Gas-liquid reaction method and special device

A technology for gas-liquid reaction and special device, which is applied in chemical methods, series/parallel reactions, chemical instruments and methods for reacting liquid and gas medium, etc. Unreasonable, affecting normal operation, etc., to avoid adhesion or precipitation, small environmental impact, and maintain energy balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

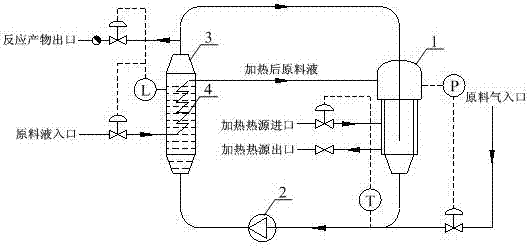

[0023] A gas-liquid reaction method, which uses a gas-liquid reaction device for reaction; the gas-liquid reaction device includes a aging reactor 1, and the outlet of the aging reactor communicates with the bottom inlet of the tubular reactor 3 through a circulation pipe; the aging reactor adopts an elongated type Structure, and directly connected to the circulation pipe, the inner diameter of the cylinder in the heating zone is consistent with the inner diameter of the circulation pipe and the tubular reactor; a mixed-flow circulation pump 2 is installed on the circulation pipe between the outlet of the aging reactor and the bottom inlet of the tubular reactor, and the mixed-flow The inlet of the circulating pump is connected with the outlet of the aging reactor and the inlet of the raw material gas; the central area of the tubular reactor is equipped with a feed heat exchanger 4 to recover part of the heat of reaction, increase the temperature of the reaction raw material l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com