Automatic whole-section external rotor low-speed motor cutting rotation drum anchor driving machine

A cutting drum and outer rotor technology, applied in cutting machinery, bolt installation, mining equipment, etc., can solve the problems of difficult installation, disassembly and handling, high labor intensity and high maintenance cost, and can prevent the roof from delaminating and risking. The effect of falling and anchoring is good, and the maintenance cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

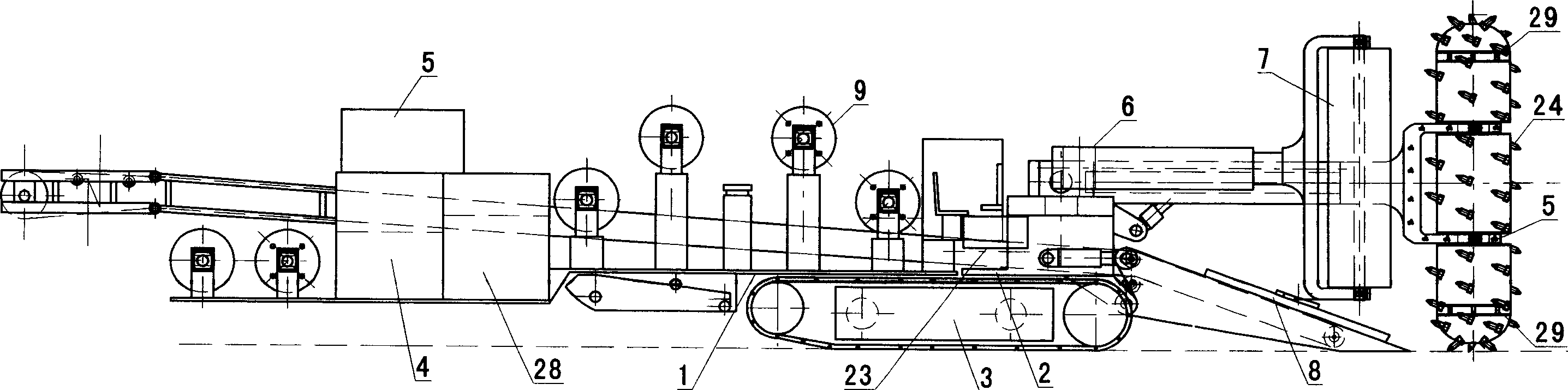

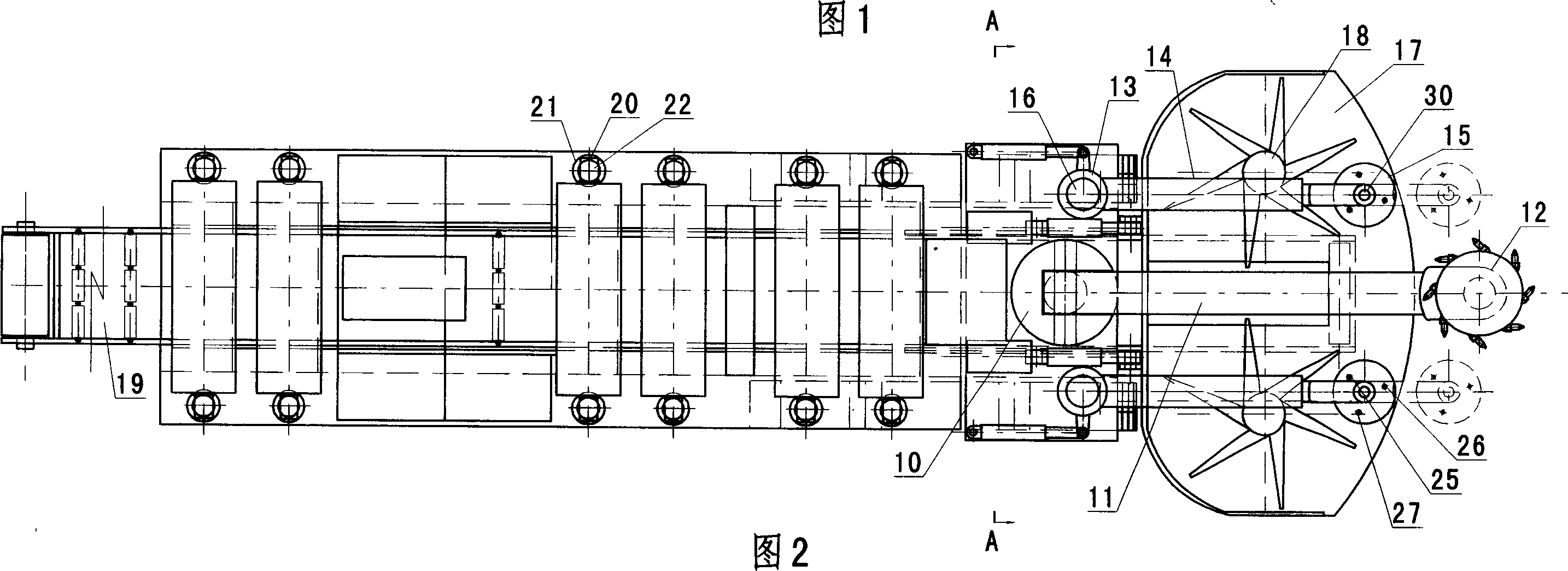

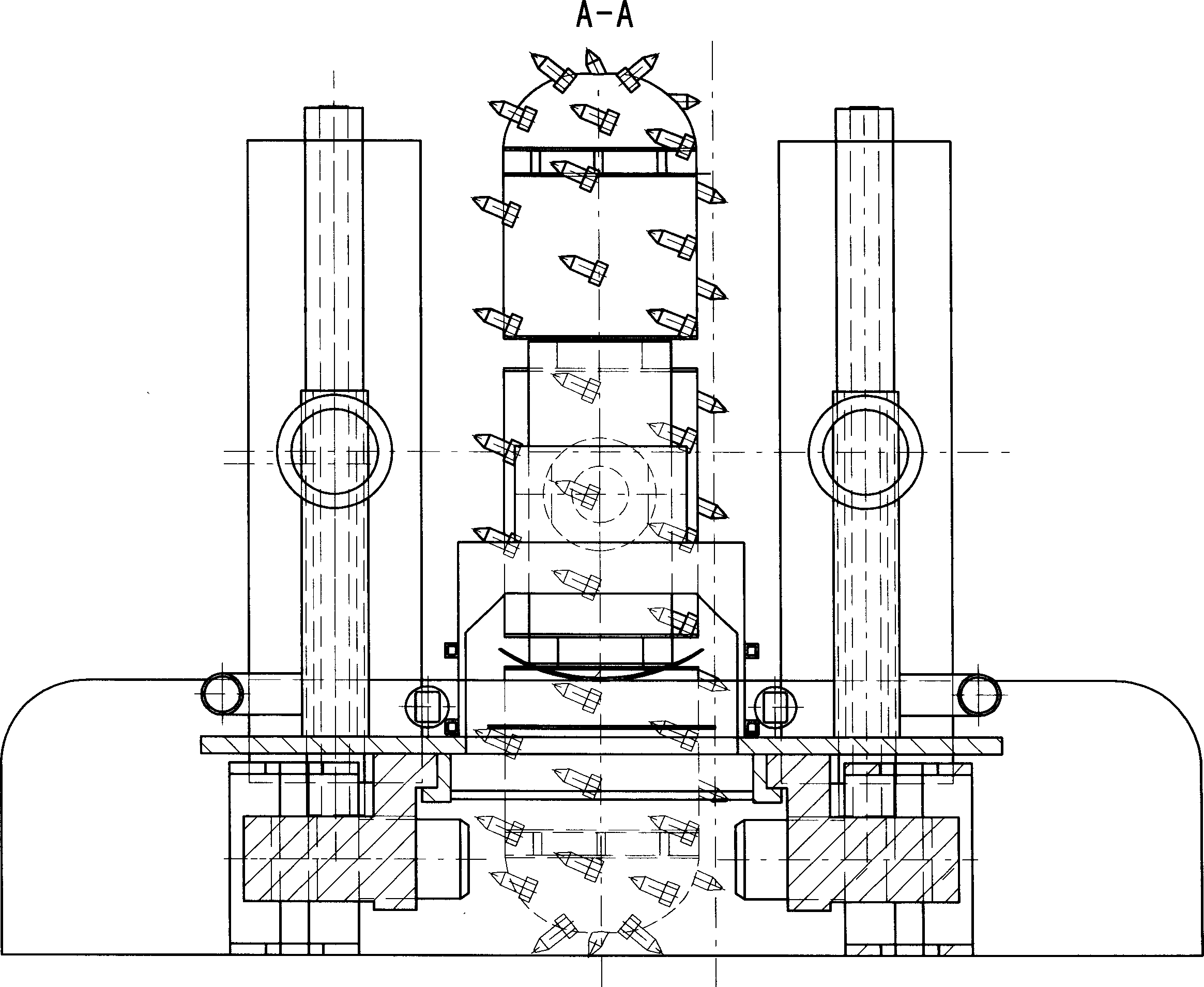

[0023] As shown in Figures 1, 2, and 3, the automatic full-section external rotor low-speed motor cutting drum bolter consists of a main frame 1, a sliding frame 2, a running part 3, a hydraulic system 4, and a spray dust removal system 5. The cutting part 6, the top anchoring device 7 and the shipping part 8 are installed on the horizontal sliding frame 2, and the sliding frame 2 is embedded on the main frame 1. Under the push of the pushing device, the sliding frame 2 The main frame 1 slides back and forth. When the cutting part 6, the top support device 7 and the shipping part 8 are working, the side anchor device 9 installed on the main frame 1 simultaneously anchors the left and right side parts; the cutting part 6. It consists of a rotating mechanism 10, an extendable working arm 11, and an outer rotor low-speed motor cutting drum 12 verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com