Novel omnibearing drill boom of drill loader

An all-round, drilling and rigging technology, which is applied to earthwork drilling, drilling equipment, support devices, etc., can solve the problems of unguaranteed worker safety, inability to drill holes in all directions, and high labor intensity of workers, so as to enhance production safety Sex, reduce the number of workers and labor intensity, reduce the effect of the probability of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

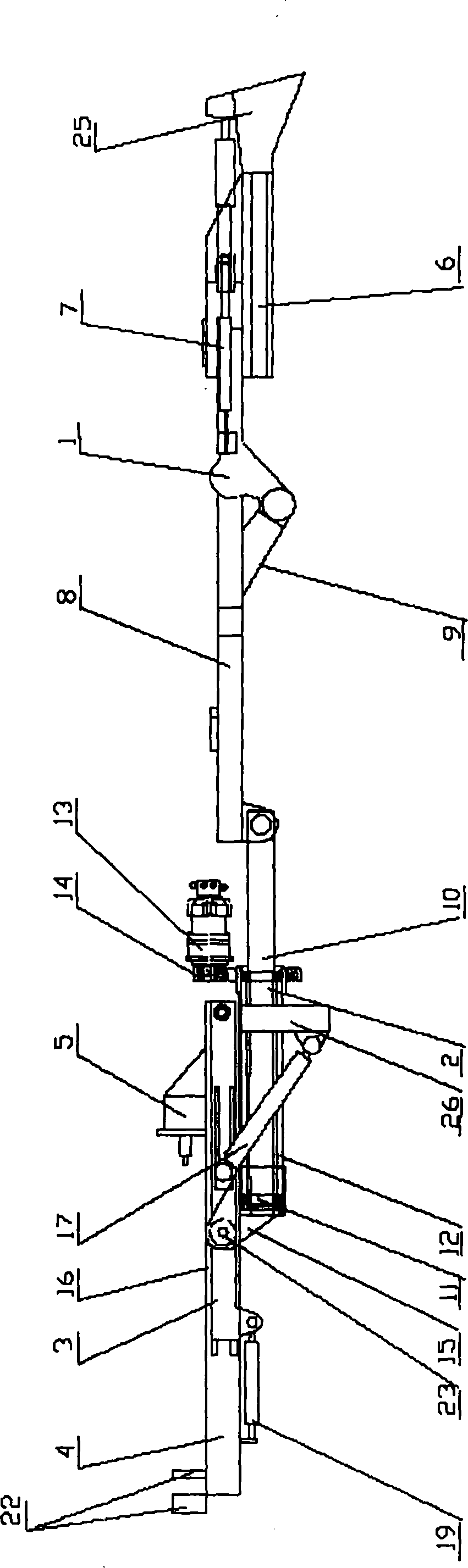

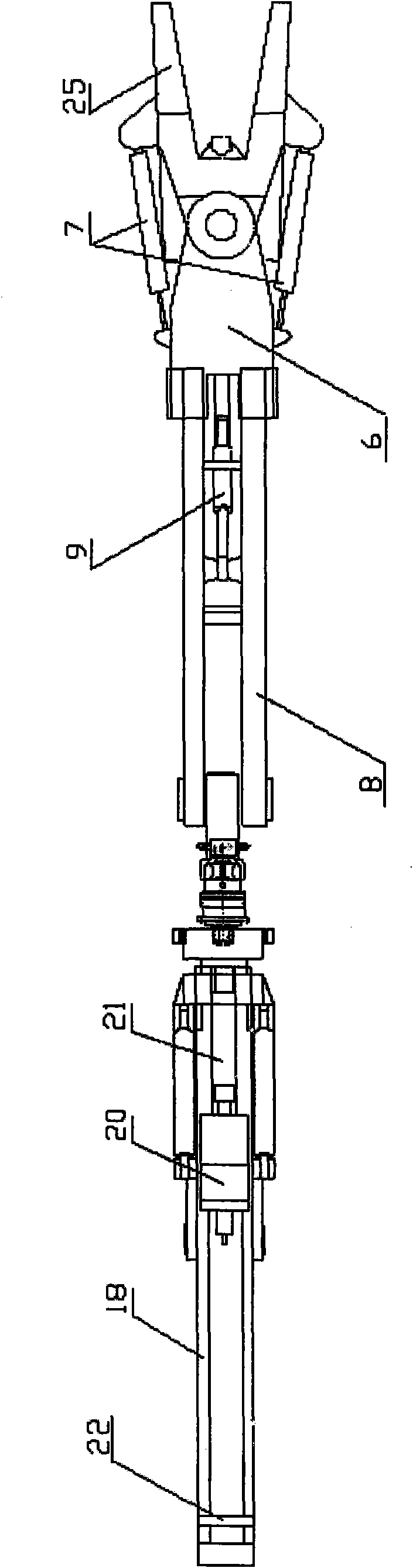

[0030] The new omni-directional drill arm, such as figure 1 , 2 , 3, the main swing arm mechanism 1 includes a rotary table 6, a rotary oil cylinder 7, a lifting arm 8, a lifting oil cylinder 9, and a fixed frame body 25, and the fixed frame body 25 is hinged with the rotary table 6 and the lifting oil cylinder 9, and the rotary oil cylinder 7. The lifting cylinder 9 drives the lifting arm 8 to carry out various transpositions, so that the lifting arm 8 is positioned within the range of 37° up, 30° down, 30° left, and 30° right to drill holes, and the fixed frame body 25 and the rotary table 6 hinged.

[0031] The rear portion of the rotary motion mechanism 2 is fixedly connected with the front end of the main swing arm mechanism 1, and the rotary motion mechanism 2 is composed of a main shaft 10, a bearing 11, a sleeve set 12, a rotary hydraulic motor 13, a rotary gear set 14, a front bracket seat 15, a bracket 26, the sleeve set 12, the rotary hydraulic motor 13 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com