Method for removing pyrrhotite from high-sulfur iron ore concentrate

A high-sulfur iron concentrate and pyrrhotite technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as poor separation effect and loss of iron concentrate recovery rate, and achieve saving Grinding cost, solving separation problem, effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

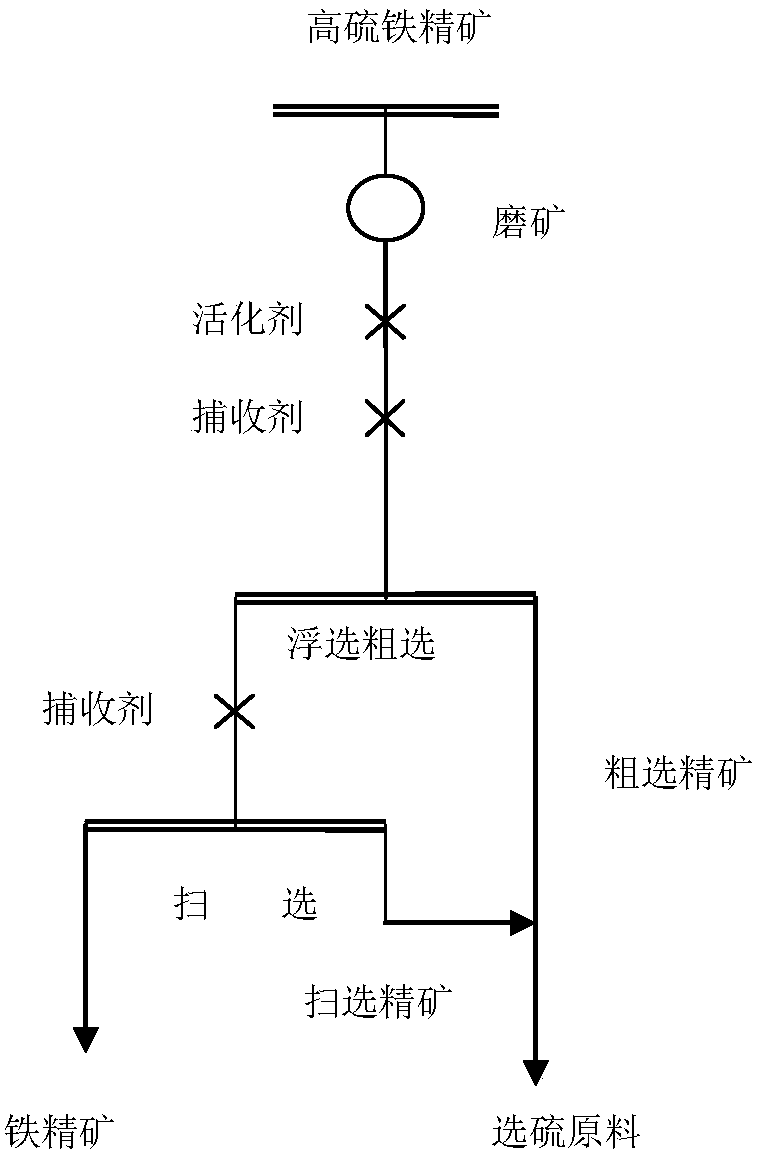

[0020] A method for removing pyrrhotite from high-sulfur iron concentrate mainly includes the following parts:

[0021] 1. Handling of raw materials;

[0022] The high-sulfur iron concentrate with a total iron grade of 67.30% and a sulfur grade of 2.02% is ground to -200 mesh, accounting for 82.1%, and then the ground product is concentrated to a pulp concentration of 40%.

[0023] 2. Activation of pyrrhotite;

[0024] The ore pulp obtained by the above steps is used as the raw material for flotation pyrrhotite, and aluminum sulfate is used as the pH regulator and activator of pyrrhotite. 5min, adjust the pH value to 5.

[0025] 3. Rough separation of pyrrhotite;

[0026] The raw material obtained in the above steps is used as the flotation roughing raw material, and the mass ratio of 2.5:1.5:0.6 amyl xanthate sodium, ethyl xanthate sodium and butyl sodium black medicine is added to the raw material as a catcher for pyrrhotite Collecting agent, stirring 2min under the cond...

Embodiment 2

[0031] A method for removing pyrrhotite from high-sulfur iron concentrate mainly includes the following parts:

[0032] 1. Handling of raw materials;

[0033] The high-sulfur iron concentrate with a total iron grade of 67.40% and a sulfur grade of 3.01% is ground to -200 mesh, accounting for 75.5%, and then the ground product is concentrated to a pulp concentration of 38.5%.

[0034] 2. Activation of pyrrhotite;

[0035] The ore pulp obtained by the above steps is used as the raw material for flotation pyrrhotite, and aluminum sulfate is used as the pH regulator and activator of pyrrhotite. The amount of pH regulator and activator is 4kg / t, and it is stirred at natural temperature for 6min , adjust the pH value to 4.6.

[0036] 3. Rough separation of pyrrhotite;

[0037] The raw material obtained in the above steps is used as the flotation roughing raw material, and the mass ratio of 3:1:0.8 amyl xanthate sodium, ethyl xanthate sodium and butyl sodium black medicine is adde...

Embodiment 3

[0042] A method for removing pyrrhotite from high-sulfur iron concentrate mainly includes the following parts:

[0043] 1. Handling of raw materials;

[0044] The high-sulfur iron concentrate with a total iron grade of 66.70% and a sulfur grade of 1.41% is ground to -200 mesh, accounting for 76.5%, and then the ground product is concentrated to a pulp concentration of 41.1%.

[0045] 2. Activation of pyrrhotite;

[0046]The ore pulp that obtains with above-mentioned steps is as the raw material of flotation pyrrhotite, adopts the mixture of mass ratio 1:1 sodium phosphate and aluminum sulfate as the pH adjuster and the activator of pyrrhotite, the pH adjuster and the activator consumption are 2.0kg / t, stirred at natural temperature for 5min, and adjusted the pH value to 5.1.

[0047] 3. Rough separation of pyrrhotite;

[0048] The raw material obtained in the above steps is used as the flotation roughing raw material, and a mass ratio of 2:2:0.5 amyl xanthate sodium, ethyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com