Patents

Literature

152results about How to "Achieve pickup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

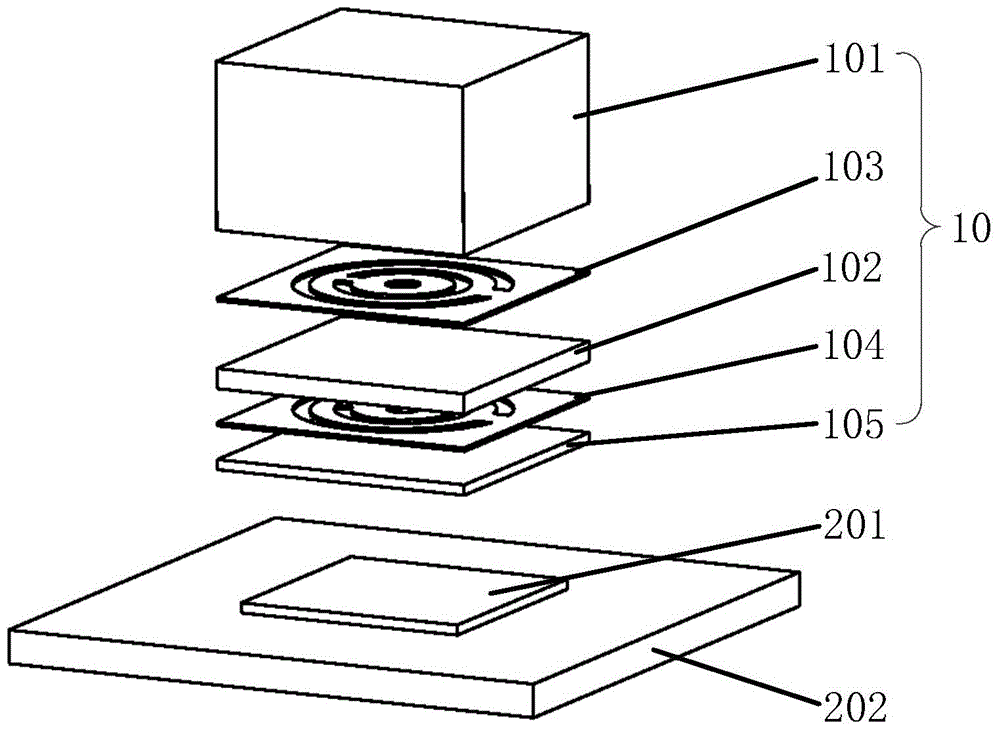

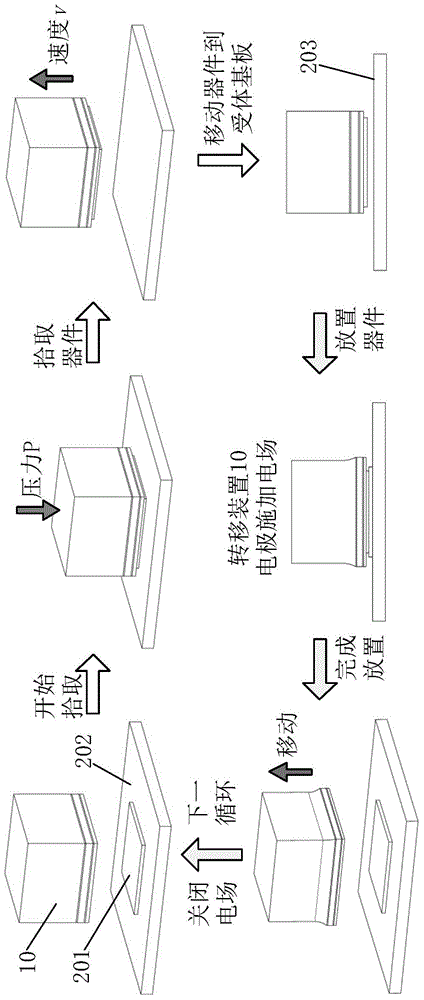

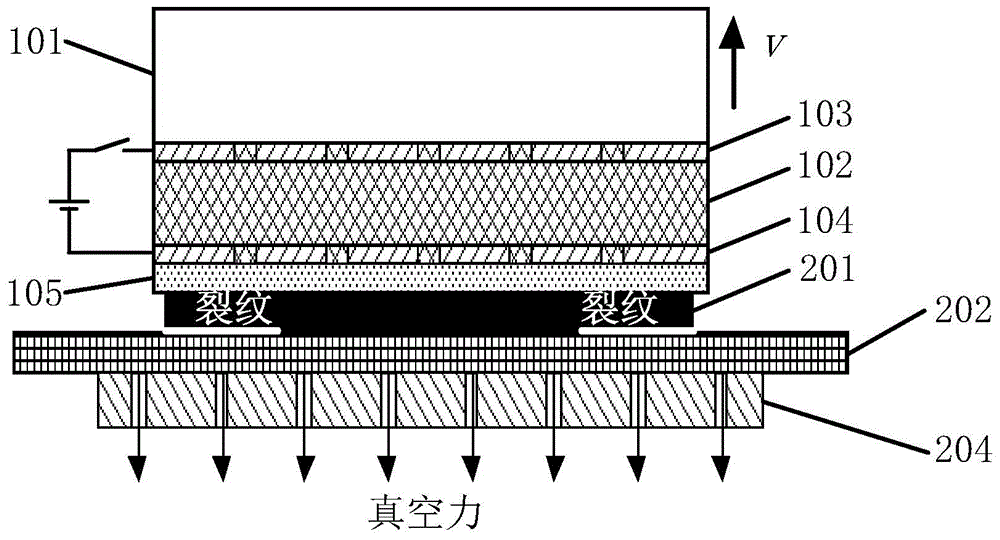

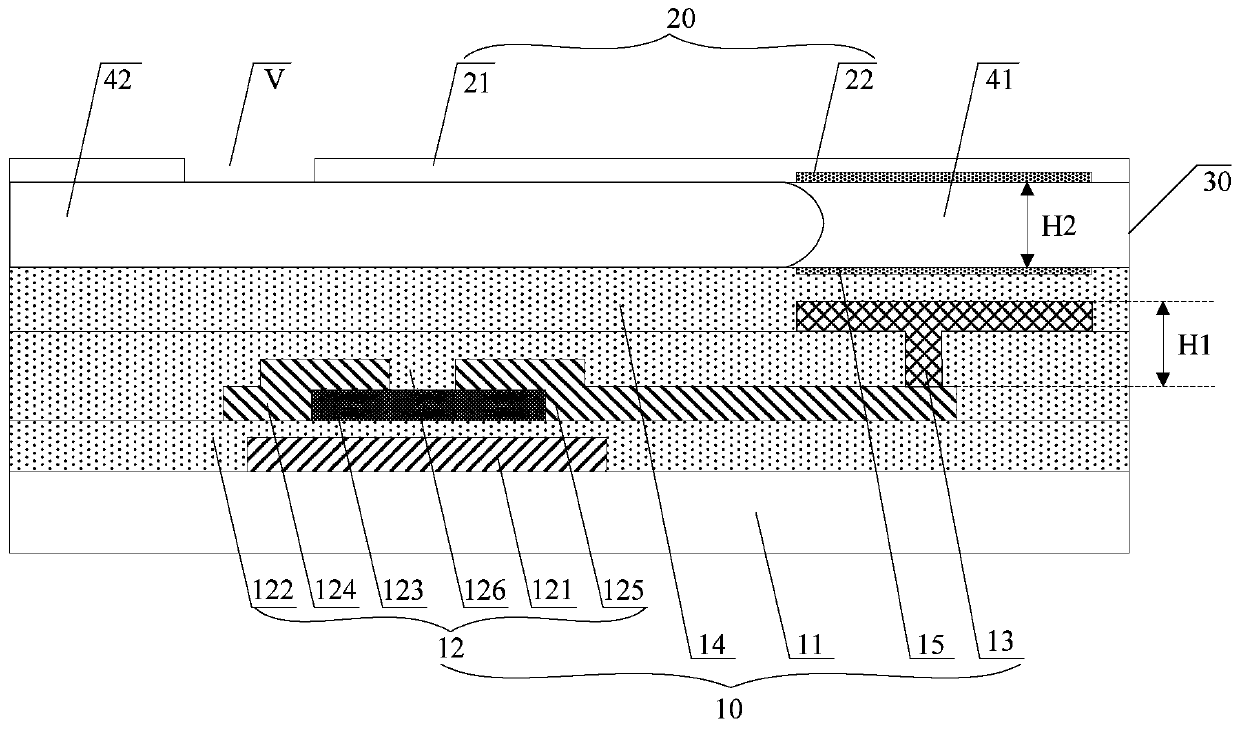

Device and method for ultrathin and flexible electronic device transfer and application of device

ActiveCN104538344APick and placeEasy to useSemiconductor/solid-state device manufacturingConveyor partsFlexible electronicsElectric field

The invention discloses a device for electronic device transfer. The device comprises an upper electrode layer, a lower electrode layer, a viscous layer and an electrical active layer, wherein the upper electrode layer and the lower electrode layer are arranged oppositely in a spaced mode, an electric field can be generated between the upper electrode layer and the lower electrode layer after electrification, the viscous layer is fixedly connected to the lower surface of the lower electrode layer, the electrical active layer is arranged between the upper electrode layer and the lower electrode layer and can be squeezed to deform longitudinally or horizontally under the action of the electric field generated between the two electrode layers after electrification, the deformation of the electrical active layer drives the electrode layers and the viscous layer to deform so that shearing force and / or concave-convex ejecting force can be generated, and then the electrode layers and the viscous layer are debonded to be placed on a receptor substrate. The invention further discloses a method for electronic device transfer by means of the device and the application of the device. The method and device can be used for active placing of electronic devices. The device is simple in structure, quick and reliable in use, easy to control and the like. The method and device can be used for transfer of ordinary ultrathin and flexible electronic devices in various specifications as well as transfer of large-area array micro-electronic devices / structures.

Owner:HUAZHONG UNIV OF SCI & TECH

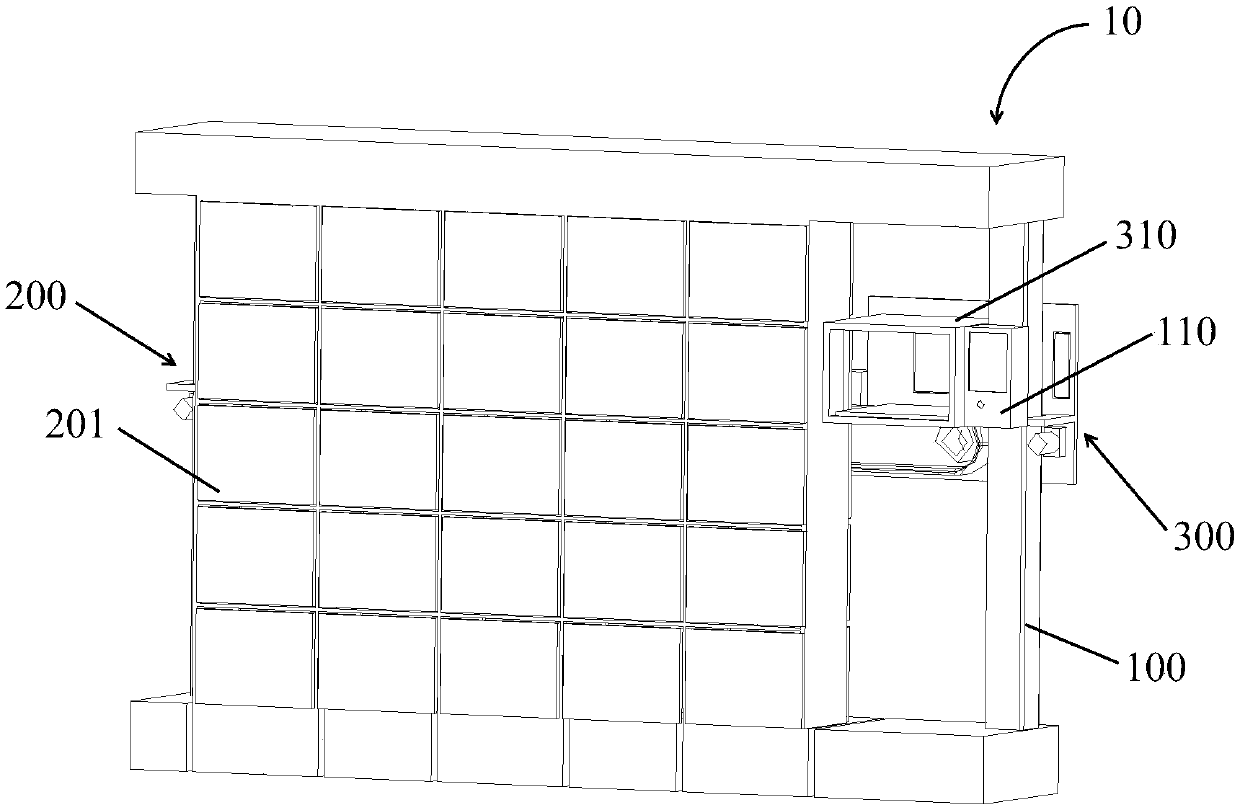

Intelligent express delivery locker, express delivery system and express delivery method

ActiveCN108682081ARealize intelligenceShorten the timeApparatus for meter-controlled dispensingLogisticsLogistics managementComputer science

The invention relates to an intelligent express delivery locker, an express delivery system and an express delivery method. The intelligent express delivery locker comprises an express delivery box group and a sorting and delivery device. The express delivery box group comprises express delivery boxes of different sizes and specifications. The storing and delivery device acquires size informationof packages and delivers the packages to express delivery boxes of corresponding sizes and specifications. When a courier delivers the packages, time is saved and delivery efficiency is increased. Theintelligent express delivery locker also comprises a driverless car in order to perform tasks of assigning packages and / or fetching packages so that packages can be intelligently fetched and sent. The logistics process is smoother. The express delivery system and the express delivery method can use the above intelligent express delivery locker. Therefore, package sizes are obtained. The packagescan be sent to the express delivery boxes of corresponding sizes and specifications. The driverless car can be also used for fetching the packages and / or assigning the packages. Human resources are saved so that the logistics process is smoother.

Owner:INVENTEC(NANJING) TECH CO LTD +1

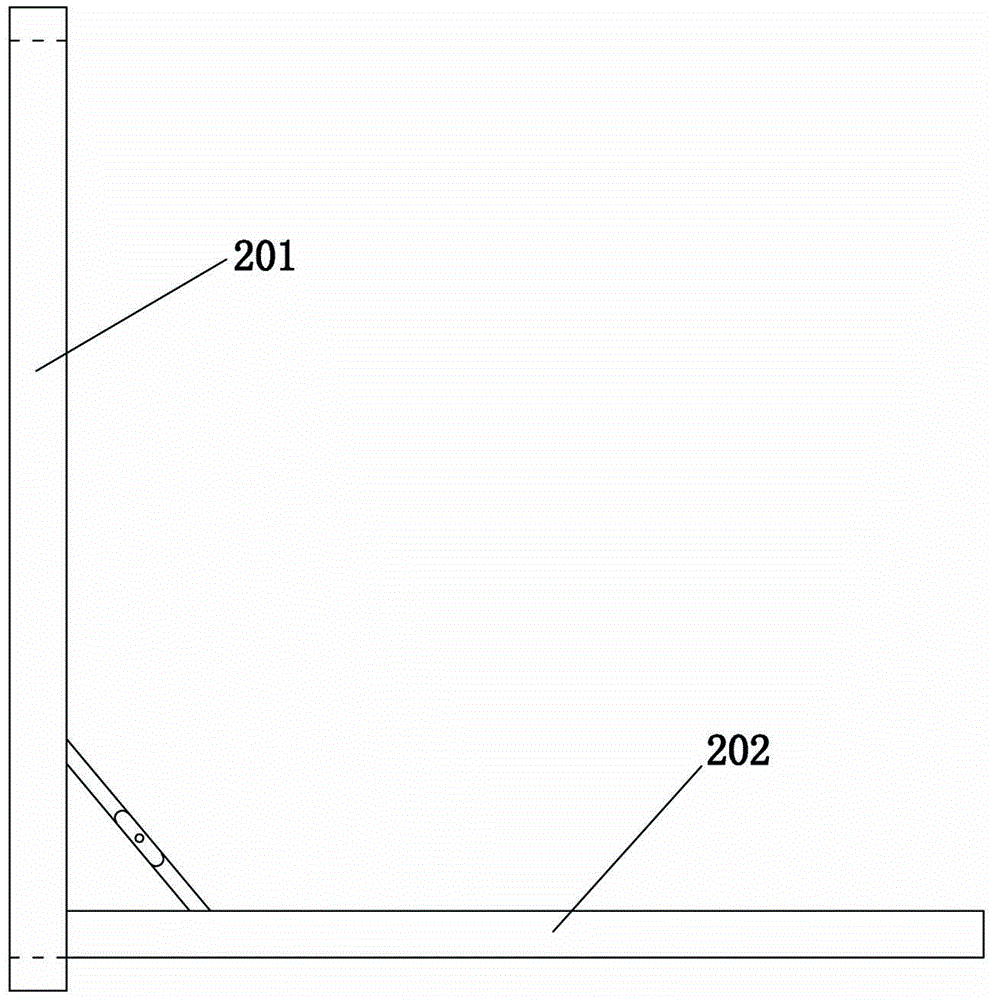

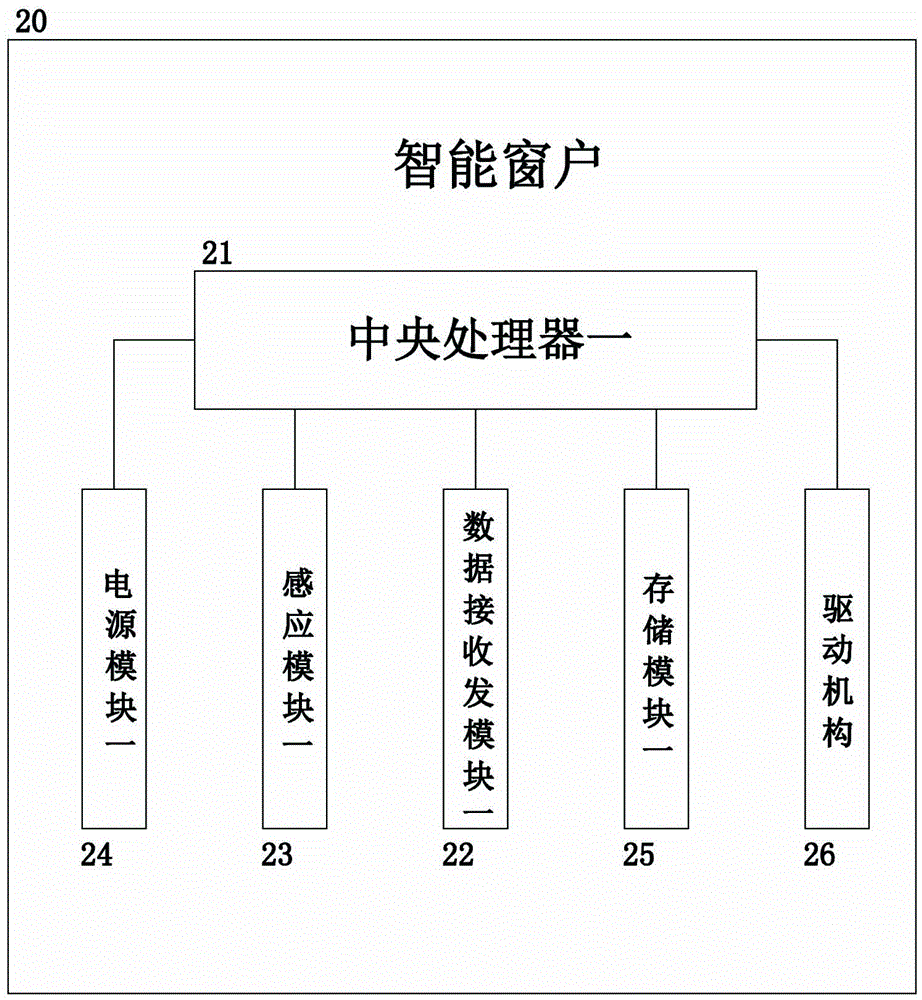

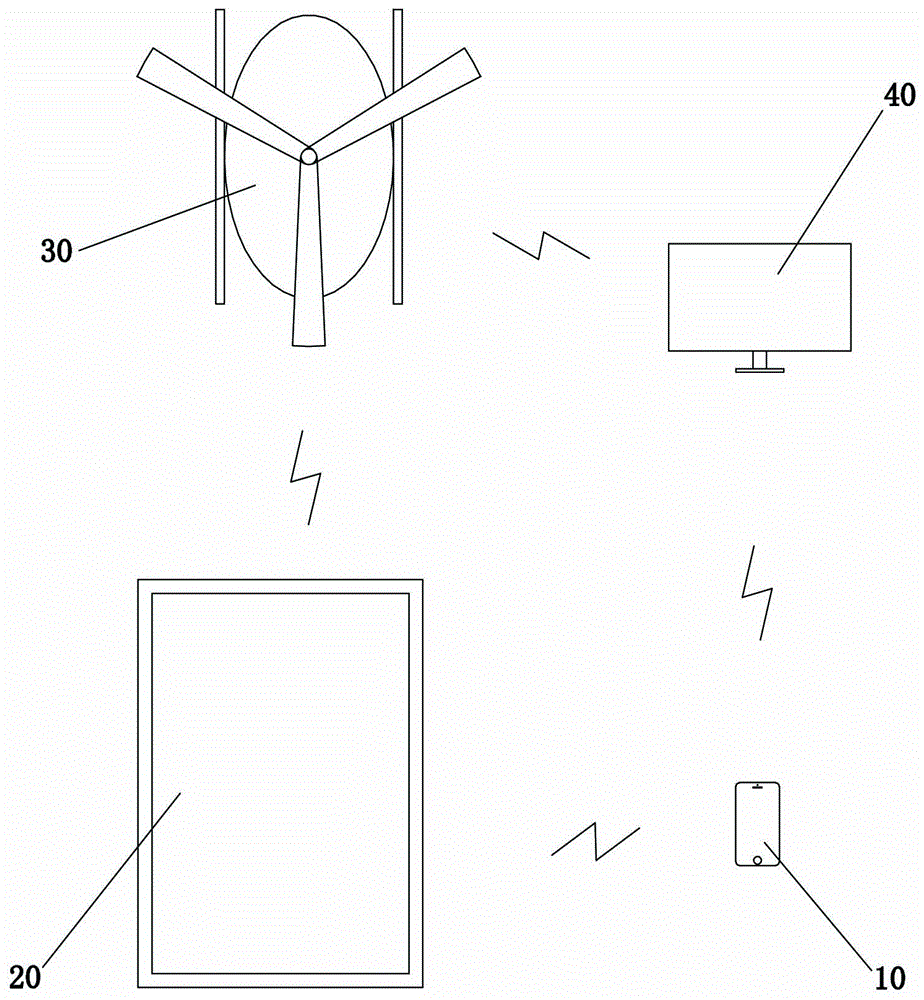

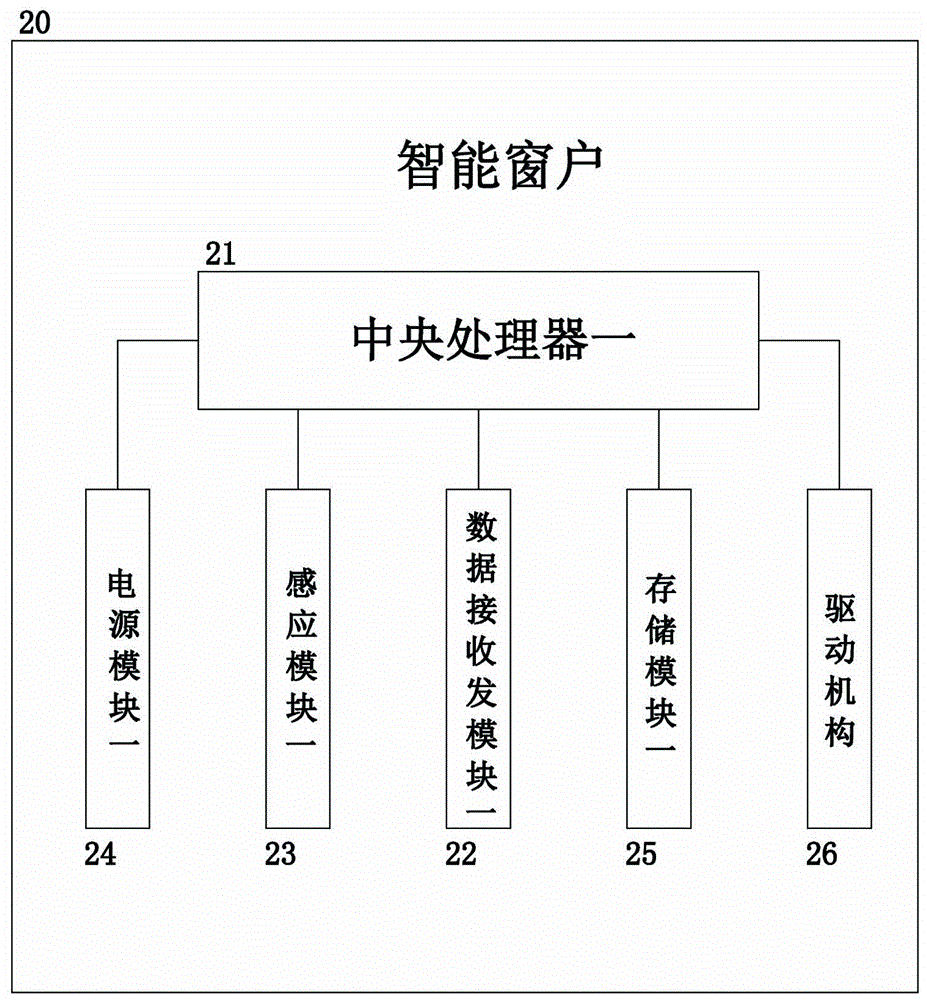

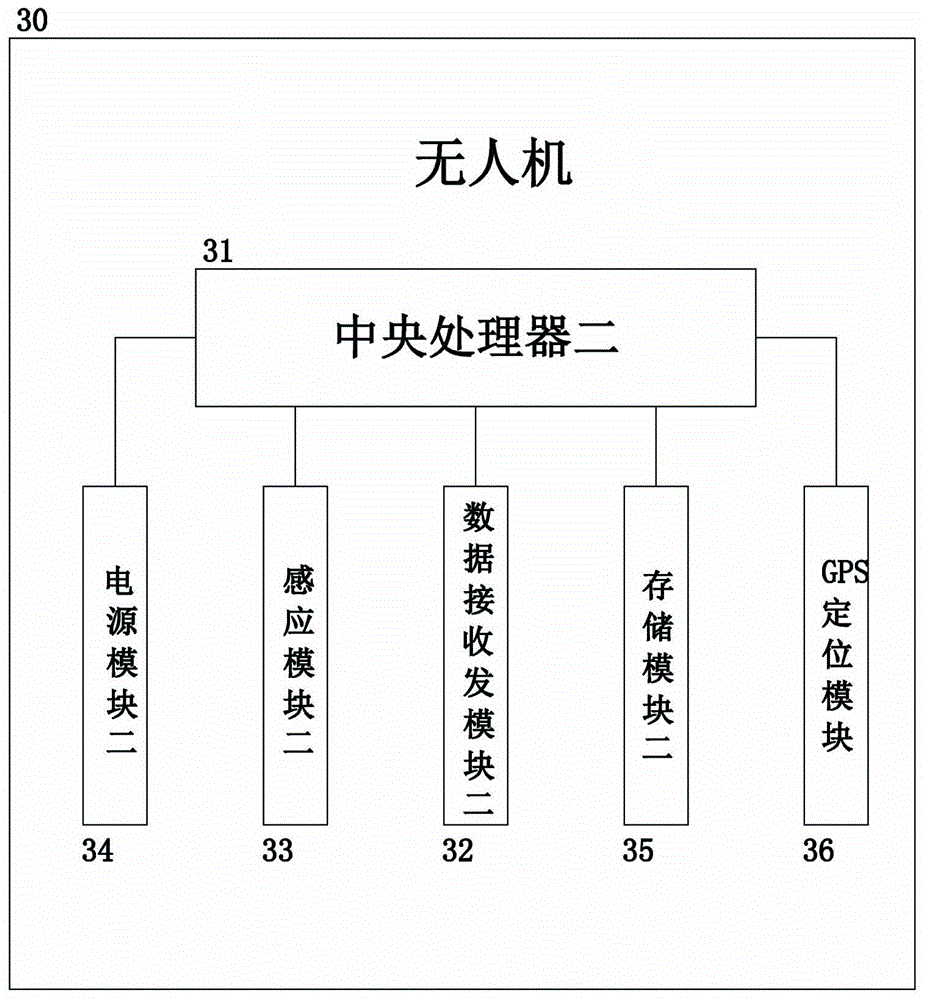

Unmanned aerial vehicle express system based on intelligent window

ActiveCN105484607ANot limited by timeRealize shippingAircraft componentsPower-operated mechanismIdentity recognitionComputer module

An unmanned aerial vehicle express system based on an intelligent window comprises a user side, the intelligent window, an unmanned aerial vehicle and an express operation control side. The user side and the express operation control side are in communication connection. The express operation control side and the unmanned aerial vehicle are in control connection. The intelligent window at least comprises a first induction module and a drive mechanism. The unmanned aerial vehicle is provided with a second induction module. When the first induction module and the second induction module are successfully connected, the drive mechanism of the intelligent window acts so that the intelligent window can be opened. When the first induction module and the second induction module are disconnected, the drive mechanism of the intelligent window acts so that the intelligent window can be closed. By means of the characteristic that a window is arranged on a wall in a user home, the intelligent window is assembled in the user home, the unmanned aerial vehicle stays nearby the intelligent window, identity recognition is carried out on the unmanned aerial vehicle through the intelligent window, automatic opening is carried out after verification succeeds, and a user can send or pick up an express item. The method for sending and delivering express items is simple and reliable, the limitation of time and weather is avoided, and the user can send or pick up an the express item without going out.

Owner:XIAMEN SCHMIED INTELLIGENT TECH CO LTD

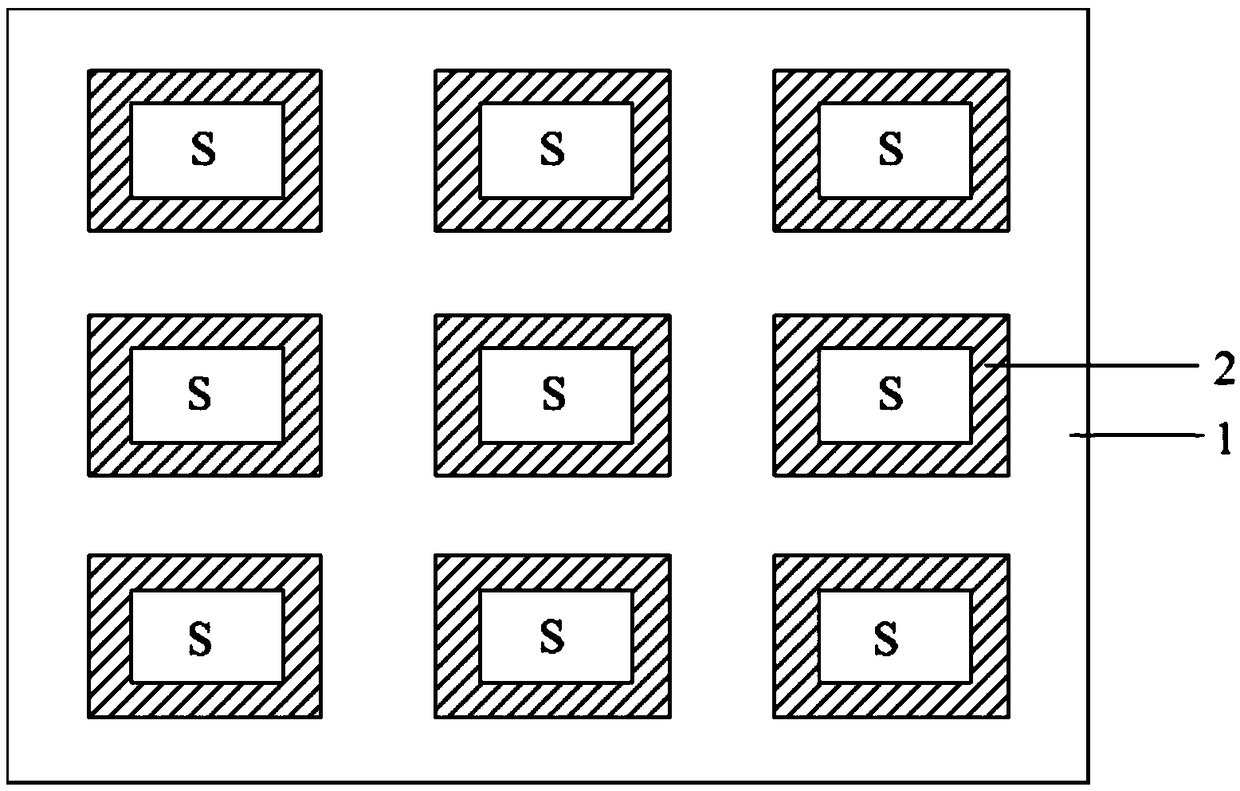

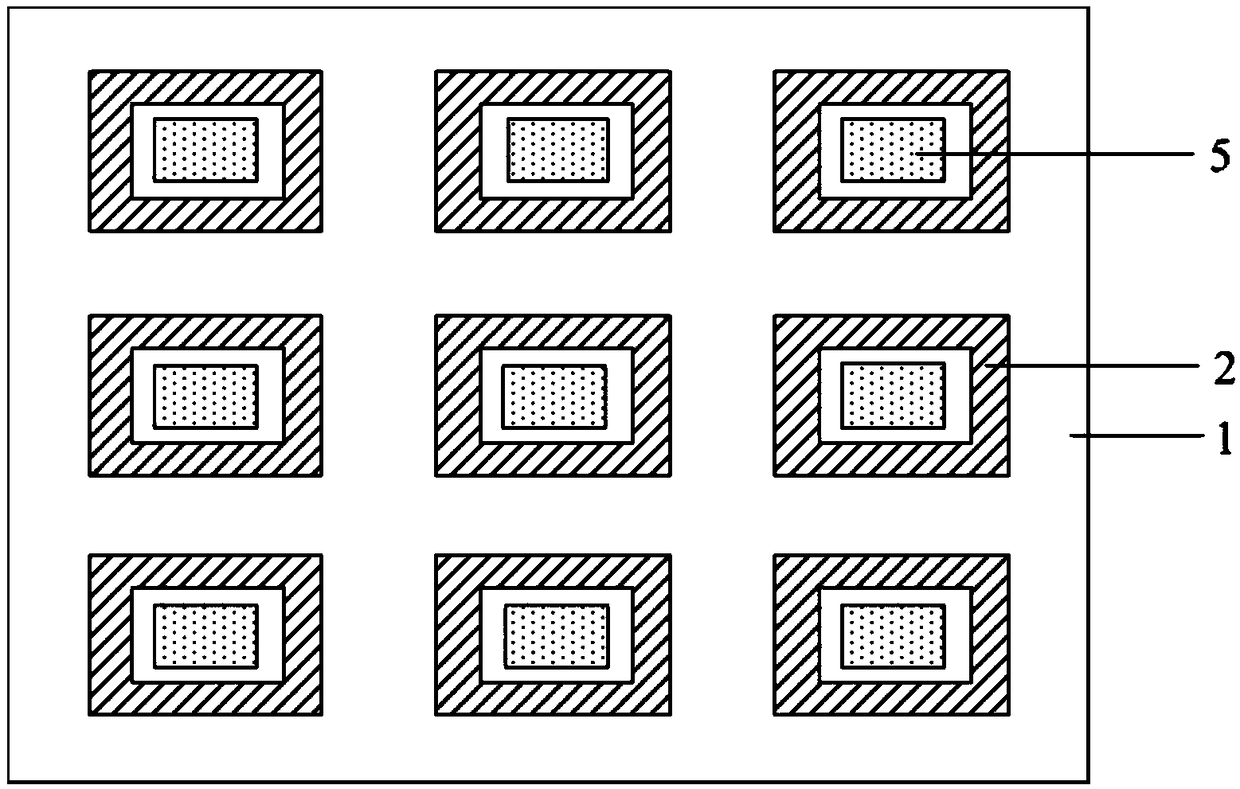

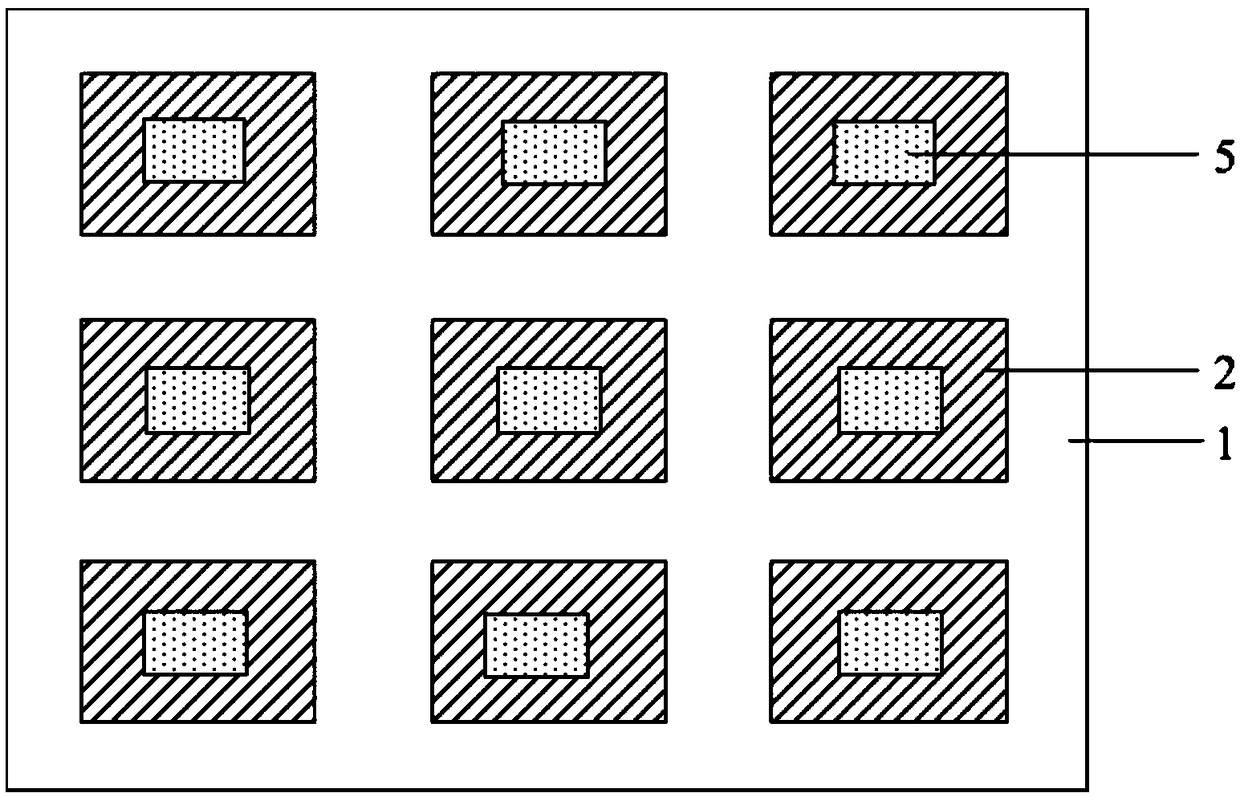

Transfer substrate, manufacturing method and transfer method

ActiveCN109273459AEfficient transferAchieve pickupSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

The invention discloses a transfer substrate, a manufacturing method and a transfer method, so as to provide a novel transfer substrate and a transfer method applied to a massive transfer process of amicro light emitting diode. The transfer substrate comprises: substrate substrate, a plurality of electrodeformed frames located on the substrate and distributed in a manner matched to the distribution manner of the microlight emitting diodes of the original substrate, the inner side of the frame is surrounded and formed with a hollow area which is larger than the area occupied by the orthogonalprojection of the micro light emitting diode on the original substrate when the frame is not subjected to an electric field; The hollow area is reduced to be smaller than the area occupied by the orthogonal projection of the micro light emitting diode on the original substrate; As that electric field is remove, shrinkage occurs and the hollow area return to the original state.

Owner:BOE TECH GRP CO LTD +1

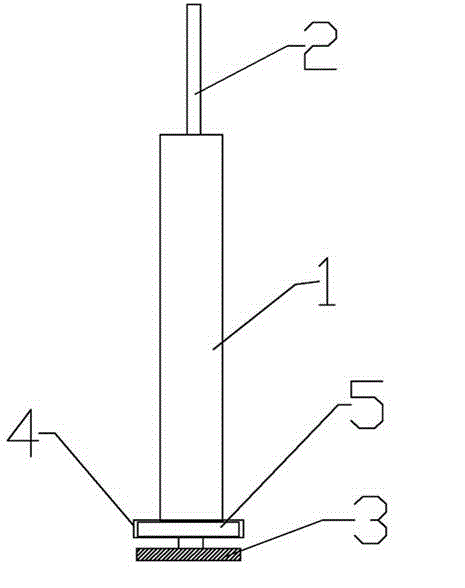

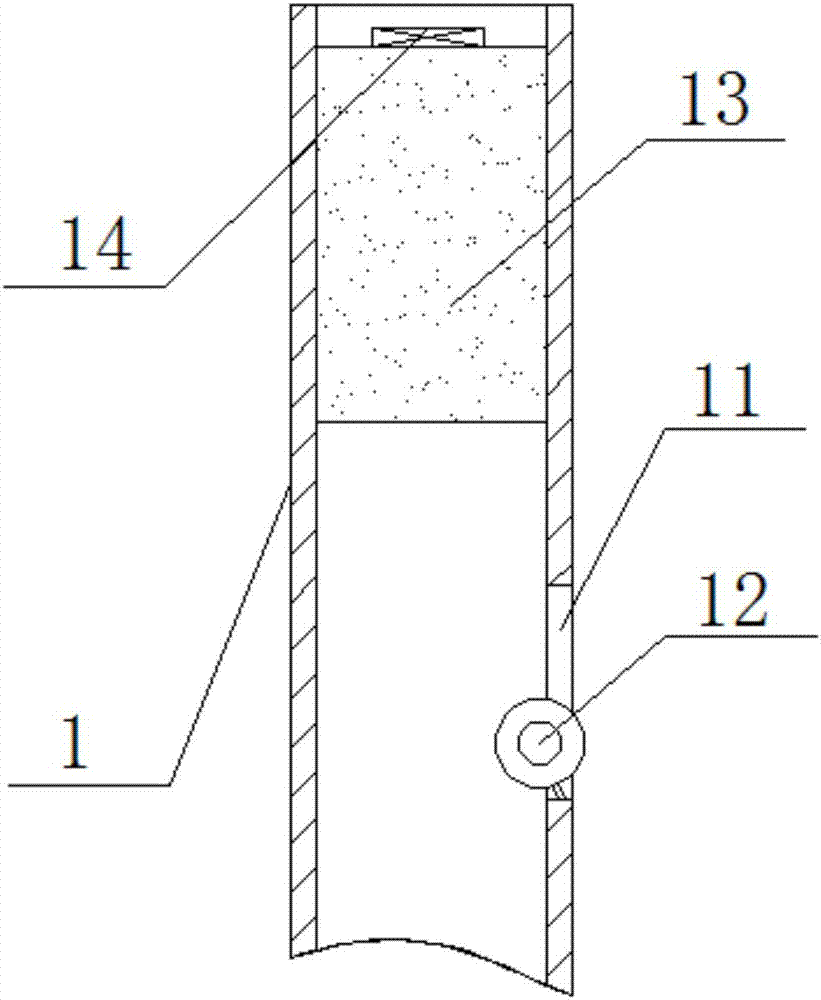

Garage pickup device for sanitation workers and using method thereof

The invention discloses a garage pickup device for sanitation workers. The device comprises a pipe body, a first arc-shaped clip and a second arc-shaped clip are hinged to the bottom end of the pipe body, an elastic piece is arranged between the first arc-shaped clip and the second arc-shaped clip, the top end of the pipe body is sleeved with a pipe sleeve, a support is arranged at one side of the pipe sleeve, a handle is hinged to the support, a spring is arranged between the handle and the pipe sleeve, the pipe body is provided with a through hole, a fixed pulley arranged in the pipe body is arranged at the through hole, a steel wire rope connected between the elastic piece and the handle penetrates through the pipe body, the steel wire rope penetrates out of the through hole, the steel wire rope is connected to the fixed pulley in a sliding mode, and an electromagnet block is arranged at one side of the second arc-shaped clip. Accordingly, garbage can be clamped through the first arc-shaped clip and the second arc-shaped clip, the first arc-shaped clip and the second arc-shaped clip can be clamped by pressing the handle, and garbage pickup is achieved; meanwhile, by means of the electromagnet block, when the electromagnet block works, adsorptive pickup can be conducted on iron objects which are not convenient to clamp, and garage pickup is more convenient.

Owner:嘉兴尚云自动化设备有限公司

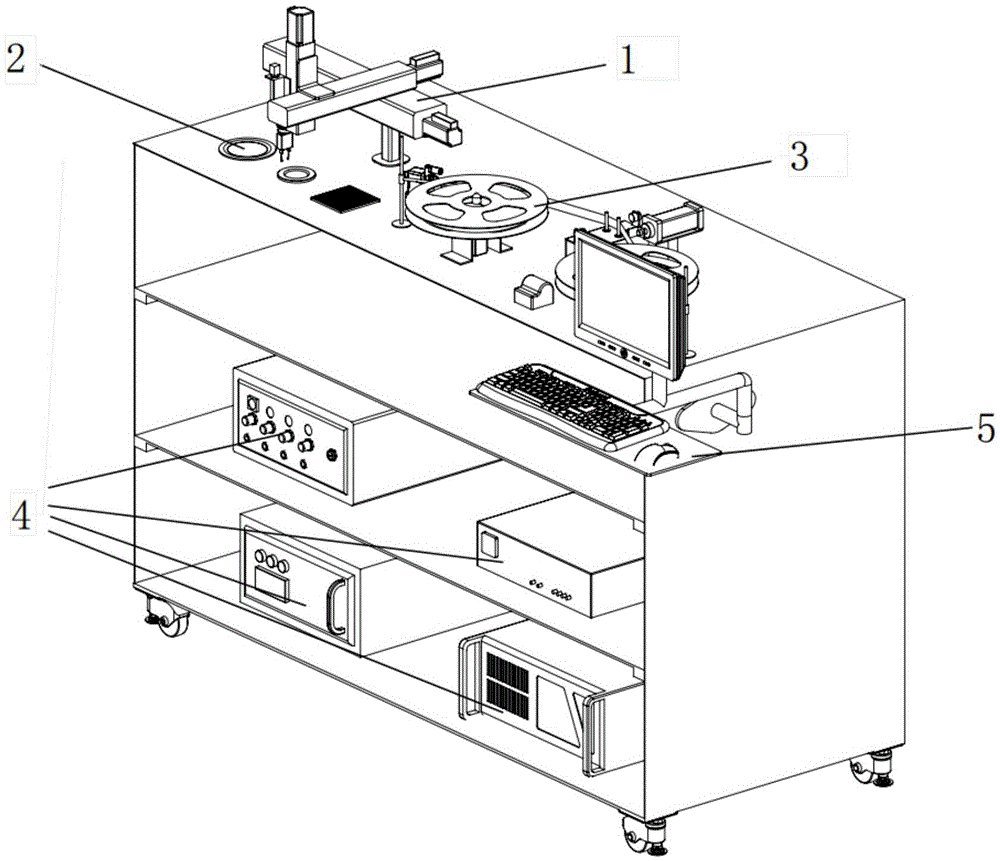

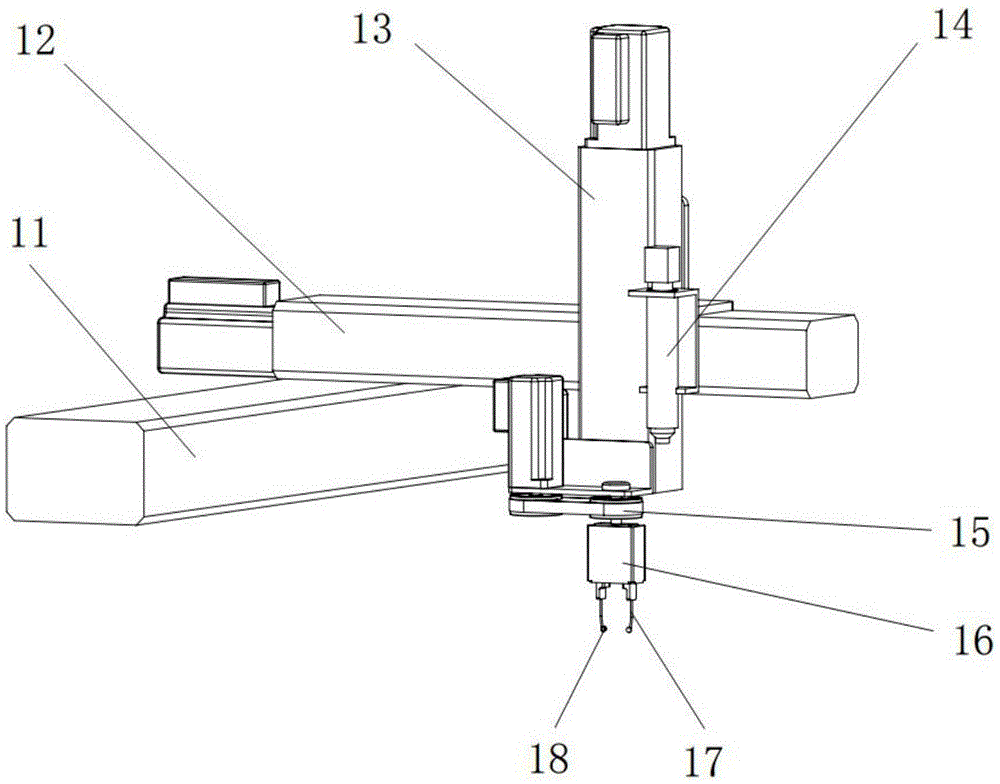

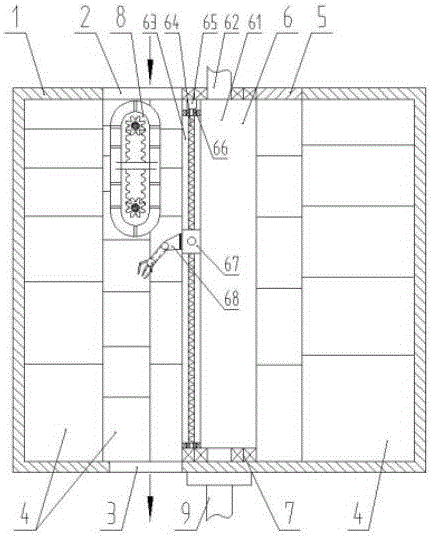

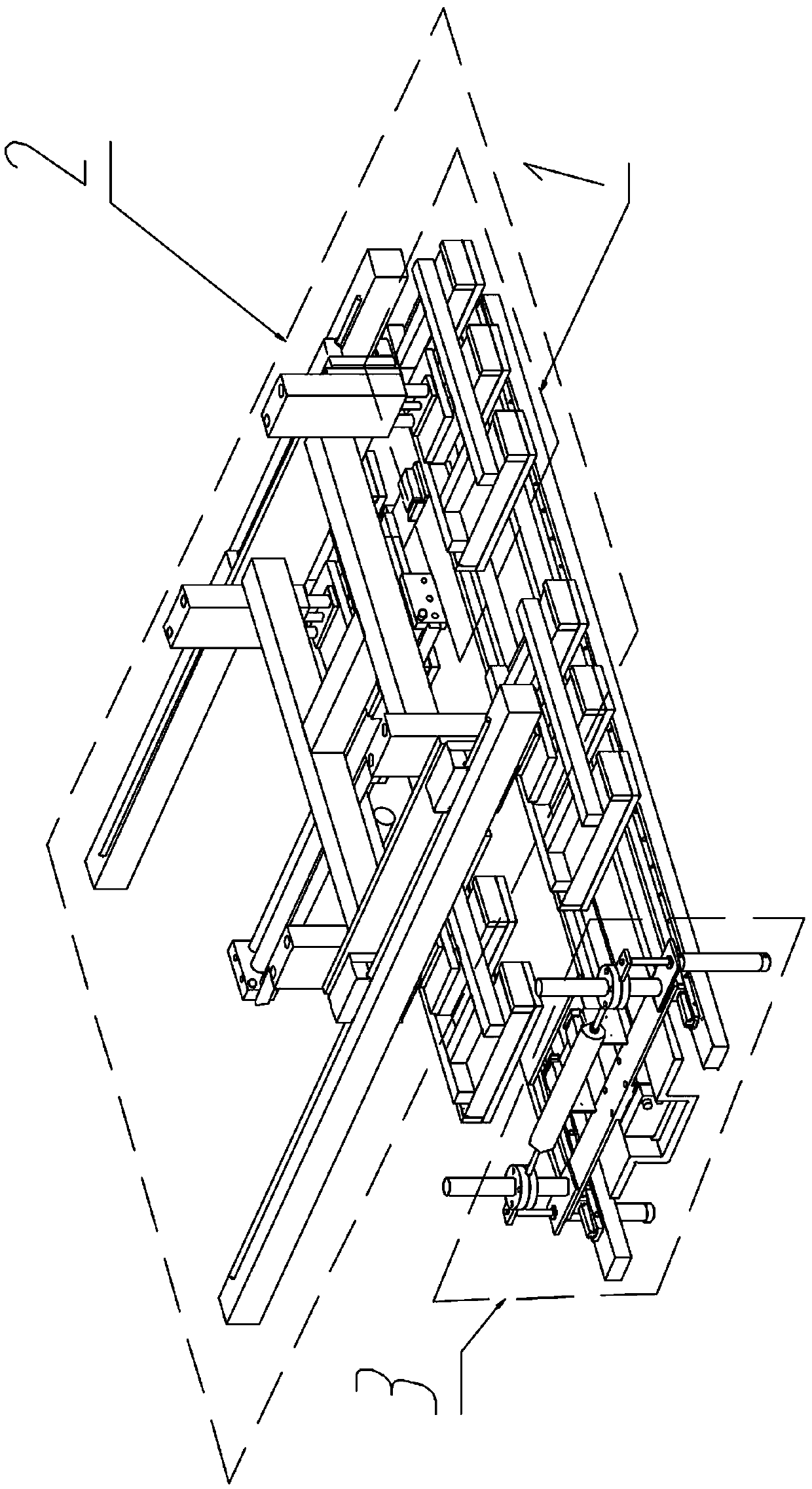

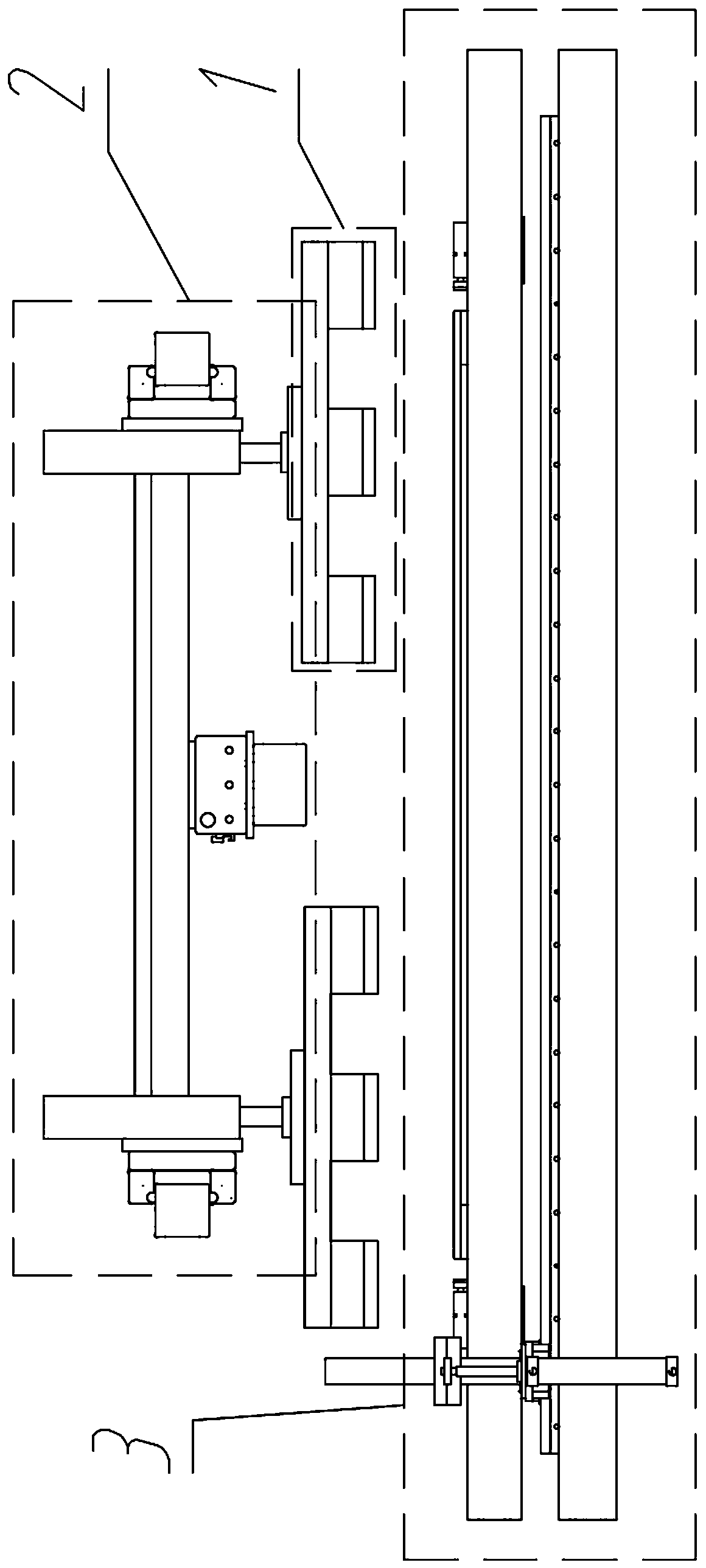

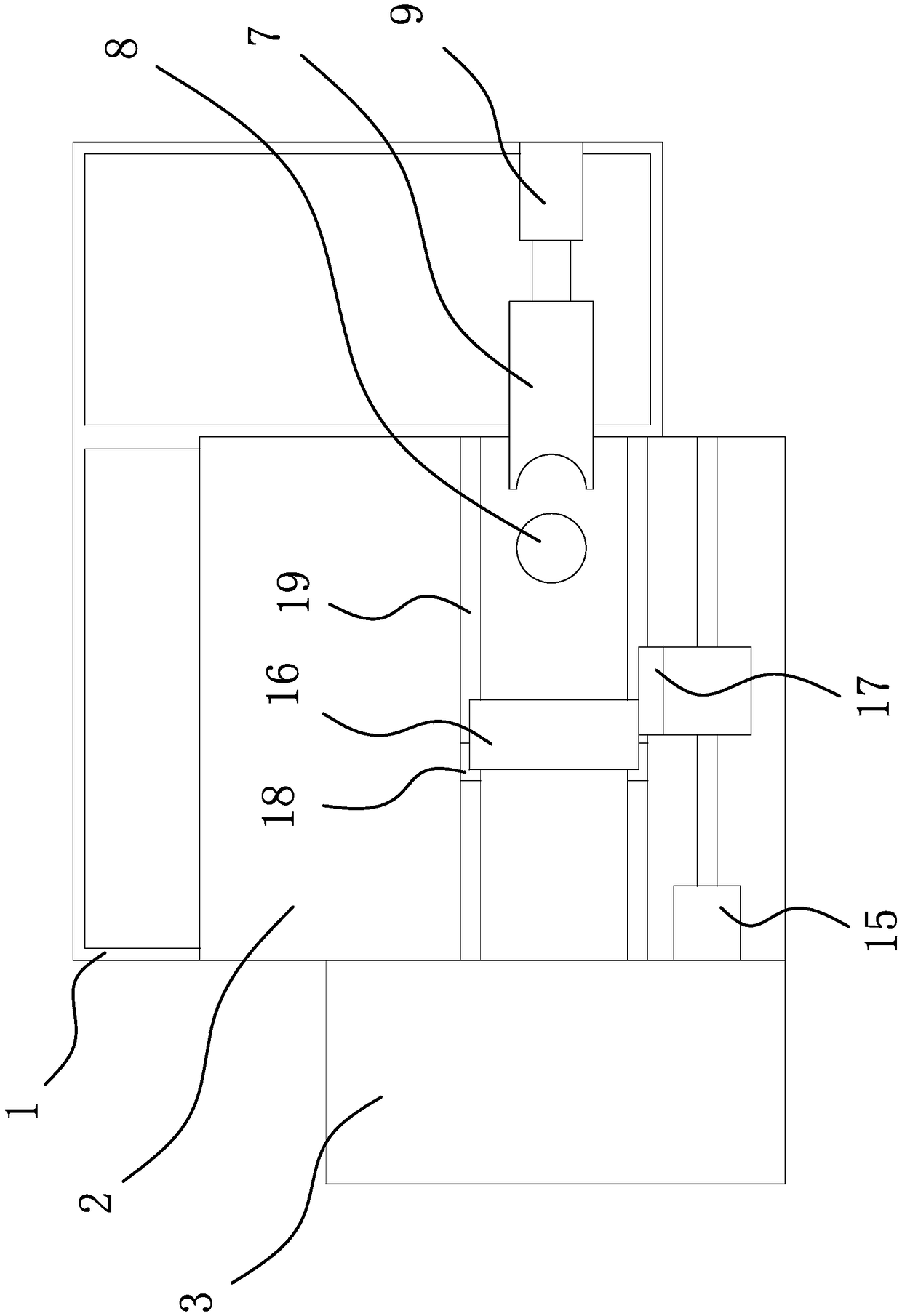

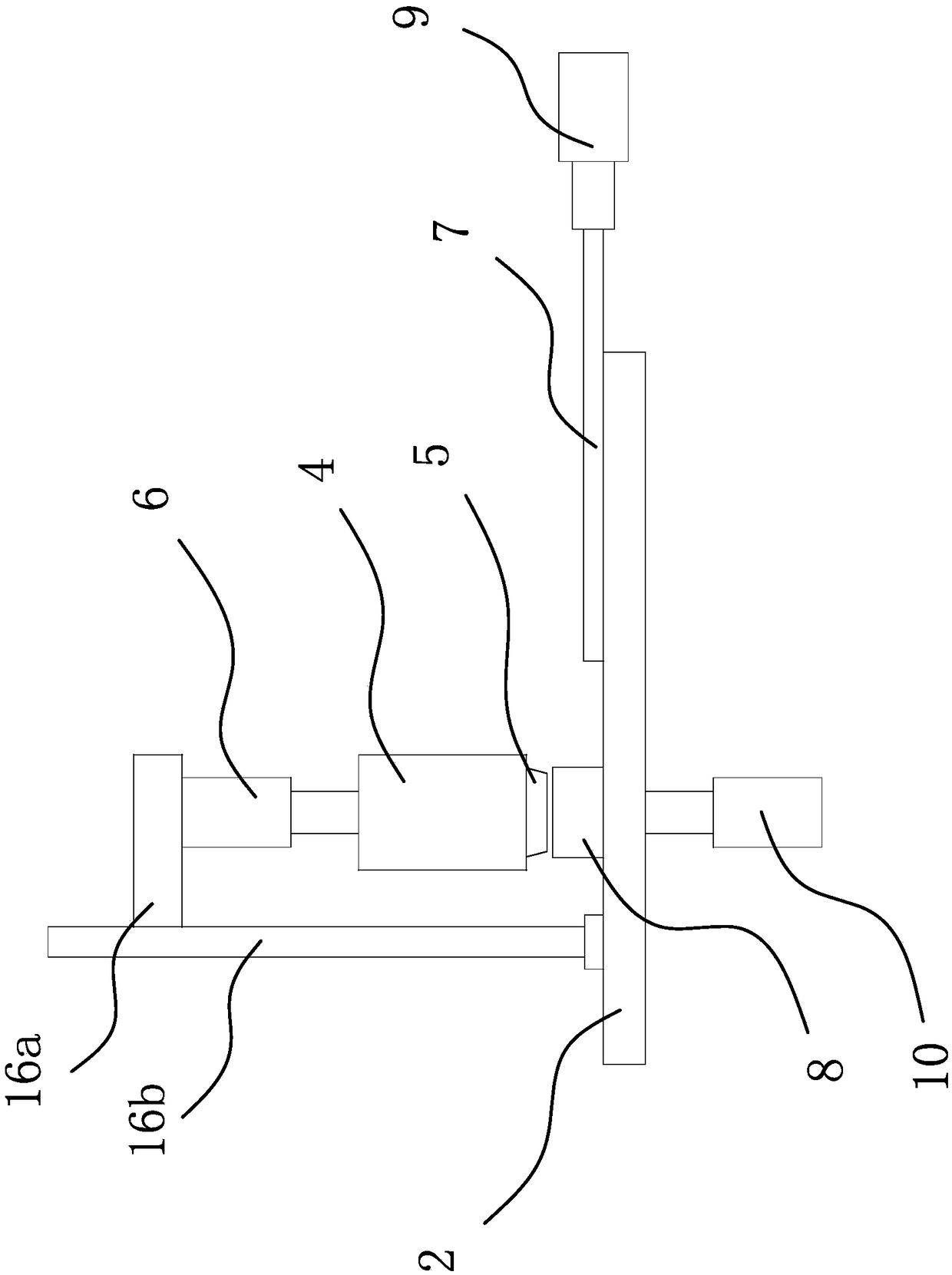

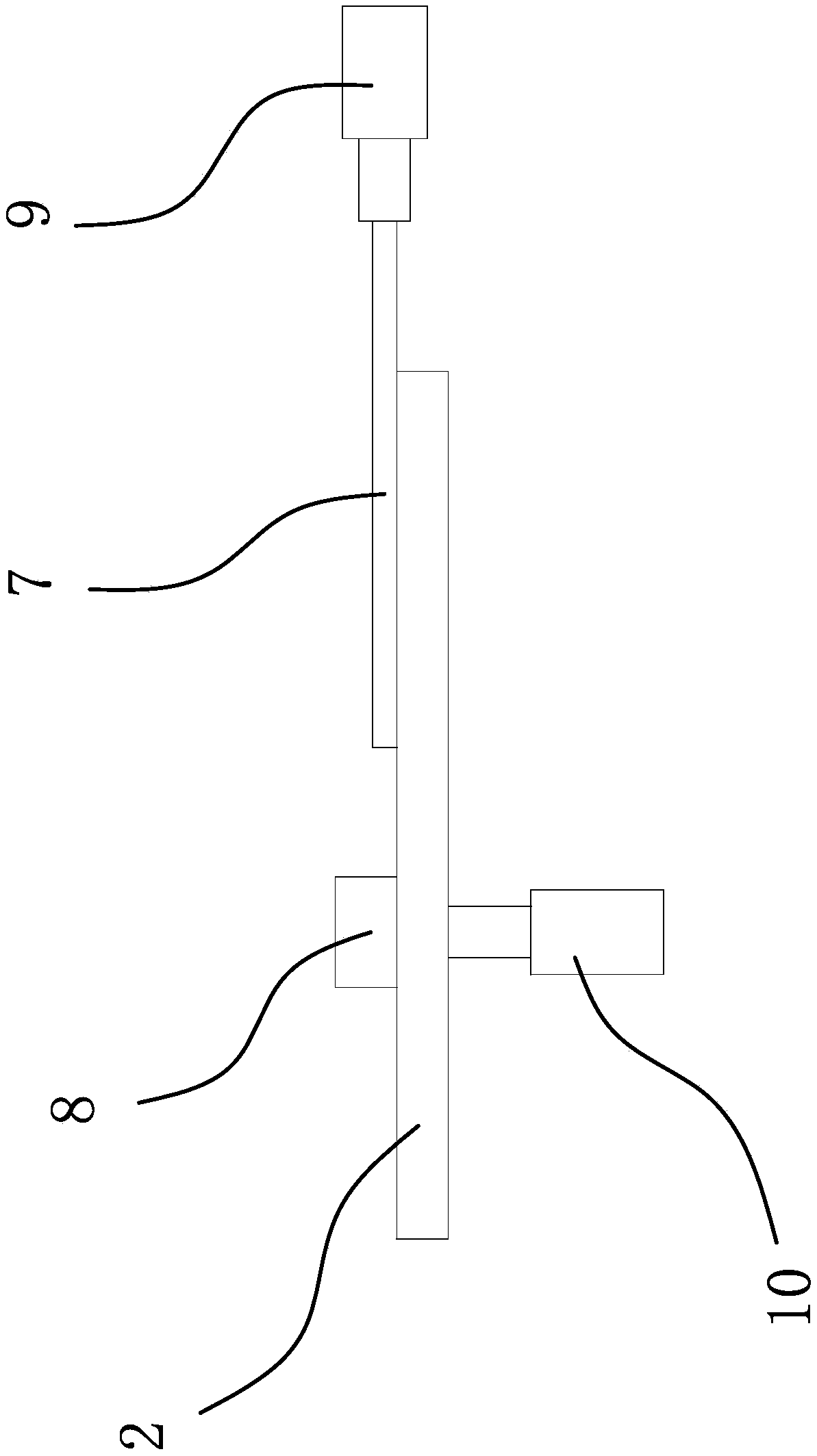

Tray-oriented SMD sampling and counting equipment

ActiveCN105555123ARealize targeted sampling inspectionEnsure operabilityElectrical componentsAutomatic controlSurface mounting

The invention belongs to the field of related equipment for manufacturing surface mount devices, and discloses tray-oriented SMD sampling and counting equipment. The tray-oriented SMD sampling and counting equipment comprises a material counting module, a pickup detection module, a material holding module, a matched control module and the like, wherein the material counting module is used for achieving conveying and slitting of a material strip and counting of to-be-detected elements; the pickup detection module is used for achieving visual positioning of to-be-detected elements, picking up the to-be-detected elements by a multi-degree-of-freedom manipulator and synchronously achieving the detection function; the material holding module is used for placing the elements before and after detection, and ensuring the accuracy of the positions and the postures of the elements; and the control module is used for achieving automatic control on the complete equipment. Through the tray-oriented SMD sampling and counting equipment, sampling of the elements on an SMD tray can be quickly finished; the sampled elements are recycled; in addition, counting of the elements on the tray can also be quickly and accurately finished; and slitting is selectively carried out under needed working conditions.

Owner:HUAZHONG UNIV OF SCI & TECH

Unmanned aerial vehicle article sending and delivering method based on intelligent window

ActiveCN105894225ANot limited by timeRealize shippingDomestic articlesLogisticsIdentity recognitionUncrewed vehicle

Owner:XIAMEN SCHMIED INTELLIGENT TECH CO LTD

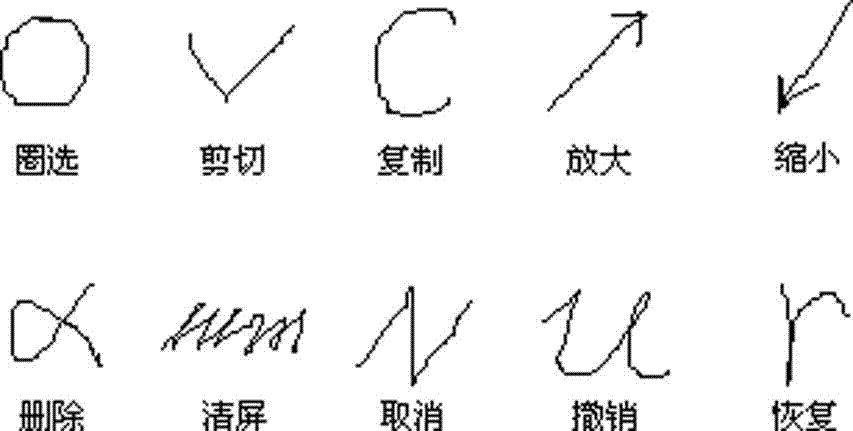

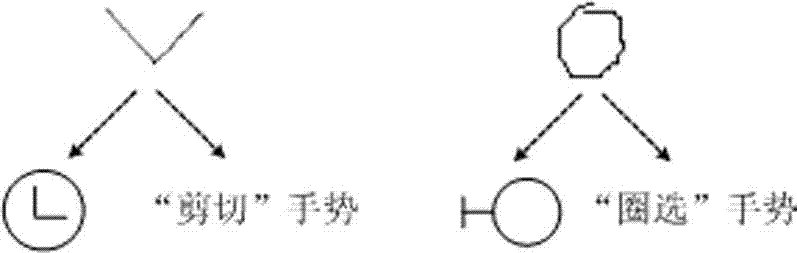

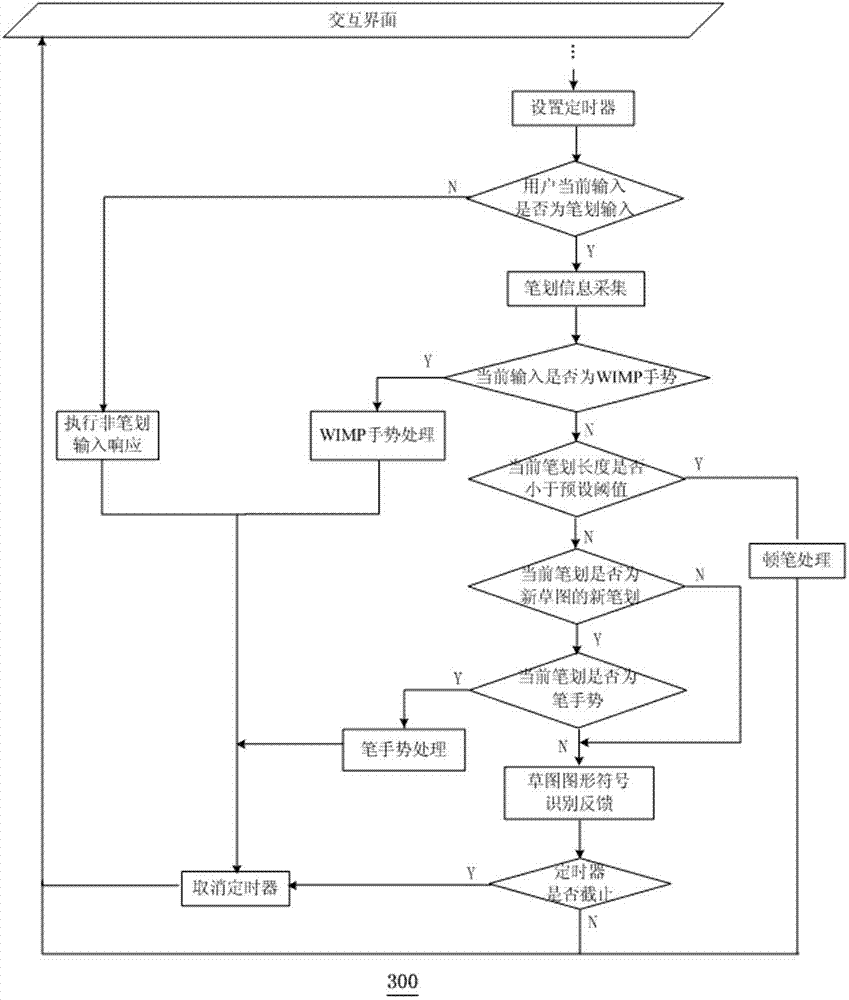

Pen type interactive method based on free-hand sketch and gesture input judging and processing

ActiveCN103399698AEasy to drawReduce Interaction Cognitive BurdenCharacter and pattern recognitionInput/output processes for data processingInteraction deviceEngineering

Provided is a pen type interactive method based on a free-hand sketch and gesture input judging and processing. Under the condition that a user keeps conducting inputting, the input state of the user can be automatically judged, and processing can be conducted according to different input states. The method defines no less than ten types of pen gestures including graphic object pickup class gestures, graphic object editing class gestures and operation state control class gestures, and part of the pen gestures and elements have semantic ambiguity definitions. In the process of judging and processing the input state, the pen gesture judging and processing method and the writing stopping processing method are designed, therefore, under the condition that no other interactive devices such as right click menus or mice or keys are involved, and a method for controlling graphic symbol free-hand sketch input, sketch editing and operation state does not need explicit state switching and is provided for the user so that the user can smoothly express interactive intention through pen type interaction. The method has certain universality and extendibility, can be applied to different professional fields, and achieves machine-aided design or military plotting and the like based on pen type interaction.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

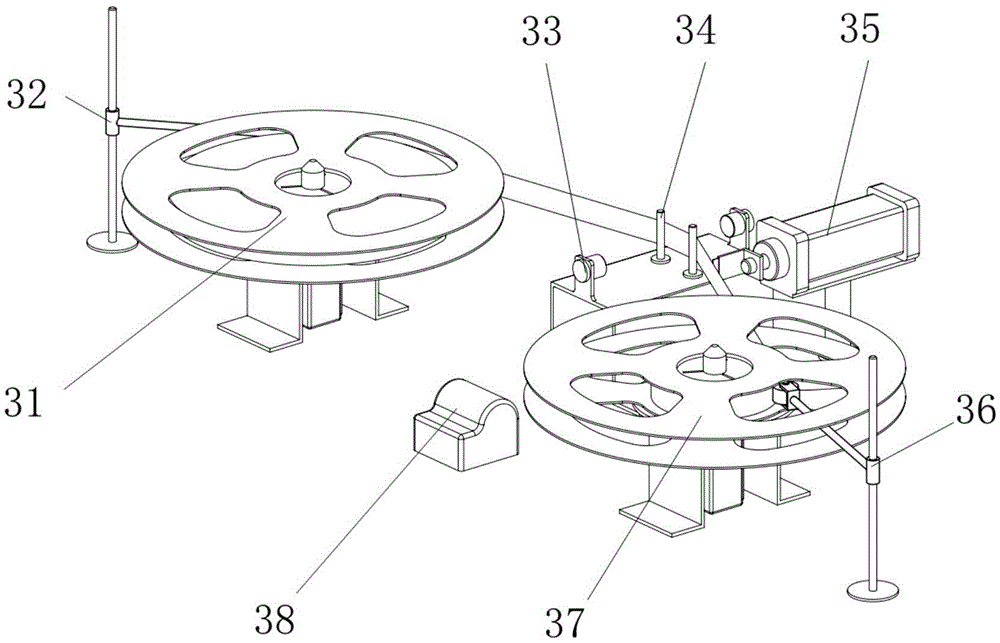

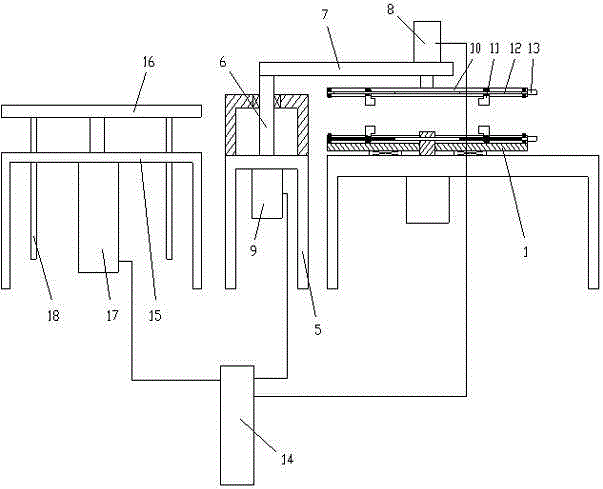

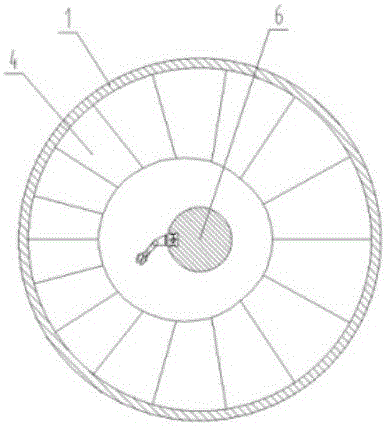

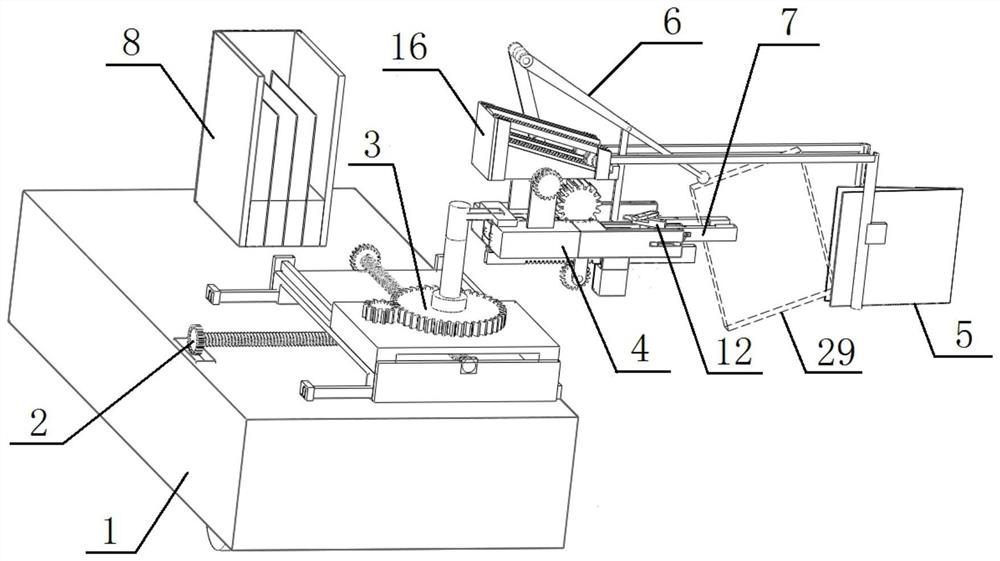

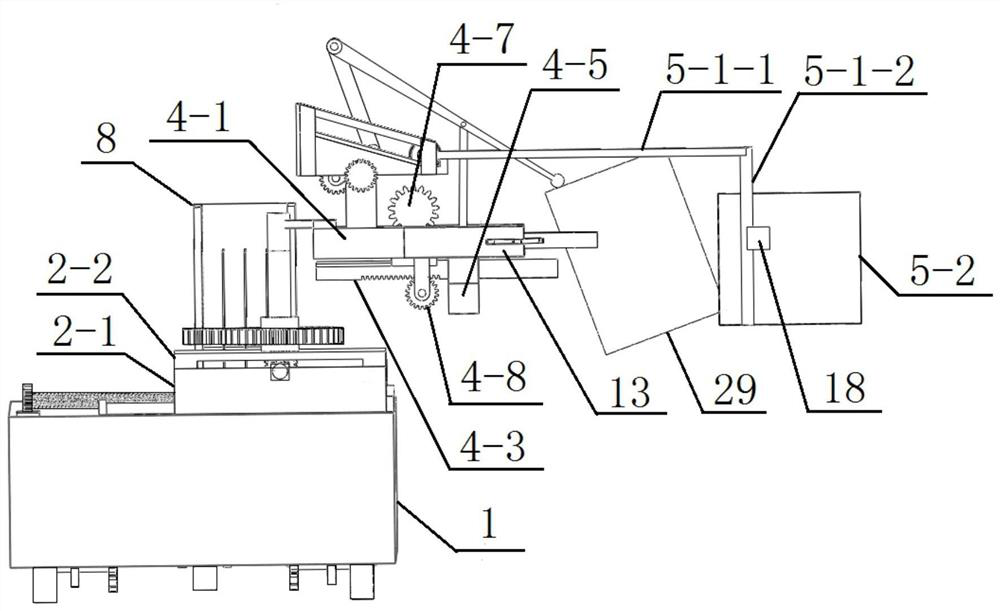

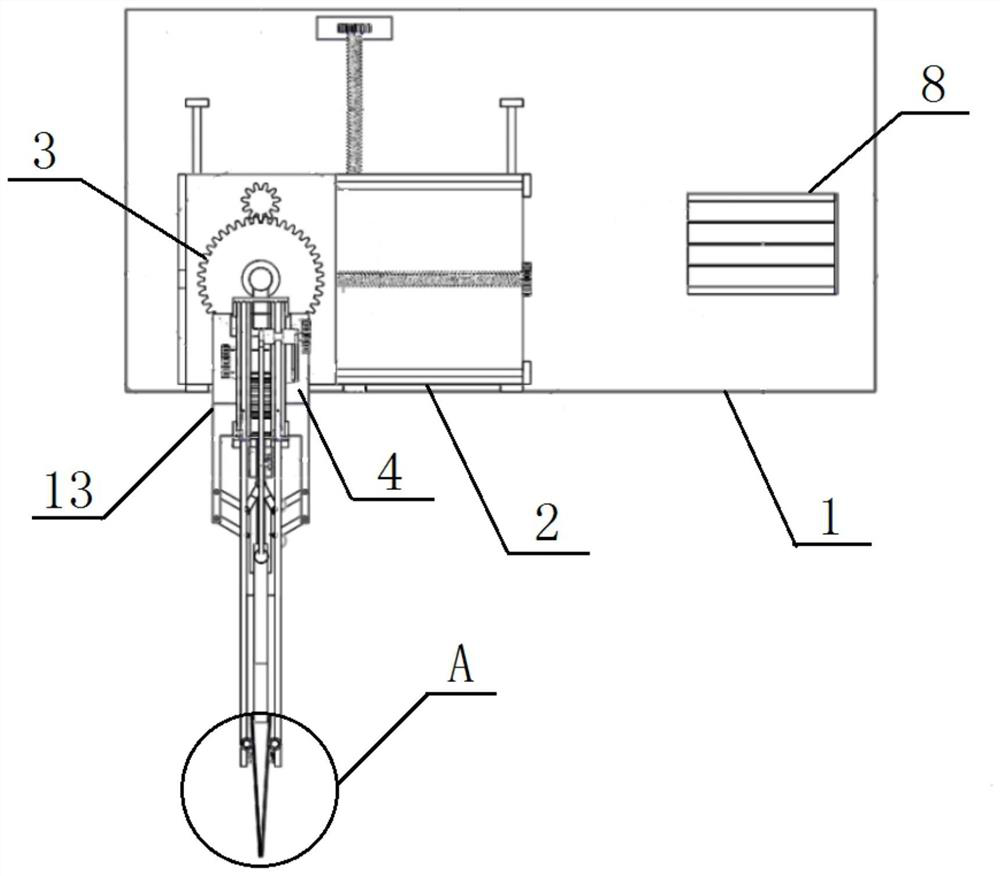

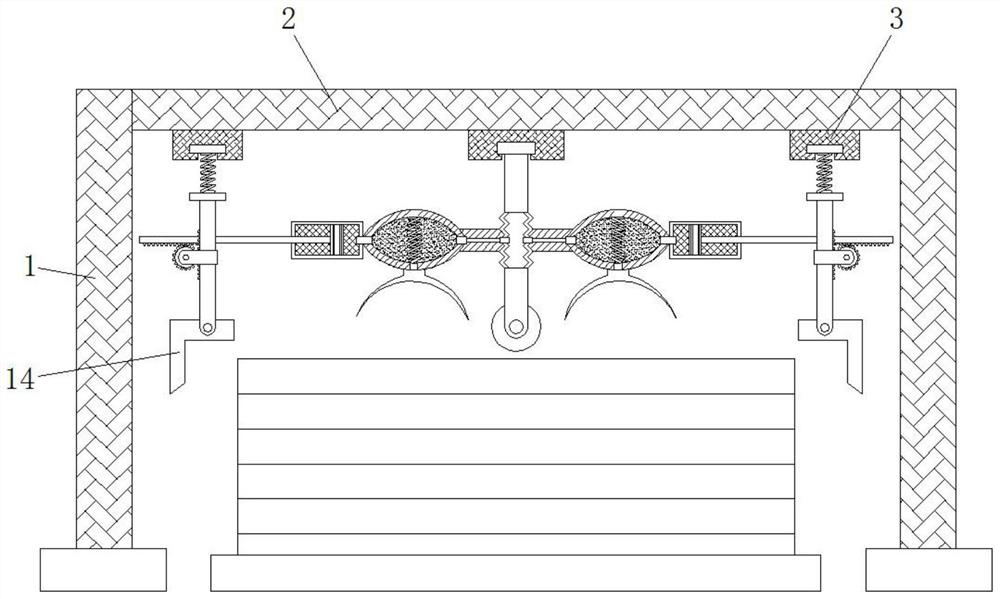

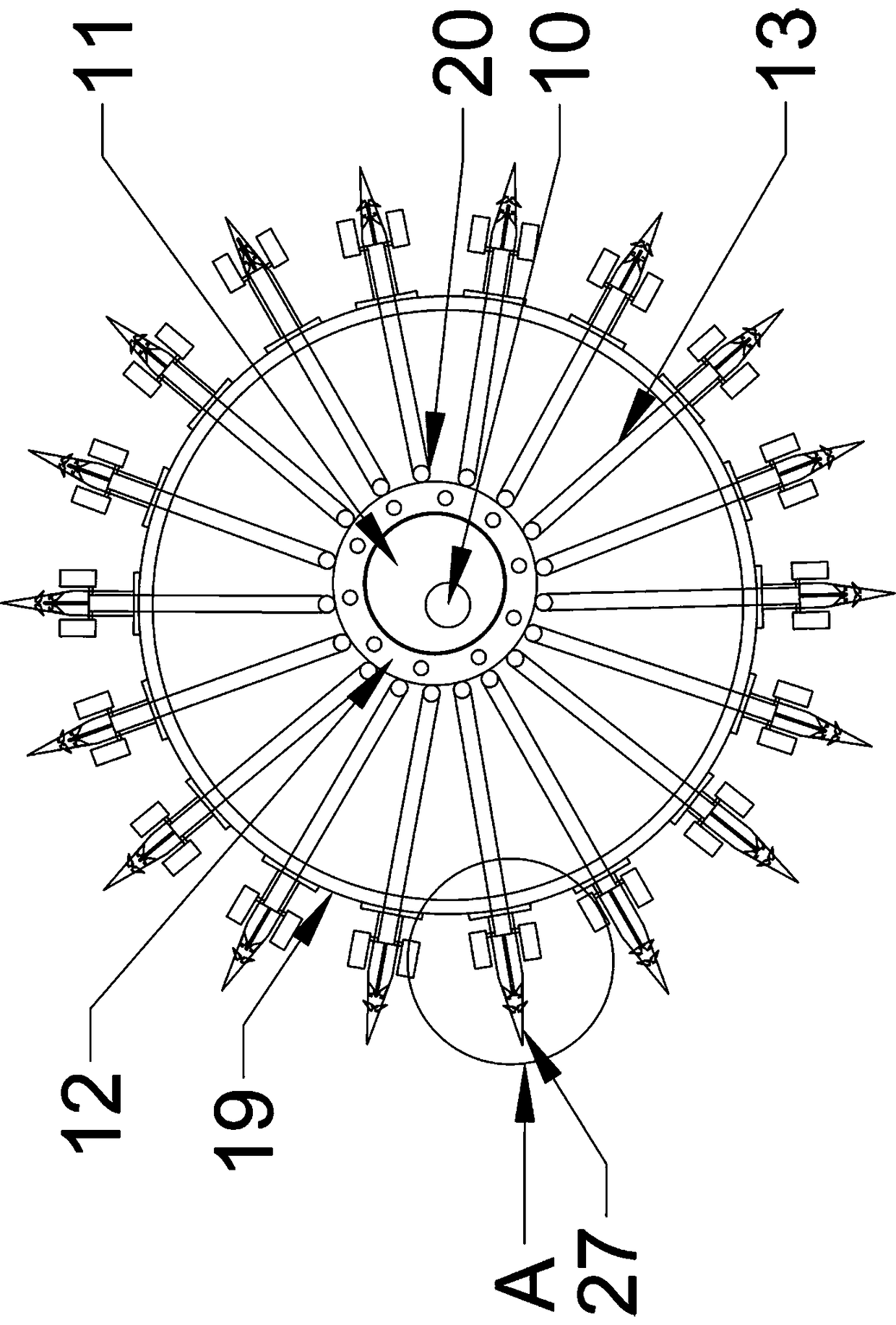

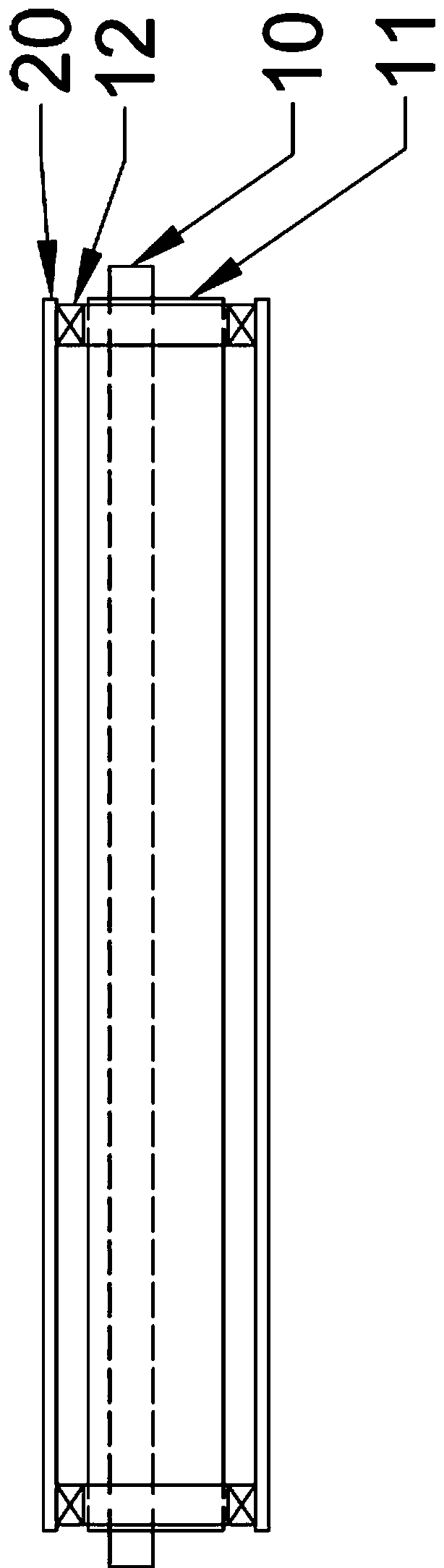

Automatic material taking and placing machine for detecting radial runout of gear rings

The invention discloses an automatic material taking and placing machine for detecting radial runout of gear rings. The automatic material taking and placing machine comprises a rotary material paw device, a detection worktable device, a to-be-detected material placing device, a qualified material placing device and an unqualified material placing device, wherein the rotary material paw device comprises a bearing, a rotary shaft, a cross beam, a first electric cylinder, a mechanical paw and a first servo motor, wherein the mechanical paw comprises a straight guide rail, a clamping plate, a screw rod and a second servo motor. Through the automatic material taking and placing machine for detecting radial runout of gear rings, workpieces can be automatically taken and placed in the process of detecting the roundness of the gear rings; the efficiency of operation for detecting the radial runout of the gear rings can be greatly improved.

Owner:QIJIANG YONGYUE GEAR

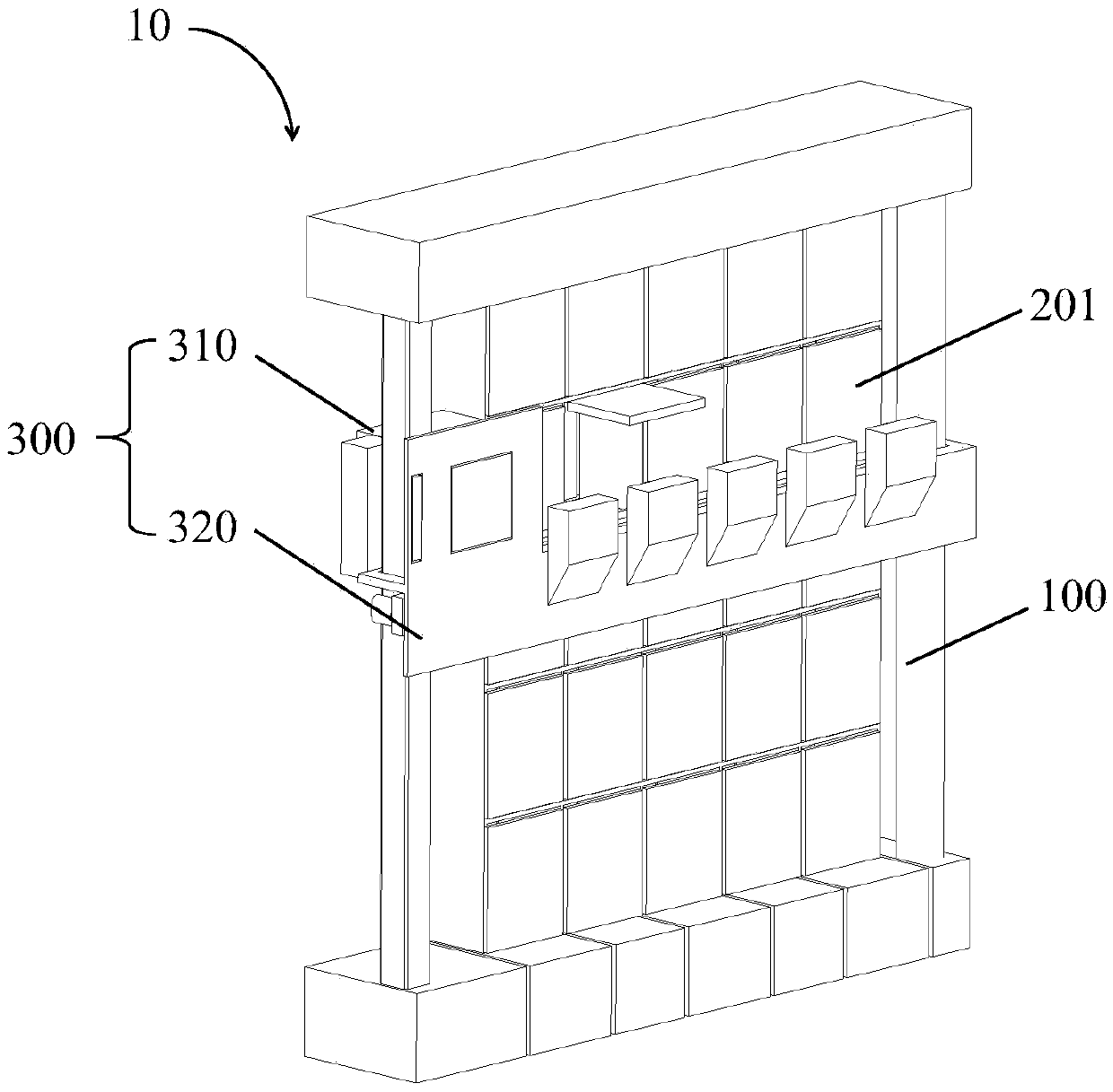

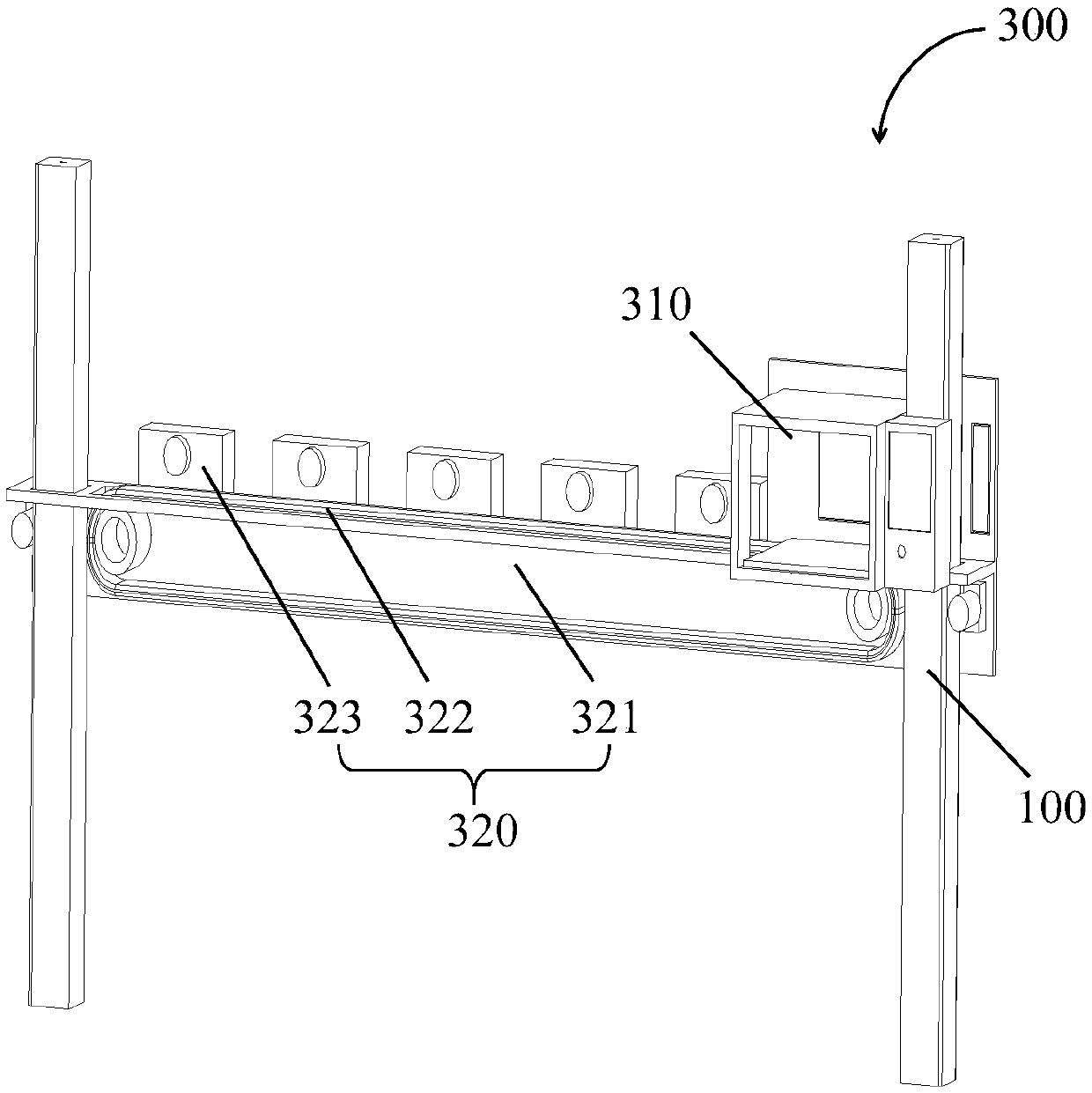

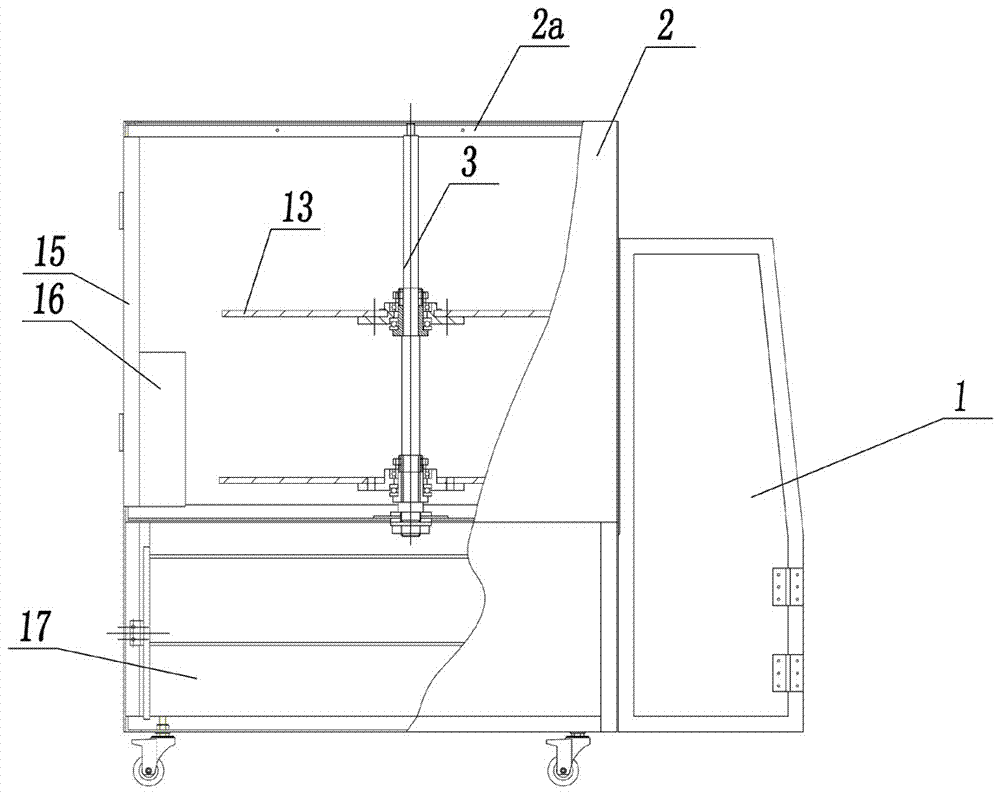

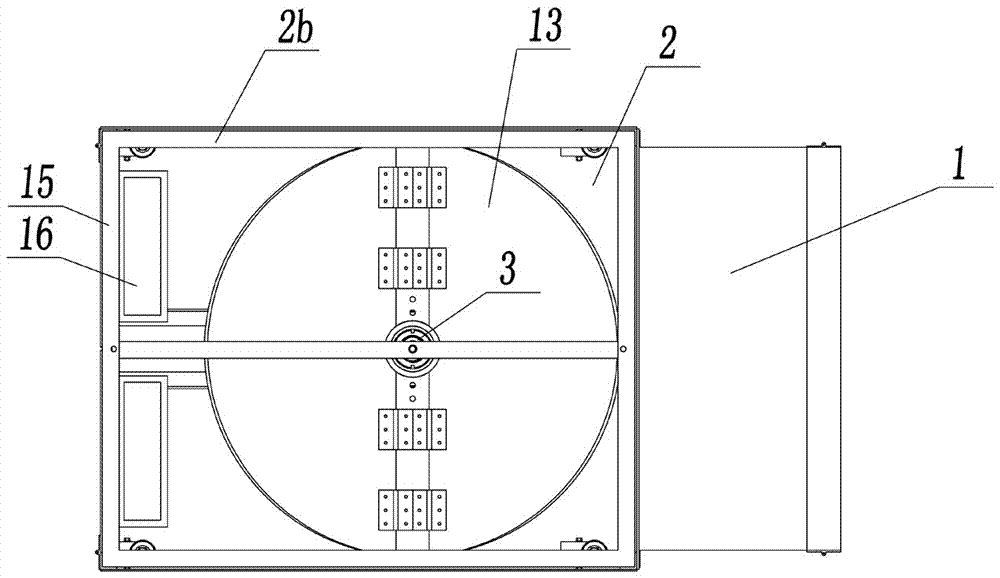

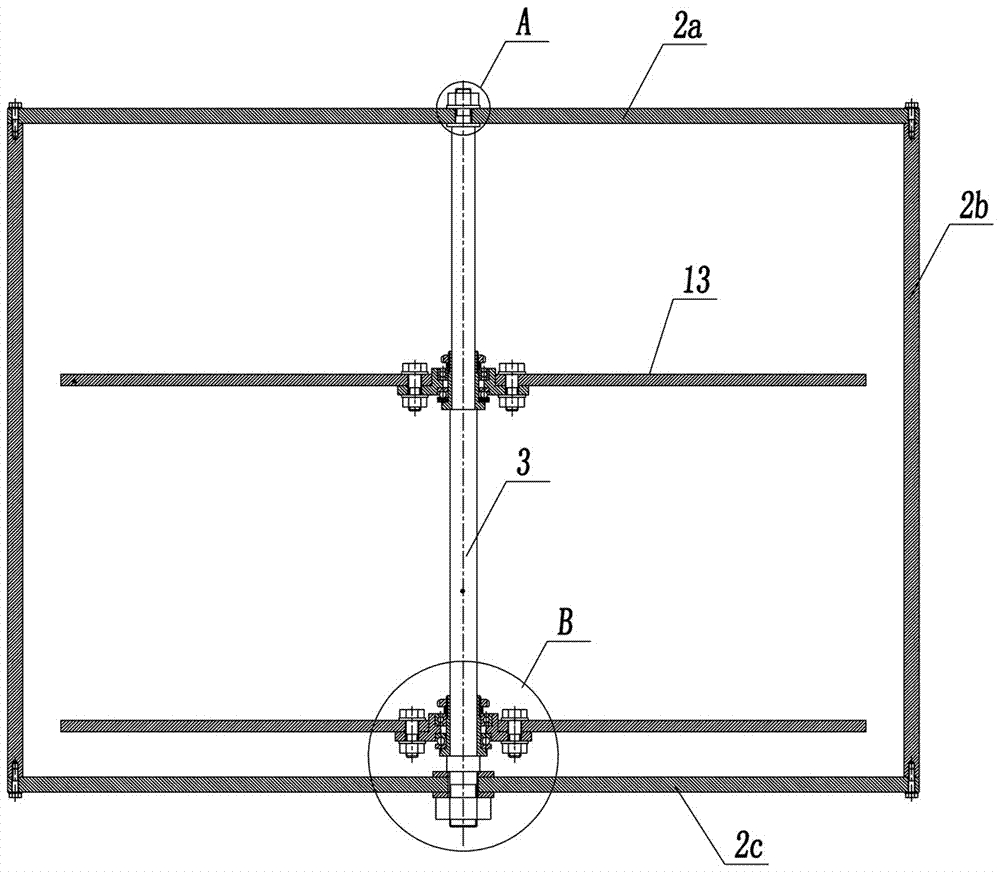

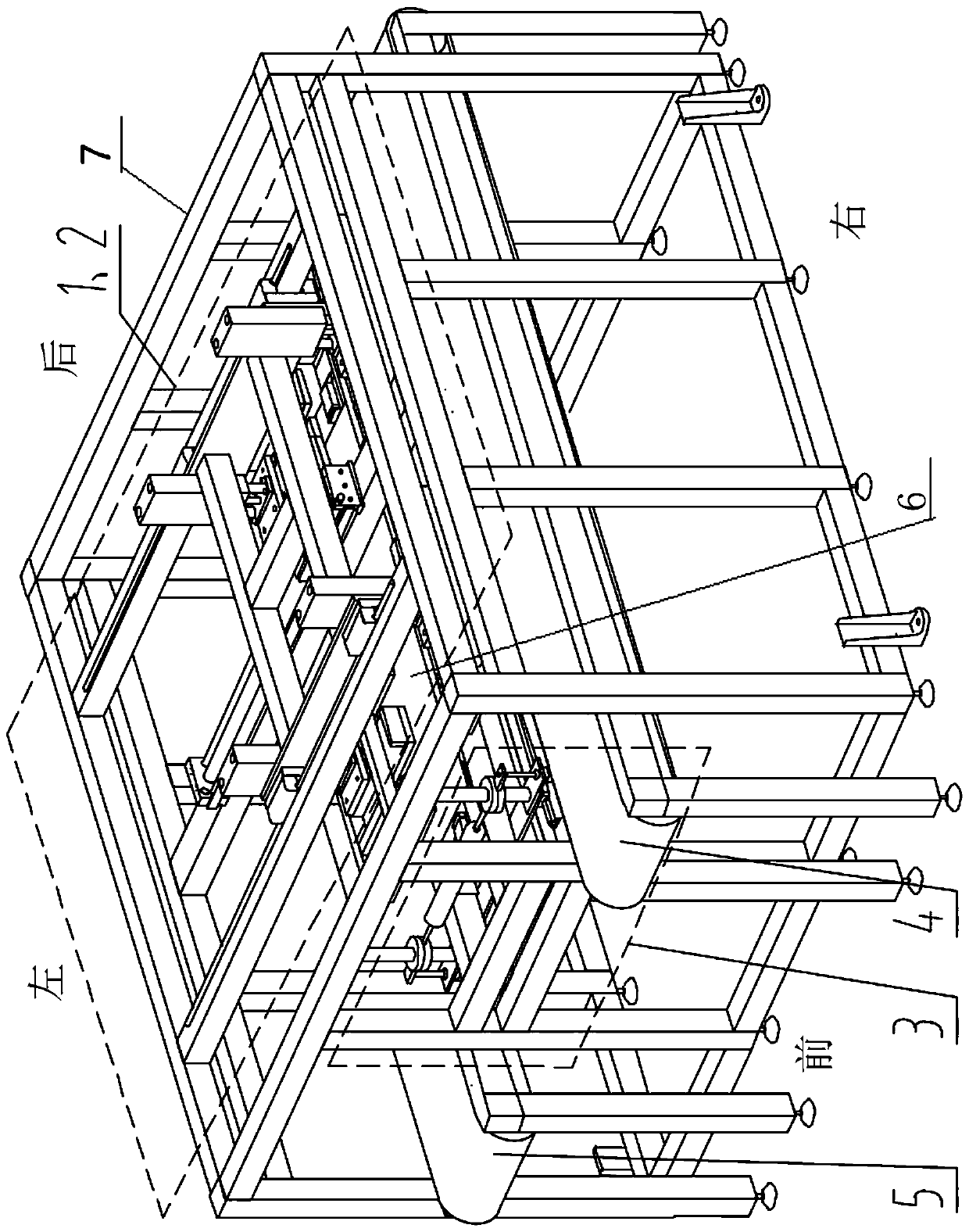

Building delivery system storage device capable of processing remained parcels

InactiveCN107521890ACompact structureSmall footprint for installationApparatus for meter-controlled dispensingStorage devicesControl systemObject store

The invention discloses a building delivery system storage device capable of processing remained parcels. The building delivery system storage device comprises a box, a grabbing mechanism, a delivery mechanism and a control system. The box is provided with an object storage port and an object taking port which are used for storing and taking, and the grabbing mechanism and the delivery mechanism are arranged in the box. The box is a rotary box, and a plurality of storage boxes different in volume and size are arranged on the inner side wall of the box. The storage boxes include storage box bodies and retention storage boxes. The grabbing mechanism is located at the middle portion of the box and used for storing / taking objects out of the storage boxes. The delivery mechanism is located at the position of the object storage port. According to the building delivery system storage device capable of processing the remained parcels, the space utilization rate is high, the remained objects can be processed in time, storage space is emptied, rapid response and object storing and taking can be achieved, and the object storing and taking efficiency is high. The building delivery system storage device is simple in structure, installation and usage are convenient, and the problems that an existing storage box is complex in structure, the box space utilization rate is low, object taking and storing are not convenient, and the using cost is high are achieved, operation is simple, and practicability is high.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

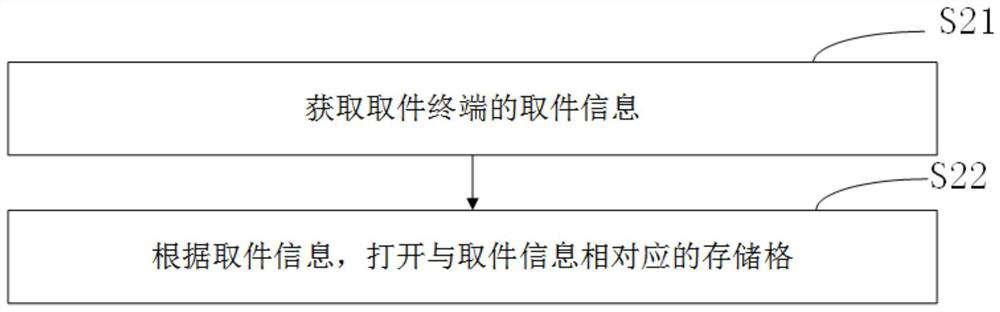

Intelligent express-storage-cabinet express-item storing and picking-up method

InactiveCN107705458AEnable self-storageAchieve pickupApparatus for meter-controlled dispensingLogisticsSecurity checkComputer science

The invention provides an intelligent express-storage-cabinet express-item storing and picking-up method. The method includes the following steps that 1) a user sends sending information, and an express system sends the sending request to a server of an express storage cabinet; 2) the user obtains express sending codes and the order number; 3) the user puts to-be-sent express packages into the express storage cabinet; 4) the express packages firstly pass through a weighting device to fall into a conveying belt; (5) the express packages are scanned through a security check scanner; 5) the express packages fall into the conveying belt of the express storage cabinet, and an infrared distance measurement device measures the volumes of the express packages; 6) tongs put the express packages into the corresponding express-package storage cabinets; 7) a controller transmits the information of the express packages to couriers; 8) the couriers input into express picking-up codes, and pick up express items. By means of the intelligent express-storage-cabinet express-item storing and picking-up method, self-help storage and picking-up of the express packages can be achieved, the labor cost isgreatly reduced, the user can place an order in a self-help mode and can send express items in a self-help mode, and the convenience efficiency of sending is greatly improved.

Owner:绿源美味(天津)网络科技有限公司

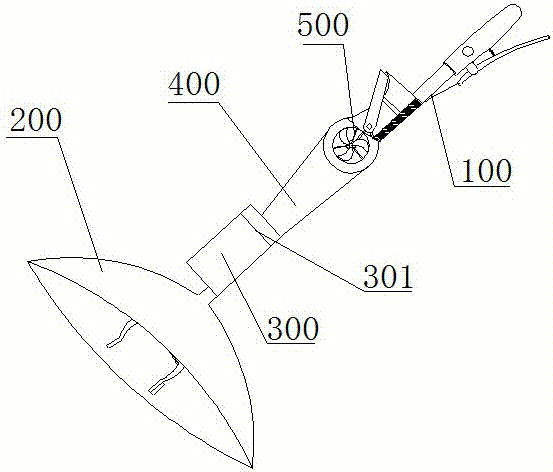

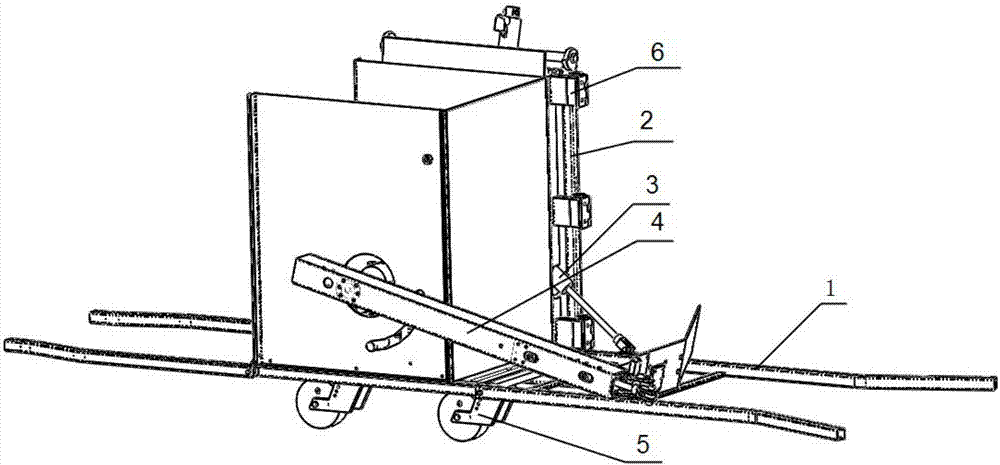

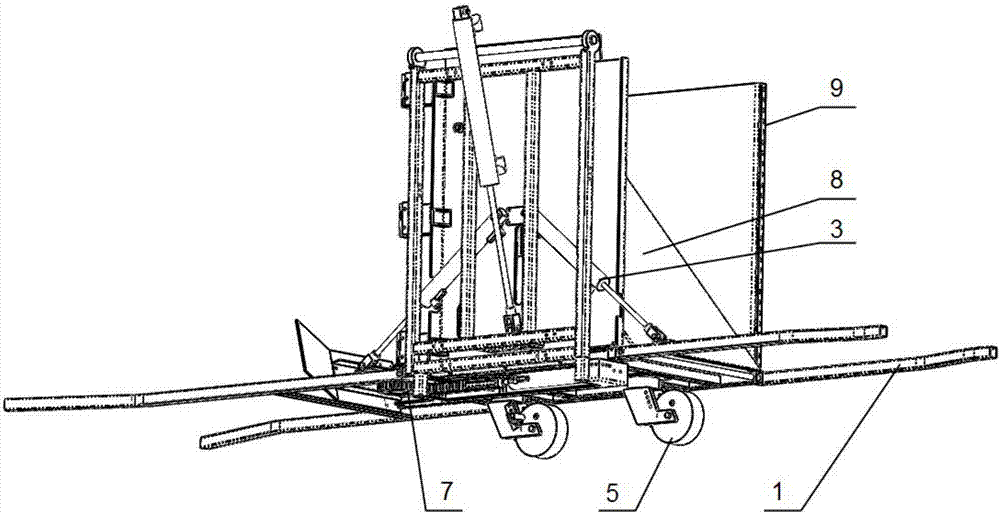

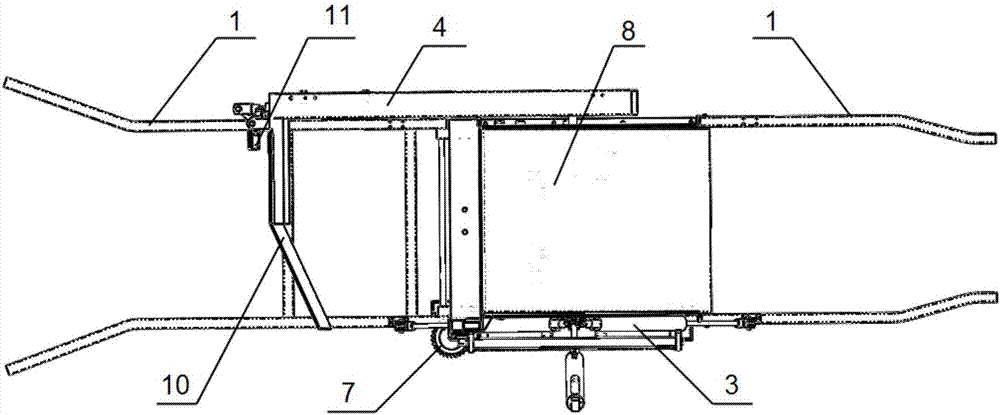

Device for picking and placing traffic cones and control method

ActiveCN107268482AAchieve pickupAchieve placementClimate change adaptationTraffic signalsStructural engineeringRoad surface

The invention discloses a device for picking and placing traffic cones and a control method. The device comprises a base and a box, the two ends of the base are provided with a pair of clamping rods respectively, the clamping rods comprise the wide-opening clamping rod and the narrow-opening clamping rod, and a rotating arm rod is arranged on the side, facing the wide-opening clamping rod, of the box; the tail end of the rotating arm rod is provided with a diffuse reflection photoelectric sensor and a clamping finger part, the diffuse reflection photoelectric sensor is used for recognizing the traffic cones entering the area of the wide-opening clamping rod, and the clamping finger part is used for clamping the traffic cones. When the traffic cones are placed, the traffic cones slide onto a road surface through a limiting downward sliding slope, and the traffic cones sliding to the road surface can be linearly set right by the narrow-opening clamping rod while a vehicle moves; when the traffic cones are picked, the traffic cones enter the area of the wide-opening clamping rod and are clamped by the clamping finger part; the clamping finger part is loosened when the rotating arm rod rotates to a vertical position, and the traffic cones enter a traffic cone storage device along a free sliding slope. The traffic cones can be quickly picked and placed by means of the device, and the work efficiency is greatly improved.

Owner:广州市图之灵计算机技术有限公司

Microphone wind noise prevention device and electronic equipment

ActiveCN106878839AAvoid enteringEffective pressure reliefMouthpiece/microphone attachmentsEngineeringElectronic equipment

The invention discloses a microphone wind noise prevention device and electronic equipment. The device comprises a first sound hole, a second sound hole, a first cavity, a second cavity and a connecting channel. The first sound hole and the second sound hole are communicated through the first cavity. The first cavity is internally provided with a first flow blocking part which is opposite to the first sound hole and a second flow blocking part which is opposite to the second sound hole. The connecting channel is used for connecting the first cavity and the second cavity. The second cavity is communicated with a microphone sound hole. The entrance of the connecting channel is arranged between the first flow blocking part and the second flow blocking part. One technical problem to be solved is high wind noise of the present microphone body. One application of the microphone wind noise prevention device is used for the electronic equipment.

Owner:GOERTEK INC

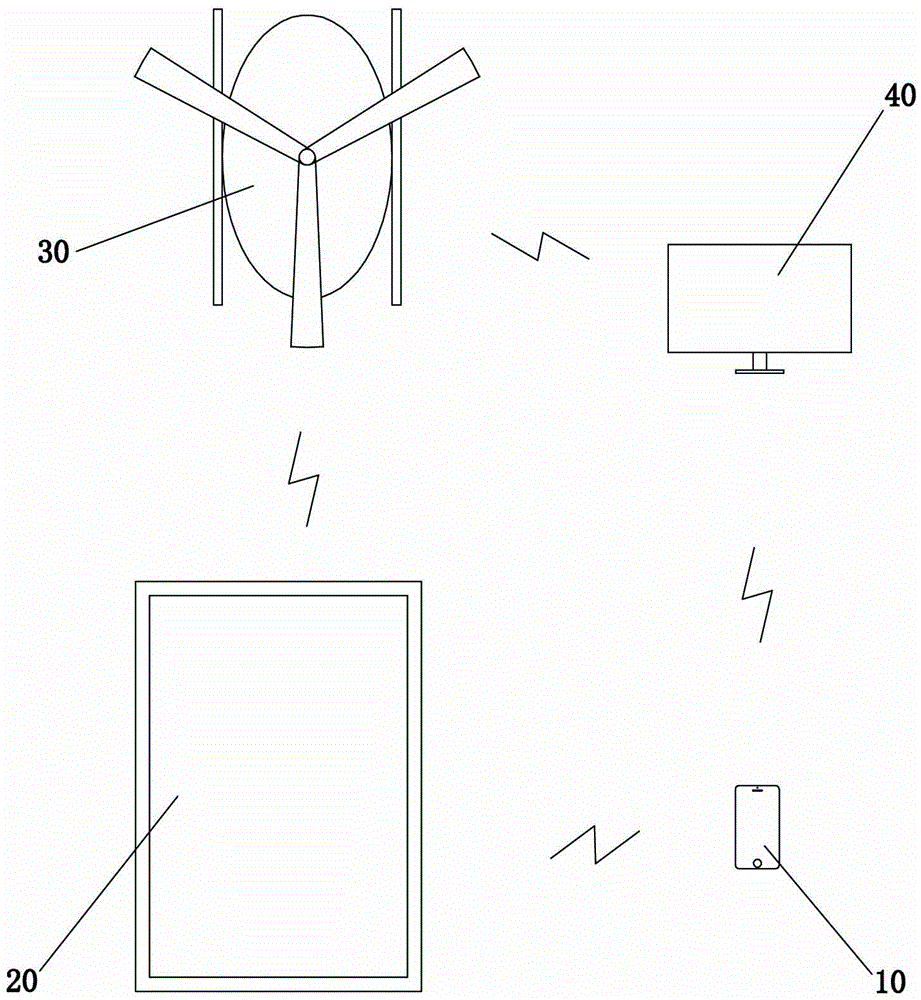

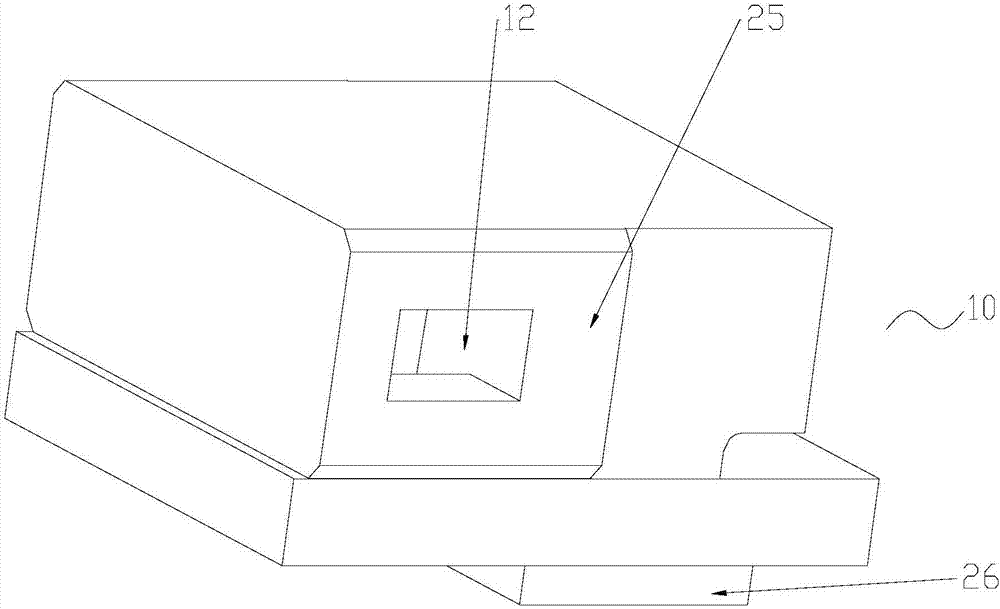

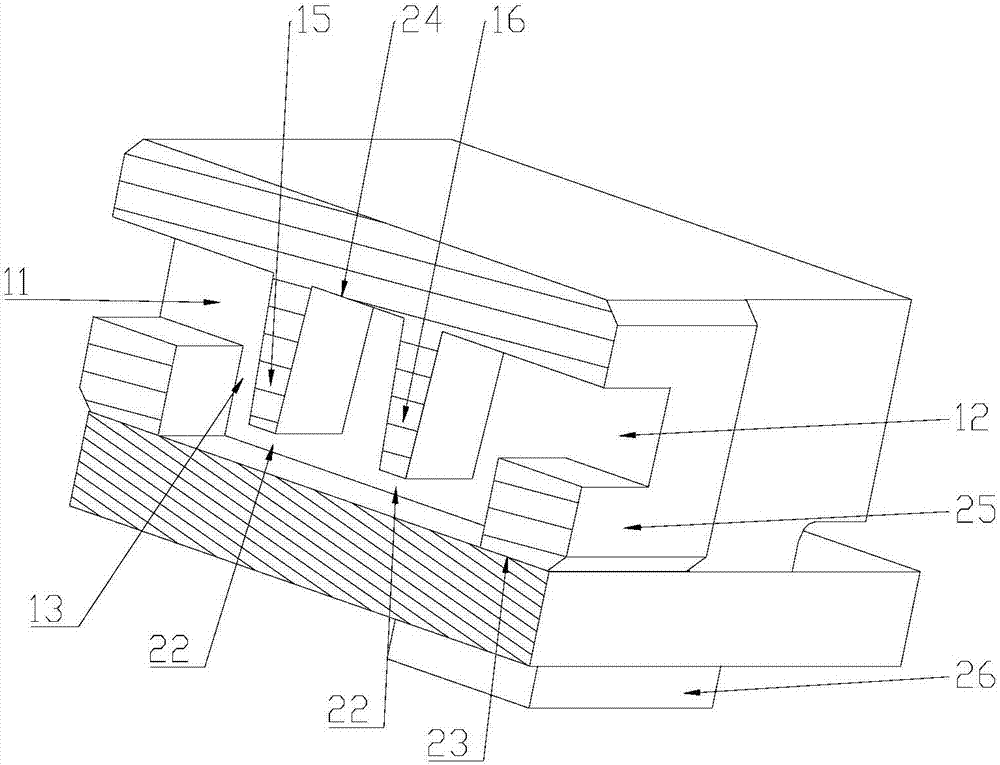

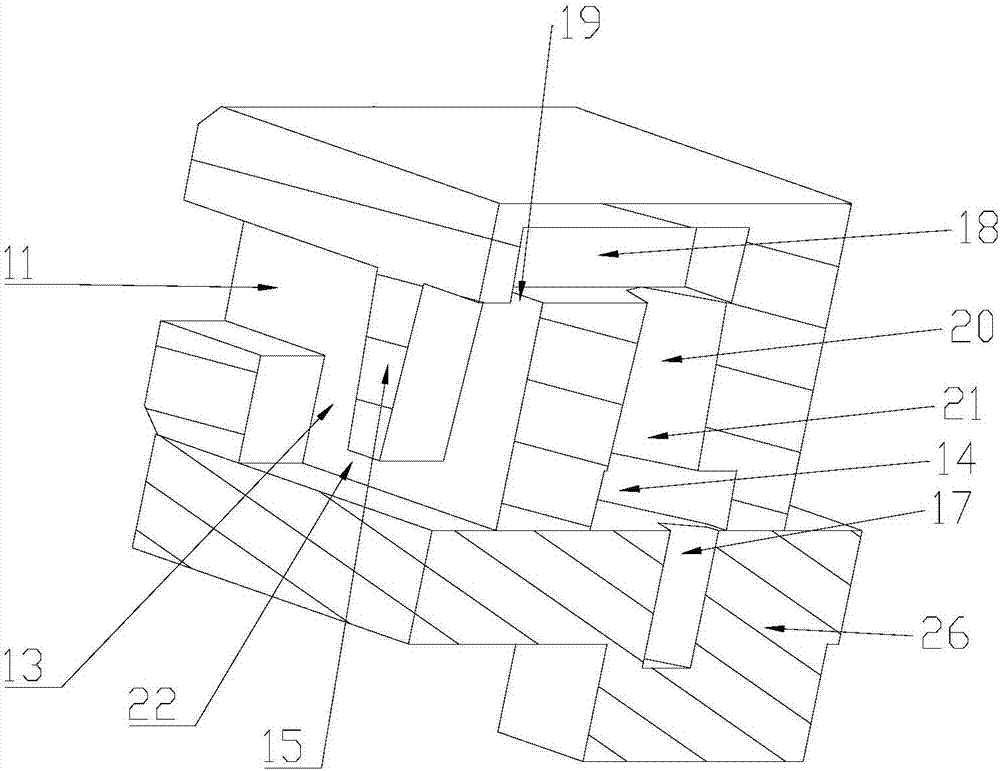

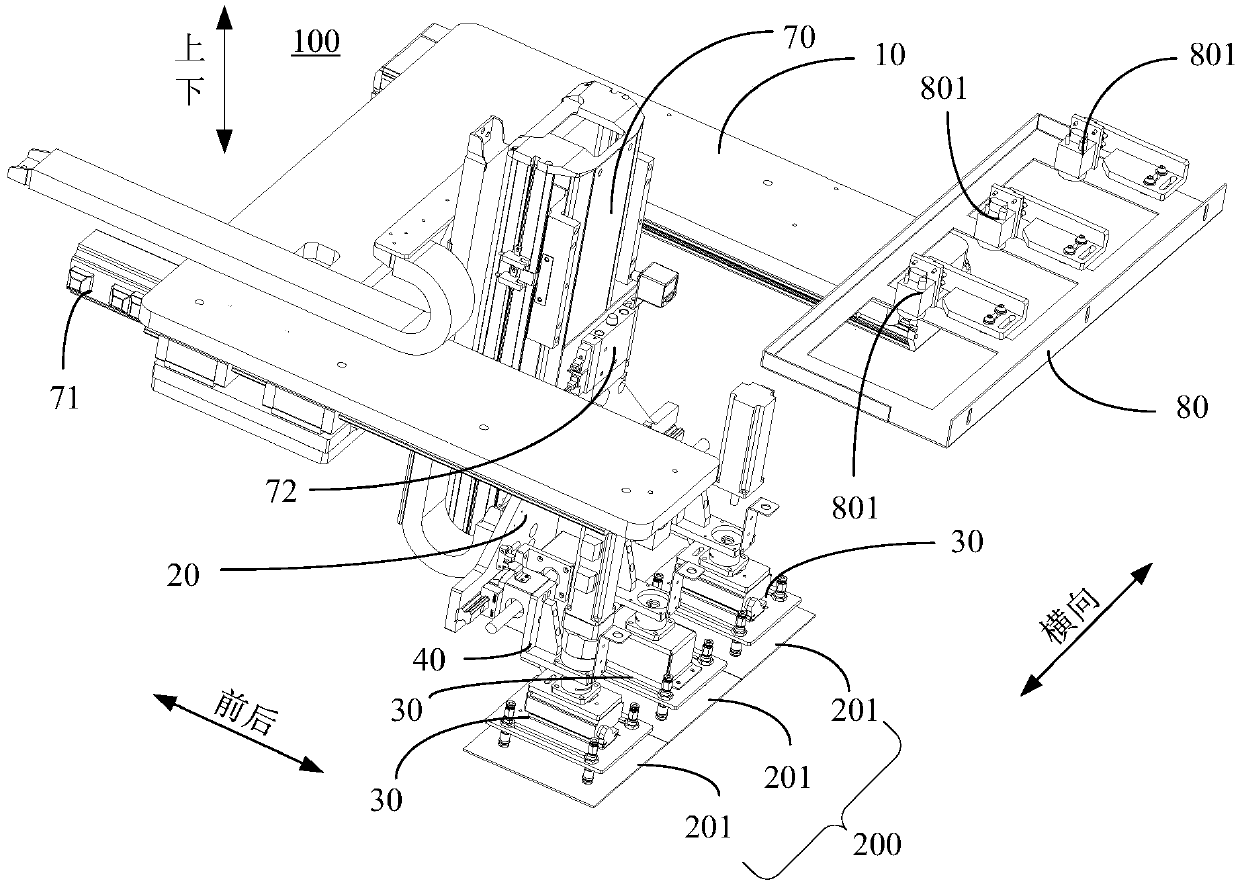

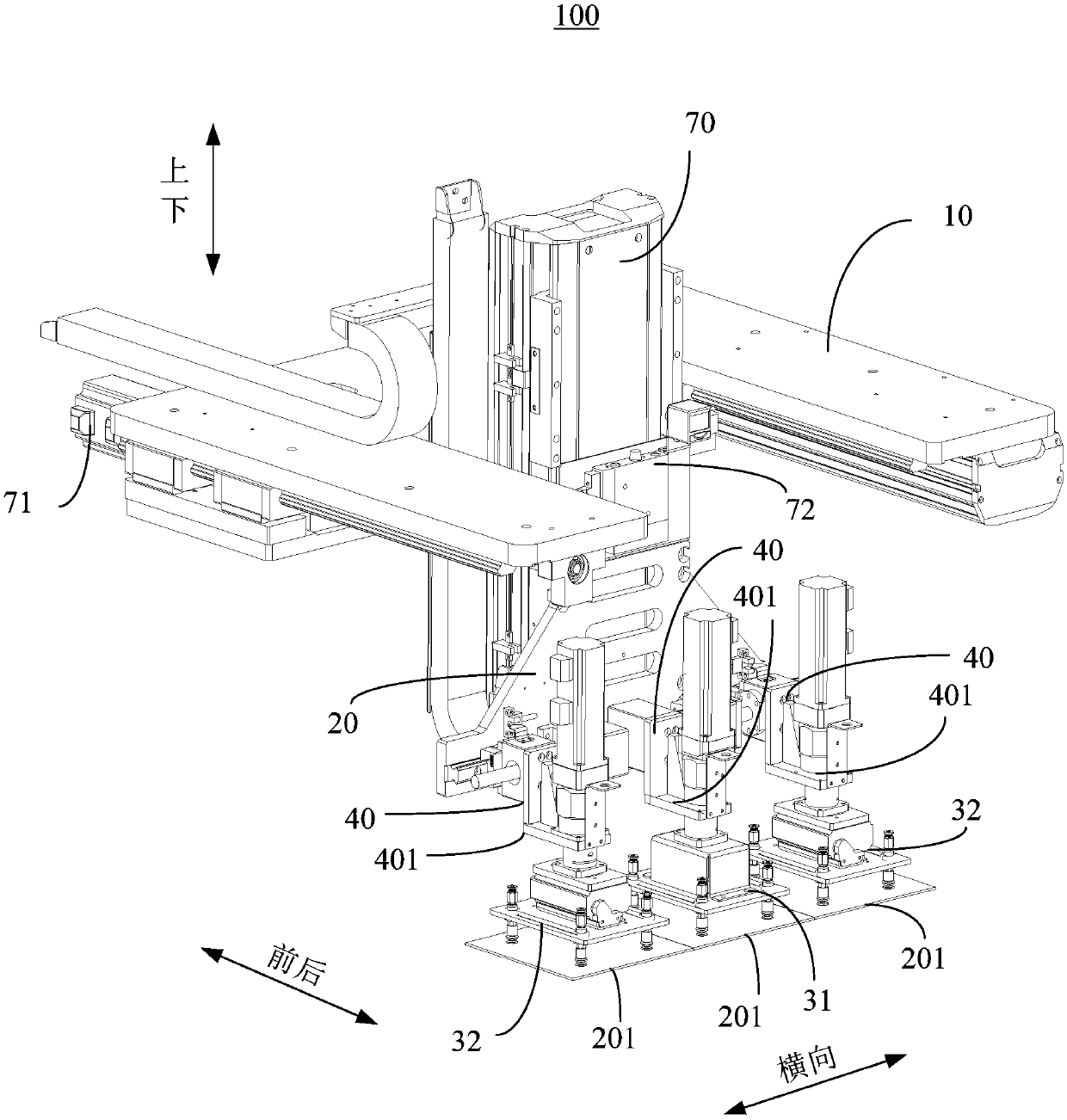

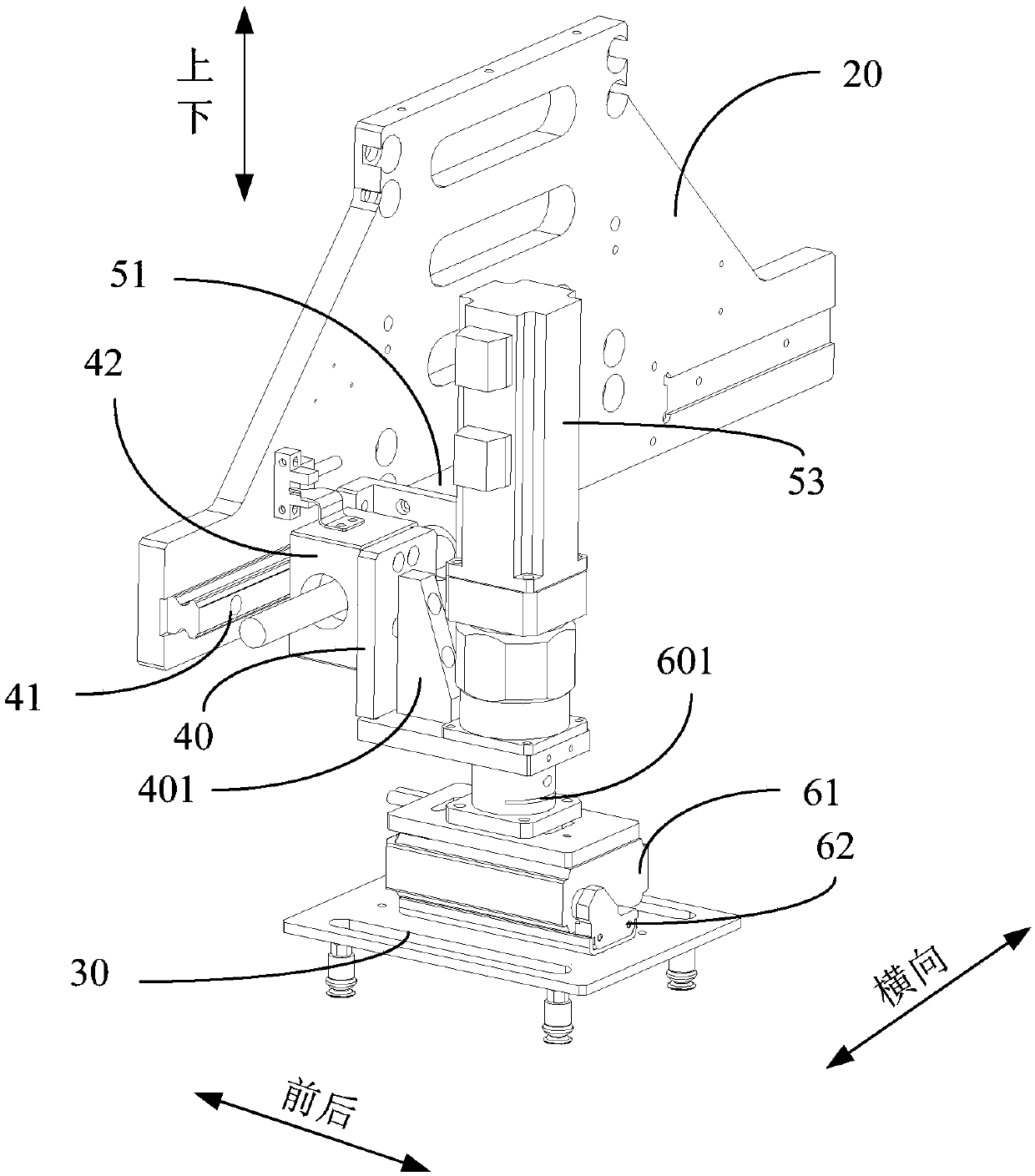

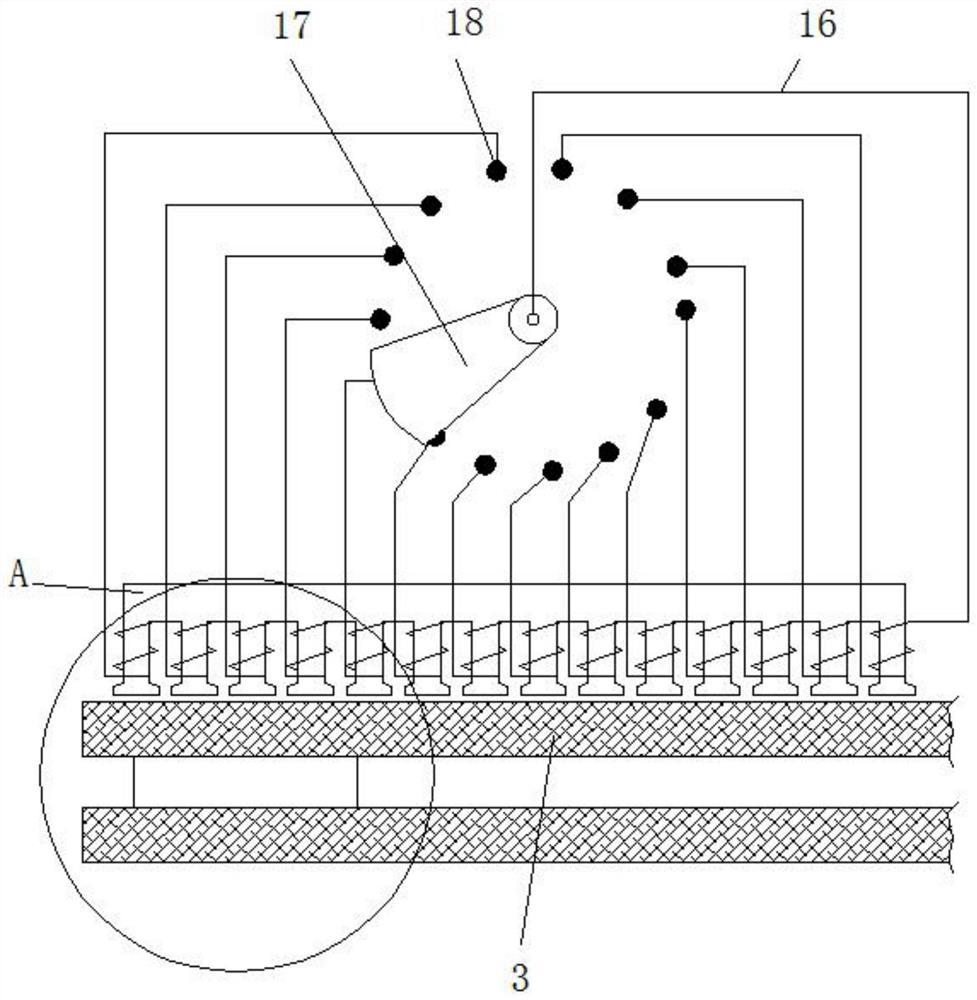

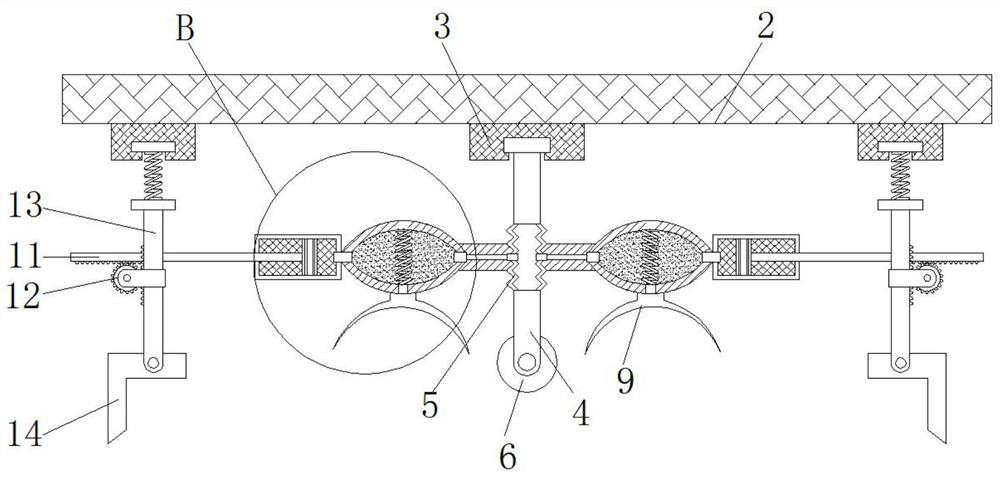

Battery sheet discharging device and solar cell welding machine

PendingCN109623222AAchieve pickupMeet the needs of side-by-side welding processesFinal product manufactureWelding/cutting auxillary devicesElectrical batteryEngineering

The invention discloses a battery sheet discharging device and a solar cell welding machine. The solar cell welding machine comprises the discharging device for discharging a battery sheet group; thebattery sheet group is provided with a plurality of battery sheets; the discharging device comprises a base, a moving base and a plurality of pickup components; the moving base is movably arranged onthe base; the plurality of pickup components are movably arranged on the moving base; the pickup components are horizontally arranged side by side; and each pickup component is separately used for picking up one battery sheet to achieve the pickup of the battery sheet group. A first driving system is used for driving the moving base to move on the base in order to achieve the discharge of the battery sheet group; and a second driving system is separately used for driving each of the pickup components to move on the moving base in order to adjust the relative position between the battery sheetsin the battery sheet group. According to the device, efficient and accurate discharge of multiple battery sheets at the same time can be achieved and the needs of the welding process of multiple series of solar cells can be met.

Owner:WUHAN SUNIC INTELLIGENT EQUIP MFG CO LTD

Metal chip safe cleaning device

The invention belongs to the technical field of tools, in particular to a metal chip safe cleaning device, and aims at providing the metal chip safe cleaning device which protects workers from being scratched and is simple to operate. By means of the technical scheme, the metal chip safe cleaning device comprises a shell body, a connecting rod, an annular groove, a magnet ring and a blocking plate. The annular groove is fixed at one end of the shell body, the connecting rod is arranged in the shell body and in coaxial connection with the shell body, the length of the connecting rod is larger than that of the shell body, one end of the connecting rod is fixed on the blocking plate, and the magnet ring is arranged in the annular groove.

Owner:SHENYANG XINDA INFORMATION SCI & TECH

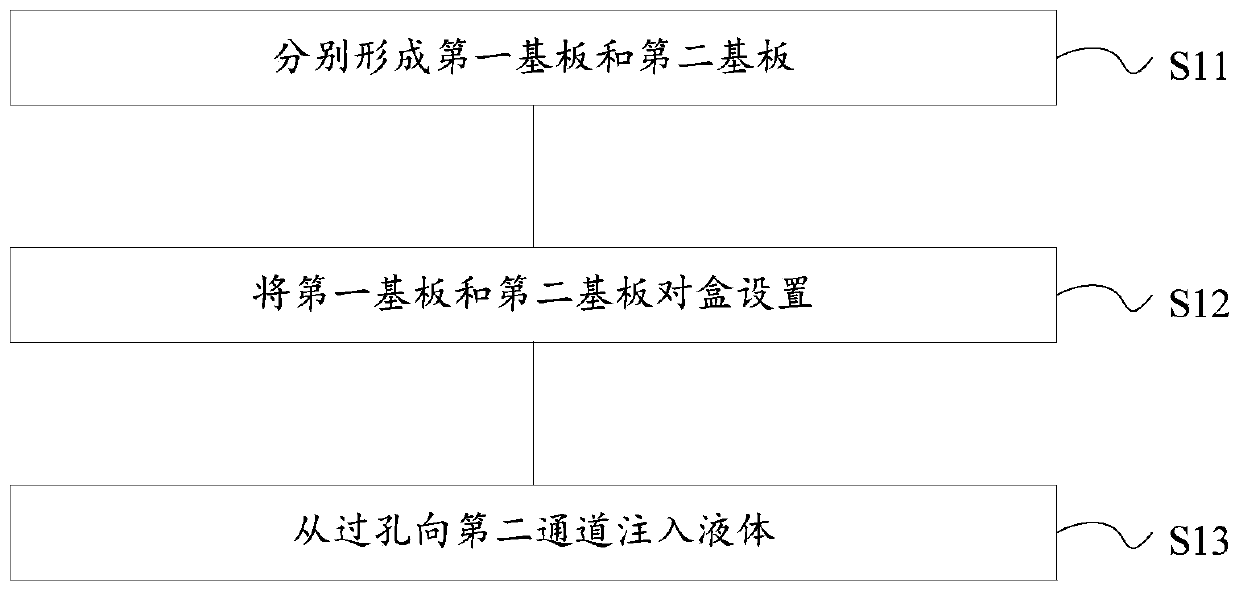

Transfer substrate and manufacturing method and transfer method thereof

ActiveCN110854057AAchieve pickupAchieve releaseSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention relates to a transfer substrate and a manufacturing method and a transfer method thereof. The transfer substrate comprises a first substrate and a second substrate. A via hole is arranged in the second substrate; an accommodating space is formed between the first substrate and the second substrate; and the accommodating space comprises a first channel and a second channel. Gas is accommodated in the first channel, and liquid is accommodated in the second channel; the contact angle of the liquid in the first channel is greater than an angle threshold value; and the gas in the first channel changes under the control of the first substrate to switch a contraction state and an expansion state. In the expansion state, the liquid in the second channel flows out from the via hole under the pushing of the gas to form a transfer head for picking up a to-be-transferred element, or the transfer head releases the to-be-transferred element to a target substrate; and in the contractionstate, negative pressure is formed in the first channel, and the transfer head is tightly attached to the to-be-transferred element under the action of the negative pressure, so that the transfer head can drive the to-be-transferred element to transfer. According to the invention, transfer of Micro LEDs can be realized.

Owner:BOE TECH GRP CO LTD

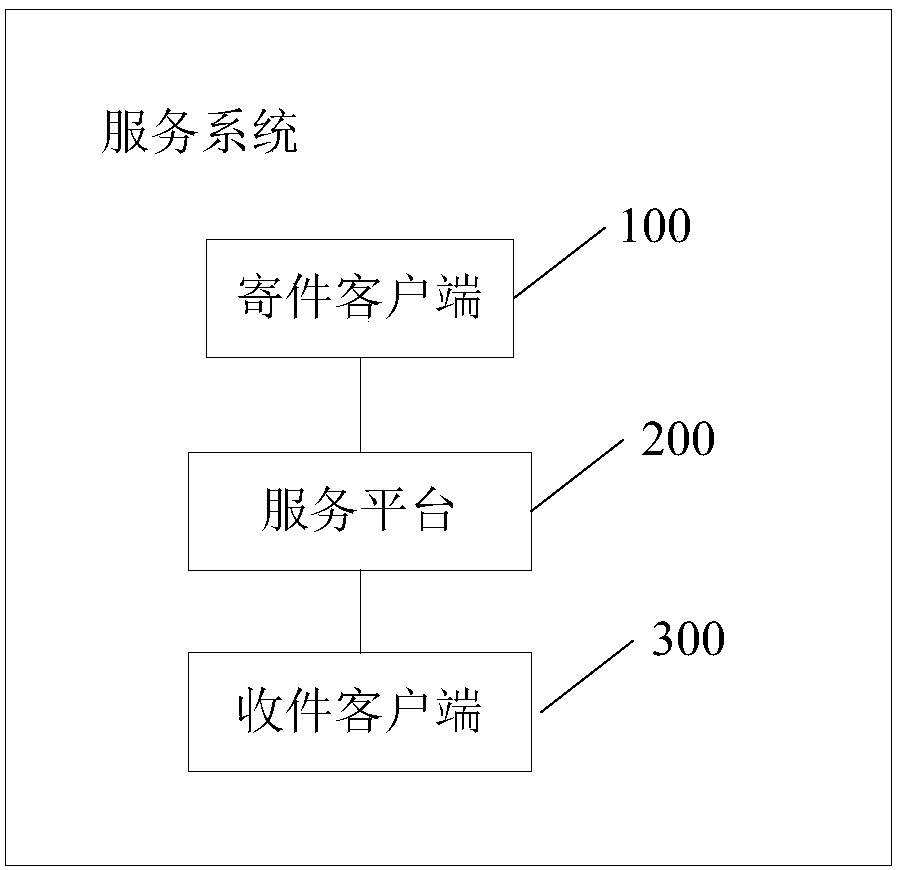

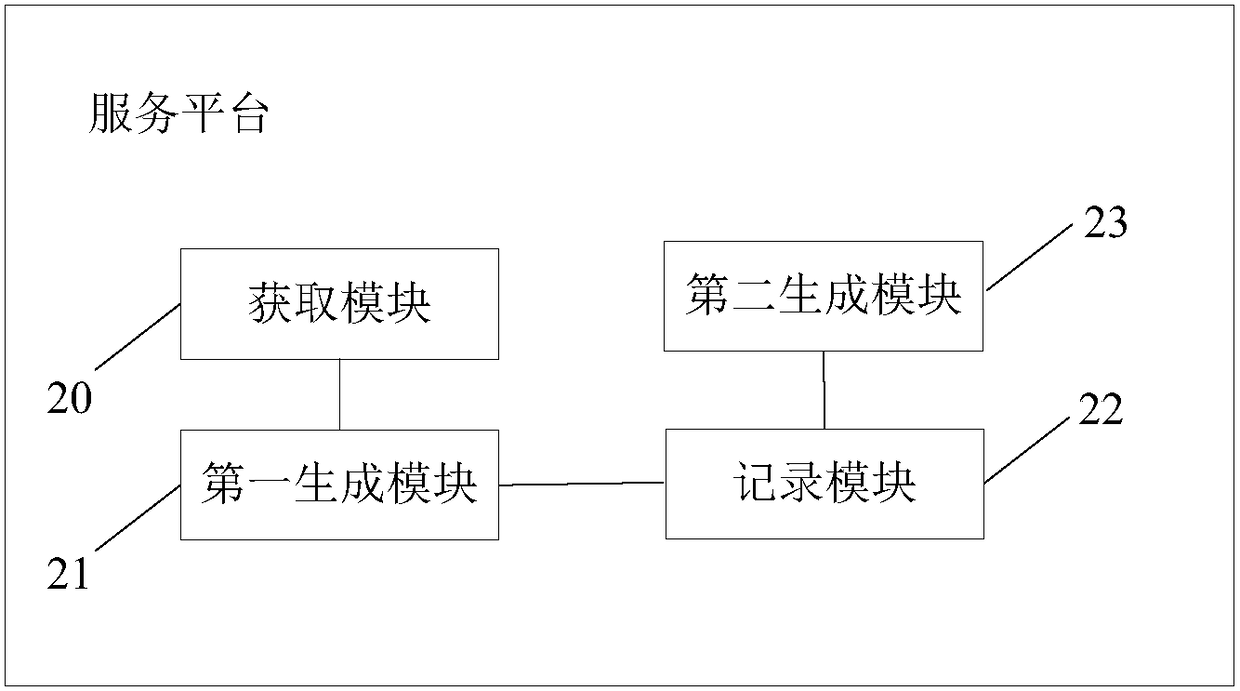

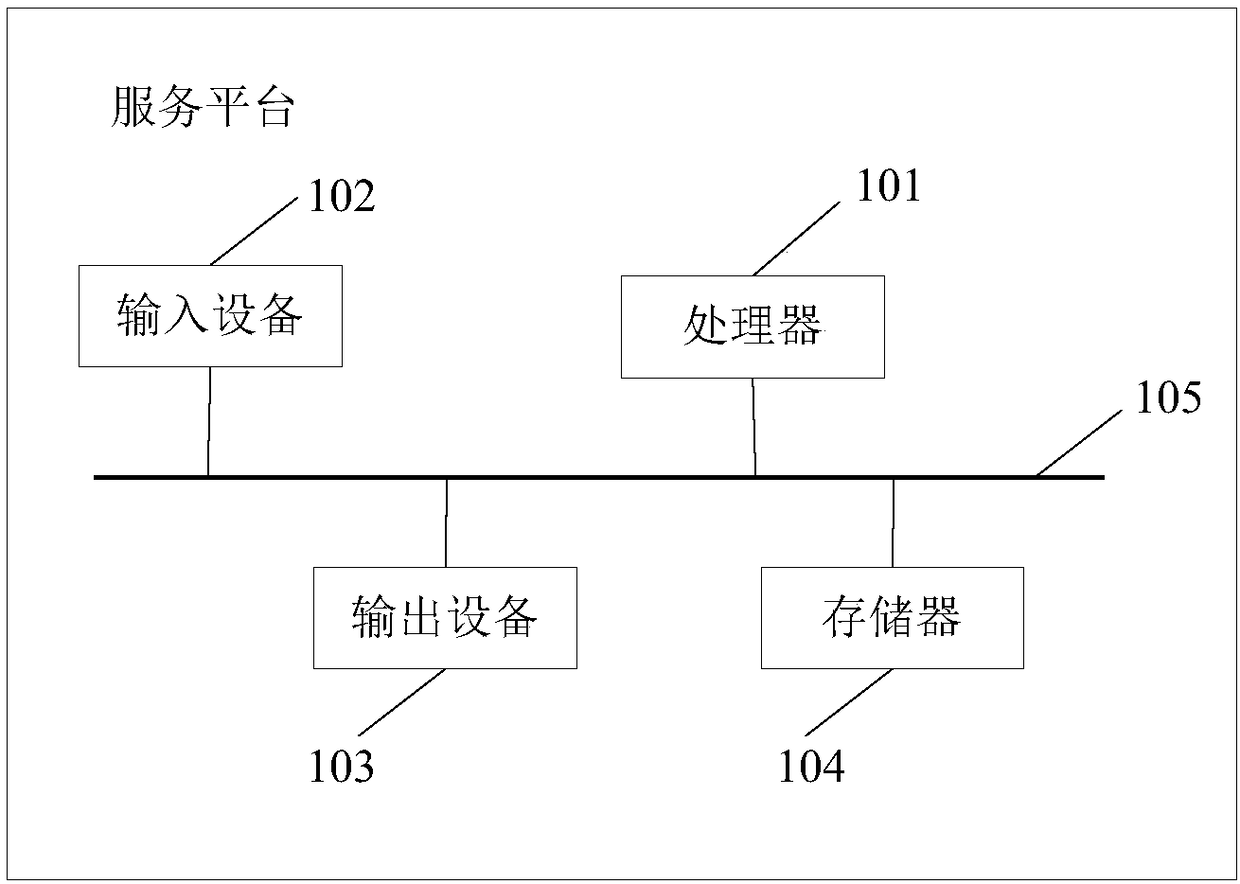

Block-chain-based parcel service system, platform and method

InactiveCN108537478AImprove securityAchieve pickupCo-operative working arrangementsLogisticsOperating systemBlockchain

The embodiments of the invention disclose a block-chain-based parcel service system, platform and method. The block-chain-based parcel service system includes a mailing client, a service platform anda receiving client, wherein the mailing client logs in the service platform to complete the mailing process; the mailing process includes logging in the service platform, placing an order, uploading apicture including the recipient information and the parcel information; the service platform generates a QR code according to the recipient information and the parcel information, generates a block chain according to the mailing process and the generating node of the QR code, verifies the receiving client according to the block chain, and transmits the verification result including the QR code tothe receiving client; and the receiving client initiates a receipt request to the service platform and completes pickup based on the verification result including the QR code. The block-chain-based parcel service system, platform and method can realize pickup so as to improve safety of the parcel, on the basis of the block chain technology and the QR code technology.

Owner:朱里

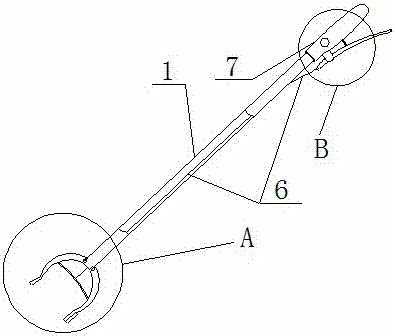

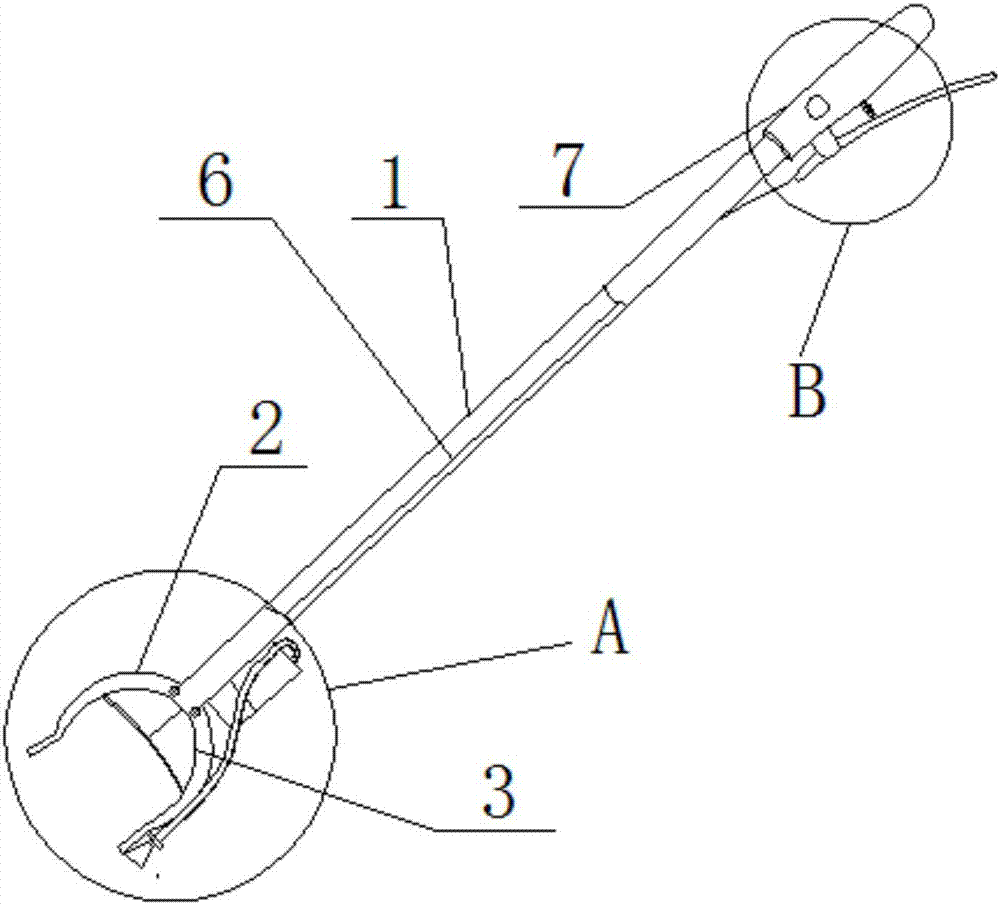

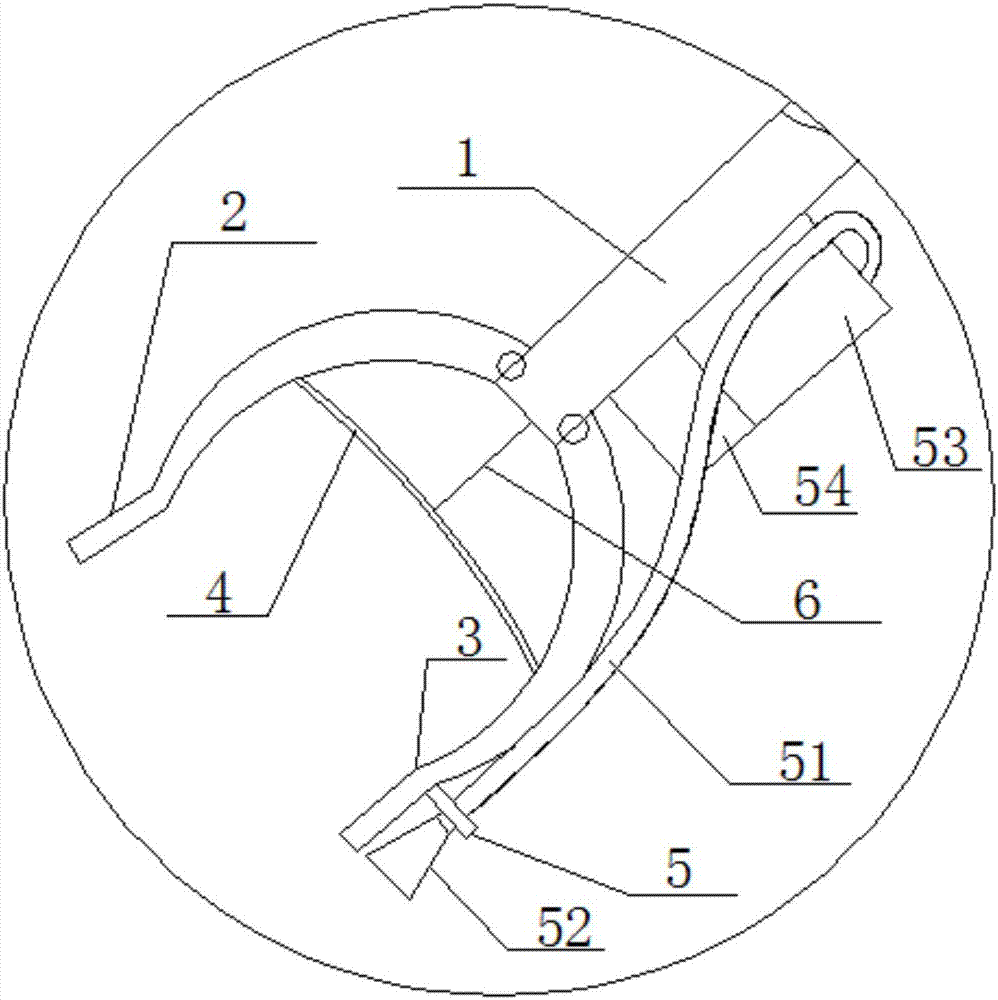

Garbage pickup device for sanitation worker and usage method thereof

The invention discloses a device for picking up garbage for sanitation workers, comprising a pipe body, the bottom end of the pipe body is hinged with a first arc-shaped clip and a second arc-shaped clip, and the first arc-shaped clip and the second arc-shaped clip are There is an elastic piece between them, the top of the pipe body is covered with a pipe sleeve, a bracket is provided on one side of the pipe sleeve, a handle is hinged on the bracket, a spring is provided between the handle and the pipe sleeve, and the pipe sleeve The body is also provided with a through hole, and the fixed pulley arranged in the pipe body is also provided at the said through hole. The present invention can pick up the rubbish through the first arc clip and the second arc clip, and the first arc clip and the second arc clip can be clamped by pressing the handle, so as to realize the picking of rubbish. Garbage can be picked up conveniently, and sanitation workers do not need to bend over to operate, making garbage picking more convenient. At the same time, the setting of the fan can clean up some inconvenient powder garbage, which is very convenient for powder garbage cleaning.

Owner:安陆市万众创新智能科技有限公司

Chicken egg picking and carrying manipulator

The invention discloses a chicken egg picking and carrying manipulator and belongs to electromechanical devices. The chicken egg picking and carrying manipulator comprises a first pneumatic motor, a second pneumatic motor, a first air cylinder, a first position sensor, a CCD (charge coupled device) sensor, a sucker, a second air cylinder, wheels, a base, a storage box, a second position sensor, a second pneumatic motor, a first support arm, a fourth pneumatic motor, an electromagnetic valve, an air pump, a support, a second support arm and a fifth pneumatic motor. The wheels are mounted below the base, the electromagnetic valve and the air pump are mounted above the base, the support and the base are connected through the fourth pneumatic motor, the storage box is mounted on the support, the upper end and the lower end of the support are connected through the fifth pneumatic motor, the upper end of the support is connected with the first support arm through a third pneumatic motor, the first support arm and the second support are connected through the first pneumatic motor, the second support arm is connected with the first air cylinder through the second pneumatic motor, and the second air cylinder is fixed on the first air cylinder. The chicken egg picking and carrying manipulator is capable of assisting picking and carrying of chicken eggs.

Owner:郭玉华

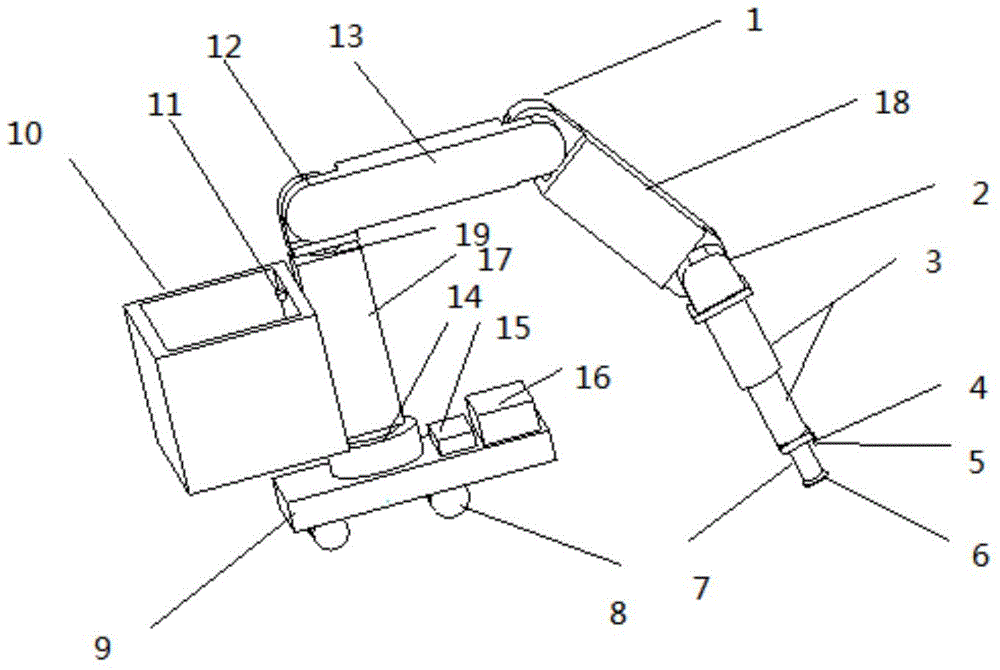

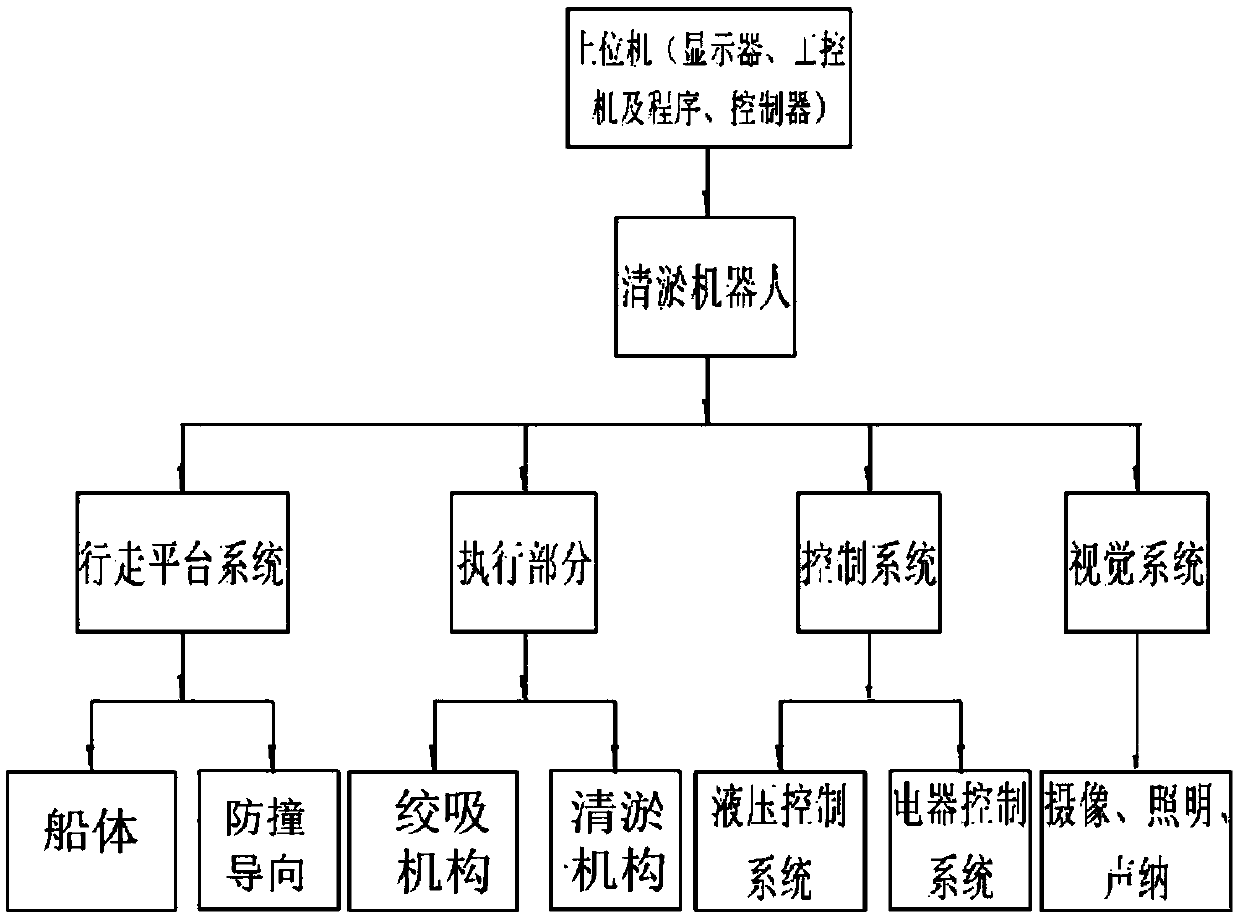

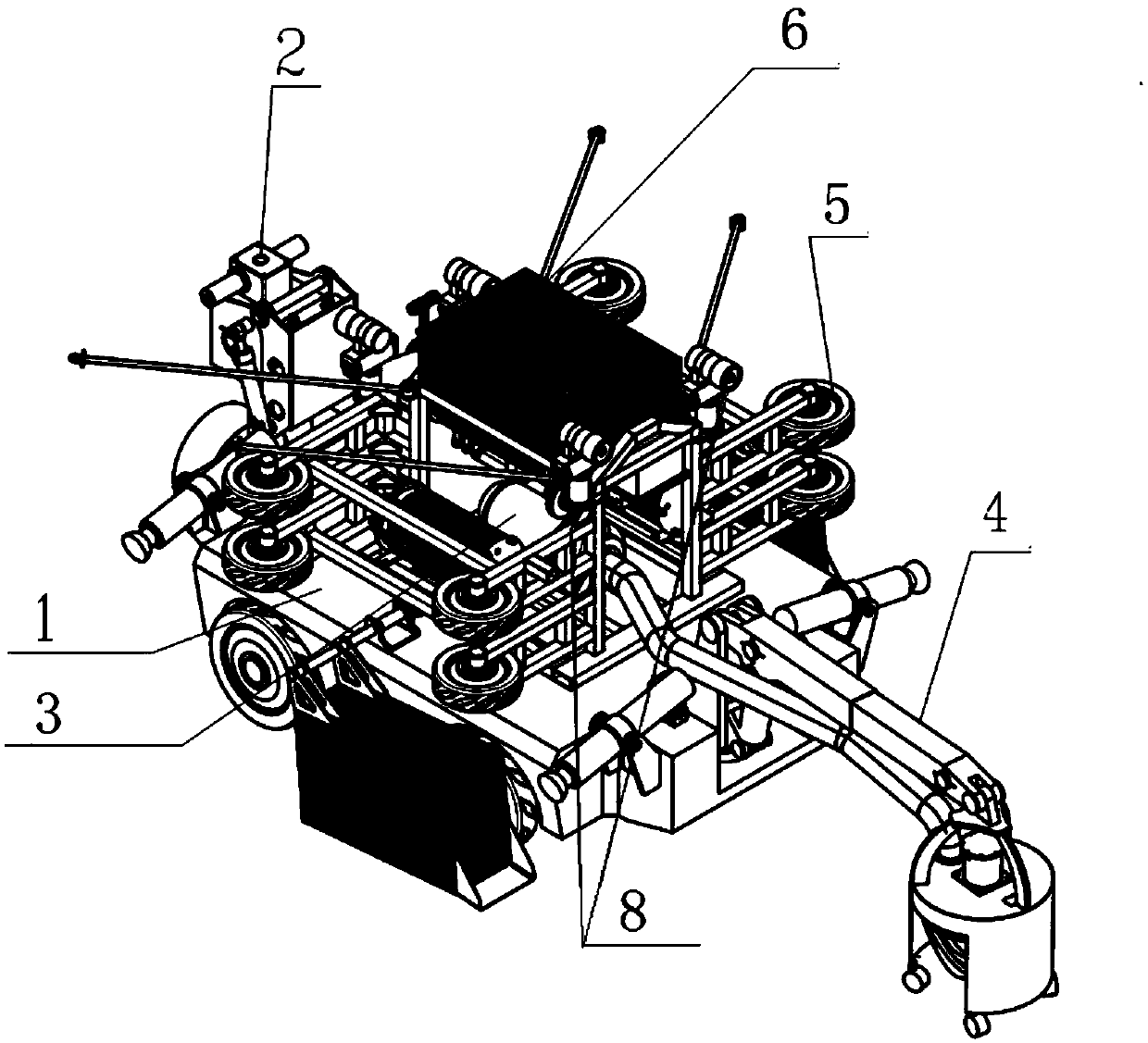

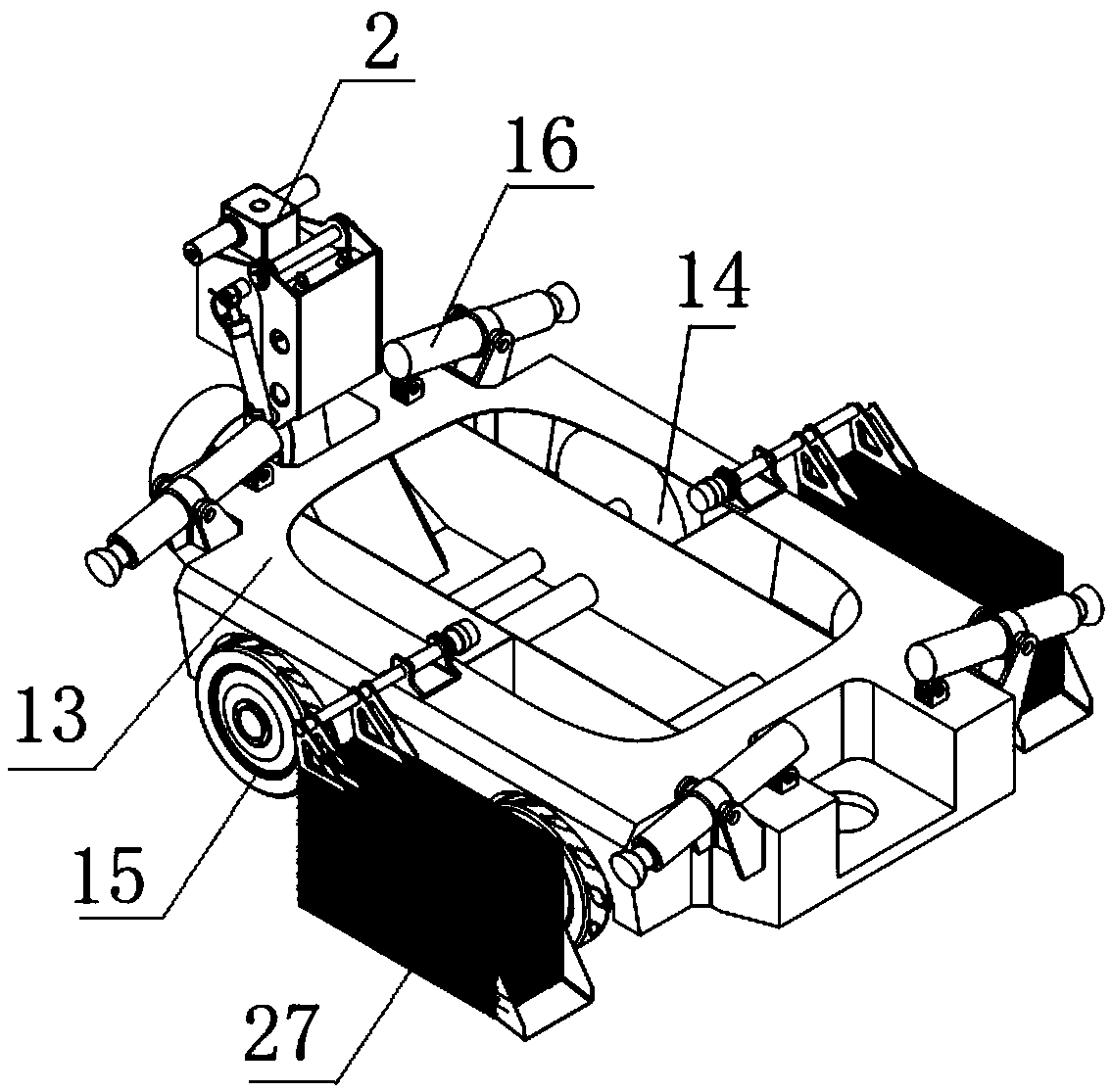

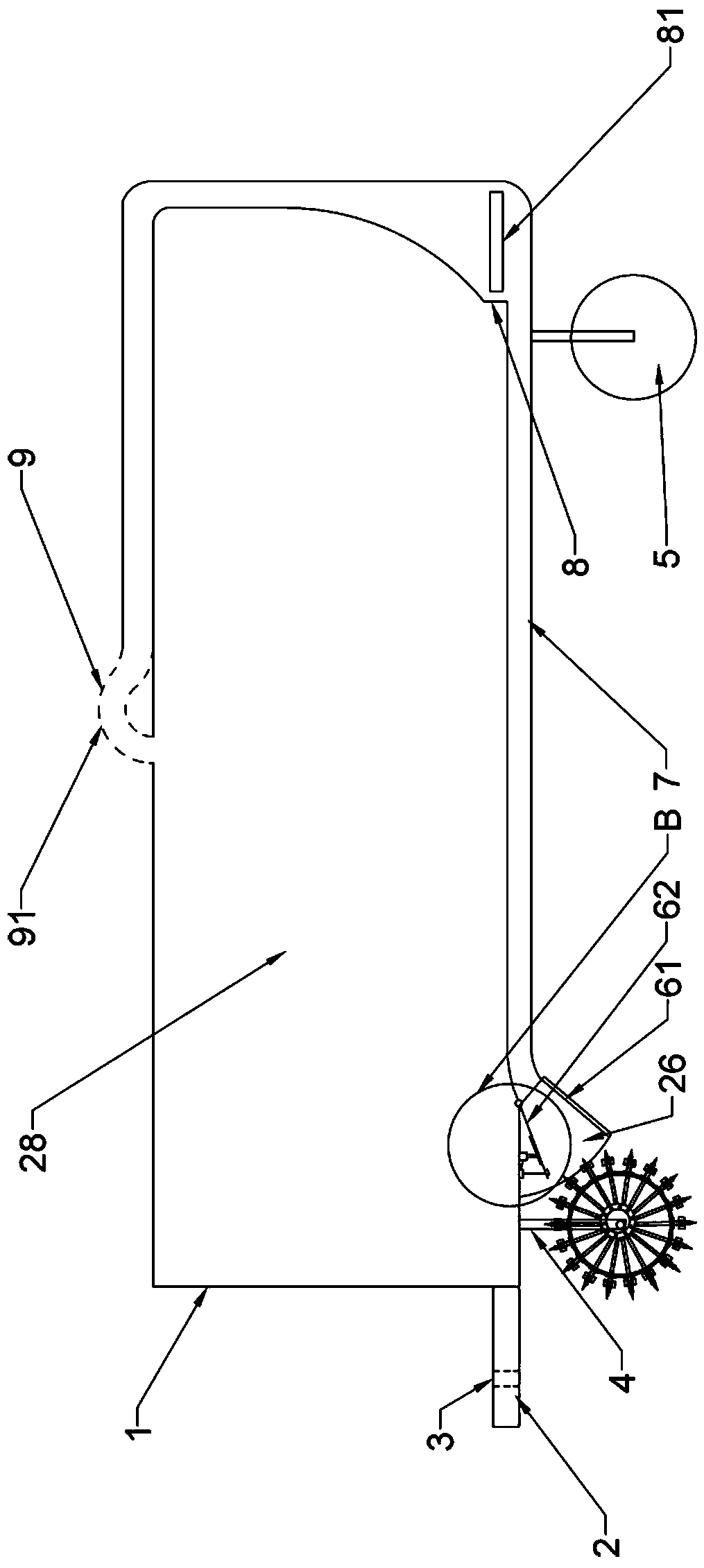

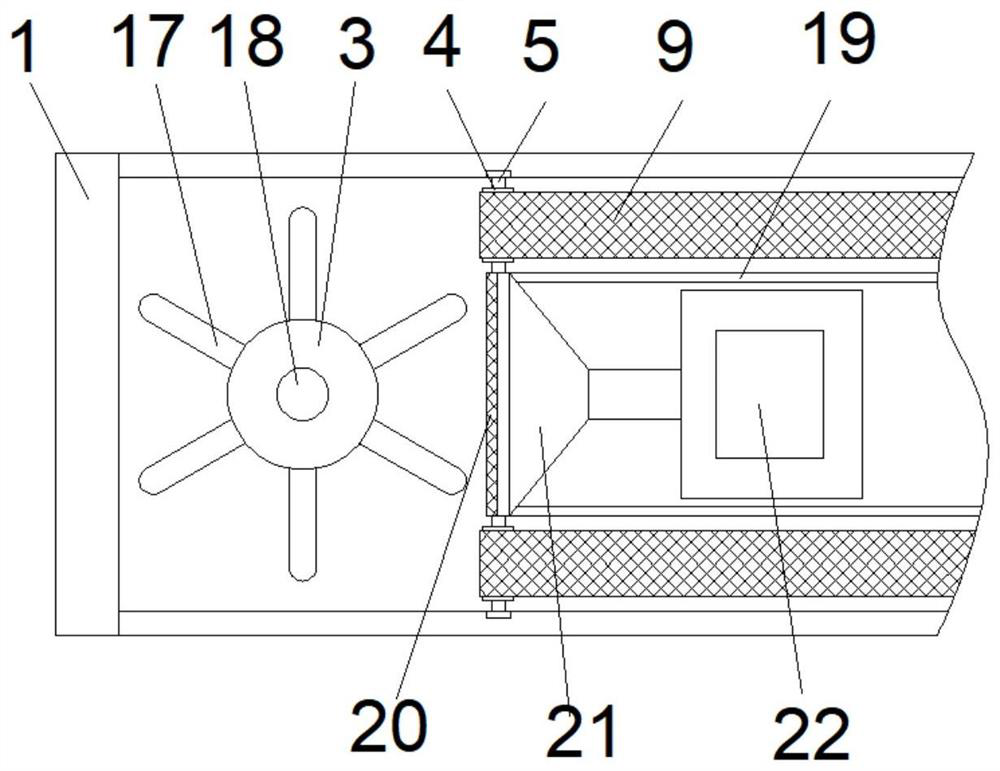

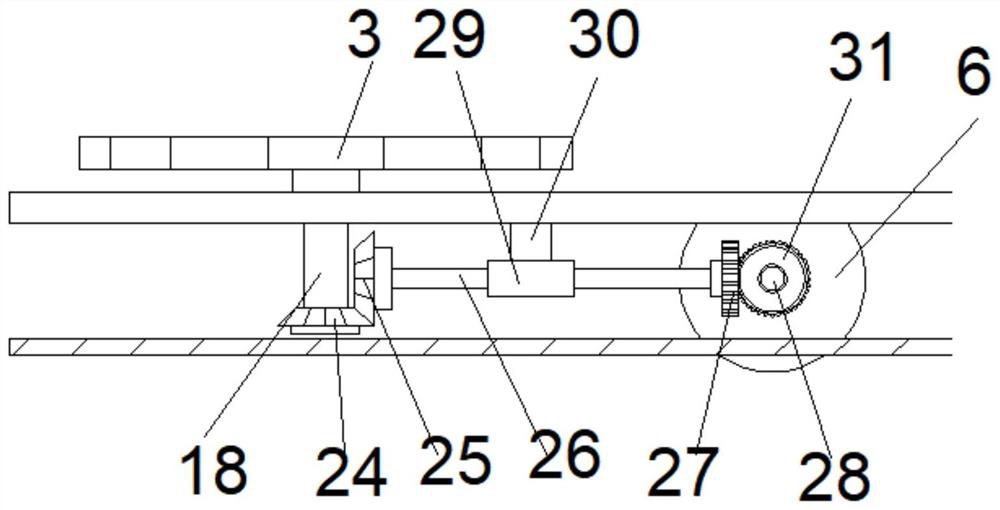

Propeller-driving left-right swinging cutter-suction type desilting robot with self-correction function

The invention discloses a propeller-driving left-right swinging cutter-suction type desilting robot with a self-correction function. The propeller-driving left-right swinging cutter-suction type desilting robot with the self-correction function includes a platform frame, a ship body, a propeller, a left-right swinging cutter-suction mechanism, a desilting mechanism, a pumping mechanism, a self-correction unit, a controlling unit and a visual unit; the ship body is used as a walking mechanism of the desilting robot and is positioned at the bottom of the platform frame; the propeller offers power to the ship body to move forward under the control of the controlling unit; a buoyancy tank is arranged in the ship body; and the left-right swinging mechanism and the desilting mechanism are operative sections. According to the propeller-driving left-right swinging cutter-suction type desilting robot with a self-correction function, a propeller-driving submarine-type marching method and a left-right swinging cutter-suction desilting method are adopted, sludge collection and sludge pumping are conducted, different environments such as channel deposit and culvert inverted siphon stagnating are fitted, and harmless sequent movable quick desilting is achieved, and the desilting robot can be corrected through the self-correction unit, so that the sludge clearing and barrier eliminating are conducted by the desilting robot reliably.

Owner:CSIC ZHONGNAN EQUIP

Book taking and placing management robot for library

PendingCN111941442ANo damageScientific and reasonable structureProgramme-controlled manipulatorGripping headsEquipment useIndustrial engineering

The invention discloses a book taking and placing management robot for a library. Existing book tidying equipment used in the library can only achieve the clamping processing effect, single-book or multi-book whole-process mechanical operation is difficult to achieve, and detail tidying accuracy is difficult to achieve. A moving base is horizontally arranged, a moving mechanism and a book storageframe are both arranged on the top face of the moving base, a swing mechanism is arranged on the moving mechanism, a pushing base body is arranged on the swing mechanism, a book guiding assembly and aclamping assembly are arranged on the pushing base body, and a picking ball is arranged at one end of a connecting rod. The other end of the connecting rod is mounted on the pushing base body. The book guiding assembly picks up books and conveys the books to the clamping assembly to complete the book taking process, and the book guiding assembly enables the books clamped by the clamping assemblyto penetrate through a guiding gap of the guiding assembly to complete the book placing process. The robot is used for book shifting.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Rapid and efficient bamboo hot-pressing propelling device

InactiveCN112060255AWon't skewSolve the problem of uneven susceptibilityWood compressionCane mechanical workingCompression deviceEngineering

The invention relates to the technical field of hot-pressing auxiliary devices, and discloses a quick and efficient bamboo hot-pressing propelling device. The quick and efficient bamboo hot-pressing propelling device comprises a support, a workbench is fixedly connected to the top end of the support, a sliding groove is fixedly connected to the bottom end of the workbench, a sliding block is slidably connected into the sliding groove, a compression device is fixedly connected to the outer side of the sliding block, a pressing block is rotatably connected to the bottom end of the sliding block,a connecting pipeline is fixedly connected to the outer side of the compression device, an air bag is fixedly connected to the outer side of the connecting pipeline, and a vacuum sucker is fixedly connected to the outer side of the air bag. According to the rapid and efficient bamboo hot-pressing propelling device, through connection of the support and the pressing block, rapid propelling of a bamboo plate is achieved, and the problem that according to an existing hot press plate-dividing propelling device, a telescopic rod is used for propelling a plate, and uneven stress is prone to happening is solved, bamboo cannot incline, a hot-pressing process is facilitated, practicability is high, reliability is high, and propelling of the bamboo plate is facilitated.

Owner:江西安竹科技有限公司

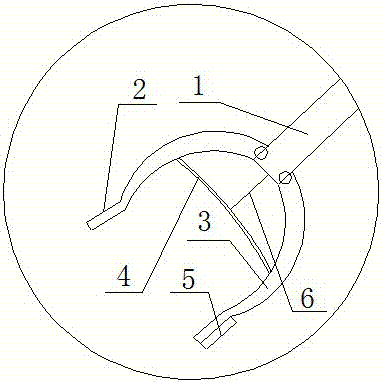

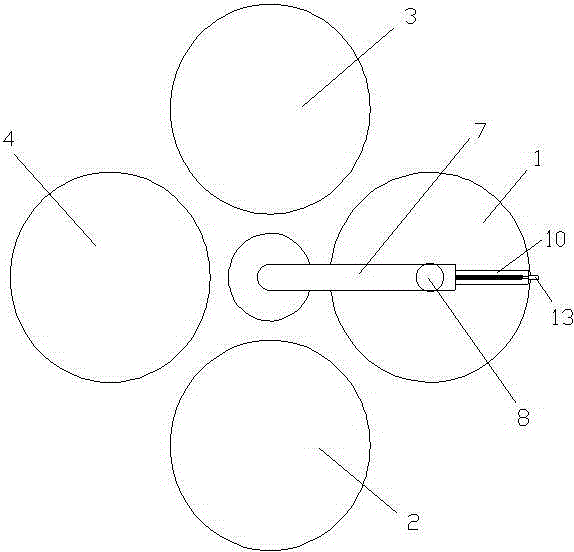

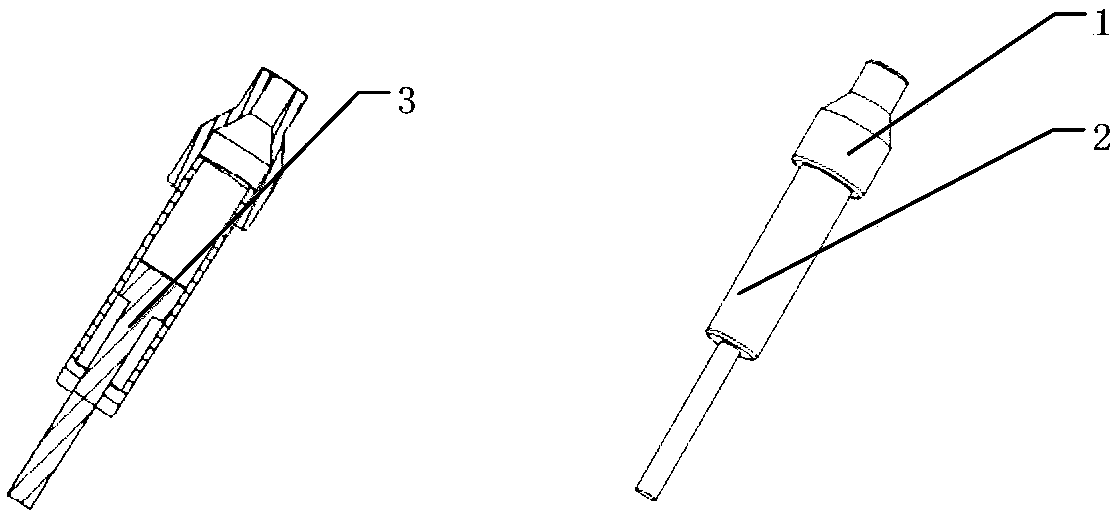

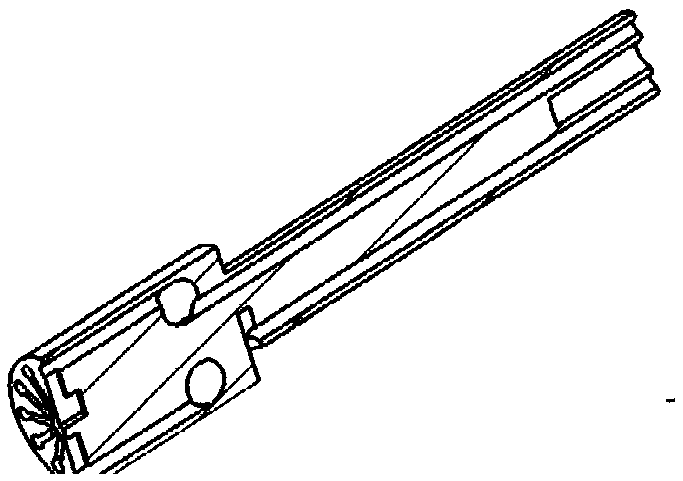

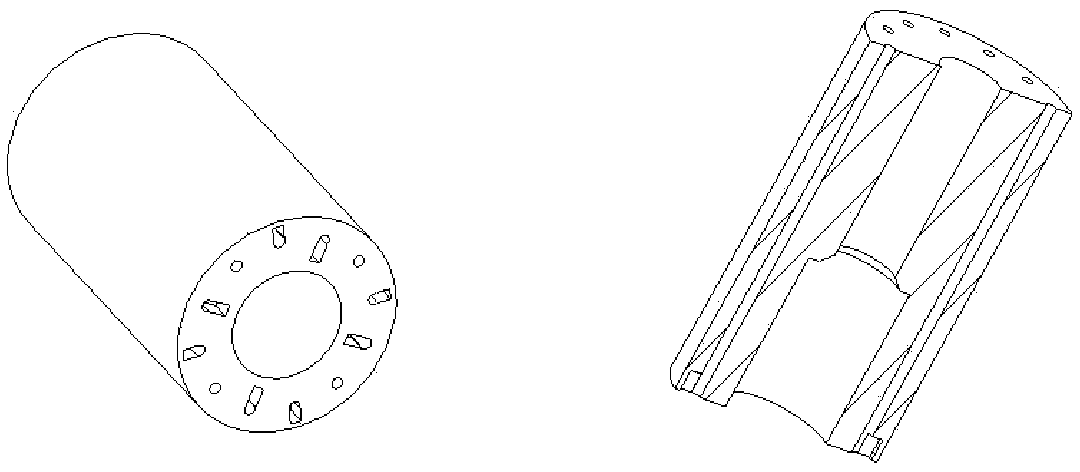

Igniter miniature ring part multi-stage grabbing mechanism

ActiveCN109093432AImprove adaptabilityReduce the type and quantity of equipmentMetal working apparatusSpray nozzleCircular surface

The invention relates to an igniter miniature ring part multi-stage grabbing mechanism. The miniature ring part multi-stage grabbing mechanism comprises at least two-stage suction cups and a grading plate. The first-stage suction cup is fixedly installed at the central position of a mounting plate. An inner hole of the second-stage suction cup forms shaft hole fit with the outer circle of the first-stage suction cup, the inner hole of each stage of suction cup outside the second-stage suction cup is matched with the grading plate mounted on the mounting plate, and a shell is installed on the outermost side in a sleeving mode. The suction cups except the first-stage suction cup perform axial limiting through steps arranged on the outer circular surfaces being in contact with the suction cups except the first-stage suction cup. Spray nozzles on the mounting plate communicate with air holes of the suction cups, and the adsorption is achieved by forming negative pressure on the outer end surface of each stage of suction cup. An air cylinder mounted on the mounting plate is used for pushing the suction cups except the first-stage suction cup to extend out, and the retraction of the suction cups is realized by introducing positive pressure into movable line cavities formed between the suction cups and adjacent structural members, so that the working adsorption area of the mechanism can be changed step by step. The igniter miniature ring part multi-stage grabbing mechanism realizes the completion of picking up ring parts of various sizes by a same machine head, the equipment flexibility is high, single control energy source is achieved, compatibility is good, the size and quantity of part picking devices in automatic equipment development can be effectively reduced, and the equipment development cost is reduced.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

Forestal leftover collecting device

The invention relates to a forestal leftover collecting device. The forestal leftover collecting device comprises a car frame, a collecting cabin arranged on the car frame, a fallen leaf pickup devicearranged below the car frame and a fallen leaf sucking device, the fallen leaf pickup device comprises a rotatable central shaft, an eccentric shaft, a bearing and a roller, the eccentric shaft sleeves the central shaft and is fixedly arranged on the car frame, the bearing is arranged on the eccentric shaft in a sleeving manner, the roller and the central shaft are coaxial and fixedly connected,hollow pickup rods are uniformly arranged on a side face of the roller, a plurality of cross rods with axes parallel to a bearing axis are uniformly arranged outside the bearing, a plurality of telescopic rods are hinged to the cross rods, outer ends of the telescopic rods extend from the roller and extend into the pickup rods, side faces of the outer ends of the telescopic rods are connected withinner walls of hollow cylinders through connecting rods, the hollow cylinders are arranged outside the pickup rods in a sleeving manner, the fallen leaf sucking device comprises an air passage and afan arranged in the air passage, and an air outlet of the air passage is connected with the collecting cabin.

Owner:石柱土家族自治县八龙农业开发有限公司

Rotary express delivery logistics vehicle

ActiveCN106926876AEasy to findImprove delivery efficiencyHand carts with multiple axesLayered structureAerospace engineering

The invention discloses a rotary express delivery logistics vehicle and belongs to the technical field of freight vehicles. The rotary express delivery logistics vehicle comprises a vehicle head and a compartment, a vertical thrust fixing shaft is arranged inside the compartment and is provided with at least two horizontal and spaced passing boards in a penetrating mode, and the passing boards and the thrust fixing shaft are rotationally connected. The rotary express delivery logistics vehicle adopts the concept of three-dimensional type storage layering and partitioning, the internal space of the compartment is divided into a layered structure through the thrust fixing shaft and the passing boards, disordered express packages are put straight to be put on the passing board on each layer, the passing boards can be partitioned according to different areas and different specifications of express packages, and express packages are convenient and fast to find out.

Owner:EAST CHINA UNIV OF TECH

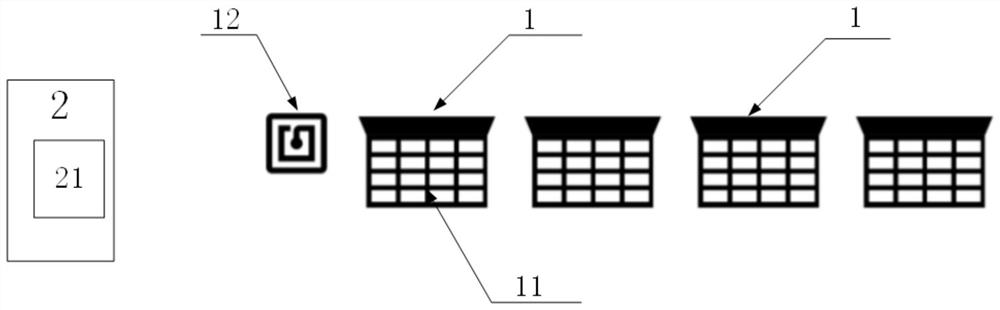

Express cabinet pickup system, method and equipment based on NFC (Near Field Communication)

InactiveCN113240861AAchieve pickupAcutation objectsApparatus for meter-controlled dispensingEmbedded systemMobile phone

The invention relates to an express cabinet pick-up system, method and device based on NFC, and belongs to the technical field of express, the system is provided with an NFC read-write device in an express cabinet, and an NFC module matched with the NFC read-write device is arranged at a pick-up terminal, so that when a user holds the pick-up terminal to approach an NFC touch pick-up area, a control module obtains pick-up information of the pick-up terminal, and according to the pick-up information, the storage cell corresponding to the pick-up information is opened. In the pick-up process, a user does not need to manually input a pick-up code and does not need to scan a two-dimensional code, and pick-up can be achieved only by touching the corresponding NFC touch pick-up area of the express cabinet through a mobile phone, so that convenience and rapidness are achieved.

Owner:SHANGHAI ZHONGTONGJI NETWORK TECH CO LTD

Automatic rubber sheet stacking device

PendingCN110371654AShorten the timeImprove work efficiencyStacking articlesDe-stacking articlesRubber sheetBlack rubber

The invention discloses an automatic rubber sheet stacking device. The device comprises a supporting frame, a sheet stacking workbench, a conductive black rubber sheet conveying belt and an insulatingwhite rubber sheet conveying belt. Different from the prior art, the automatic rubber sheet stacking device also comprises a picking assembly, a transfer assembly and a roller press assembly which are arranged in the supporting frame. The work of the picking assembly is to complete rubber sheet picking and placing actions. The work of the transfer assembly is to transfer picked rubber sheets to the stacking workbench and putting down the rubber sheets. The work of the roller press assembly is to press the rubber sheets. The automatic sheet stacking device is compact in structure and reasonable in layout, continuous work of picking, transferring and stacking of the rubber sheets can be realized, and the working efficiency is improved. The device is applicable to automatic stacking of the rubber sheets with the thickness smaller than 1 mm and also suitable for automatic stacking of the rubber sheets with the thickness larger than 1 mm, manual labor can be replaced, automatic sheet stacking is achieved, the sheet stacking efficiency is improved, the material loss is reduced, and the product precision is improved, so that the stacking device better meets development requirements of modern production enterprises.

Owner:GUILIN UNIV OF AEROSPACE TECH

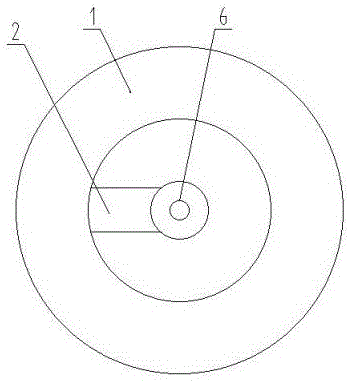

Ring pick-up mechanism of sealing ring in sealing ring feeding device

The invention provides a ring pick-up mechanism of a sealing ring in a sealing ring feeding device, and belongs to the technical field of luggage accessory assembly. The ring pick-up mechanism of thesealing ring in the sealing ring feeding device is provided, the feeding device comprises a supporting frame, a material taking table is arranged at one end of the supporting frame, and the other endof the supporting frame is provided with a workbench; the ring pick-up mechanism is characterized in that the ring pick-up mechanism comprises a material carrying column, the material carrying columnis cylindrical, and a round groove is formed in the lower end of the material carrying column, and a circular truncated cone is fixed at the bottom of the round groove; and the wide face of the circular truncated cone is fixedly connected with the bottom of the round groove, the narrow face of the circular truncated cone faces downwards, and a gap for clamping the sealing ring is formed between aconical face of the circular truncated cone and a side wall of the round groove; and a lifting positioning structure capable of driving the material carrying column to vertically ascend and descend and positioned is arranged between the material taking table and the upper end of the material carrying column, and a conveying and positioning structure capable of conveying the sealing ring to a designated station is further arranged on the material taking table. The ring pick-up mechanism of the sealing ring in the sealing ring feeding device has the advantages that the sealing ring can be pickedup.

Owner:浙江御匠箱包股份有限公司

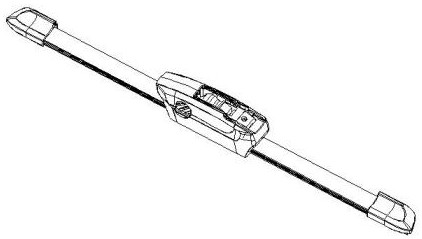

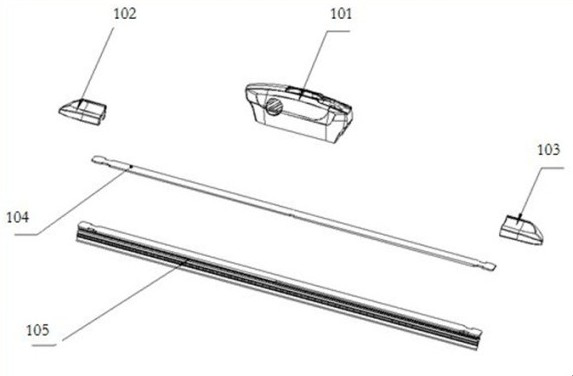

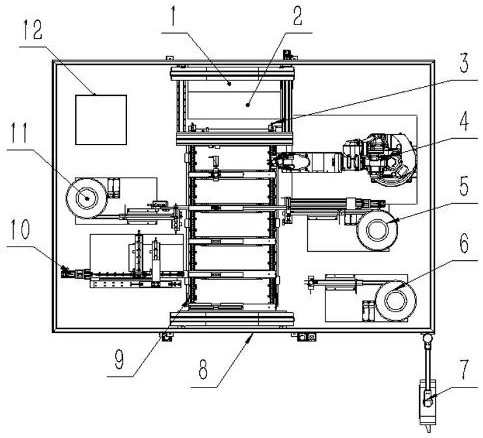

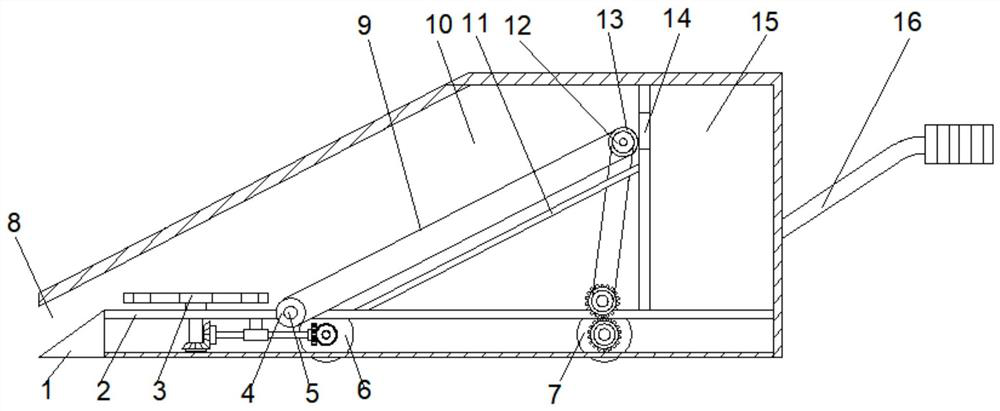

Automatic assembling system and method for automobile boneless windshield wiper

ActiveCN114571230AAchieve pickupAchieve installationAssembly machinesMetal working apparatusManufactured materialLaser sensor

The invention relates to an automatic assembling system and method for an automobile boneless windshield wiper. The assembling system comprises a conveying mechanism, an elastic piece assembling mechanism, a left end rubber buckle assembling mechanism, a right end rubber buckle assembling mechanism, an automatic brush head assembly distributing system, a robot system, a collecting mechanism, a master control and a robot control cabinet. According to the assembly system and the assembly method, picking and mounting of the brush head assembly can be achieved; a laser sensor is arranged to detect whether each part of a tested and assembled product is assembled in place so as to judge whether the assembly fitting degree standard is met or not, and an alarm is given out when continuously produced unqualified products reach a certain preset value so as to remind a worker to detect or maintain equipment and raw materials in time; in addition, the quality of an assembled boneless windshield wiper product can be subjected to spot check, and the strength of the boneless windshield wiper product can be detected. And the automation degree of the system is high, the labor intensity of manpower can be reduced, the assembly fitting degree is improved, and a good foundation is laid for improving the efficiency and the assembly quality.

Owner:TIANJIN SAIXIANG TECH +1

Portable ball picking device for badminton hall

InactiveCN112755479AAchieve pickupReduce labor intensityBall sportsStructural engineeringMechanical engineering

The invention discloses a portable ball picking device for a badminton stadium. The portable ball picking device comprises a vehicle body, a connecting plate is further arranged in the vehicle body, an exhaust fan is arranged on the upper surface of the connecting plate, an air suction hood is arranged at the output end of the exhaust fan, and the opening direction of the air suction hood faces the direction of the feeding port; conveying belts are arranged on the front side and the rear side of the exhaust fan, the right ends of the conveying belts incline upwards, a collecting bin is arranged on the right sides of the conveying belts, a discharging port is formed in the left wall of the collecting bin and located on the right side of the right ends of the conveying belts, and front wheels and rear wheels are further arranged at the bottom of the vehicle body. The front wheels are connected through a second rotating rod, and the rear wheels are connected through a third rotating rod; when the shuttlecocks are picked up, the exhaust fan is used for exhausting air, the shuttlecocks are very light, the shuttlecocks are easily sucked into the vehicle body, then the shuttlecocks enter the collecting bin under the action of the conveying belt, the collecting speed is high, and the working intensity is small.

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com