Full-automatic rolling device for vehicle roof panel films

A rolling device, fully automatic technology, applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve the problem of high ergonomic strength, and achieve the effect of reducing post cycle time, rolling leveling, and reducing repair costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

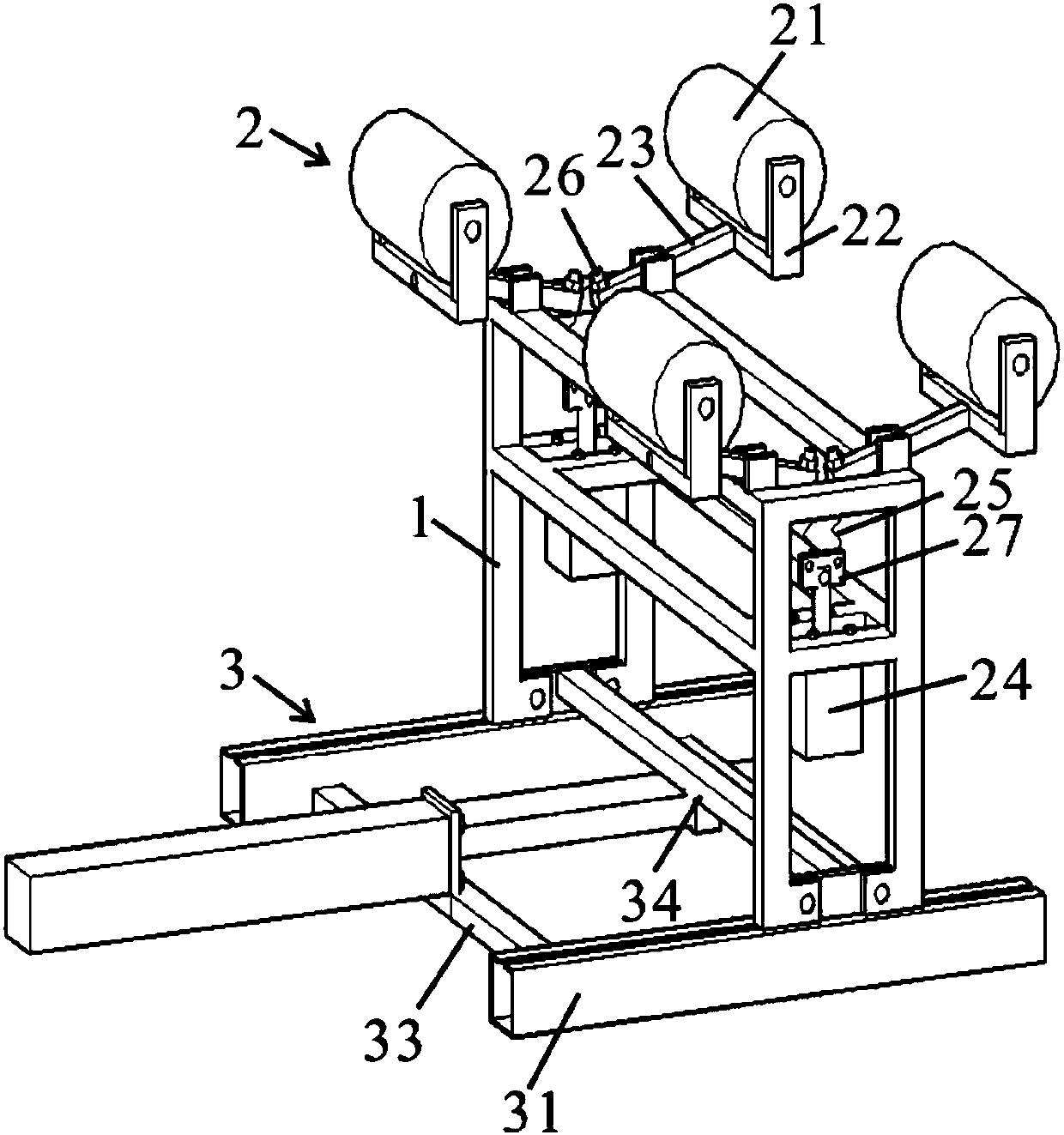

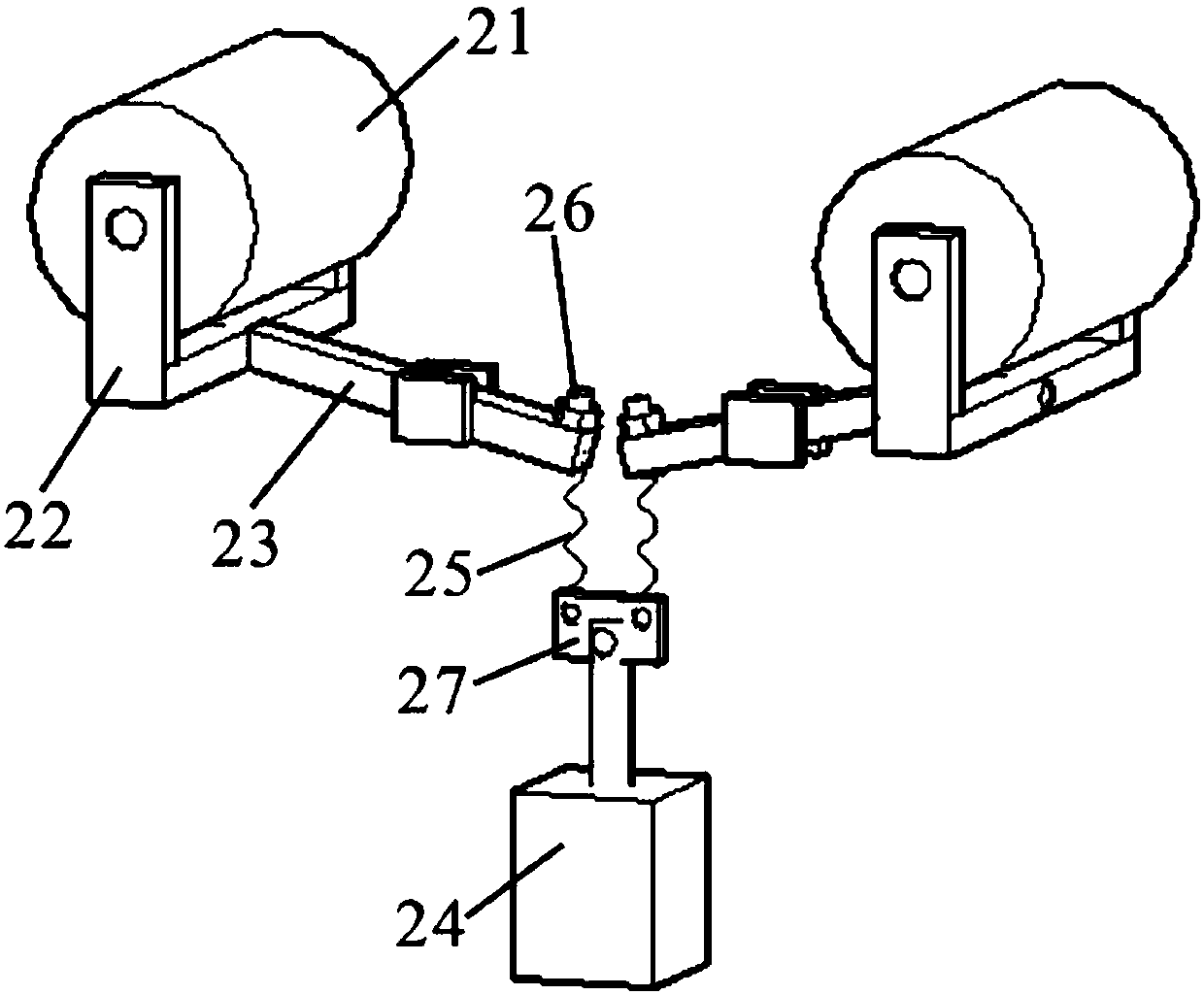

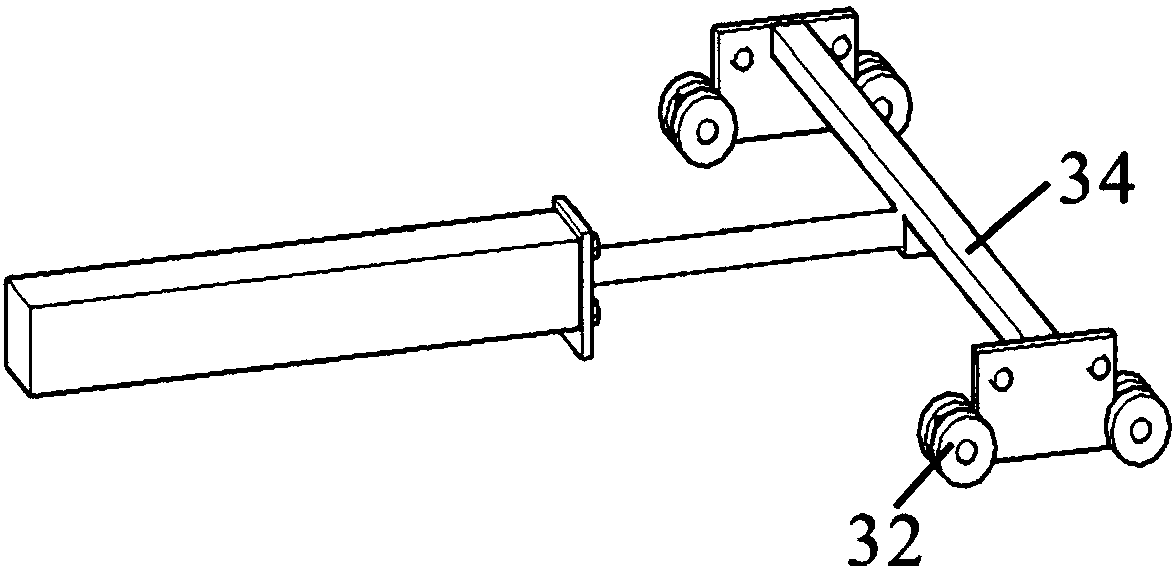

[0022] The following with attached Figure 1 to Figure 4 A fully automatic rolling device for the roof cover film of the present invention will be further described in detail.

[0023] A kind of automatic rolling device for car body top cover film of the present invention, please refer to Figure 1 to Figure 4 Relevant figures include a main frame 1, a rolling mechanism 2 and a sliding mechanism 3, the rolling mechanism 2 can be lifted and movably connected to the top of the main frame 1, and the bottom of the main frame 1 is connected to the sliding mechanism 3. Mechanism 3 reciprocating sliding connection. In this way, the rolling mechanism 2 can be lifted and movably connected to the top of the main frame 1, the sliding mechanism 3 is located at the bottom of the main frame 1, and the sliding mechanism 3 drives the main frame 1 and the rolling mechanism 2 located on the main frame 1 to reciprocate The sliding movement enables the film to stick to the roof. By setting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com