Spinning device and spinning molding method for cylindrical material

A spinning and cylindrical technology, which is applied to the spinning device of cylindrical materials and the field of spinning, can solve the problems of falling off, increased operation cycle time, deformation of the flange-shaped protruding edge 11, etc. Improve work efficiency and improve retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

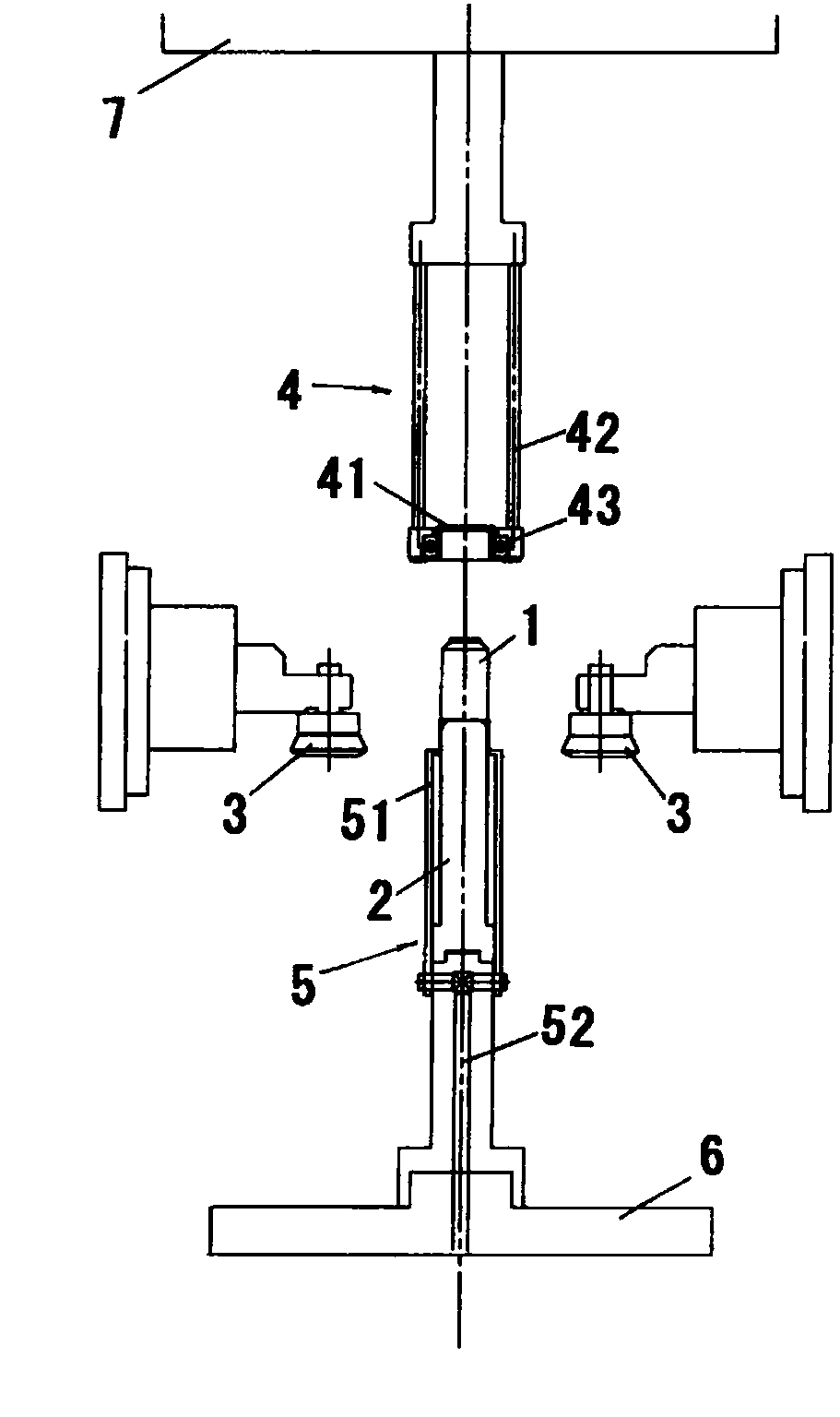

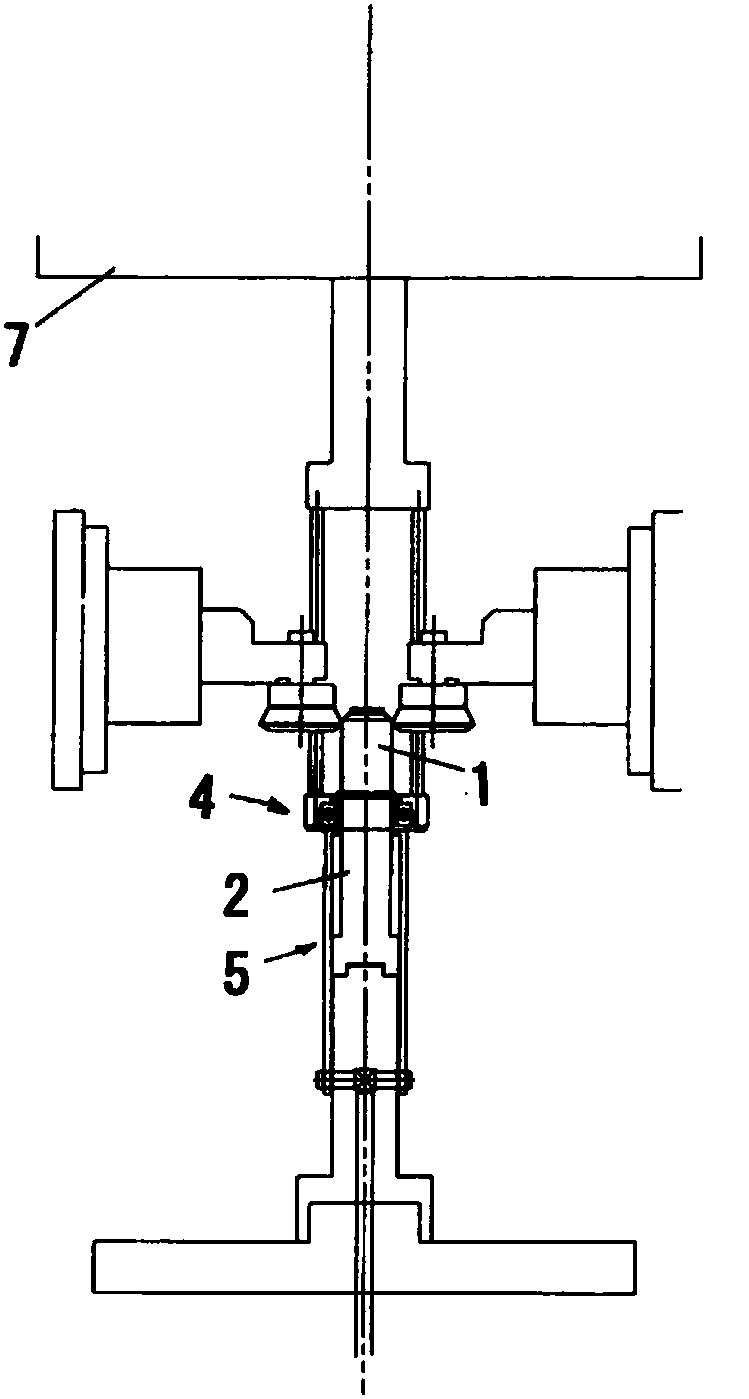

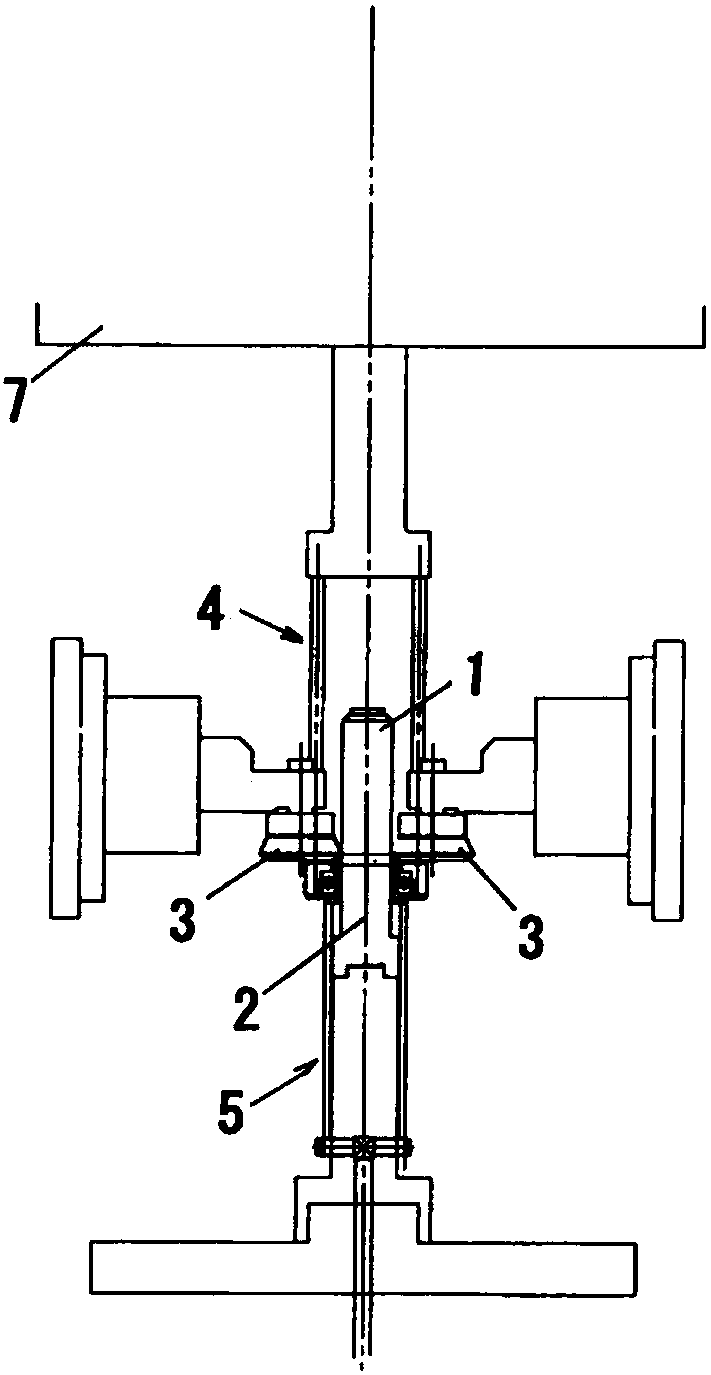

[0026] Hereinafter, embodiments of a spinning device and a spinning method for a cylindrical material according to the present invention will be described with reference to the drawings.

[0027] Figure 1(a) to Figure 2(b) An example of the spinning method using the spinning device of the cylindrical material of the present invention is shown in .

[0028] In this spinning device for cylindrical materials, a metal cylindrical material 1 is placed on a mandrel 2, and tension is applied to the axial direction of the cylindrical material 1 while the roller 3 is pressed against the cylindrical material from the outer peripheral side. 1 to perform diameter reducing extrusion processing, thereby realizing elongation and thinning of the cylindrical material 1, the spinning device is equipped with: a tension imparting mechanism 4, which passes through the protruding edge formed at the open end of the cylindrical material 1 part 11 applies tension to the axial direction of cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com