Large cross-section weak surrounding rock tunnel three-step and six-part short-distance construction method

A technology of weak surrounding rock and construction method, applied in the direction of tunnel, tunnel lining, earthwork drilling and mining, etc., can solve the problems of poor self-stabilizing ability of weak surrounding rock, large deformation of initial support, slow progress of construction period, etc., which is beneficial to control The effect of deformation, less one-time investment and large construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

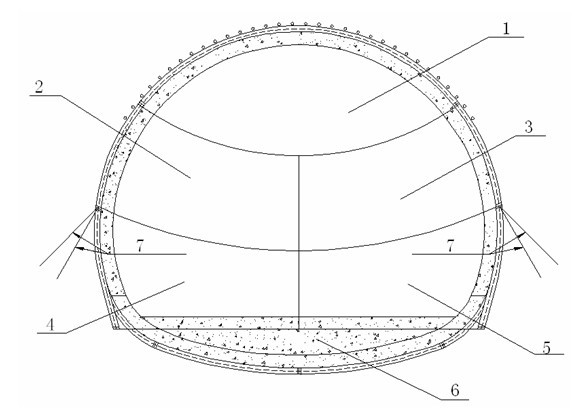

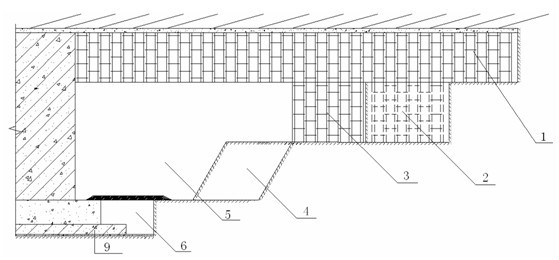

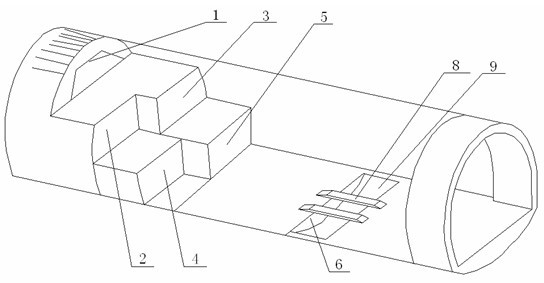

[0035] The construction method of three steps and six sections of large section and weak surrounding rock tunnel is short-distance construction method. The excavation section is divided into three steps and six working faces. Excavation, support operation, inverted arch and filling operation are carried out at the same time. The schedule of each process is reasonable, and the secondary The lining is followed up in a timely manner, and the construction of the upper, middle and lower steps is promoted synchronously, such as figure 1 , figure 2 , image 3 As shown, it mainly includes the following steps:

[0036] (1) The upper step 1 of the upper arc-shaped pilot pit is excavated in the circumferential direction, and the earthwork excavated by the upper step 1 is transferred to the lower step;

[0037] (2) After the upper step 1 lags by 4.5-5m, excavate the left part 2 of the middle step, and transfer the excavated earthwork to the lower step;

[0038] (3) After the left part...

Embodiment 2

[0044] In step 1, the upper step 1 of the upper arc-shaped pilot pit in the circumferential excavation is performed by using the steel frame erected in the previous cycle as a small conduit of Φ42 ahead of the tunnel arch, which is carried out after the arch is supported in advance.

[0045] The advanced small pipe is made of hot-rolled seamless steel pipe with Φ42mm and wall thickness of 3.5mm, with a length of 3.5m, a circumferential spacing of 30-50cm, and its longitudinal overlap length is not less than 1m; 12°, can be adjusted according to the actual situation. The drilling direction should be straight. The diameter of the drilled hole is not less than 45 mm; the leading small conduits are installed within 120° of the arc of the tunnel arch, with a total of 38 pieces, the circumferential spacing is 40 cm, and the longitudinal overlap length is not less than 1 meter.

[0046]The excavation contour shape and section size of the upper step 1 shall be staked out accordin...

Embodiment 3

[0055] In step 2, the excavation height of the left part 2 of the middle step is controlled at 3.3-4m. After excavation, the initial support of the working part is carried out in time according to the method described in Example 2, that is, the initial spraying of 4cm thick concrete, hanging steel mesh, and lengthening Steel frame, and at the lower part of the arch foot of the steel frame close to the edges of both sides of the steel frame, press the inclination angle of 45° and 60° to set up locking anchors 7, the length of the anchors is 4m, and each ring is 8, the locking anchors 7 Firmly welded with the steel frame to increase the support force of the arch foot.

[0056] In step 3, the excavation height of the right part 3 of the middle step is controlled at 3.3-4.0m, and the method used is the same as the excavation and support method of the left part 2 of the middle step, and the lower part of the arch foot of the steel frame is close to the edges of both sides of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com