Pulverized coal upgrading pyrolysis device and upgrading pyrolysis process

A technology for upgrading and pulverizing coal, applied in the petroleum industry, special forms of dry distillation, coke ovens, etc., can solve the problems of low utilization efficiency, loss, easy combustion, etc., and achieve the effect of reducing carbon loss, improving efficiency, and reducing crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

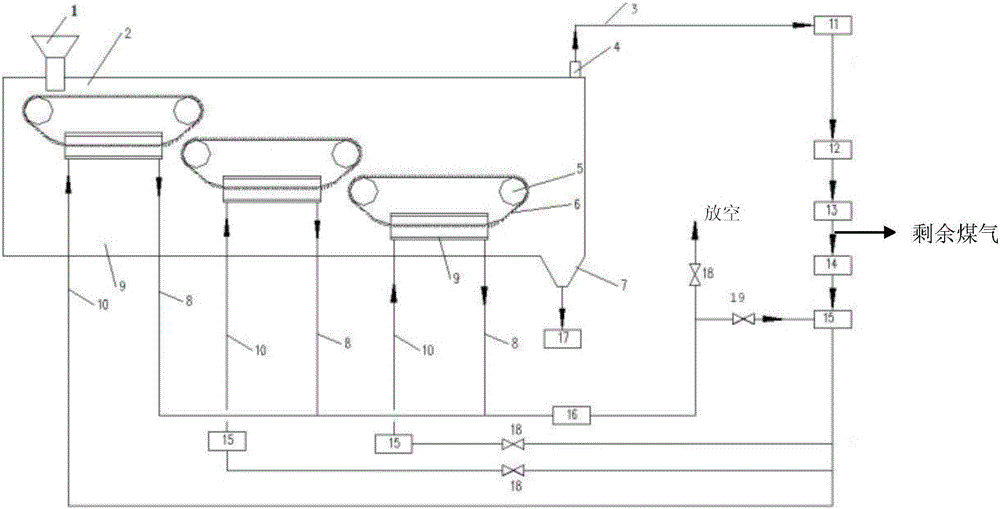

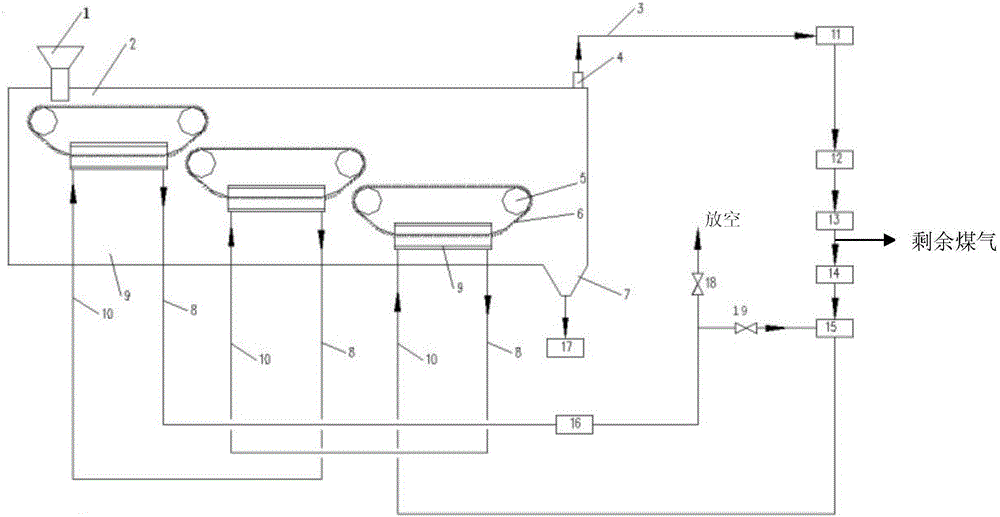

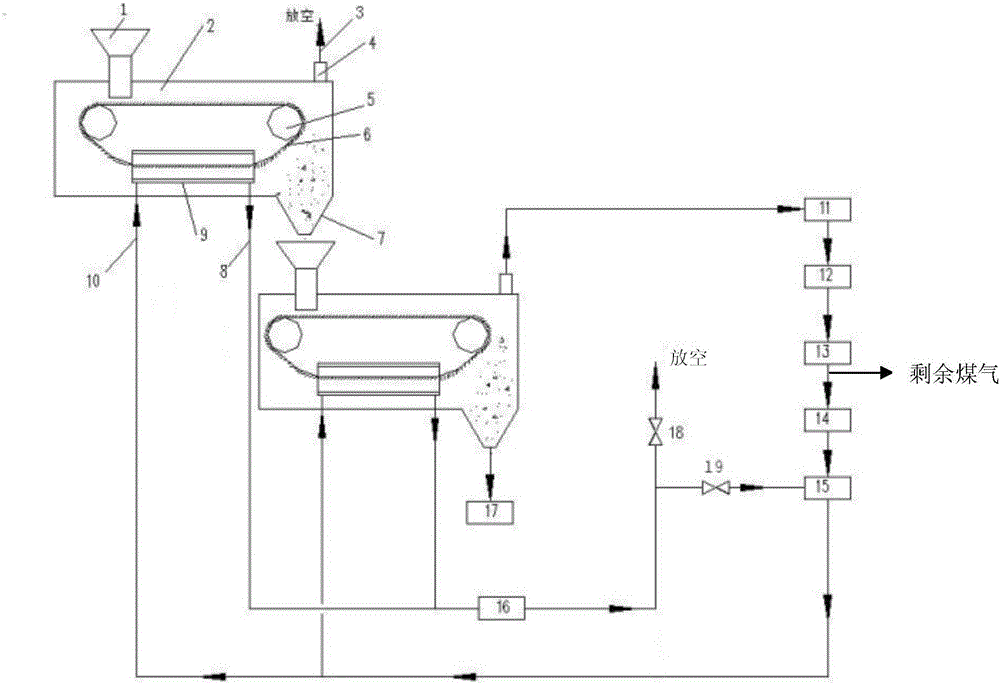

[0046] Such as figure 1 As shown, the pyrolysis upgrading reaction furnace of the present invention includes a coal drop port 1 , a upgrading furnace body 2 , a gas outlet pipeline 3 , a gas outlet 4 , a toothed drive wheel 5 , and a toothed drive wheel 6 . The coal drop port 1 is set at the upper front end of the upgrading furnace body 2, and the raw pulverized coal enters the inside of the upgrading furnace body 2 through the coal drop port 1, and falls onto the toothed steel belt 6, which is driven by the toothed driving wheel. 5 drives the pulverized coal to advance slowly; the upgrading furnace body 2 is also provided with a heat exchanger 9, which is arranged at the lower and middle position of the toothed steel belt 6, and is used to realize the heating of the toothed steel belt 6; The heat exchanger 9 includes a flue gas inlet pipeline 10 and a flue gas outlet pipeline 8. The high-temperature flue gas from the hot blast stove 14 enters the heat exchanger 9 from the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com