Bolt-free PCB wiring terminal provided with button

A connection terminal and screw-free technology, which is applied in the direction of connection, fixed connection, and parts of the connection device, etc., can solve the problems of scratched wires, inconvenient wiring, and stuck wires, so as to avoid plastic chips and ensure smooth pressing , Improve the effect of mechanical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

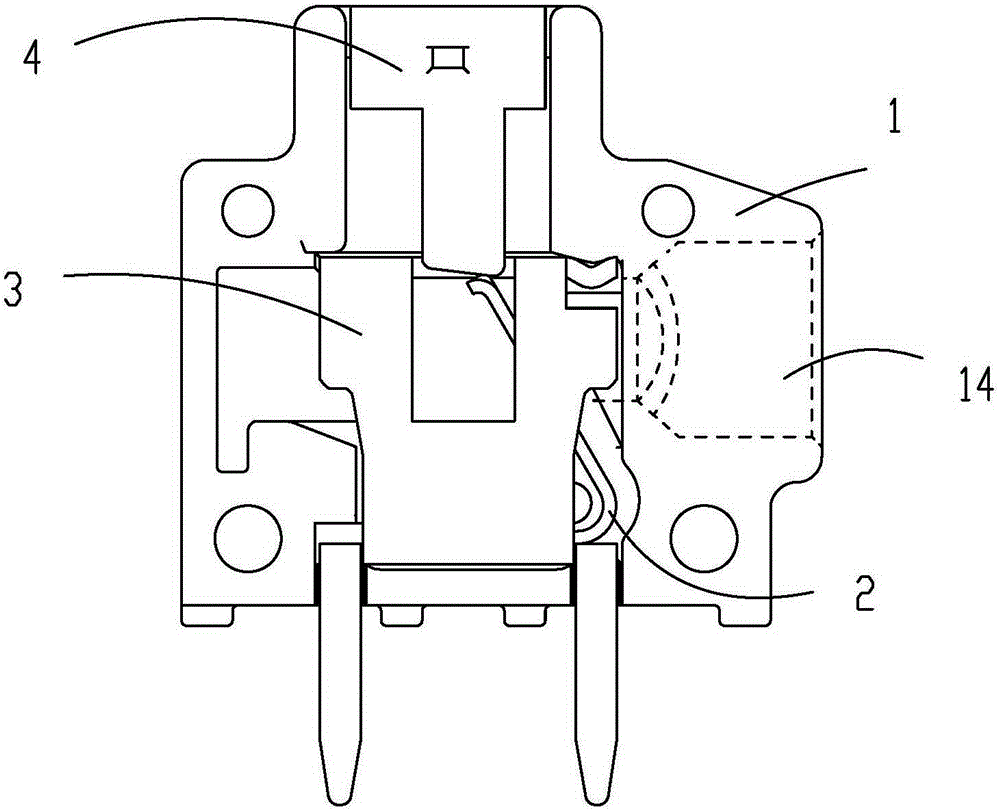

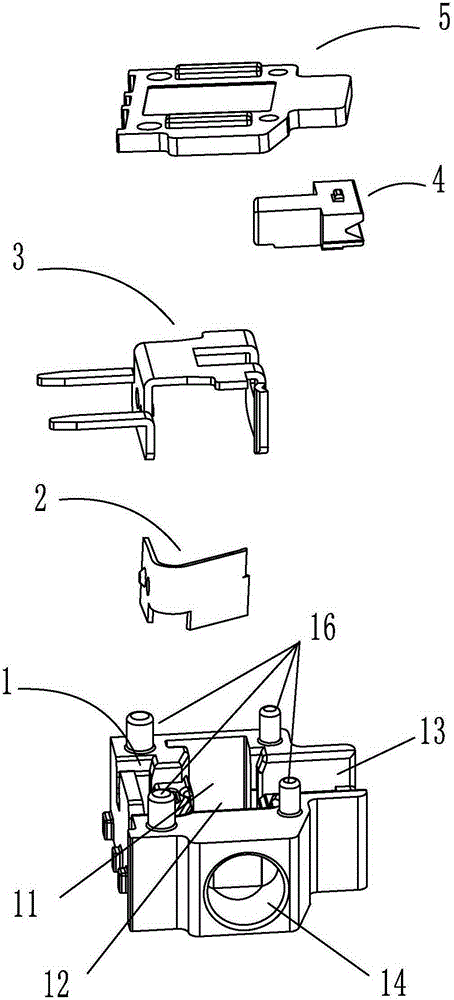

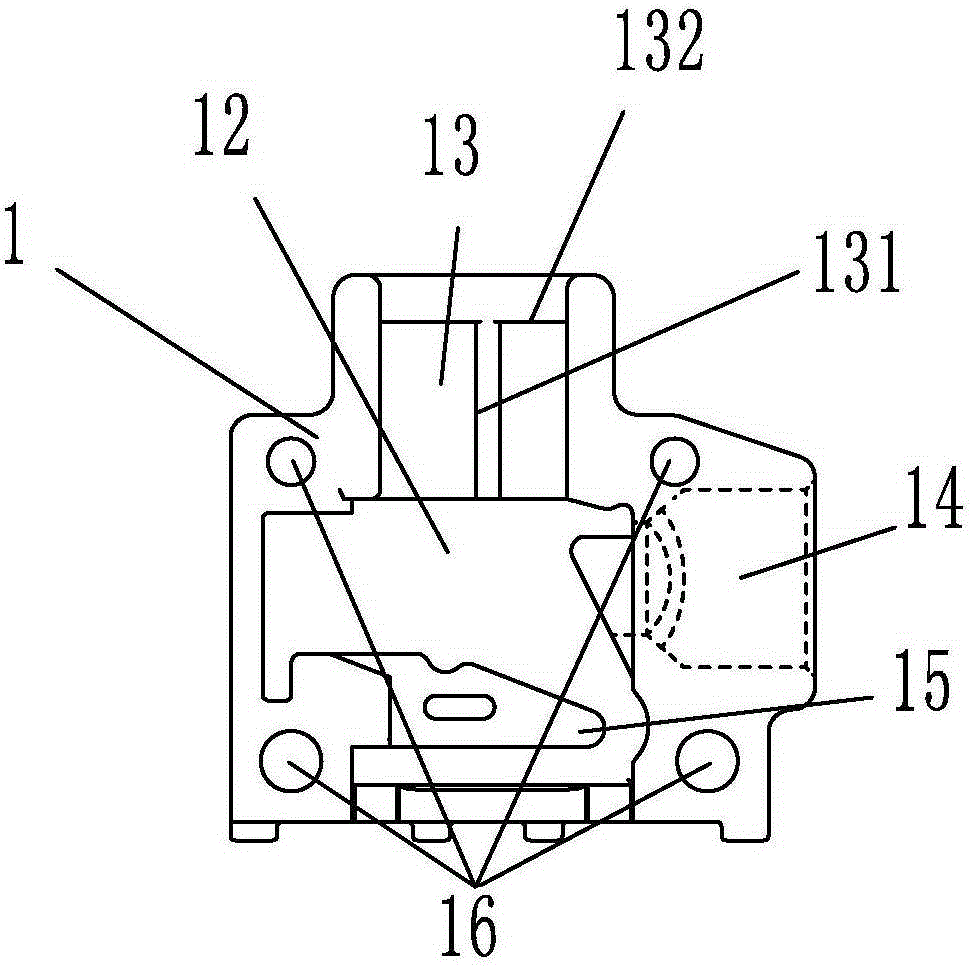

[0037] see Figure 1 to Figure 9 As shown, a screw-free PCB terminal with a button of the present invention includes a base 1, a flat spring 2, a clamping part 3 and a button 4; the base 1 is provided with a housing cavity 12 with a side opening 11 ; The flat spring 2 and the clamping part 3 are installed in the accommodation cavity 12 of the base, and the upper part of the flat spring 2 is elastically pressed against the top of the clamping part 3 in an oblique manner; The top of the base 1 is equipped with a button 4, which is biased on the top side of the flat spring, so as to realize the withdrawal of the wire when pressed against the flat spring; There is a button groove 13 leading to the accommodating chamber 12, and the button 4 is slidably limited and installed in the button groove 13; on the top of the clamping part 3, there is a button that allows the lower part of the button to pass through to press against the flat spring 2 to realize The first through hole 311 th...

Embodiment 2

[0054] see Figure 10 to Figure 11 As shown, a screw-free PCB terminal with a button of the present invention is different from Embodiment 1 in that the bottom end of the button 4 is also provided with two downwardly protruding stop bosses 45, so The pressing portion 22 of the flat spring is fitted between the two stop bosses 45 so that the pressing portion 22 of the flat spring is limited to slide between the two stop bosses 45 when the button 4 is pressed.

[0055] When the button is pressed, in order to protect the pressed part of the flat spring, the present invention adds two stop bosses at the bottom of the button, so that the shrapnel can only slide between the two bosses, avoiding the side of the flat spring. Squeeze the button to the other side with counter force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com