Igniter miniature ring part multi-stage grabbing mechanism

A technology of ring-shaped parts and grasping mechanism, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to automatically adjust, small picking range, etc., to reduce the type and quantity of equipment, reduce the complexity of the device, ensure The effect of device reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

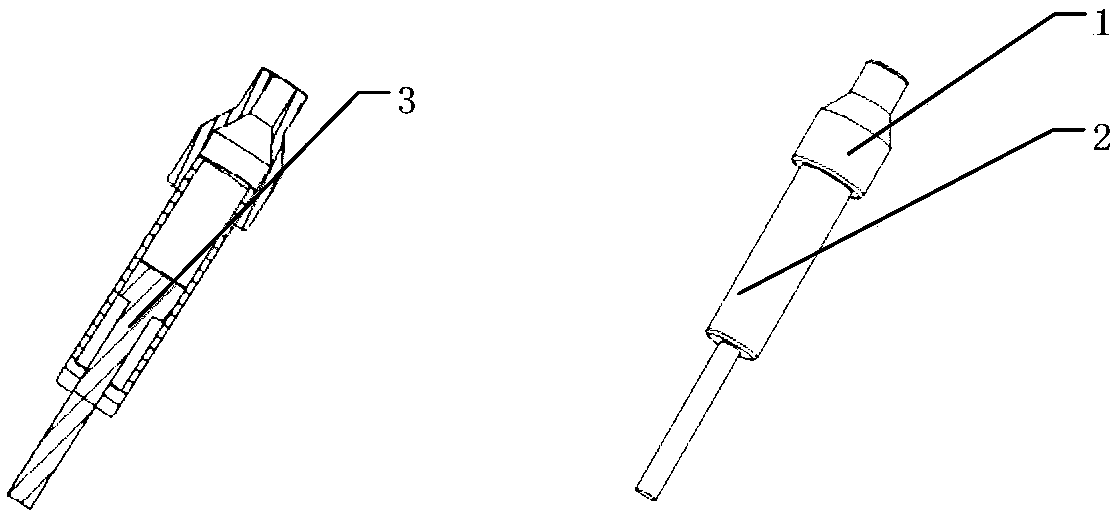

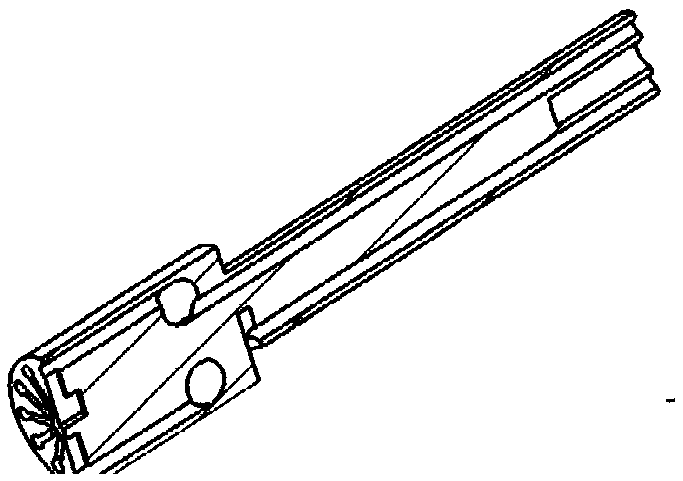

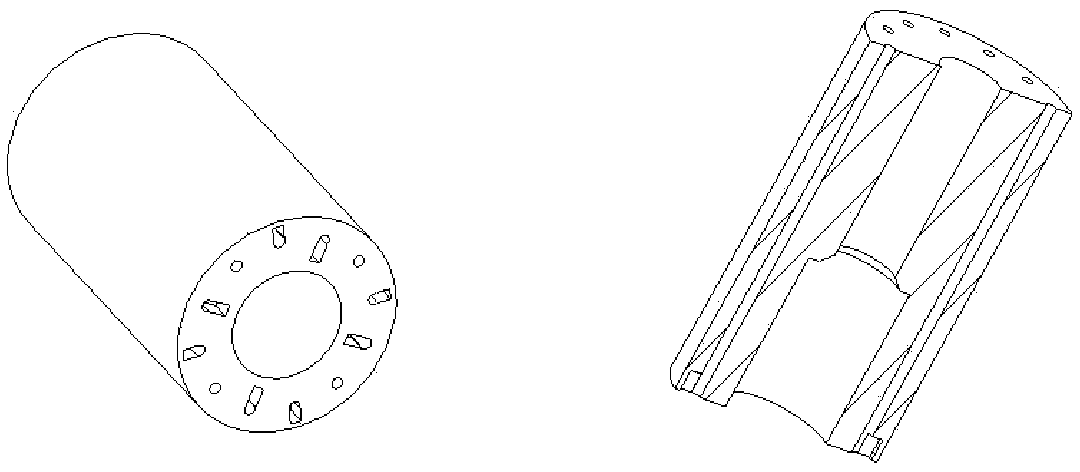

[0030] The invention forms a pneumatic piston structure through the internal air channels of the suction cups at all levels, and the suction cups at all levels can realize expansion and contraction to form a combination of suction cups with different diameters, so that a single head can pick up ring parts of various sizes.

[0031] The first-level suction cup 6 is fixed on the central position of the mounting plate 7; the inner hole of the second-level suction cup (5) is matched with the outer circle of the first-level suction cup (6) to form a shaft hole, and the inner hole of each level of the second-level suction cup is outwardly aligned with the mounting plate. The grading plate 10 on the mounting plate 7 cooperates, and the housing 1 is set on the outermost side; each level of suction cup except the first-level suction cup 6 is axially limited by the steps provided on the outer circular surface in contact with it; the mounting plate The nozzle on 7 communicates with the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com