A method of hydrogen and oxygen plasma combined enhanced coal slime flotation

A technology of oxygen plasma and plasma, which is applied in the field of plasma enhanced flotation, can solve the problem of lack of surface hydrophobicity modification of coal slime, and achieve the effects of improving buoyancy, improving quality upgrading efficiency, and reducing chemical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

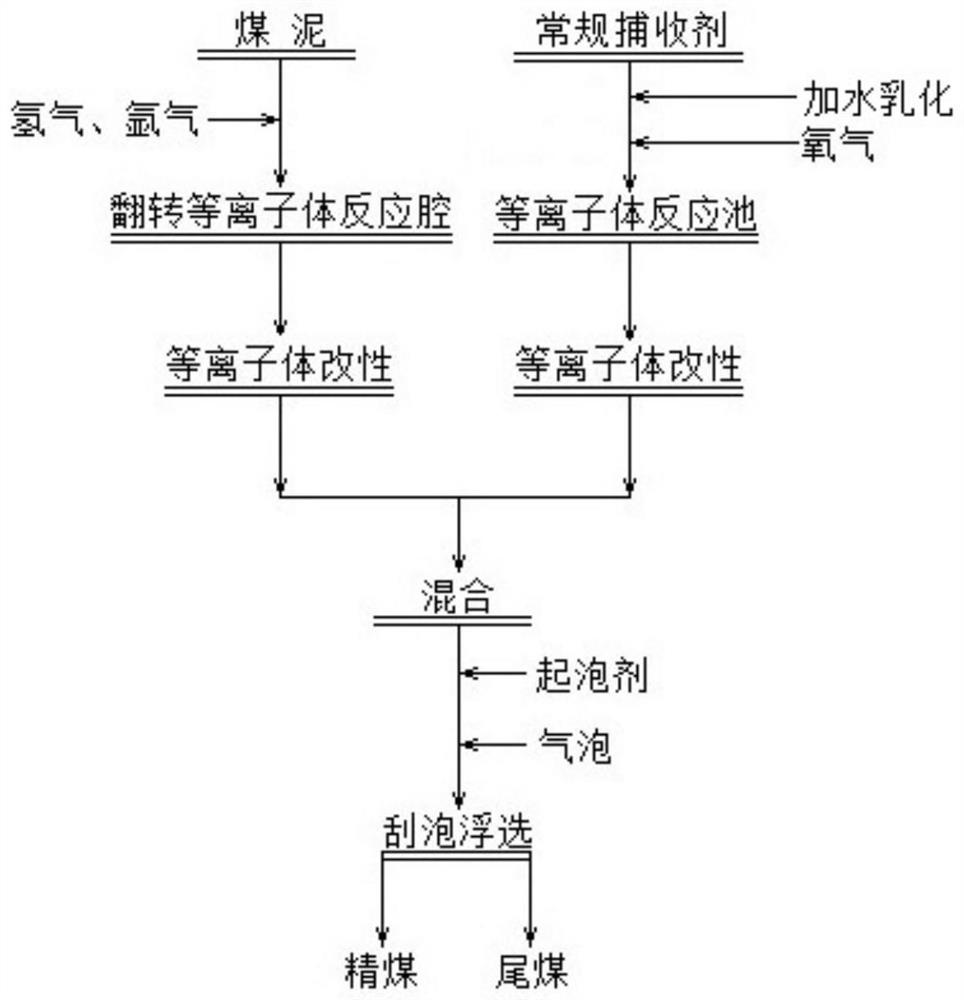

Method used

Image

Examples

Embodiment

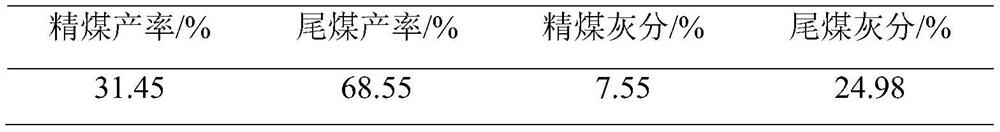

[0026] Example: Shendong low-rank coal was used as the test coal sample, the moisture content was <10%, it was ground to -0.074mm, the floating ash content was 19.77%, and the impurity minerals were mainly quartz, kaolinite, etc.

[0027] First, the direct flotation test of test coal samples was carried out. The flotation conditions were: flotation concentration 80g / l, collector was diesel oil, dosage 7500g / t, flotation machine speed 1800rpm, gas filling volume 500ml / min, foaming The agent is 2-octanol, the dosage is 2500g / t, after one flotation, the foam and the tank bottom product are collected, the foam becomes clean coal, and the tank bottom product is tailing coal. The results are shown in Table 1.

[0028] Table 1 Low-rank coal direct flotation results

[0029]

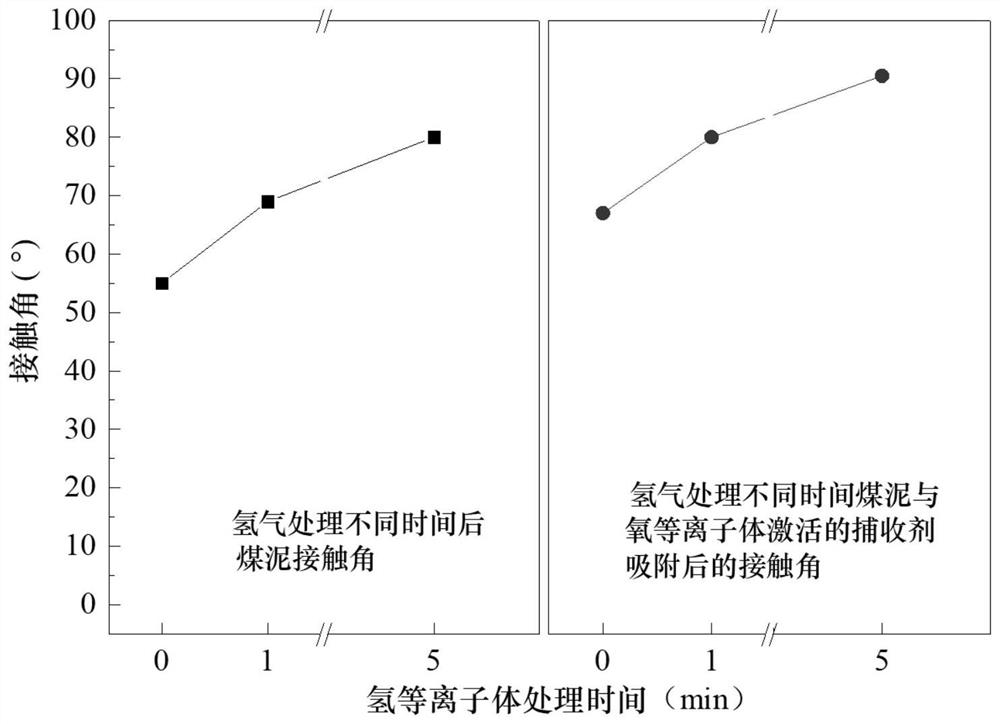

[0030] Then use hydrogen plasma to modify the coal slime for 5 minutes, and mix it evenly with the aqueous collector solution activated by oxygen plasma for 5 minutes, add a foaming agent, inflate and scrape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com