Semiautomatic ribbon spreading machine and its spreading technology

A semi-automatic and ribbon technology, applied in printing presses, rotary printing presses, screen printing presses, etc., can solve the problems of poor control of tape laying quality, inability to meet production needs, high labor intensity, etc., to reduce labor production costs, The effect of high production efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with specific embodiment:

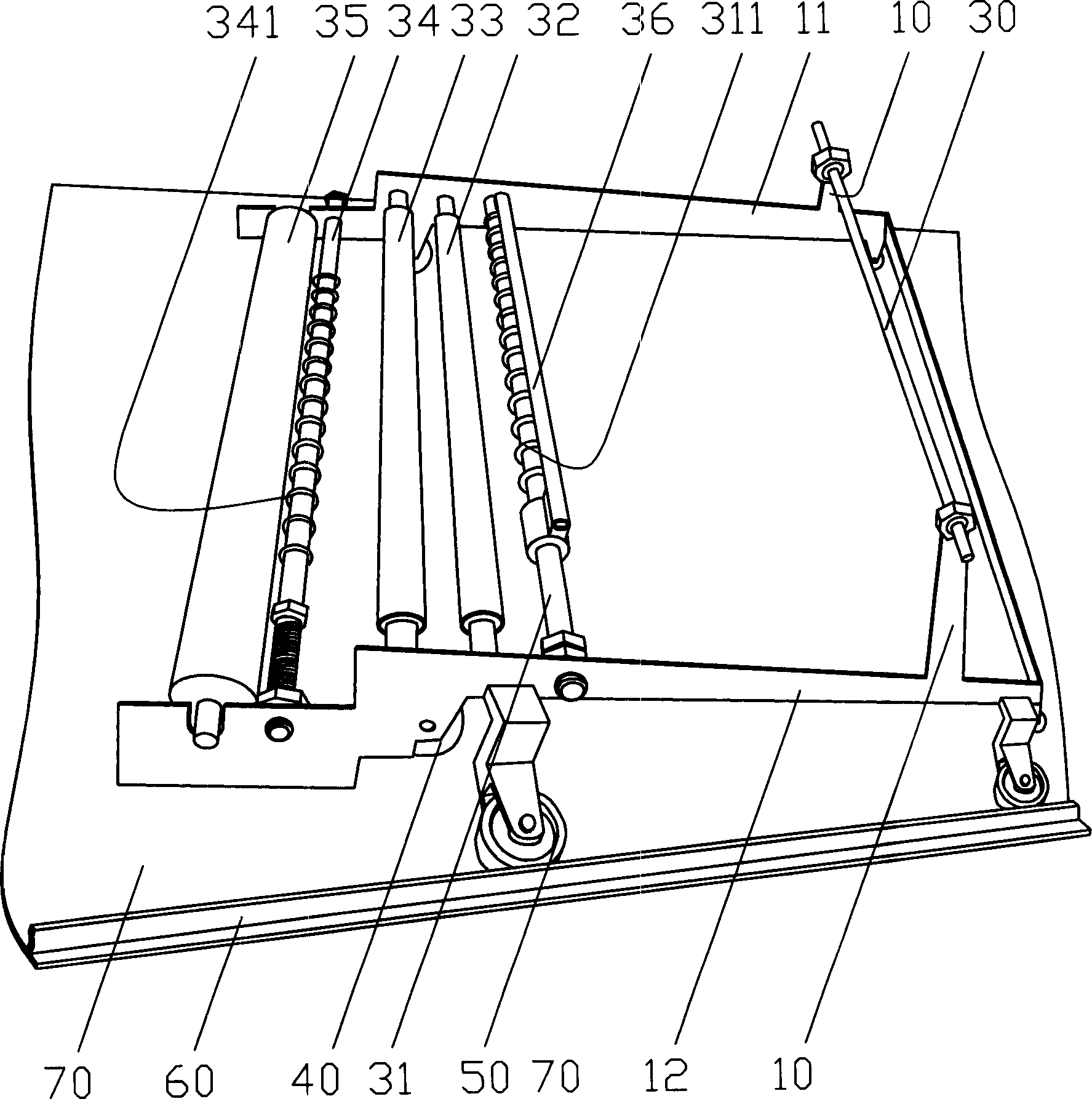

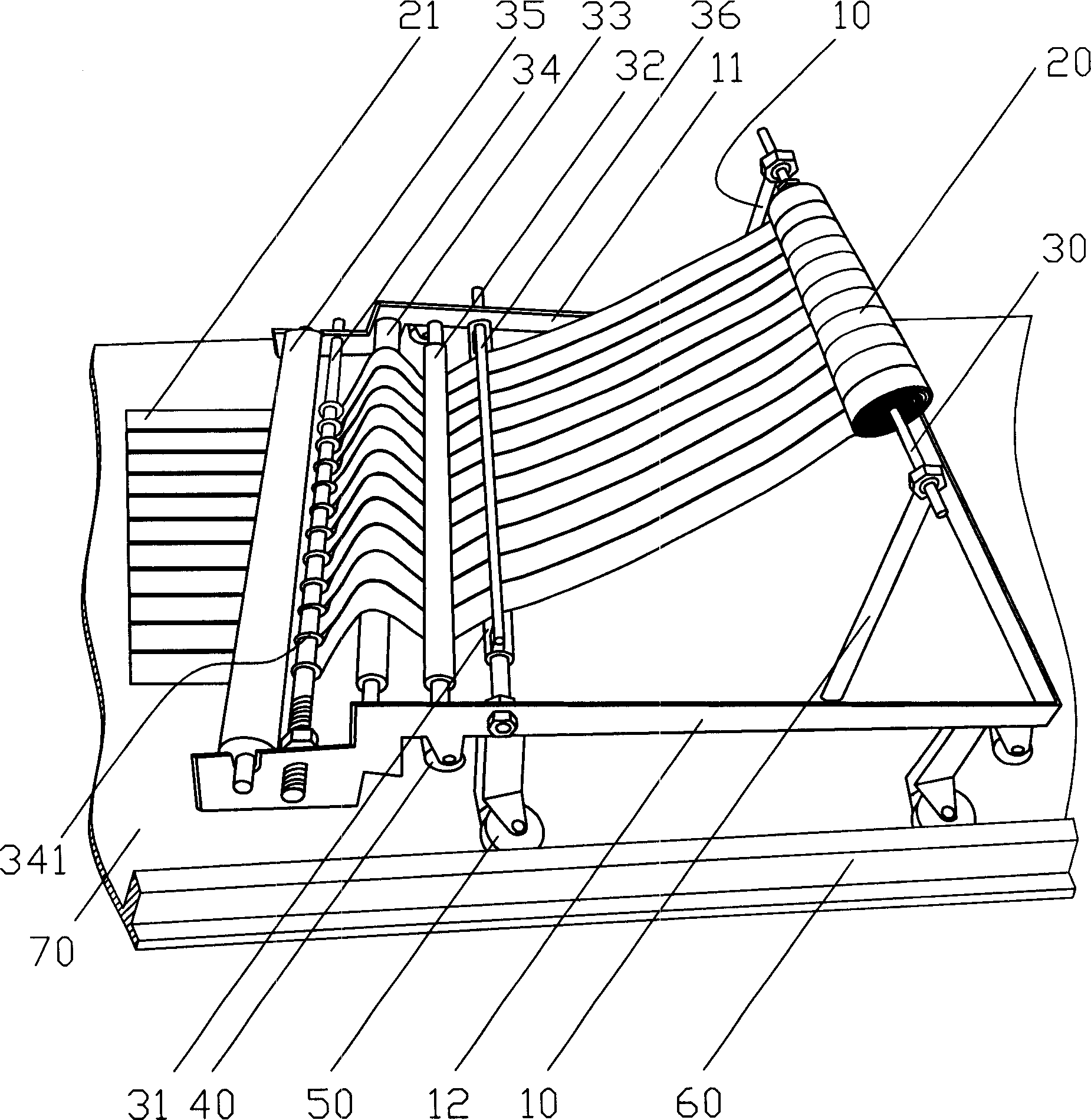

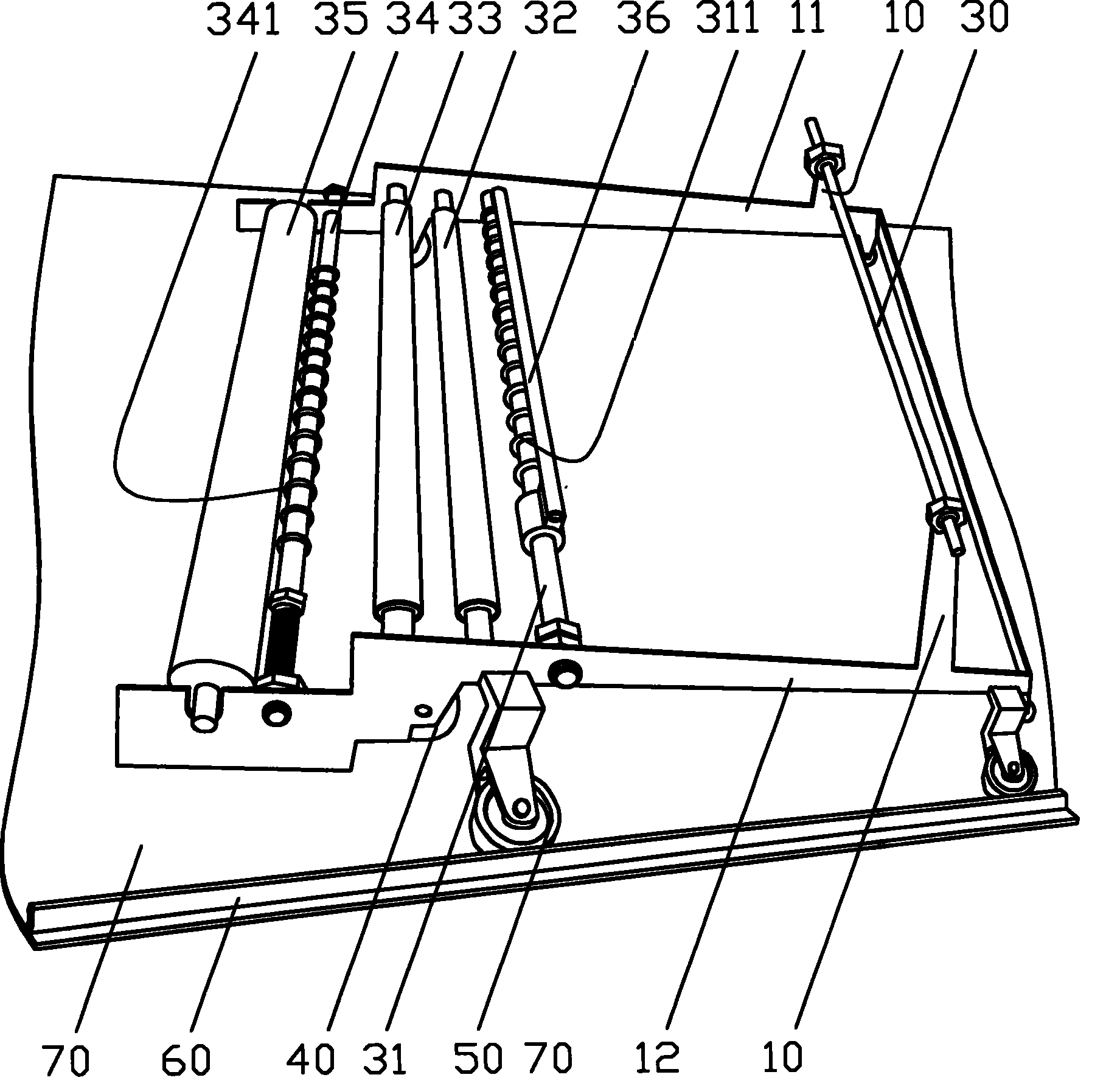

[0018] see Figure 1-2 : Semi-automatic webbing tape laying machine and tape laying process thereof, characterized in that upward supports 10 are respectively arranged on the left and right sides of one end of the rectangular frame, and the webbing roll suspension shaft 30 that can penetrate the webbing roll 20 is placed on the upper end of the support 10 , from one end to the other end of the rectangular frame, there are successively provided with the first tape-distributing shaft 31, the second pinch roller 32, the webbing support roller 33, the second tape-sharing shaft 34 and the third pinch roller 35 installed on the left and right frames , a first pinch roller 36 is arranged above the first tape-distributing shaft 31, a load-bearing travel wheel 40 is arranged below the left and right frames of the rectangular frame, and a walking guide is arranged outside the left frame 11 and / or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com