Networking reinforcement method for cross drilling holes of outburst coal seam

A technology for drilling through layers and high outburst coal seams, which is applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc. protection and other issues, to achieve the effect of wide practicability, reduction of reinforcement workload, and elimination of danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

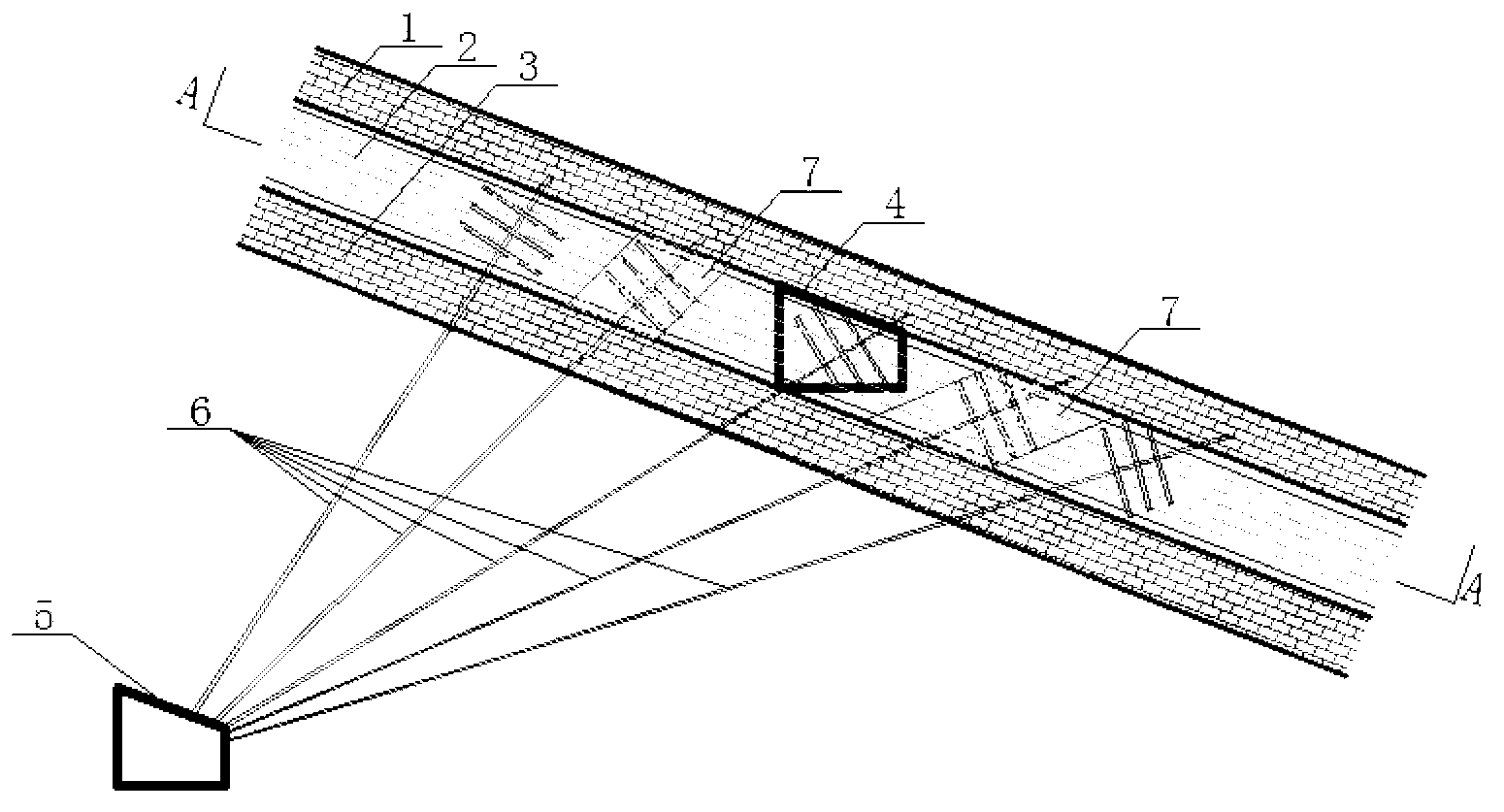

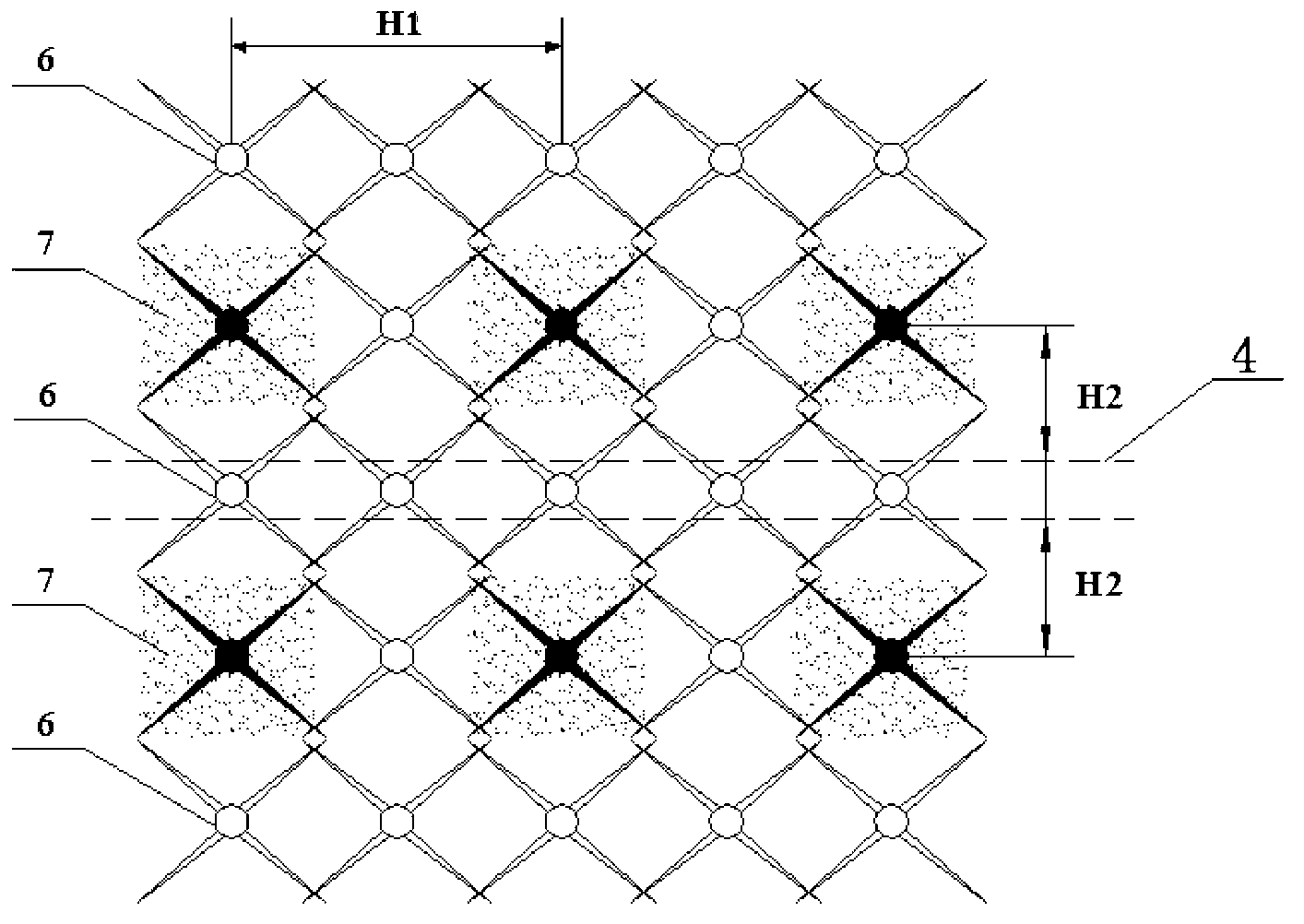

[0016] Such as figure 1 and figure 2 As shown, the high outburst coal seam penetration drilling network reinforcement method of the present invention:

[0017] First, arrange the bottom pumping roadway 5 along the direction of the working face in the coal seam 2 floor rock layer, arrange the drilling field in the bottom pumping roadway 5, and construct the layer-penetrating drilling 6 from each drilling field of the bottom pumping roadway to the coal seam 2 direction;

[0018] Then, according to the inclination angle of the coal seam 2 and the extraction radius of the through-bed borehole 6, the control range of the through-bed borehole 6 is determined, in which the slope and sharply inclined coal seam (with an inclination angle between 25° and 90°) outside the roadway upper contour line The control distance is at least 20m, the control distance outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com