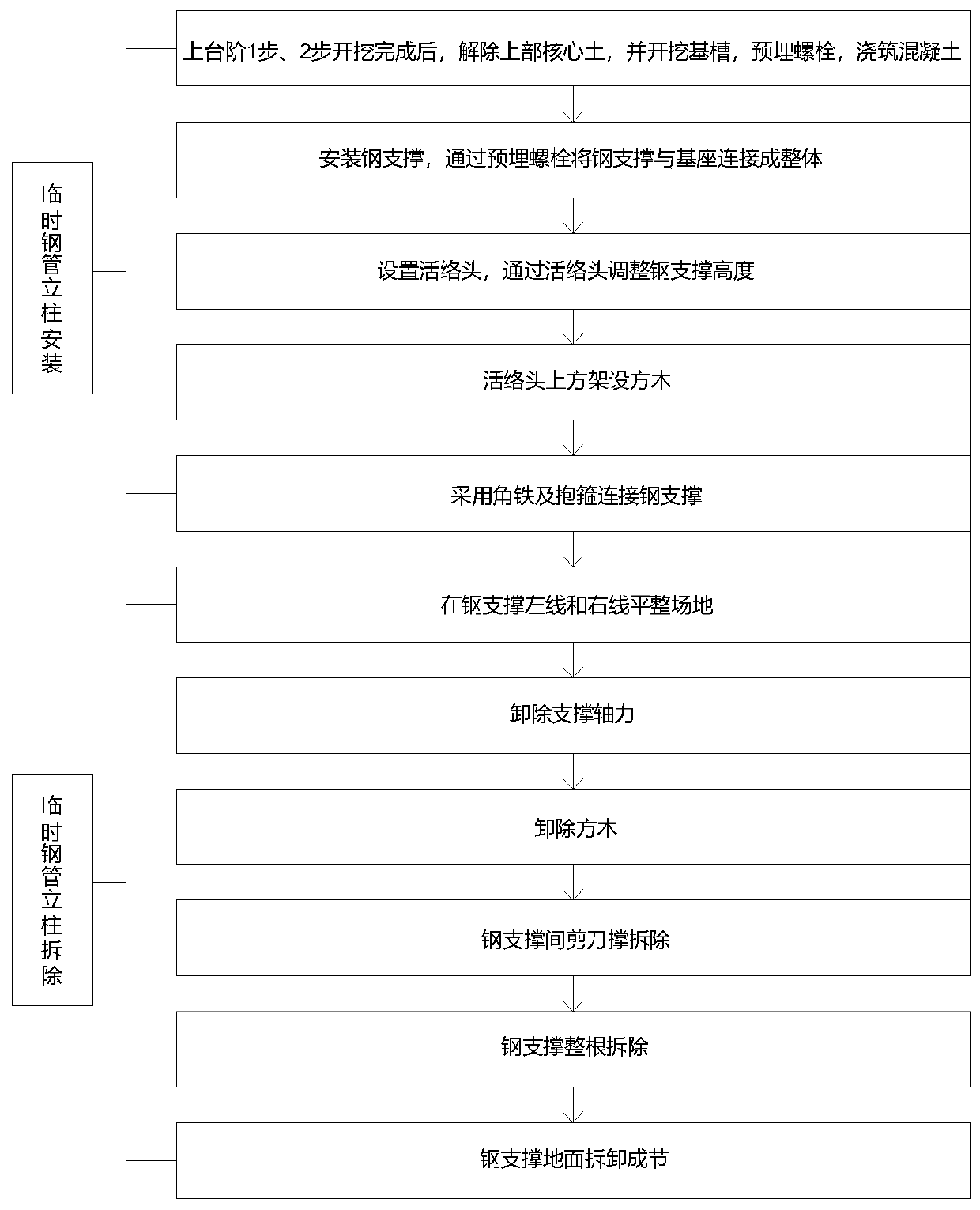

[0029] A method for excavating a steel pipe column in the middle of a subway station, comprising the following steps:

[0030] S1: Temporary steel pipe column installation

[0031] 1) In this embodiment, the method of reserving the core soil on three steps is used for excavation. After the first and second steps of the upper step are excavated, the core soil in the middle of the upper step is removed, and the foundation trench is excavated above the core soil of the middle step. Set double-layer two-way steel mesh, pre-embed the bolts, and pour concrete;

[0032] 2) After the concrete pouring is completed, the steel support installation shall be carried out. The steel support installation shall be constructed in sections, and the construction section shall be divided into one section every 8m; The length of the section steel pipe is 1m; the steel support is pre-spliced on the ground before installation to check the straightness of the steel support, the deviation of the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com