Micro-expansive moderate-heat Portland cement and production method thereof

A technology of Portland cement and production method, applied in the field of building materials, can solve problems such as low expansion performance, and achieve the effects of improving crack resistance, high clinker quality and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

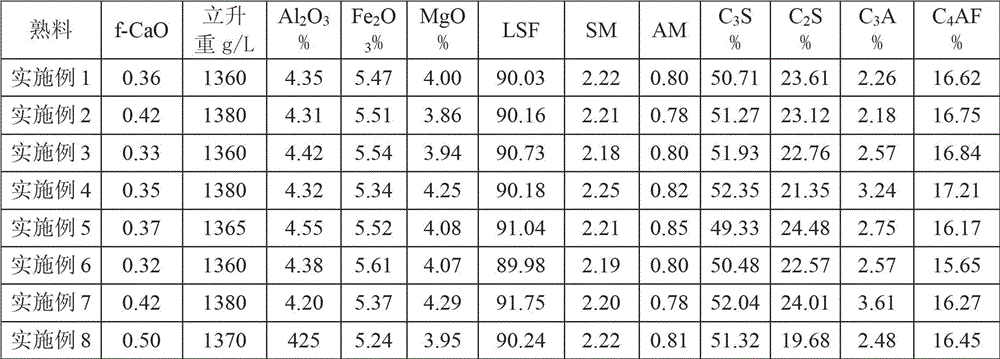

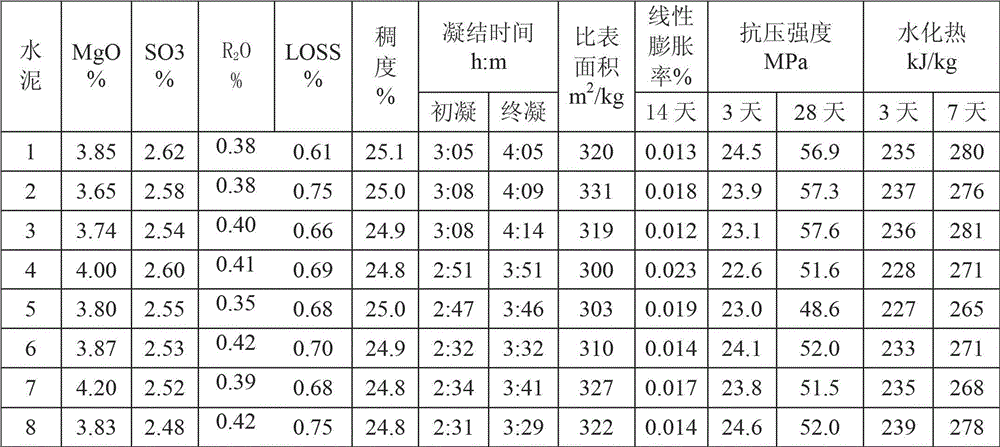

Examples

Embodiment 1

[0040] 1. Raw material preparation: add 75% limestone, 10% sandstone, 10% sulfuric acid slag, and 5% dolomite that meet the quality requirements, add water, grind, then filter to obtain a slurry with a water content of 33%, and stir evenly;

[0041] 2. Slurry dehydration: After the slurry is dehydrated by a vacuum suction filter, a filter cake with a water content of 20% is formed;

[0042] 3. Filter cake drying and crushing: the filter cake is fed into the drying crusher through the box feeder, and the waste gas (600°C) from the kiln tail is used to dry it into raw meal powder with a water content of 3%. The drying exhaust gas is brought into the cyclone separator for material gas separation, and the separated raw meal powder enters the cyclone preheater and decomposition furnace of the firing system, and the exhaust gas (about 150°C) exiting the cyclone separator is sent by the kiln tail fan. After entering the electrostatic precipitator for purification, it is discharged in...

Embodiment 2

[0046] 1. Raw material preparation: add 65% limestone, 20% sandstone, 12% sulfuric acid slag, and 3% dolomite that meet the quality requirements, add water, grind, then filter to obtain a slurry with a water content of 36%, and stir evenly;

[0047] 2. Slurry dehydration: After the slurry is dehydrated by a vacuum suction filter, a filter cake with a water content of 18% is formed;

[0048] 3. Filter cake drying and crushing: the filter cake is fed into the drying crusher through the box feeder, and the waste gas (600°C) from the kiln tail is used to dry it into raw meal powder with a water content of 1%. The drying exhaust gas is brought into the cyclone separator for material gas separation, and the separated raw meal powder enters the cyclone preheater and decomposition furnace of the firing system, and the exhaust gas (about 150°C) exiting the cyclone separator is sent by the kiln tail fan. After entering the electrostatic precipitator for purification, it is discharged in...

Embodiment 3

[0052] 1. Raw material preparation: Add 45% of marl, 32% of chalk, 8% of silica, 7% of sulfuric acid slag, and 8% of magnesite that meet the quality requirements, add water, grind, and then filter to obtain a water content of 35%. slurry, stir evenly;

[0053] 2. Slurry dehydration: After the slurry is dehydrated by a vacuum suction filter, a filter cake with a water content of 17% is formed;

[0054] 3. Filter cake drying and crushing: the filter cake is fed into the drying crusher through the box feeder, and the waste gas (600°C) from the kiln tail is used to dry it into raw meal powder with a water content of 2%. The drying exhaust gas is brought into the cyclone separator for material gas separation, and the separated raw meal powder enters the cyclone preheater and decomposition furnace of the firing system, and the exhaust gas (about 150°C) exiting the cyclone separator is sent by the kiln tail fan. After entering the electrostatic precipitator for purification, it is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydration enthalpy | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com