Method for recovering disc ore on incline ore block

A recovery method and ore body technology, applied in ground mining, earth square drilling, underground mining, etc., can solve problems such as low production efficiency, increased cutting blast holes, loss of triangular column ore bodies, etc., achieving flexible and convenient construction and simple methods easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

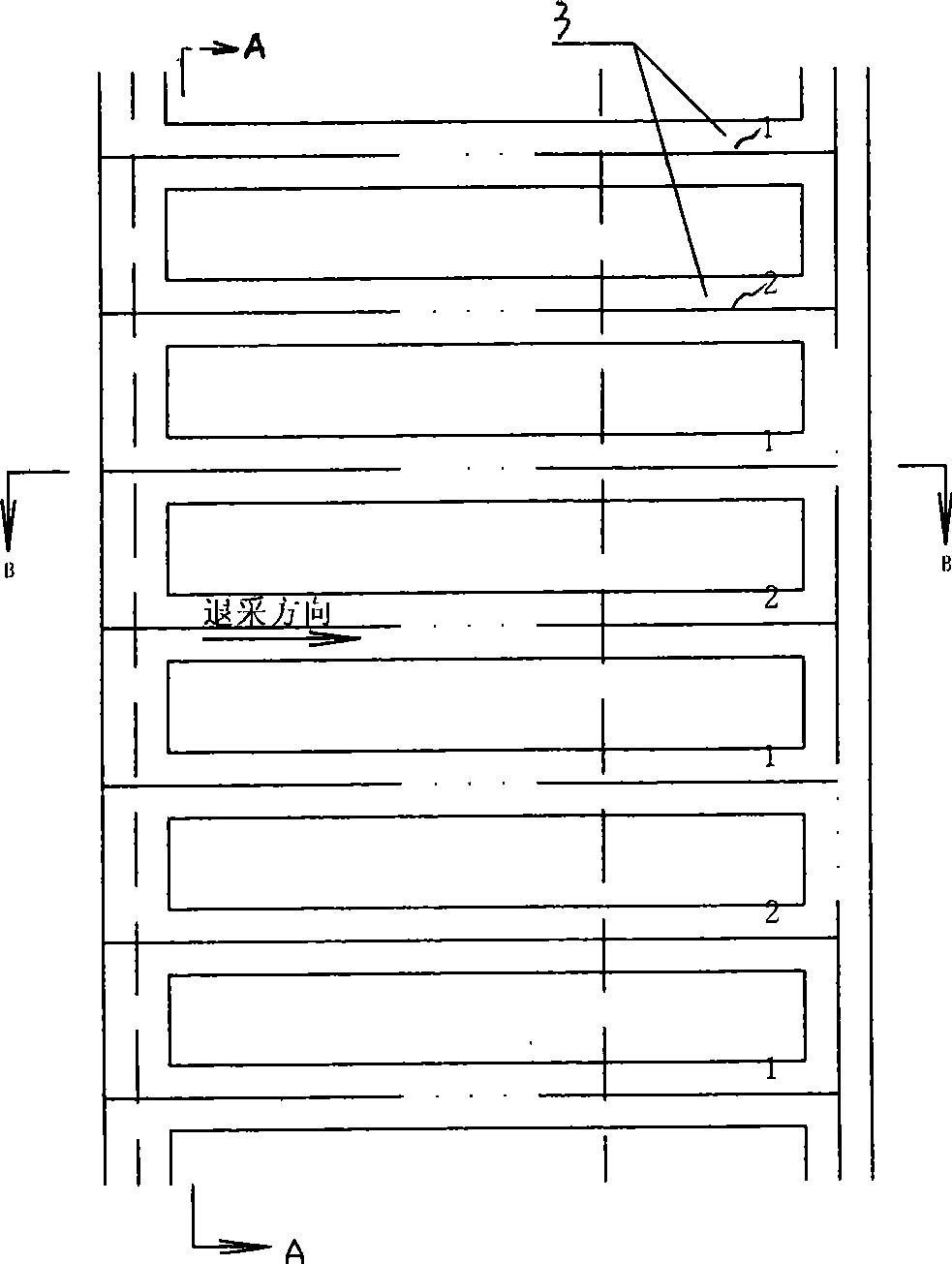

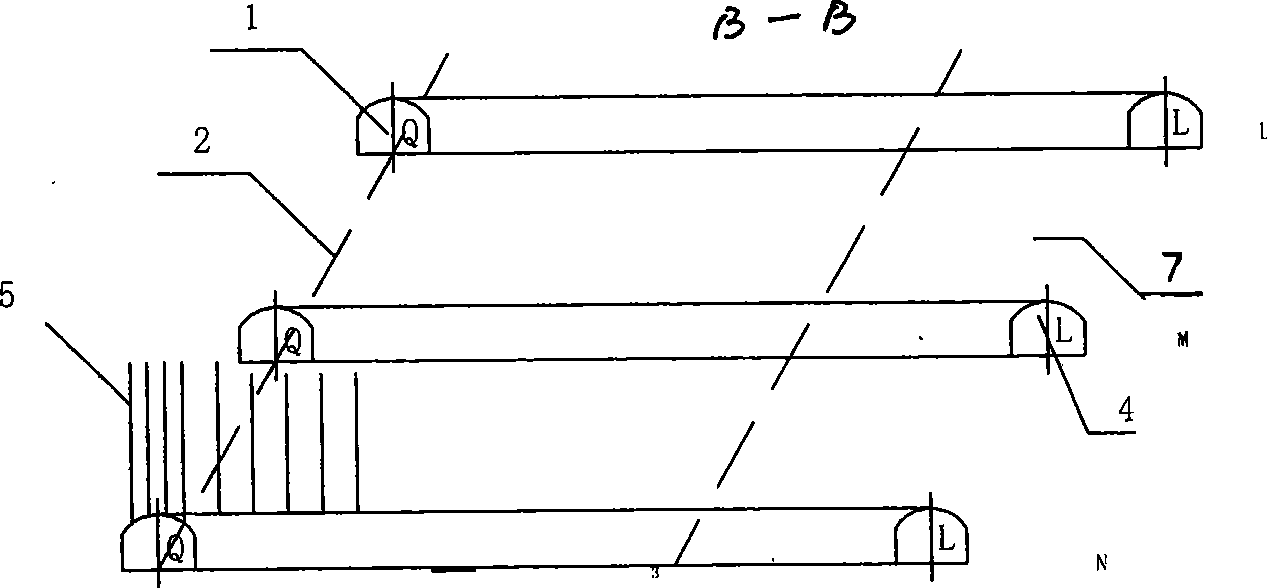

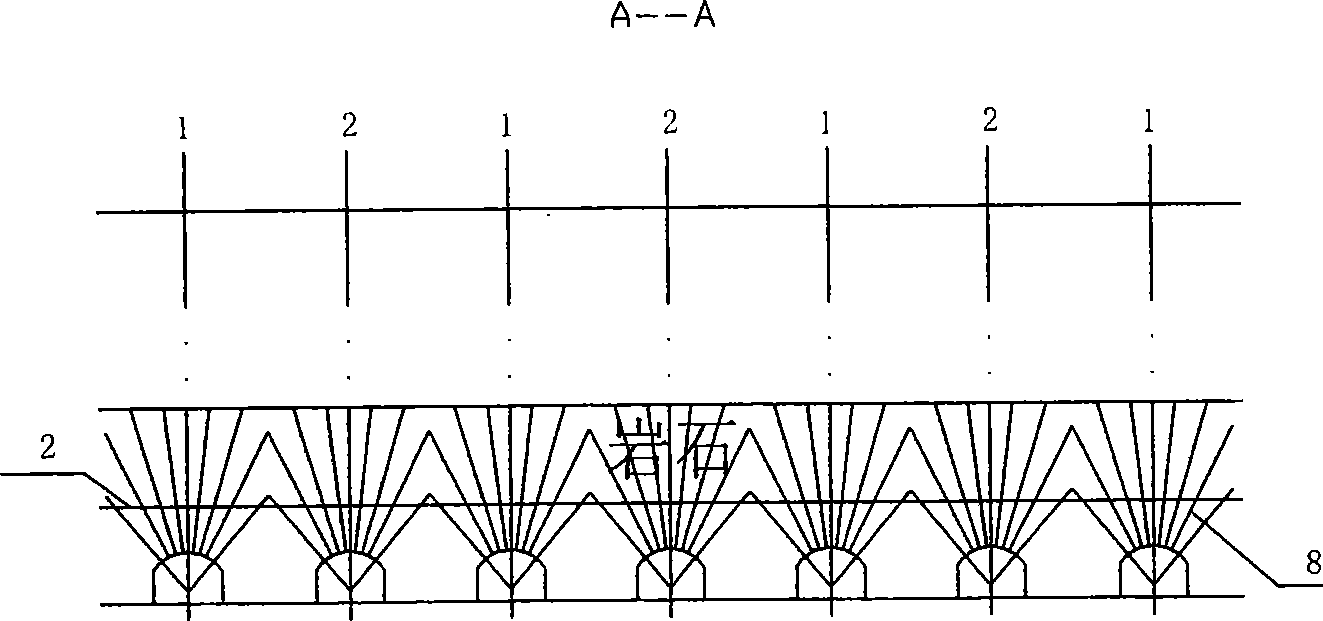

[0025]Example 1: In a production mine, the ore body has a strike length of 240m, a width of 45m, and an inclination angle of 45°. According to the occurrence conditions and shapes of the ore body, the mining method of segmental caving without pillars is adopted. The stage height is 120m, and the segment height is 120m. is 12m, and the approach distance is 10m. When the mining production progresses to -138m~-150m section, the mining approach 3 is constructed according to the layout of 1-2-1 on the section plane, and the construction progress of the prospecting roadway is ahead of other roadways, and the prospecting roadway is excavated The ore-rock boundary line is about 2m; the position of the cutting roadway is determined according to the ore-rock boundary line revealed by the roadway excavation. The body height can be smaller), carry out the excavation work of the cutting roadway; according to the requirements of the mine production process and parameters, set the vertically...

Embodiment 2

[0026] Example 2: In a large underground iron mine, the ore elevation is -89m. Above -186m, the plane projection of the ore body is in the direction of NE20°, the strike length of the ore body is 300m, the dip angle is 45°-60°, and the thickness varies greatly. According to the occurrence conditions of the ore body, the sub-section caving mining method without pillars is adopted, the sub-section height is 12m, and the approach distance is 10m. The first section is -90~-100m, which is used as the caving section in the initial stage of mine production, and the second section is -100~-112m, which undertakes the normal mining production tasks of the mine. When mining -100~-112m segmented ore, according to the traditional method, all the mining routes will be excavated from the ore body, and the cutting roadway will be arranged on the boundary of the upper wall ore rock to provide accurate excavation, mining rock drilling, and mining blasting. Waiting for work has brought a lot of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com