Multi-point sensing and intelligent control method for temperature of gas heating stove

A technology of gas heating and intelligent control, applied in the direction of electrical program control, furnace control device, thermometer, etc., can solve the problems of failure to effectively detect the difference and uniformity of the temperature in the furnace, achieve uniform heating and heat treatment, improve quality, Guaranteed temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

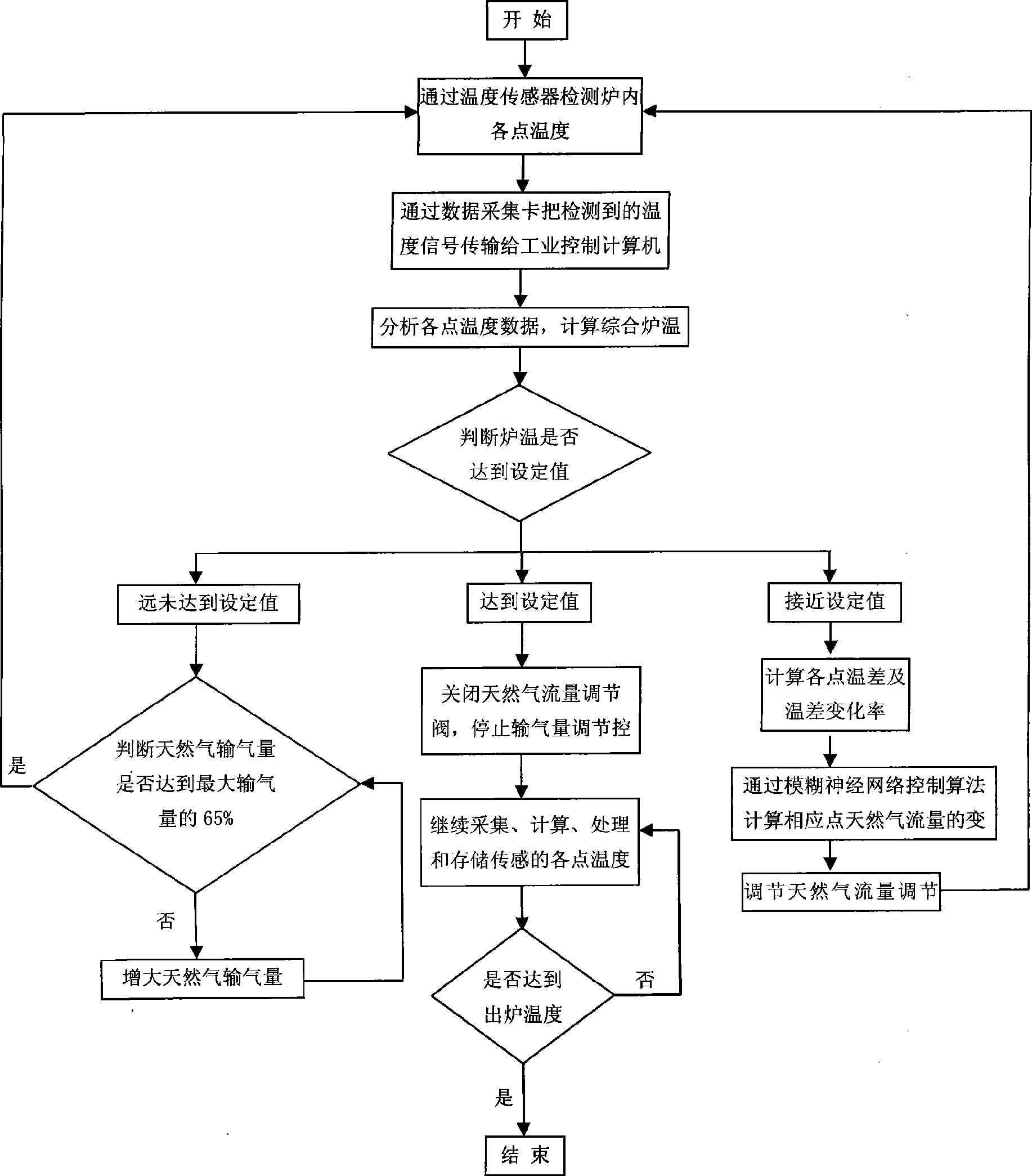

[0019] combine figure 1 , a gas heating furnace temperature multi-point sensing and intelligent control method of the present invention is characterized in that it comprises the following steps:

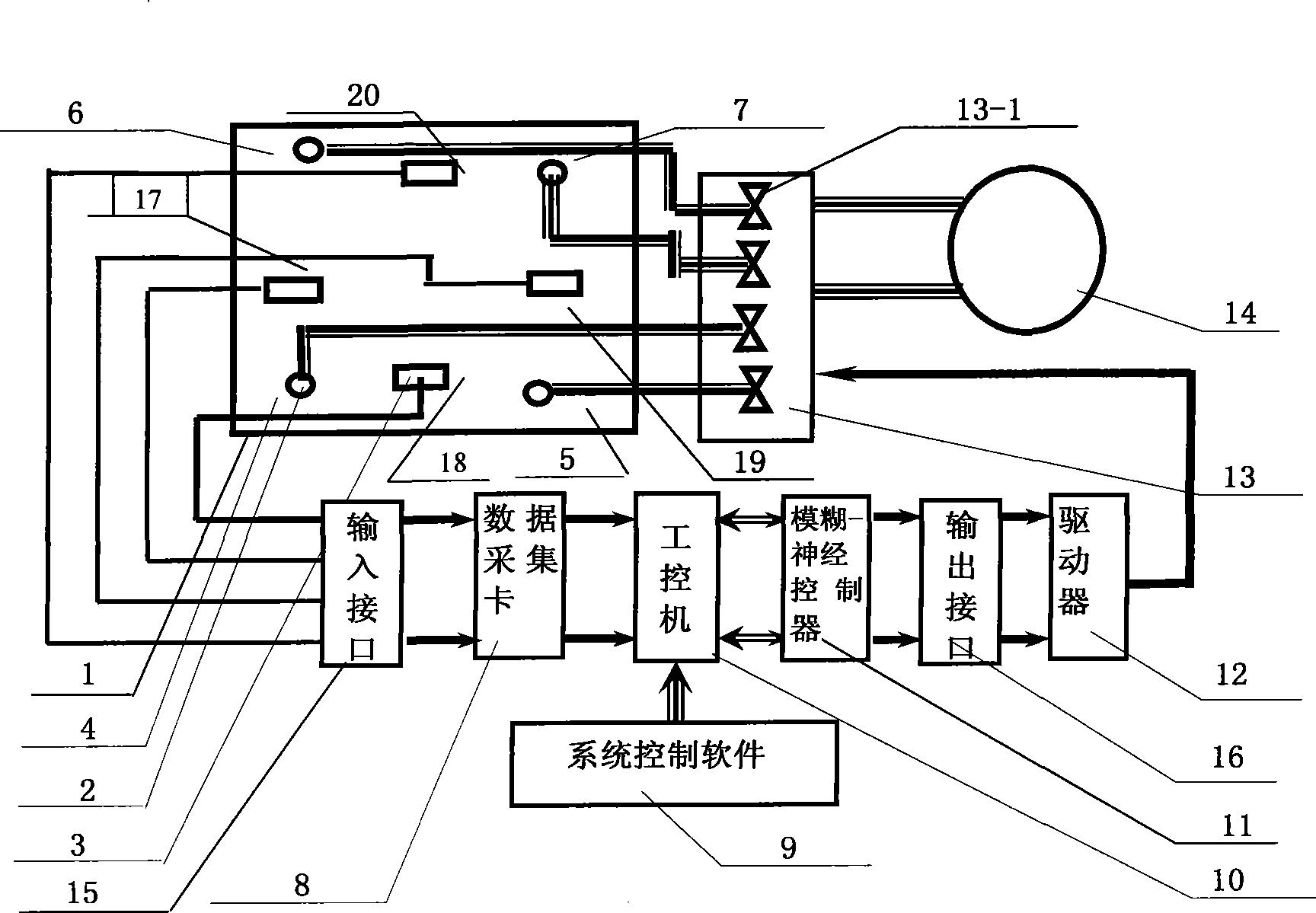

[0020] 1.1. Synchronize and continuously detect the temperature of each point in the furnace in real time through the temperature sensors 3 evenly distributed in the natural gas heating furnace 1;

[0021] 1.2, the detected temperature signal is transmitted to the industrial control computer 10 through the input interface 15 and the data acquisition card 8;

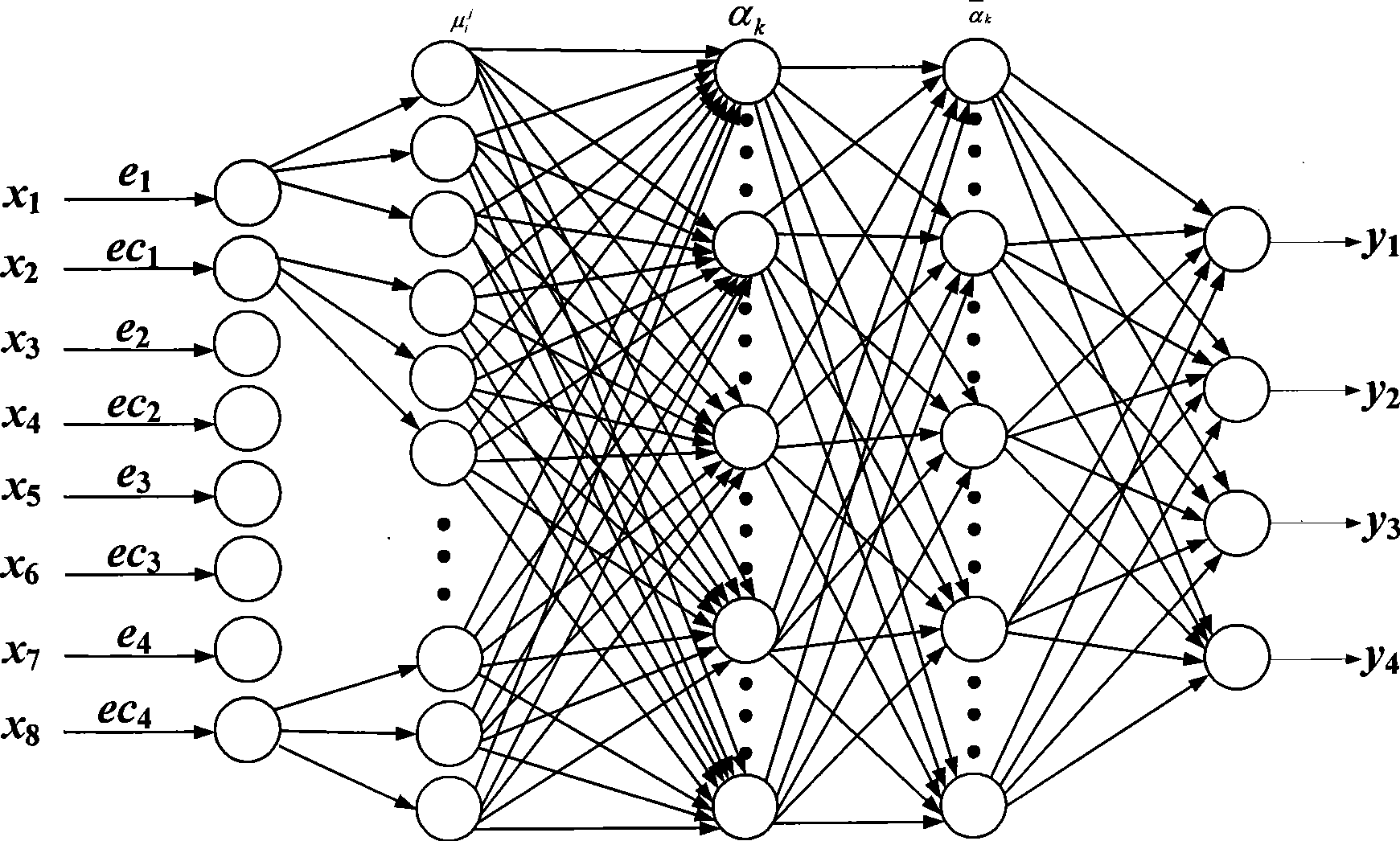

[0022] 1.3. The industrial control computer 10 calculates and analyzes through the system control software 9 and stores the temperature difference and the temperature difference change rate of each point in real time, and calculates the comprehensive temperature in the furnace in real time;

[0023] 1.4. Dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com