Rough-terrain wheeled crane

A technology for off-road tires and cranes, applied in cranes, fluid steering mechanisms, vehicle maintenance, etc., can solve the problems of increased vehicle weight, poor working condition performance, and reduced operating efficiency, and achieve shortened operating cycle time, good strength and rigidity , the effect of making full use of the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

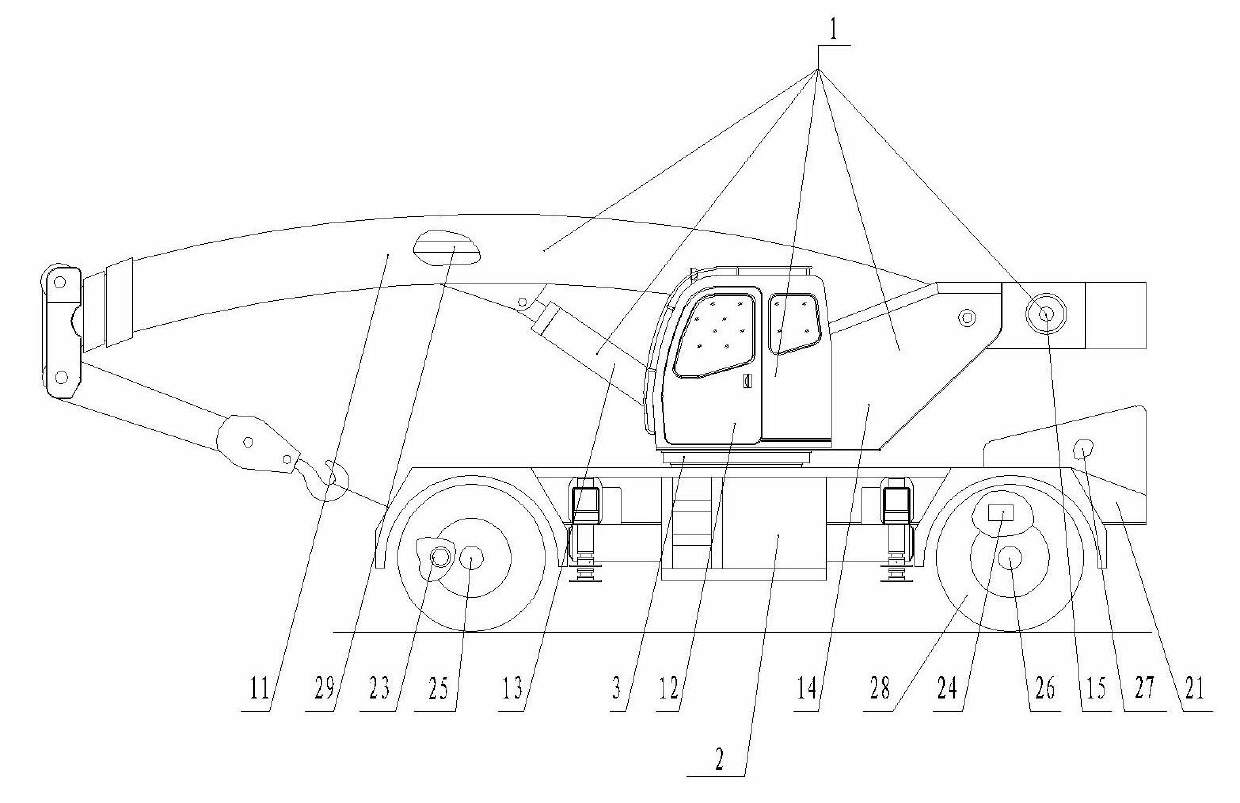

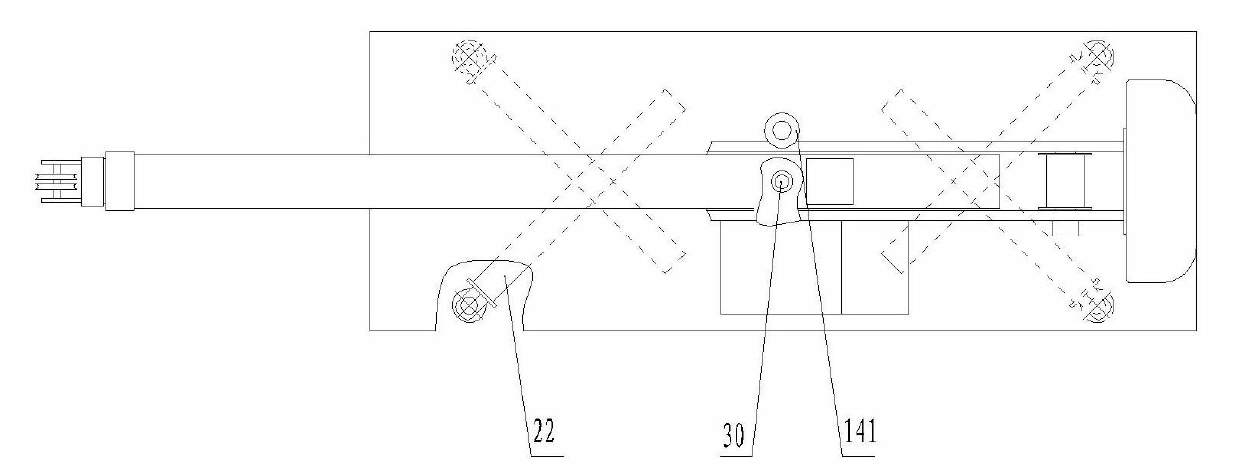

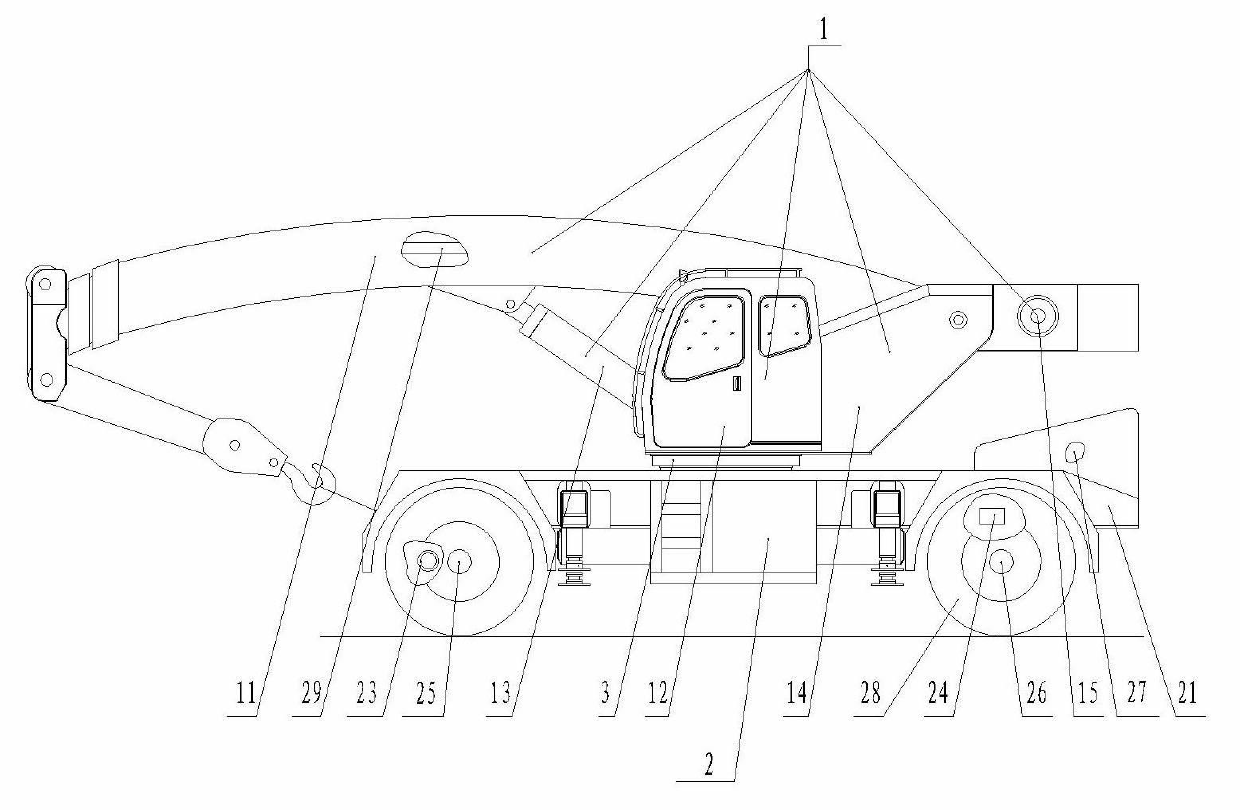

[0016] Embodiments of the present invention see figure 1 and figure 2 . The hoisting part 1 on board is mainly composed of an arc-shaped boom 11, a control room 12, a luffing cylinder 13, a turntable 14, a lifting mechanism 15 and a telescopic mechanism 29 located inside the boom. The driving chassis 2 is mainly composed of an integral box-shaped closed structure chassis 21, telescopic outriggers 22, front drive axle 25, rear drive axle 26, low-speed high-torque hydraulic motor 23, engine 27, multiple hydraulic pumps 24, wheels 28, etc. composition.

[0017] like figure 1 As shown, the slewing bearing 3 is fixed on the underframe 21 . The turntable 14 is fixed on the slewing support 3, and the slewing mechanism 141 is fixed on the turntable 14. Driven by the slewing mechanism 141, the turntable 14 realizes 360-degree continuous rotation to realize all-round hoisting operation. The control cabin 12 with the cab function is fixed on the left side of the turntable 14, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com