Corrosion-resistant roller and manufacturing method thereof

A manufacturing method and corrosion-resistant technology, applied in the field of roller manufacturing, can solve the problems of inability to effectively resist the corrosion of high-temperature zinc-aluminum solution, reduced service life of the coating, strong corrosion, etc., to improve surface quality, prolong service life, and improve Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in detail below in conjunction with accompanying drawing:

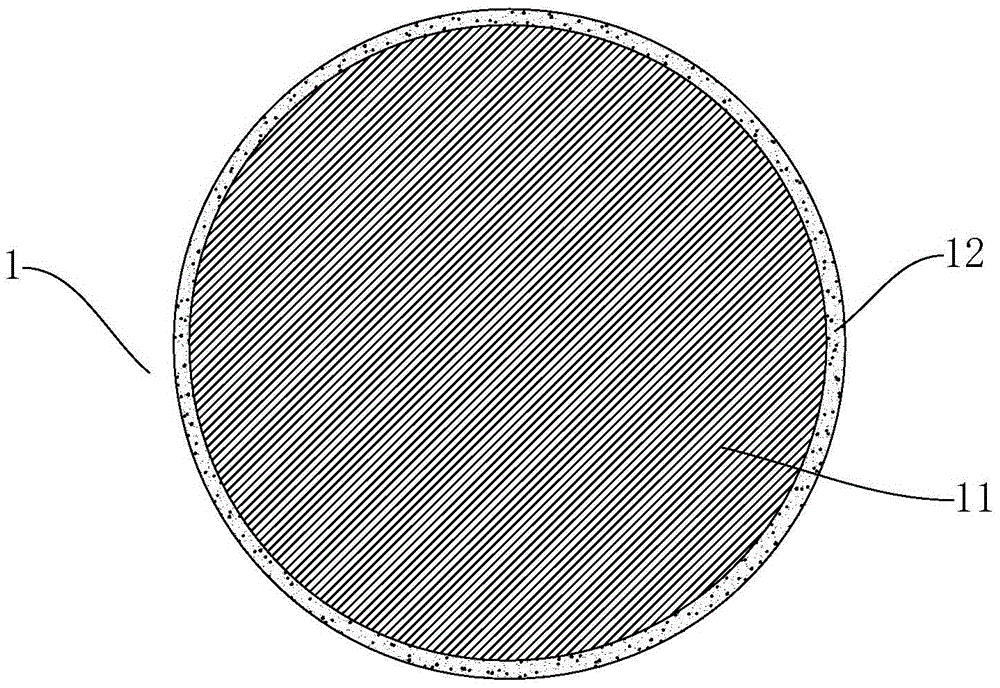

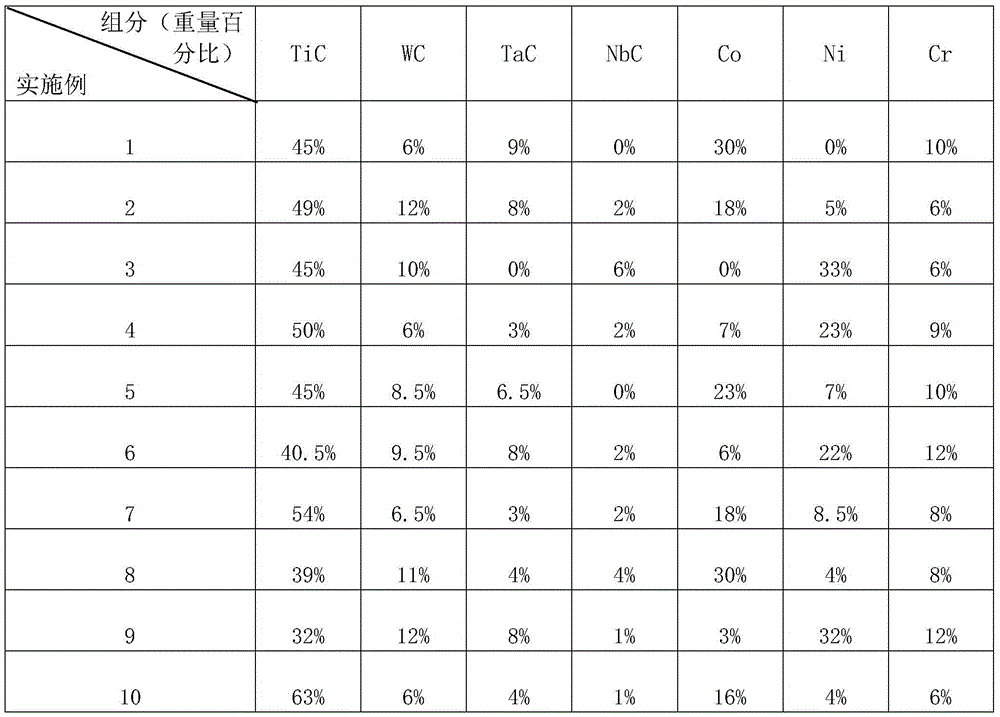

[0045] Such as figure 1 and 2Shown is the corrosion-resistant roller 1. The corrosion-resistant roll 1 includes a substrate 11 and a corrosion-resistant coating 12 covering the surface of the substrate. The base body 11 is a traditional sinking roll. The corrosion-resistant spraying powder is melted and sprayed onto the surface of the substrate 11 by using a thermal spray gun to form a corrosion-resistant coating 12 , and a corrosion-resistant roller 1 coated with the corrosion-resistant coating 12 is obtained. In each embodiment, the composition weight percentage content of the powder for corrosion-resistant spraying is as shown in Table 1:

[0046] Table I

[0047]

[0048] The preparation method of powder for corrosion-resistant spraying is as follows:

[0049] a. Add one or both of TaC and NbC to TiC and WC according to the proportions by weight in Table 2, mix un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com