A kind of flotation method of fine grain embedding copper sulfide ore

A copper sulfide and fine particle technology, applied in flotation, solid separation and other directions, can solve the problems of poor selective collection effect, inability to meet the needs of fine-grained embedded copper sulfide ore separation, and low copper recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

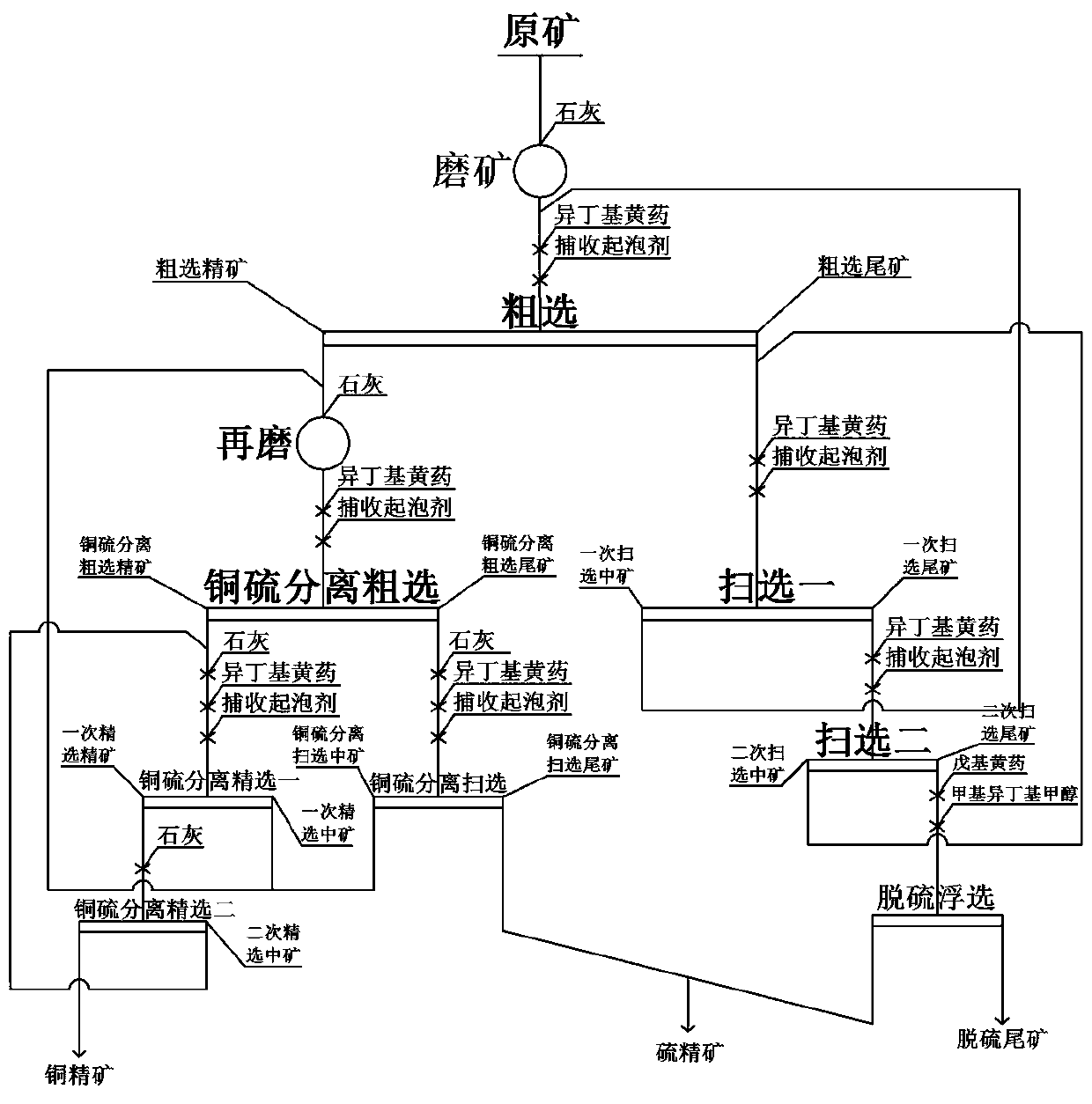

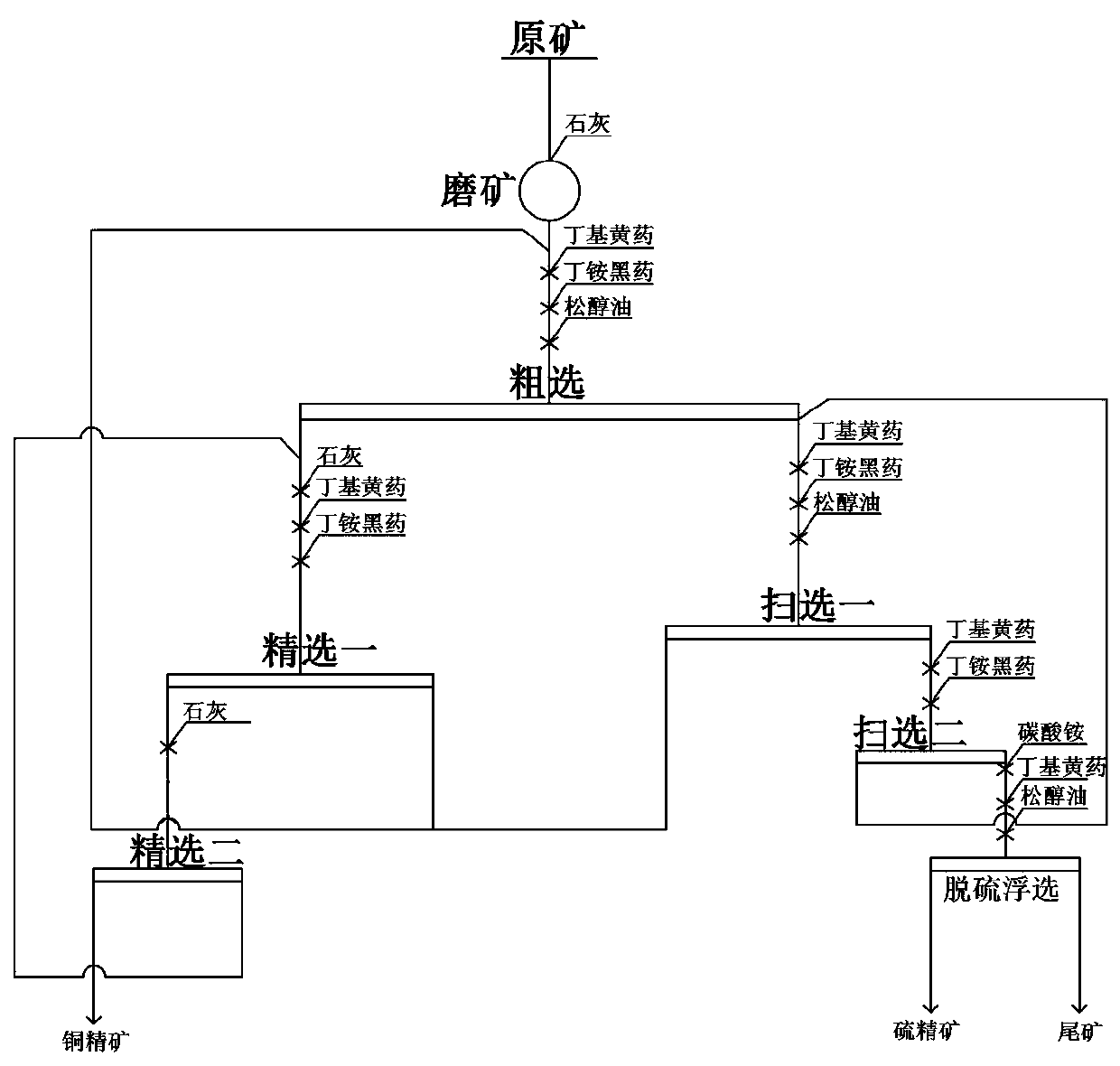

Method used

Image

Examples

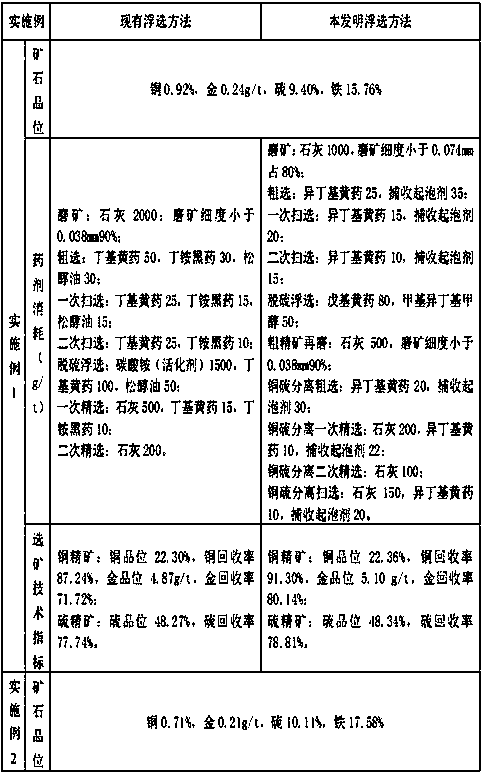

Embodiment 1

[0034] The raw ore grades in this example are copper 0.92%, gold 0.24g / t, sulfur 9.40%, and iron 15.76%. Its material composition is: the main metal minerals in the ore are pyrite, pyrrhotite, chalcopyrite, magnetite, galena, sphalerite, a small amount of marcasite, bornite, and trace minerals are chalcocite ore, arsenopyrite, blue chalcocite, natural gold, silver-gold ore; gangue minerals include pyroxene, garnet, quartz, calcite, feldspar, chlorite, epidote, etc. The results of primary mineral phase analysis show that copper sulfide minerals include primary copper minerals and secondary copper minerals, mainly primary copper minerals, copper oxide accounts for 1-3%, chalcopyrite distribution is extremely uneven, mostly in the range of 0.005 ~0.15mm, of which particles smaller than 0.038mm accounted for 89.5%. The beneficiation index of copper is basically not affected by the oxidation of the ore, but the particle size of copper minerals in the ore, the content of secondary ...

Embodiment 2

[0049] The raw ore grades in this example are copper 0.71%, gold 0.21g / t, sulfur 10.11%, and iron 17.58%. Its material composition is: the main metal minerals in the ore are pyrite, pyrrhotite, chalcopyrite, magnetite, and small and trace minerals are bornite, chalcocite, galena, arsenopyrite, natural gold , Silver and gold mines; gangue minerals include garnet, quartz, calcite, feldspar, chlorite, epidote, etc. The results of primary mineral phase analysis show that copper sulfide minerals include primary copper minerals and secondary copper minerals, mainly primary copper minerals, copper oxide accounts for 2.8%, chalcopyrite distribution is extremely uneven, mostly in the range of 0.005-0.15 mm, of which particles smaller than 0.038mm accounted for 86.3%.

[0050] A method for flotation of fine-grained copper sulfide ore, characterized in that it specifically comprises the following steps:

[0051] A. Grinding: Crushing and grinding the raw ore until the ore particles wit...

Embodiment 3

[0064] The raw ore grade of this embodiment is copper 0.47%, gold 0.15g / t, sulfur 5.34%, and iron 10.86%. Copper ore, followed by blue chalcocite, chalcocite, sphalerite, magnetite, bornite, rutile, ilmenite, a small or trace amount of marcasite, pyrrhotite, limonite, calcite Lead ore, molybdenite, etc. The gangue minerals are mainly quartz and feldspar, followed by sericite, hornblende, staurite, and a small amount of calcite. The ore is mainly composed of chalcopyrite, blue chalcopyrite and copper blue content are small, and a small amount of malachite; some chalcopyrite is fine-grained and very dispersed, and it is not easy to dissociate from the gangue as a monomer, and the chalcopyrite is distributed extremely Inhomogeneous, generally distributed in a sparsely disseminated state, and its particles are relatively fine, mostly distributed between 0.005-0.15mm, of which the particles smaller than 0.038mm account for 99.7%.

[0065] A method for flotation of fine-grained cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com