Ring pick-up mechanism of sealing ring in sealing ring feeding device

A sealing ring and material column technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency and increased production costs, and achieve the effect of simple structure, favorable coordination and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

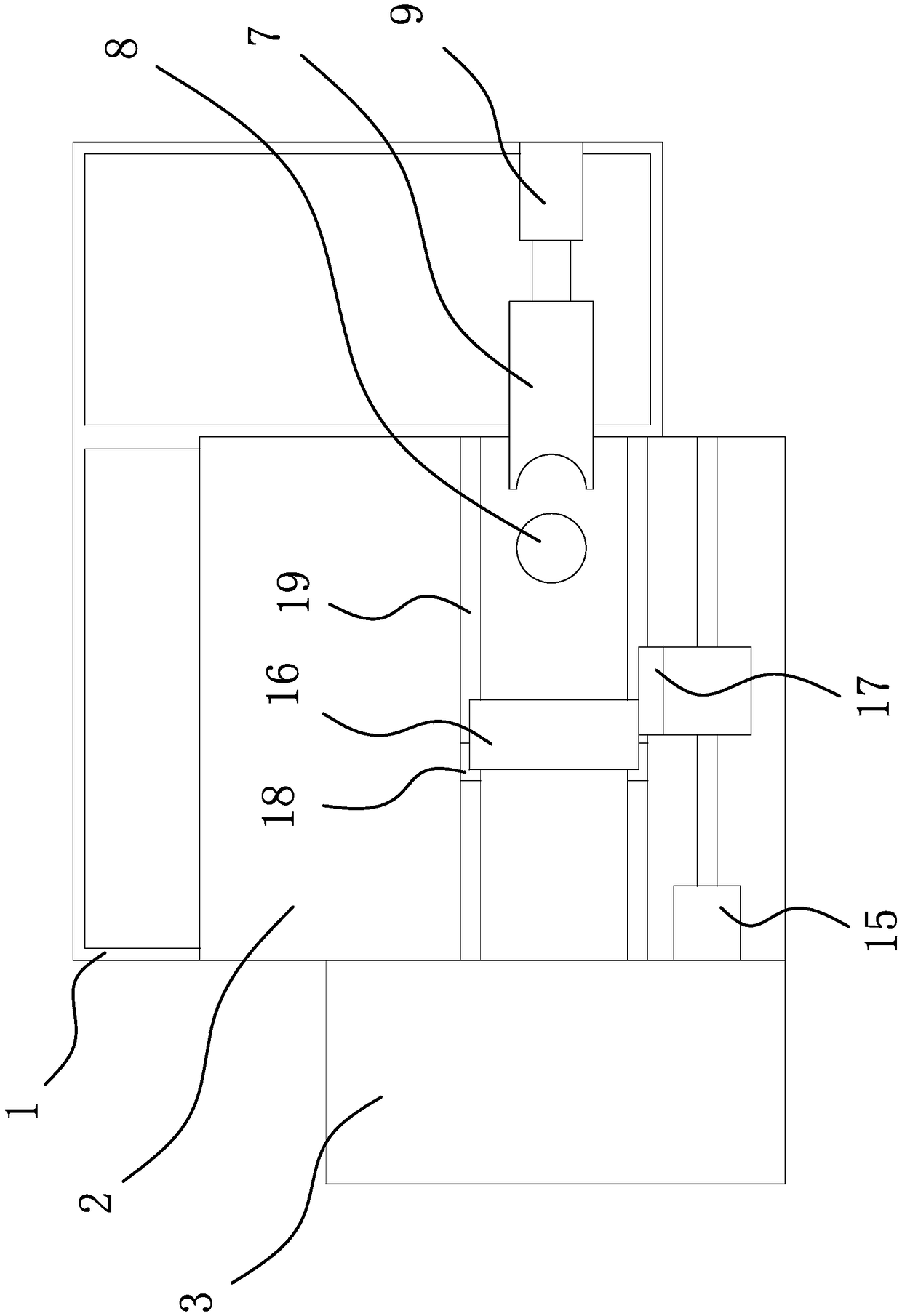

[0033] Such as figure 1 As shown, a feeding device for sealing rings in luggage accessories includes a support frame 1 , a pick-up table 2 is provided at one end of the support frame 1 , and a workbench 3 is provided at the other end of the support frame 1 . Specifically, the reclaiming table 2 is fixed on one end of the support frame 1 by bolts and nuts; the workbench 3 is fixed on the other end of the support frame 1 by bolts and nuts. The pick-up table 2 is used for picking up and conveying the sealing ring, and the working table 3 is used for unloading and assembling the sealing ring.

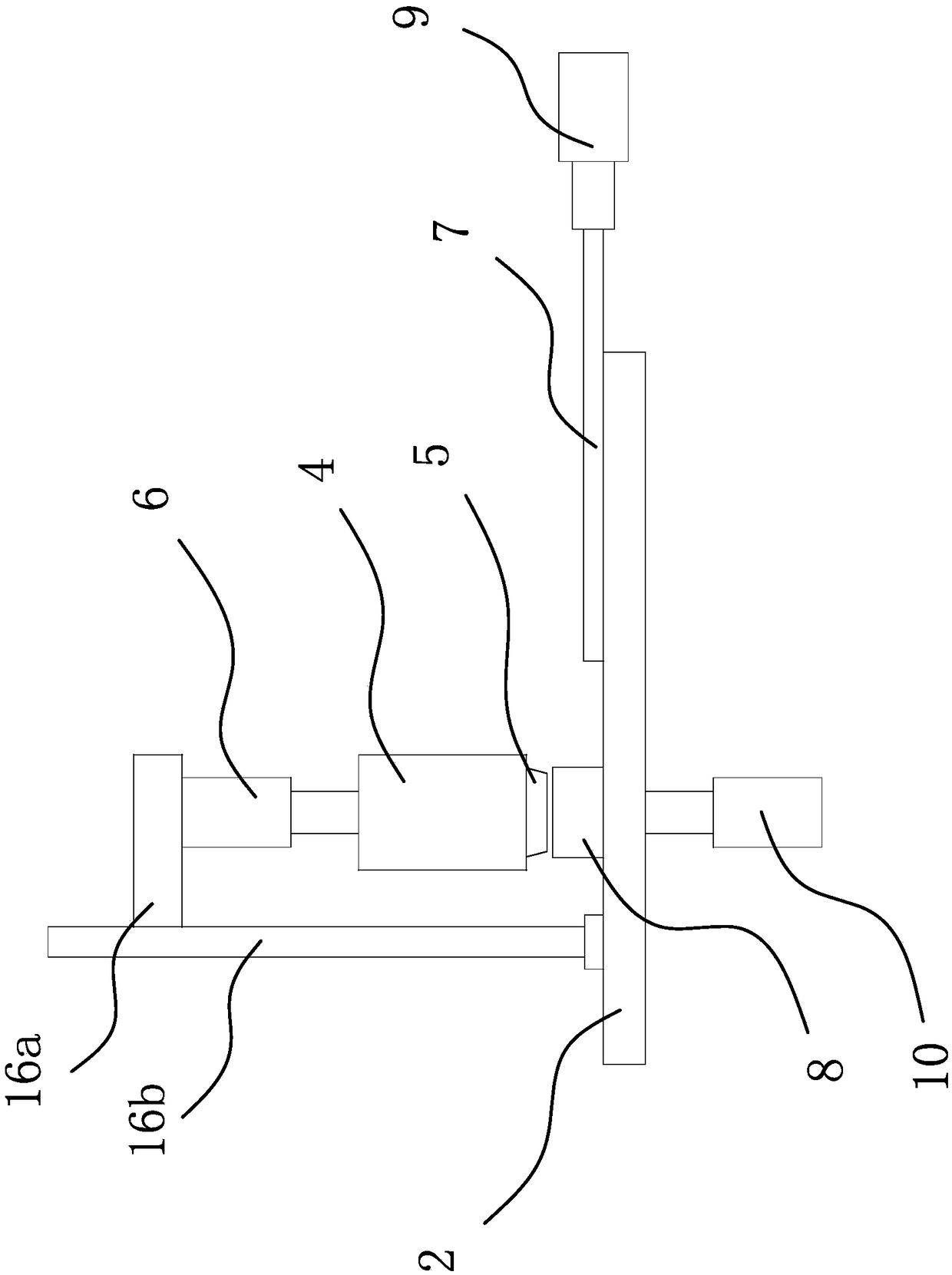

[0034] Such as Figure 4 As shown, a material-carrying propulsion mechanism in a feeding device includes a gantry bracket 16 slidably arranged on the reclaiming table 2 and a lead screw motor 15 fixed on the reclaiming table 2, and the body of the lead screw motor 15 is fixed on On the material retrieving platform 2, balls are provided on the screw mandrel of the lead screw motor 15, and a ...

Embodiment 2

[0057] The structure and principle of this embodiment are basically the same as that of the first embodiment, the difference is that in the first embodiment, the lifting and positioning structure is the lifting cylinder one 6, and the cylinder body of the lifting cylinder one 6 is fixed on the gantry support 16, and the lifting The piston rod of the cylinder one 6 is vertically downward and its end is fixedly connected with the material carrying column 4; On, the push rod of push rod motor one is vertically downward and its end is fixedly connected with material-carrying column 4. Start the push rod motor one, make the push rod of the push rod motor one stretch out, the material carrying column 4 moves downward, and the sealing ring is inserted on the round table 5 of the material carrying column 4 to realize the picking of the sealing ring; make the pushing rod motor one The push rod retracts, the material-carrying column 4 moves upward, the sealing ring and the material-carr...

Embodiment 3

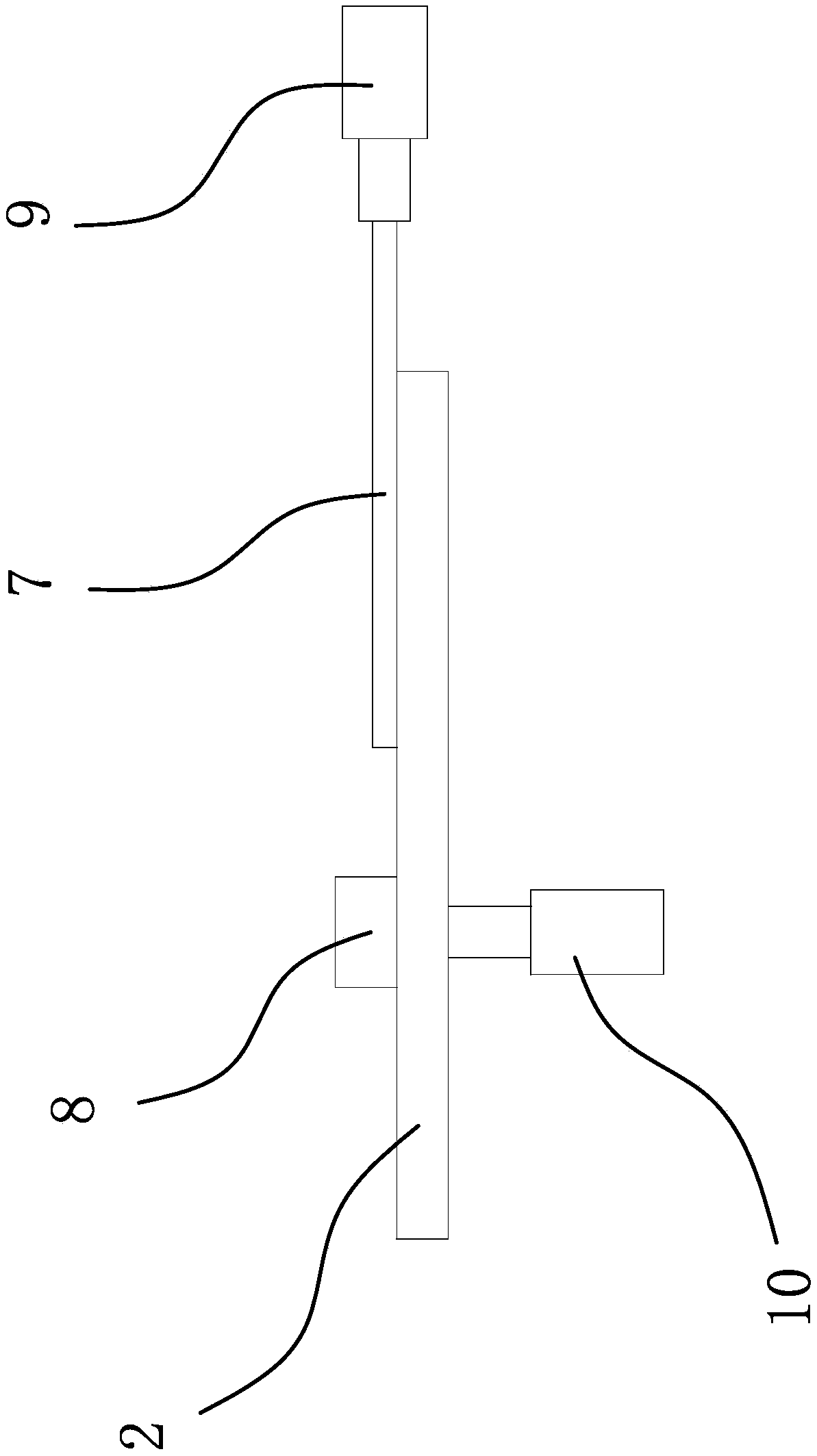

[0059] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that in Embodiment 1, the telescopic structure is the lift cylinder 2 12, and the cylinder body of the lift cylinder 2 12 is fixed on the gantry support 16, and the lift cylinder The piston rod of the second 12 is vertically upward and its end is fixedly connected with a connecting plate 13, and the two ends of the connecting plate 13 are fixedly connected with two connecting rods 14, and the other ends of the two connecting rods 14 are respectively the above-mentioned two discharge pieces. 11 is fixedly connected; and in the present embodiment three, telescopic structure comprises two push rod motors, the body of push rod motor two is fixed on the gantry support 16, and the push rod of push rod motor two is vertically upward and its end is fixedly connected There is a connecting plate 13, the two ends of the connecting plate 13 are fixedly connected with two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com