Beneficiation method of particulate sulfur oxygen mixed copper ore in high and cold area

A technology of mineral processing methods in alpine regions, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of slow flotation speed of copper minerals, large amount of mineral processing agents, low recovery rate of mineral processing, etc., to promote The effect of sustainable development of regional economy, improvement of comprehensive utilization rate and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

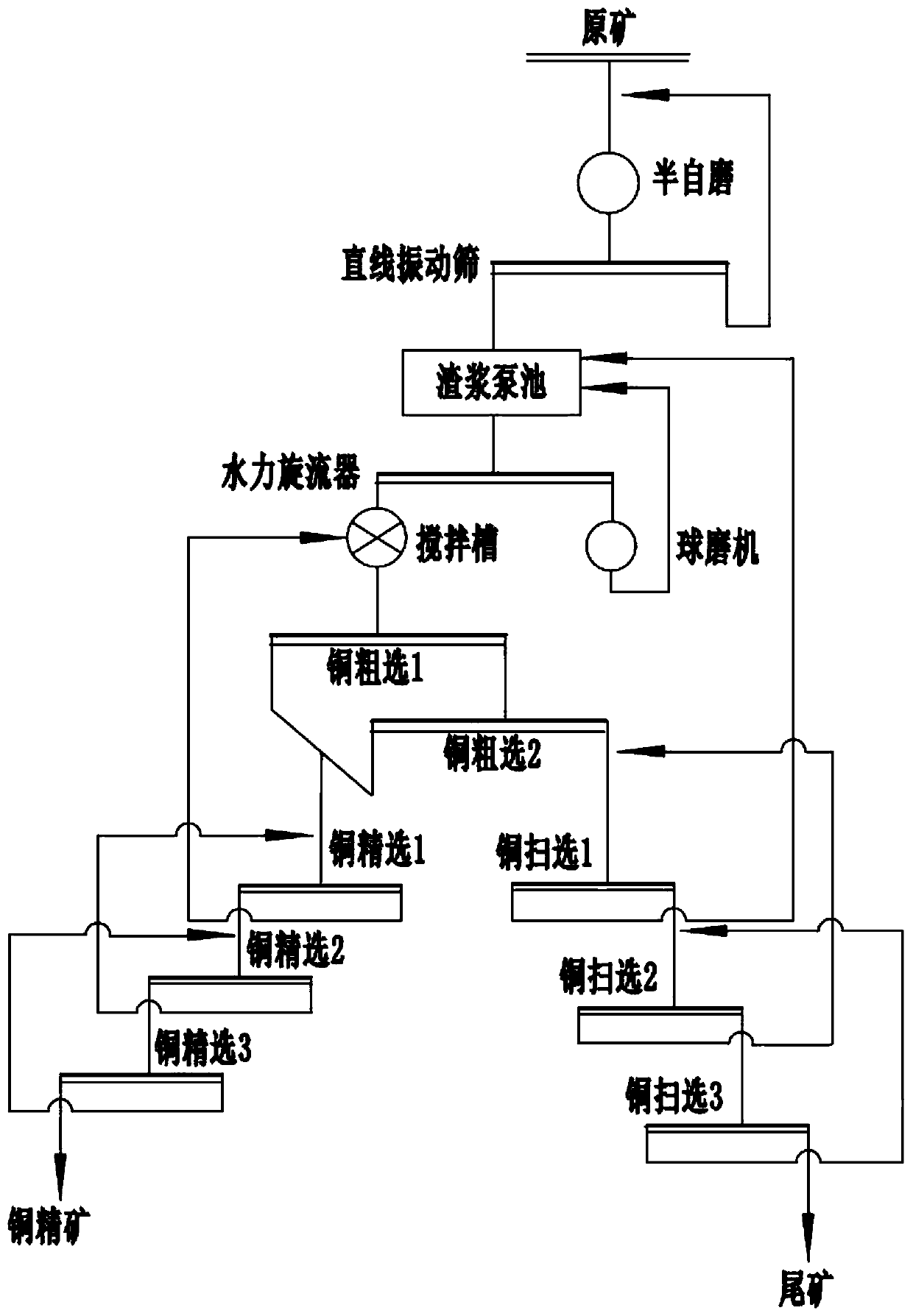

[0028] A kind of beneficiation method of particulate sulfur-oxygen mixed type copper ore in alpine region comprises the following steps:

[0029] Step 1. Grinding the raw ore to obtain a semi-autogenous grinding ore product, sieving the semi-autogenous grinding ore product to obtain the on-sieve pebbles and under-sieve pulp, and the above-sieve pebbles to return to the semi-autogenous grinding process Repeated grinding, the under-screen slurry enters the slurry pump pool;

[0030] Step 2: Add a certain amount of lime, vulcanizing agent, activator, collector HTB and foaming agent to the slurry in the slurry pump pool to classify the slurry in the slurry pump pool to obtain graded overflow and graded sand settling , the graded grit enters the ball mill for grinding to obtain a ball mill grinding product, and the ball mill grinding product is returned to the slurry pump pool for repeated classification, and the graded overflow enters the mixing tank for mixing and mixing;

[003...

Embodiment 2

[0035] A kind of beneficiation method of particulate sulfur-oxygen mixed type copper ore in alpine region comprises the following steps:

[0036] Step 1. Grinding the raw ore with a particle size grade of -160mm accounting for more than 80% of the total mass of the raw ore to obtain a semi-autogenous ore product with an ore concentration of 80-85%, and screening the semi-autogenous ore product The above-sieve obstinate with a particle size greater than 12mm and the under-sieve slurry with a particle size of -0.074mm in the contained ore accounted for 30-35% of the total mass of the ore contained in it were obtained. The above-sieve obstinate was returned to the semi-autogenous grinding for repeated grinding. The slurry under the sieve enters the slurry pump pool;

[0037] Step 2. Add a certain amount of lime, vulcanizing agent, activator, collector HTB and foaming agent to the slurry in the slurry pump pool to classify the slurry in the slurry pump pool to obtain graded overfl...

Embodiment 3

[0042] A kind of beneficiation method of particulate sulfur-oxygen mixed type copper ore in alpine region comprises the following steps:

[0043] Step 1. Grinding the raw ore with a particle size grade of -160mm accounting for more than 80% of the total mass of the raw ore to obtain a semi-autogenous ore product with an ore concentration of 80-85%, and screening the semi-autogenous ore product The above-sieve obstinate with a particle size greater than 12mm and the under-sieve pulp with a particle size of -0.074mm in the contained ore accounted for 30-35% of the total mass of the ore contained in it were obtained. The above-sieve obstinate was returned to semi-autogenous grinding for repeated grinding. The slurry under the sieve enters the slurry pump pool;

[0044] Step 2. The ore concentration of the slurry in the slurry pump pool is 48-52%. The purpose is to achieve high-concentration slurry mixing and dosing; add 1000-1500g / t lime and 30-50g / t vulcanization to the slurry i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com