Automatic control device of active coke adsorption tower flue gas balance system

A technology of automatic control device and balance system, which is applied in gas treatment, membrane technology, dispersed particle separation, etc. It can solve the problems of slow operation and adjustment, and achieve the effect of wide application scope, low investment and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

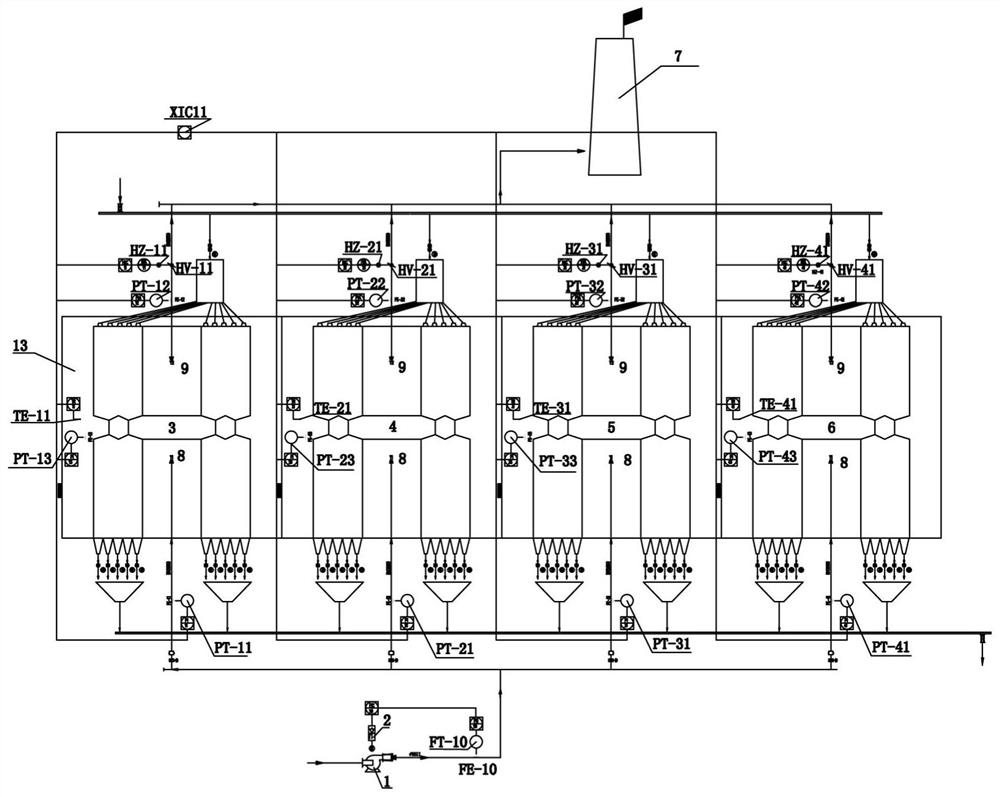

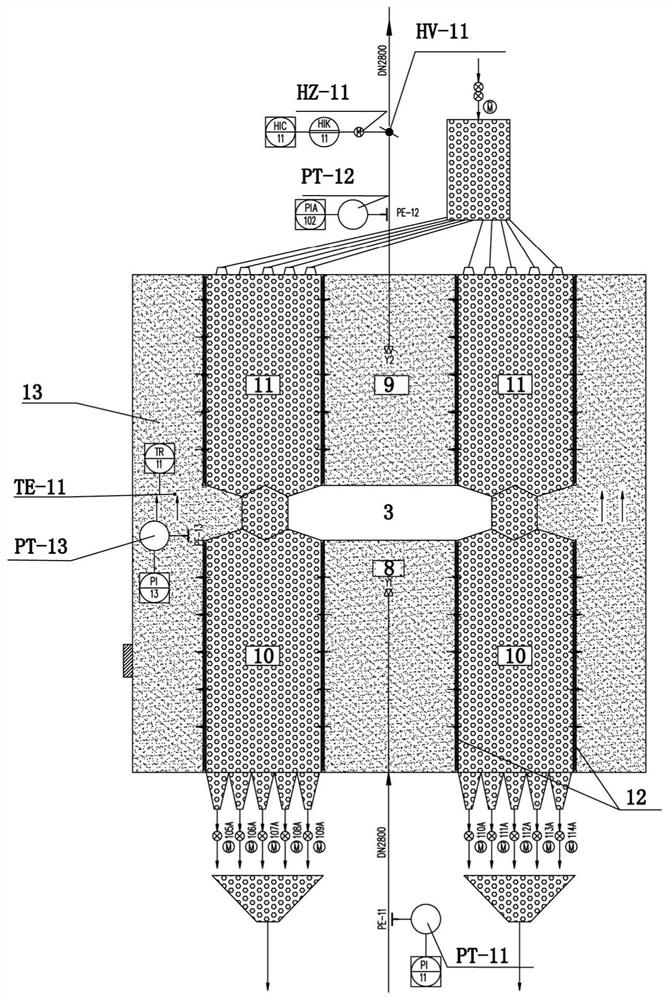

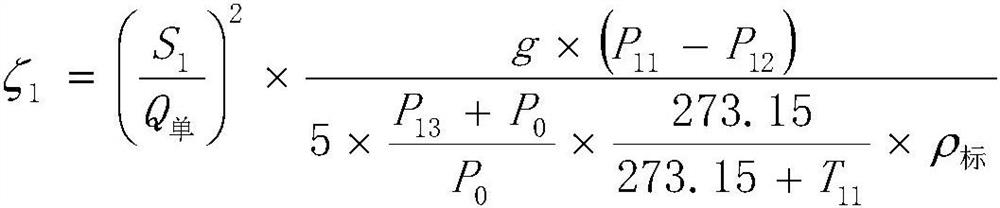

[0098] The adsorption tower of the embodiment of the present invention is composed of four adsorption units. Including: the gas flow meter FE-10 and the flow transmitter FT-10 arranged on the outlet main pipe of the booster fan 1, and the air volume adjustment is realized by controlling the frequency converter 2 of the booster fan 1, which is mainly used for the present invention Initial calibration, followed by online correction of the resistance coefficient of each adsorption unit of the adsorption tower. location such as figure 1 As shown; the adsorption tower is composed of multiple adsorption units, and the flue gas is divided into the corresponding number of sub-pipes of the adsorption units by the booster fan 1 through the main pipe. Now take the first adsorption unit 3 as an example to describe the direction of flue gas entering the adsorption unit and the setting of measuring points (such as figure 2 As shown), the adsorption unit inlet pressure detection pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com